Excavator big arm

An excavator and boom technology, which is applied in the field of mechanical processing equipment, can solve the problems of limited lifting angle of the bucket, unable to lift upwards, easy to be pressed by gravel or soil, etc., so as to improve the excavation efficiency and excavation effect, lift The effect of angle lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

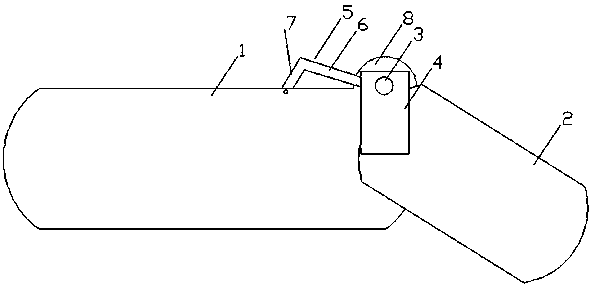

[0017] An excavator boom is characterized in that it includes a boom body 1, an extension arm 2 is arranged on the boom body 1, and the extension arm 2 is located at the end of the boom body 1, and the extension arm 2 passes through The connecting hole 3 is connected with the boom body 1, and the top of the extension arm 2 is provided with a connecting plate 4, the connecting hole 3 is located on the connecting plate 4, and the connecting plate 4 is provided with a fixing clip 5, and the fixing clip 5. The other end is fixed on the boom body 1. The application is provided with an extension arm 2 on the boom of the excavator, and the extension arm 2 can extend the length of the boom of the excavator, and can further increase the lifting angle of the excavator when digging, so as to prevent the excavator from digging soil or When crushing stones, the bucket is pressed by heavy objects and cannot be taken out. The position setting of the connecting plate 4 and the circular plate ...

Embodiment 2

[0019] An excavator boom is characterized in that it includes a boom body 1, an extension arm 2 is arranged on the boom body 1, and the extension arm 2 is located at the end of the boom body 1, and the extension arm 2 passes through The connecting hole 3 is connected with the boom body 1, and the top of the extension arm 2 is provided with a connecting plate 4, the connecting hole 3 is located on the connecting plate 4, and the connecting plate 4 is provided with a fixing clip 5, and the fixing clip 5. The other end is fixed on the boom body 1.

[0020] The fixing clip 5 includes a pillar 6 and a clip body 7 located on the pillar 6, and the clip body 7 is connected with the boom body 1 through bolts.

[0021] The connection hole 3 on the boom body 1 is located on the upwardly protruding circular plate 8 , and the circular plate 8 corresponds to the position of the connecting plate 4 of the extension arm 2 .

[0022] The boom body 1 and the extension arm 2 are each integrally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com