Wedge type double gate plate structure with V-shaped conical surface

A technology of double rams and conical surfaces, applied in the direction of sliding valves, engine components, mechanical equipment, etc., can solve the problems of spherical surfaces that cannot rotate, jam, and increase, and achieve the effect of preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

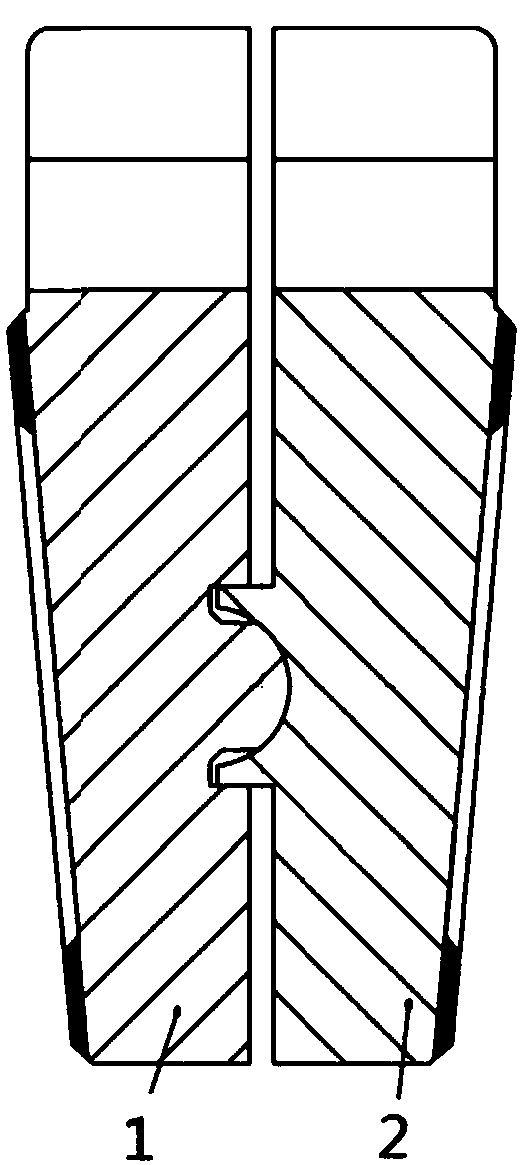

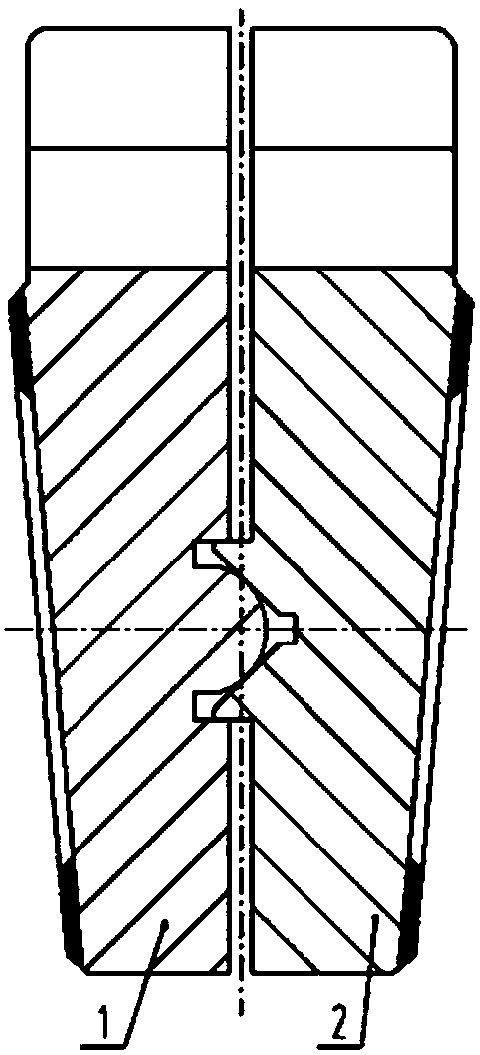

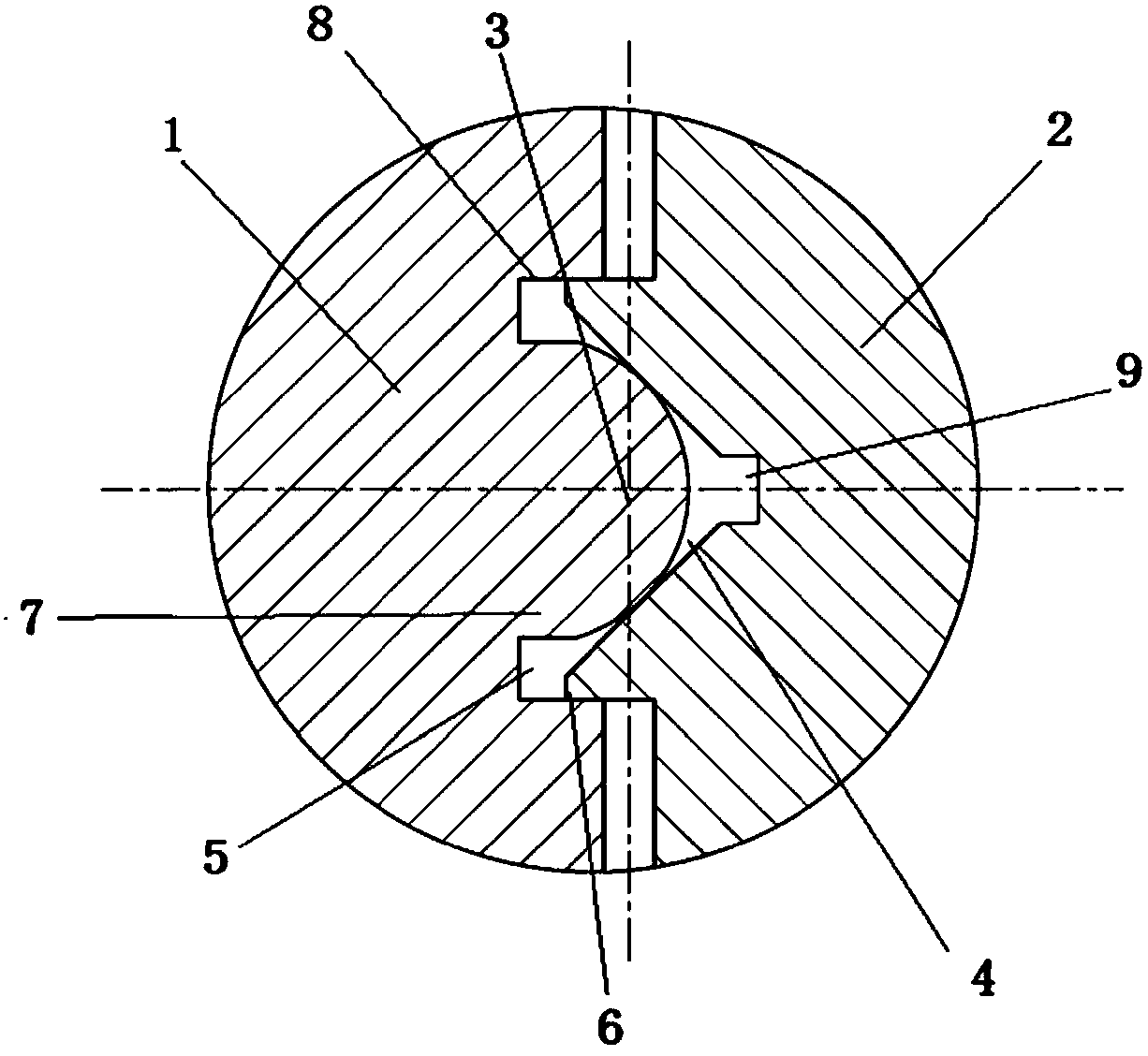

[0018] Such as figure 2 and image 3 As shown, the gate A1 and the gate B2 are placed opposite to each other, and the butt surface of the gate A1 is processed with hemispherical protrusions. The bottom of the protrusions is cylindrical, and the outer diameter of the cylinder is equal to the diameter of the ball. The hemispherical protrusion and the cylindrical shape are integrally processed, and the apex of the hemispherical protrusion 3 is located outside the butt surface where it is located, that is, higher than the butt surface.

[0019] The above-mentioned hemispherical protrusion 3 and cylindrical shape 7 are located in the sinking groove 8 processed on the butt surface of the gate A1, and an annular groove is formed between the outer surface of the integral structure formed by the hemispherical protrusion 3 and the cylindrical shape 7 and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com