Ball mill for graphene production

A technology for graphene and balls, which is applied in the field of ball mills for graphene production, can solve the problems of reducing the contact area between iron balls and the inner wall of hollow shafts, affecting the grinding effect of iron balls, and reducing the effect of crushing materials, so as to reduce impact force, Enhance fit and grip, enhance the effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

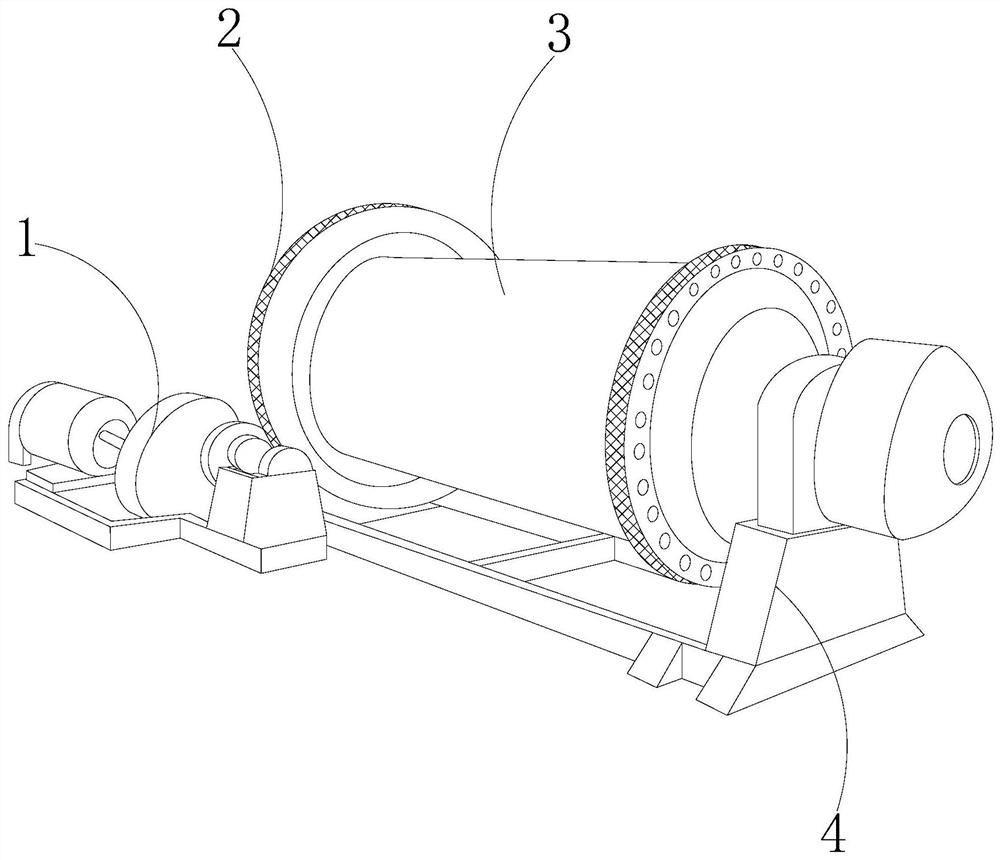

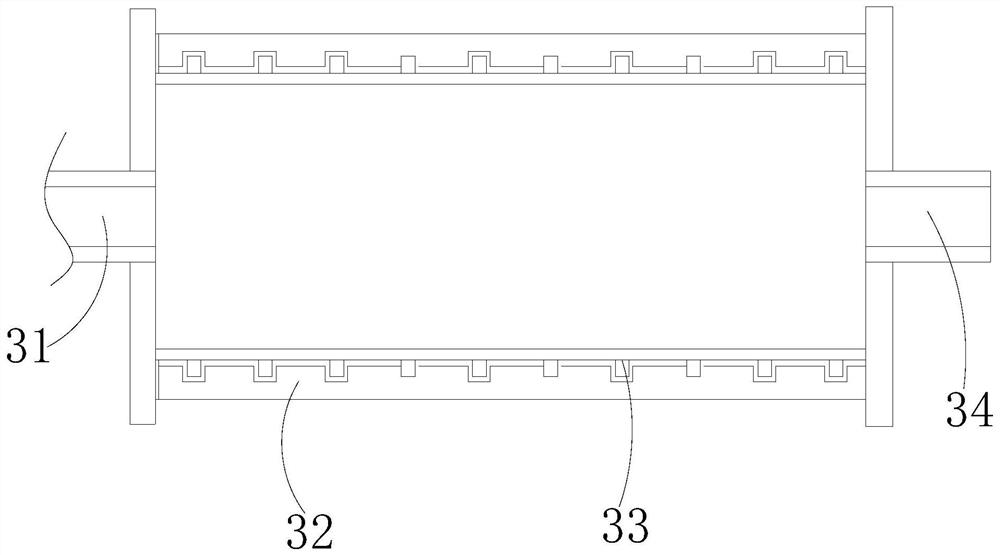

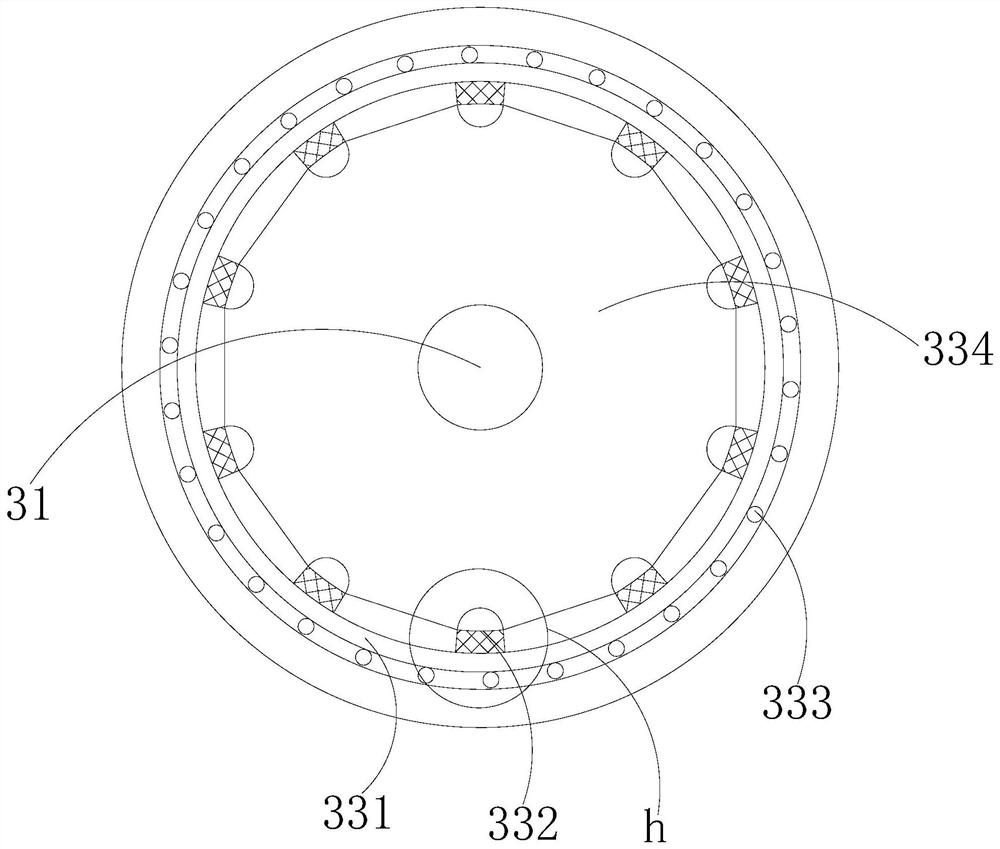

[0023] like Figure 1-Figure 5 Shown:

[0024] A kind of ball mill for graphene production of the present invention, its structure comprises motor 1, gear 2, drum mechanism 3, support frame 4, described motor 1 and gear 2 are threadedly matched, and described gear 2 is embedded and fixed on the outer side of drum mechanism 3 , the support frame 4 is located at the lower end of the drum mechanism 3, the drum mechanism 3 is provided with a material inlet 31, a drum 32, a rotating mechanism 33, and a material outlet 34, and the drum 32 is embedded on the outside of the rotating mechanism 33, The material inlet 31 is installed on the left side of the drum 32, the material outlet 34 is embedded on the right side of the drum 32, the material outlet 34 and the material inlet 31 are located on the same central axis, and the drum 32 is located on the support At the upper end of the frame 4, there is a certain gap between the roller 32 and the rotating mechanism 33, the material inlet ...

Embodiment 2

[0031] like Figure 6-Figure 7 Shown:

[0032] Wherein, the force receiving mechanism a1 is provided with a friction mechanism w1, a rubber strip w2, a fan-shaped plate w3, a ball block w4, a hollow ball w5, and a connecting plate w6. The friction mechanism w1 is attached to the outside of the fan-shaped plate w3, and the rubber The strip w2 is embedded between the fan-shaped plates w3, the rubber strip w2 is attached to the outside of the ball block w4, the hollow ball w5 is located at the lower end of the ball block w4, the hollow ball w5 is installed inside the connecting plate w6, and the ball The block w4 is embedded and fixed on the upper end of the connecting plate w6, and the connecting plate w6 is installed in the middle of the welding block a4. The fan-shaped plate w3 is evenly surrounded by a semicircle centered on the ball block w4, and is attached to the outside of the ball block w4. The ball block There is a gap between w4 and the connection plate w6, so that wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com