Cooling and collecting device for metallurgical billets

A material receiving device and technology for blanks, which are applied in the treatment of discharged materials, furnace components, and cleaning methods using tools, etc., can solve the problems of blank quality and subsequent process effects, uneven cooling of blanks, and unfavorable automatic production. To achieve the effect of good cooling and drying effect, no water residue, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

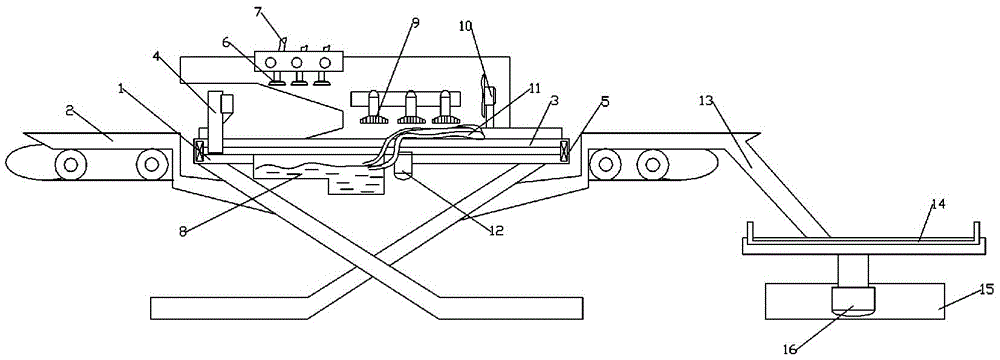

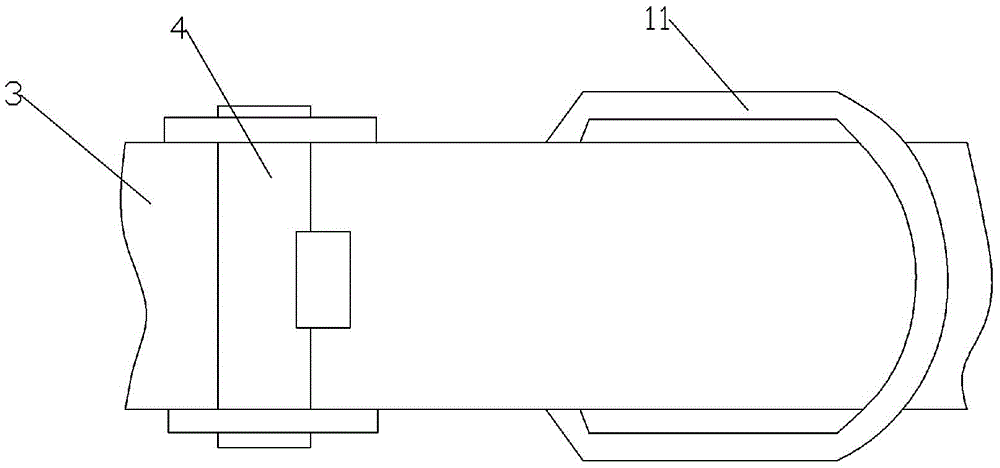

[0014] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, slide plate 3, support frame 4, slide rail 5, sprinkler head 6, water inlet pipe 7, water collection tank 8, hair brush 9, fan 10, circulation Heat dissipation pipe 11, water pump 12, sliding material plate 13, receiving tray 14, base 15, stepper motor 16.

[0015] The embodiment is basically as attached figure 1 , figure 2 Shown: the cooling and receiving device for metallurgical blanks, including frame 1 and conveyor belt 2 located on the left and right sides of frame 1, conveyor belt 2 is driven by a motor, and frame 1 is equipped with The slide plate 3 opposite to the conveyer belt 2 on both sides is provided with a support frame 4 for pushing the blank. The two ends of 4 are slidably connected with the slide rail 5, and a pusher part is provided on the support frame 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com