Wear resistant diamond roller and manufacturing process thereof

A technology of diamond roller and diamond layer, which is applied in the direction of manufacturing tools, metal processing equipment, grinding devices, etc., can solve the problems of affecting the accuracy of the grinding wheel and the quality of sharpening, and achieve the effect of prolonging the service life and avoiding fractures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

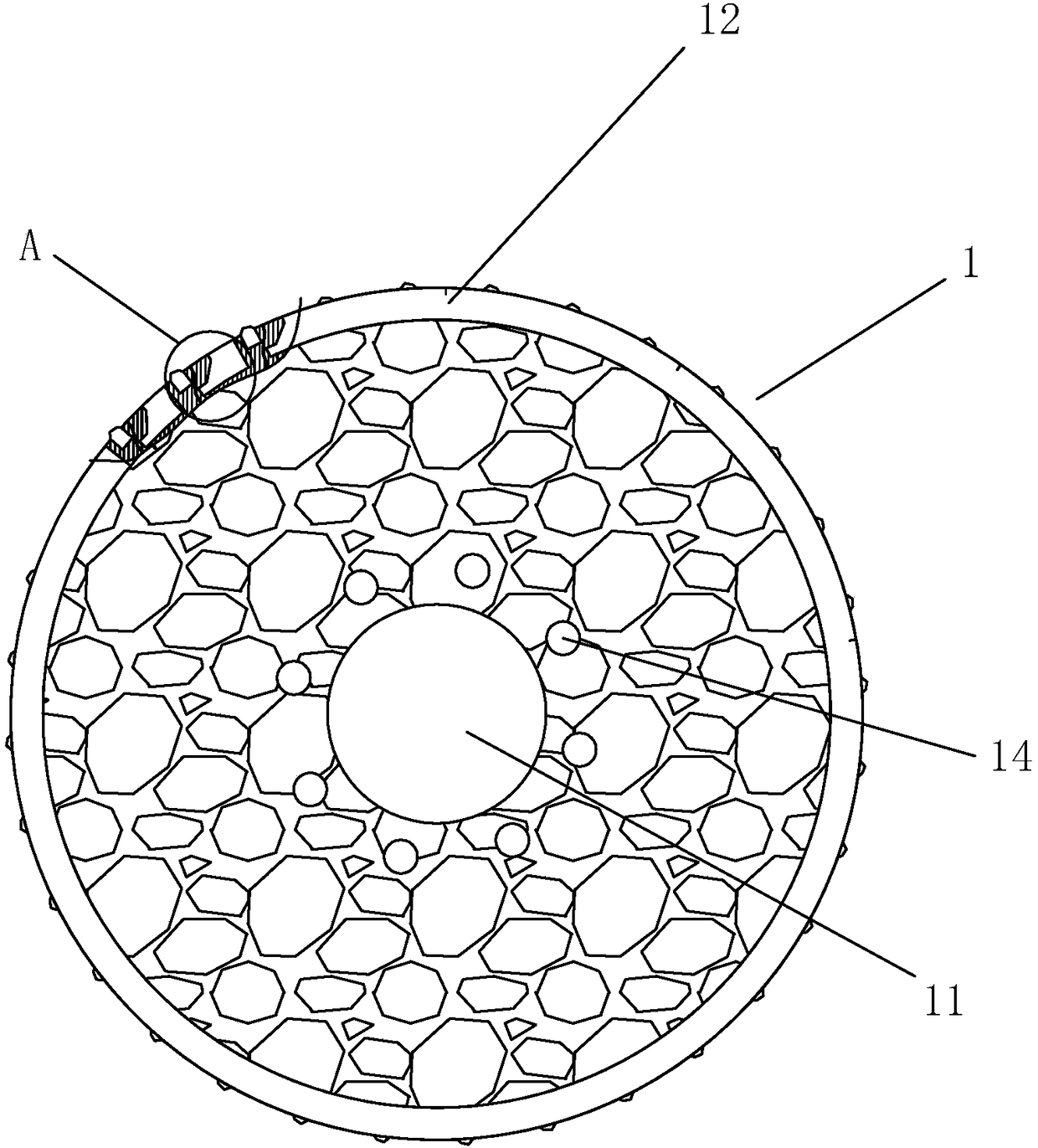

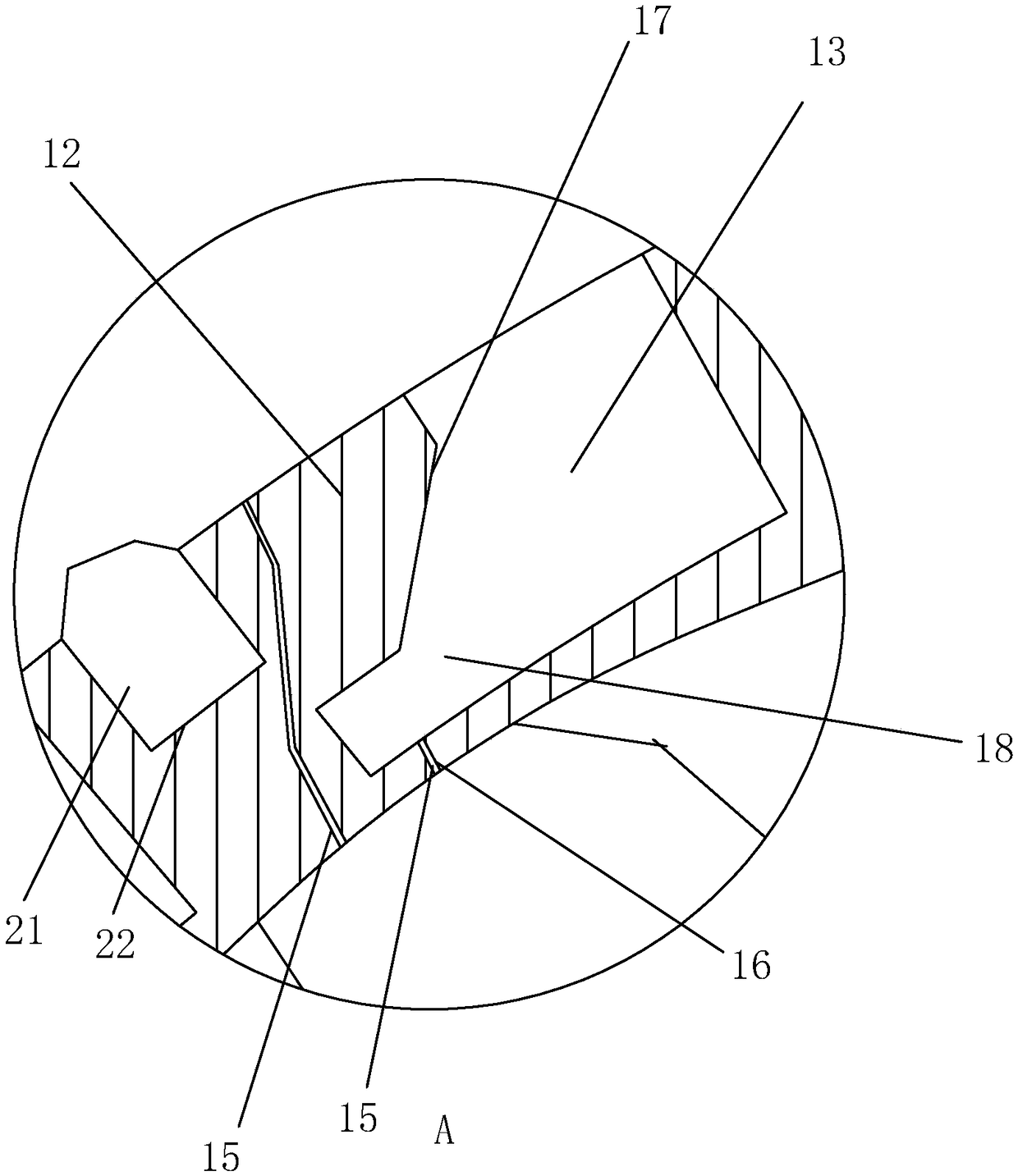

[0035] Embodiment 1: as figure 1 As shown, a wear-resistant diamond roller includes a cylindrical roller body. The center position of the circumferential end surface of the roller body is arranged along the axial direction to form a rotating hole. The rotating hole is matched with the frame of the grinding machine to grind the grinding wheel.

