Grinding device good in cooling effect for machining

A cooling effect, machine tool technology, applied in grinding/polishing safety devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of cleaning the heat that cannot be dissipated, generating a large amount of heat, etc., to facilitate lifting and reducing The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

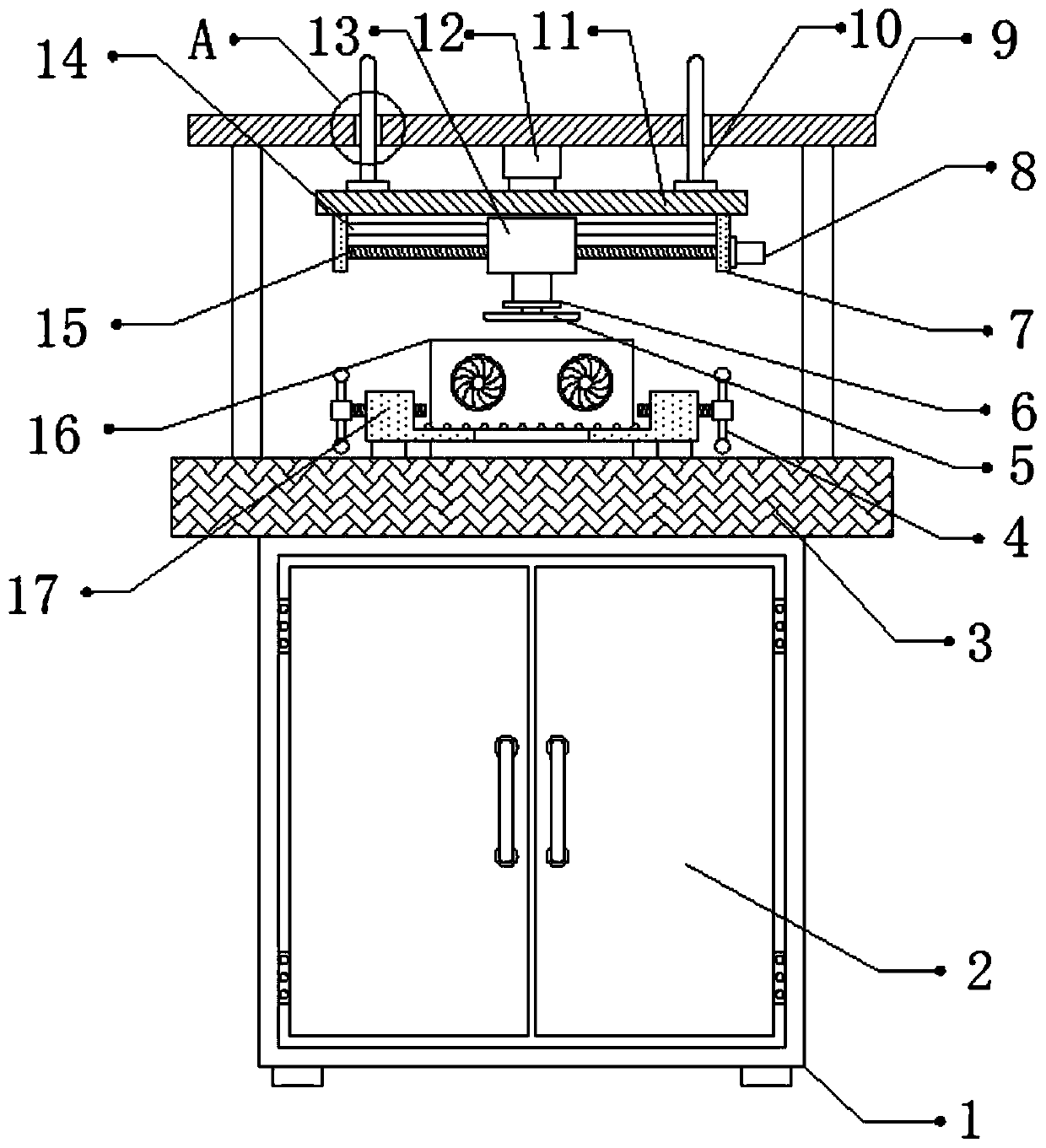

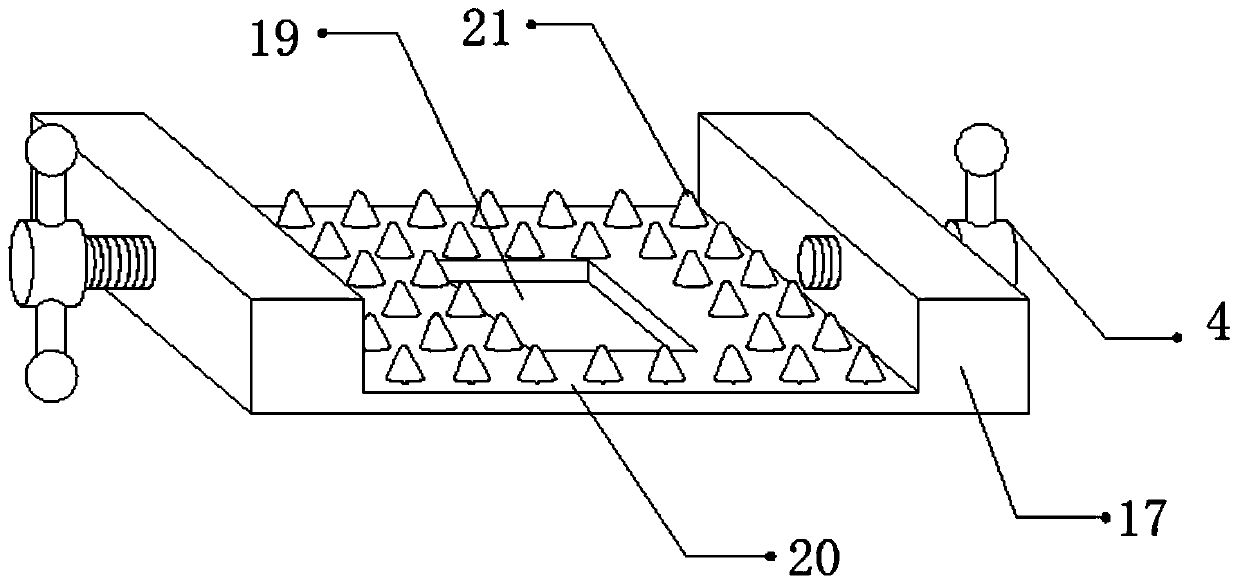

[0027] refer to Figure 1-3 , a grinding device with good cooling effect for machine tool processing, comprising a fixed seat 3, the top outer wall of the fixed seat 3 is connected with a fixed plate 17 by bolts, and the top outer wall of the fixed plate 17 is provided with a U-shaped groove 20, and the U-shaped groove The inner wall of the bottom of 20 is provided with a plurality of ribs 21 equidistantly distributed, the inner wall of the bottom of the U-shaped groove 20 is provided with an air vent 19, and one side of the outer wall of the top of the fixing seat 3 is connected with a cooling plate 16 by bolts, and the cooling plate 16 is a Both ends of the side outer wall are provided with cooling ports, and the inner walls of the two cooling ports are connected with cooling fans by bolts, and the two sides of the outer walls of the top of the fixing seat 3 are connected with fixed rods by bolts, and the top outer walls of the two fixed rods are connected to each other by bo...

Embodiment 2

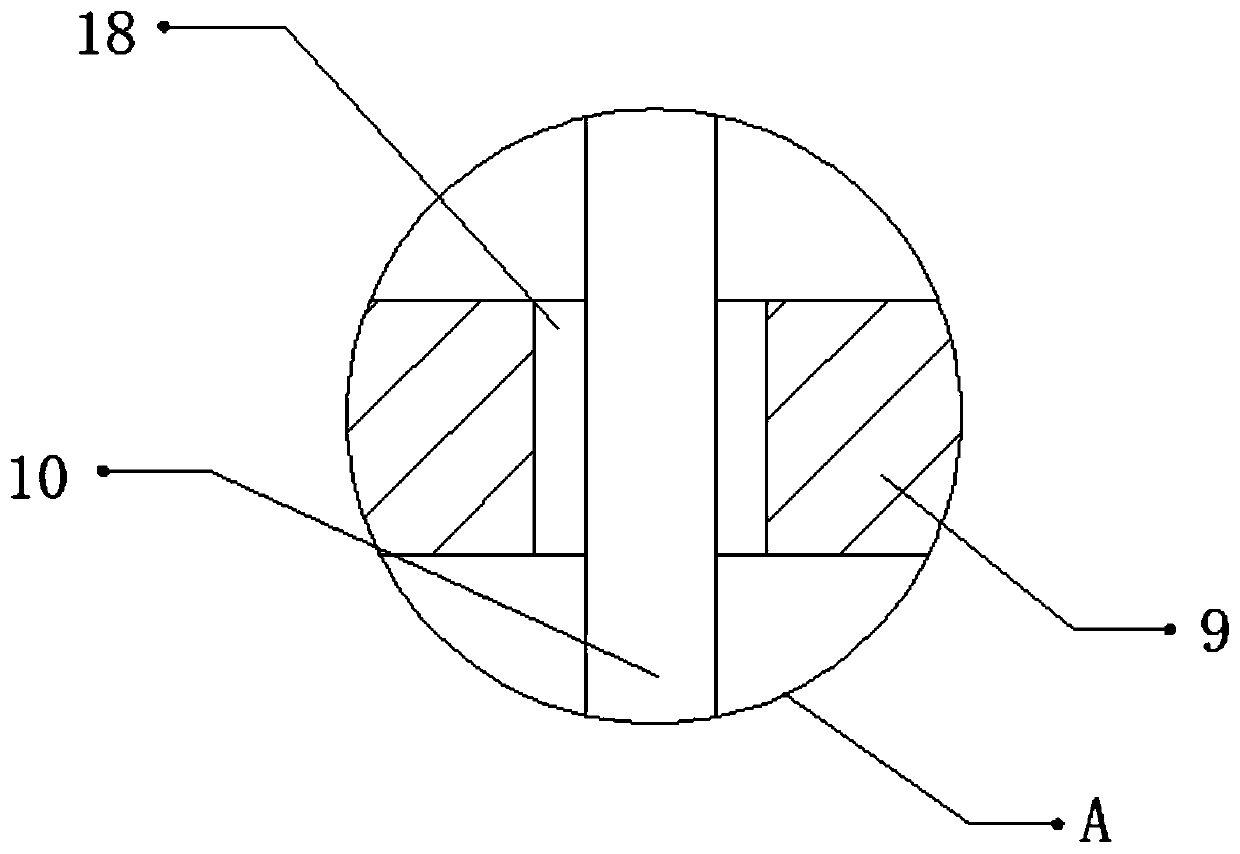

[0035] refer to Figure 4-5 , a grinding device with good cooling effect for machine tool processing. Compared with Embodiment 1, the inner walls of the two through holes 18 are provided with ball grooves, and the inner walls of the ball grooves are rollingly connected with balls 22, and the balls 22 The contact with the guide post 10 can reduce the frictional force between the guide post 10 and the through hole 18 to facilitate the lifting of the grinding disc 5 .

[0036]Working principle: when in use, place the workpiece to be ground inside the U-shaped groove 20, and by turning the threaded rod 4, the threaded rod 4 can clamp and fix the workpiece. The cutting disc 5 moves downward, and the first motor 6 will drive the grinding disc 5 to rotate, thereby grinding the workpiece. During this period, the second motor 8 drives the threaded screw 15 to rotate, so that the grinding disc 5 Move left and right, so as to carry out comprehensive grinding treatment on the workpiece, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com