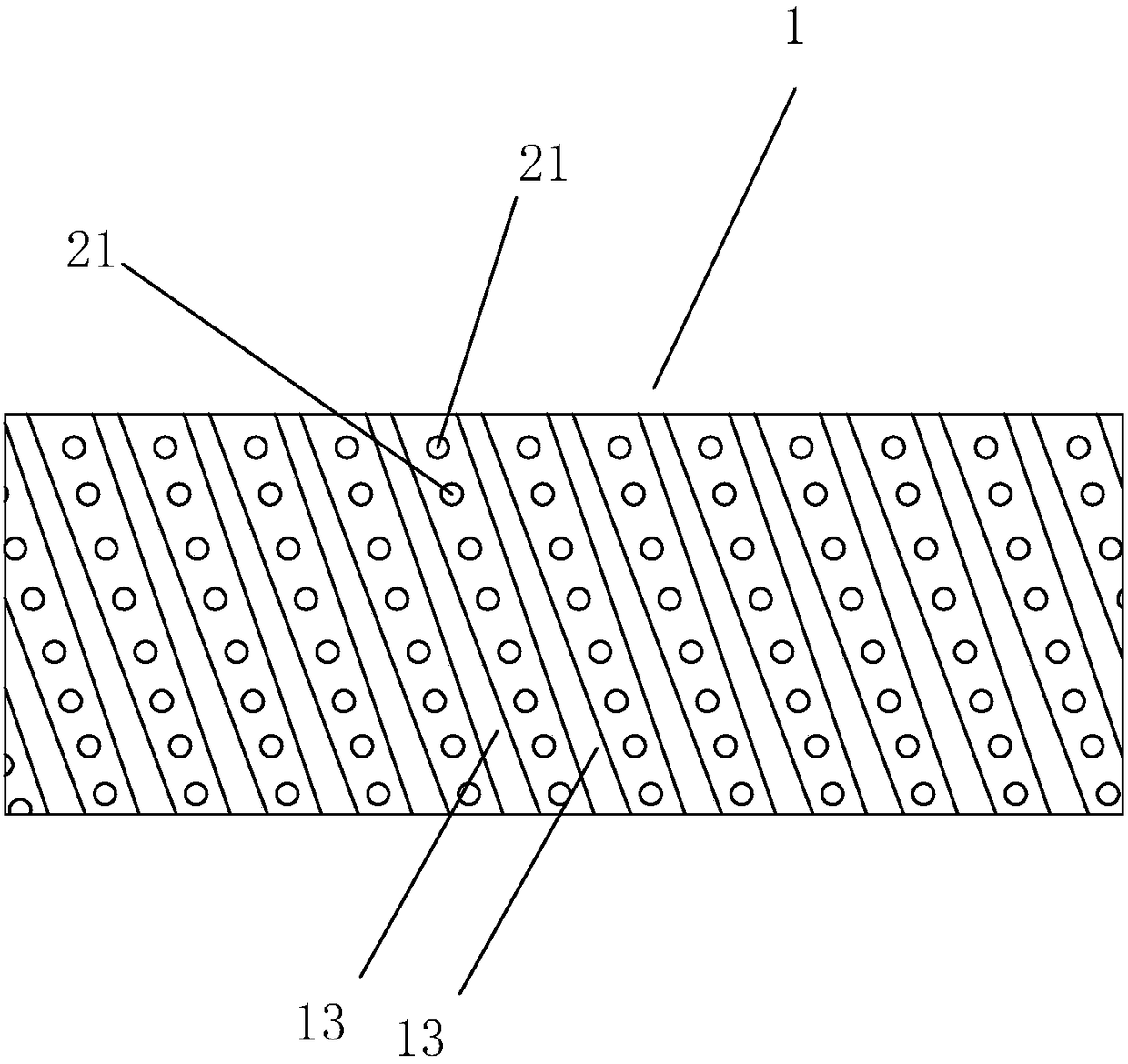

[0036] Such as figure 1 As shown, the outer surface of the roller body is provided with grooves, the grooves extend along the axial direction of the roller body, the grooves extend obliquely on the peripheral side of the roller body, and the grooves are evenly distributed along the peripheral side of the roller body, and the grooves The radial section of the roller body includes a guide groove extending inward along the circumference of the roller body, the bottom of the guide groove is recessed inward along the radial direction of the roller body to form a stacking groove, and the stacking groove and the guide groove are J-shaped in cr...

Embodiment 2

[0041] Embodiment 2: a kind of manufacturing process that is applied to wear-resistant diamond roller, is characterized in that, comprises the following steps:

[0042] Step 1. Inject the high-temperature-resistant trapezoidal polymethylsilsesquioxane into the mold and cool to form a capillary network;

[0043]Step 2. Mix the metal tungsten powder with capillary net and pour it into the sintering mold for pressing. At the same time, insert the diamond particles into the mold and carry out high-temperature sintering. The sintering temperature is 1050 degrees for 1.2 hours. After cooling, the sintering mold The roller base is unscrewed;

[0044] Step 3, the roller matrix in step 2 is drilled to form a water supply channel;

[0045] Step 4, pre-grinding the diamond particles on the side of the roller circumference;

[0046] Step 5, sharpen the groove on the side of the roller circumference;

[0047] Step 6. Soak the roller base in the dimethylformamide solution, vibrate by ult...

Embodiment 3

[0049] Embodiment 3: a kind of manufacturing process that is applied to wear-resistant diamond roller, is characterized in that, comprises the following steps:

[0050] Step 1. Inject the high-temperature-resistant trapezoidal polymethylsilsesquioxane into the mold and cool to form a capillary network;

[0051] Step 2. Mix metal tungsten powder with capillary net and pour it into a sintering mold for pressing. The mold is provided with bumps corresponding to the water supply channel. At the same time, insert diamond particles into the mold for high-temperature sintering. The sintering temperature is 1060 degrees. The duration is 1 hour, and after cooling, the roller matrix in the sintering mold is unscrewed;

[0052] Step 3, the roller matrix in step 2 is drilled to form a water supply channel;

[0053] Step 4, pre-grinding the diamond particles on the side of the roller circumference;

[0054] Step 5, sharpen the groove on the side of the roller circumference;

[0055] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com