Automatic material collecting machine

A reclaimer, automatic technology, applied in the field of rewinders, can solve the problems of extremely high stability requirements, affecting the processing effect of high-temperature furnaces, low efficiency of manual methods, etc., and achieves the effects of convenient operation, compact structure and simple appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

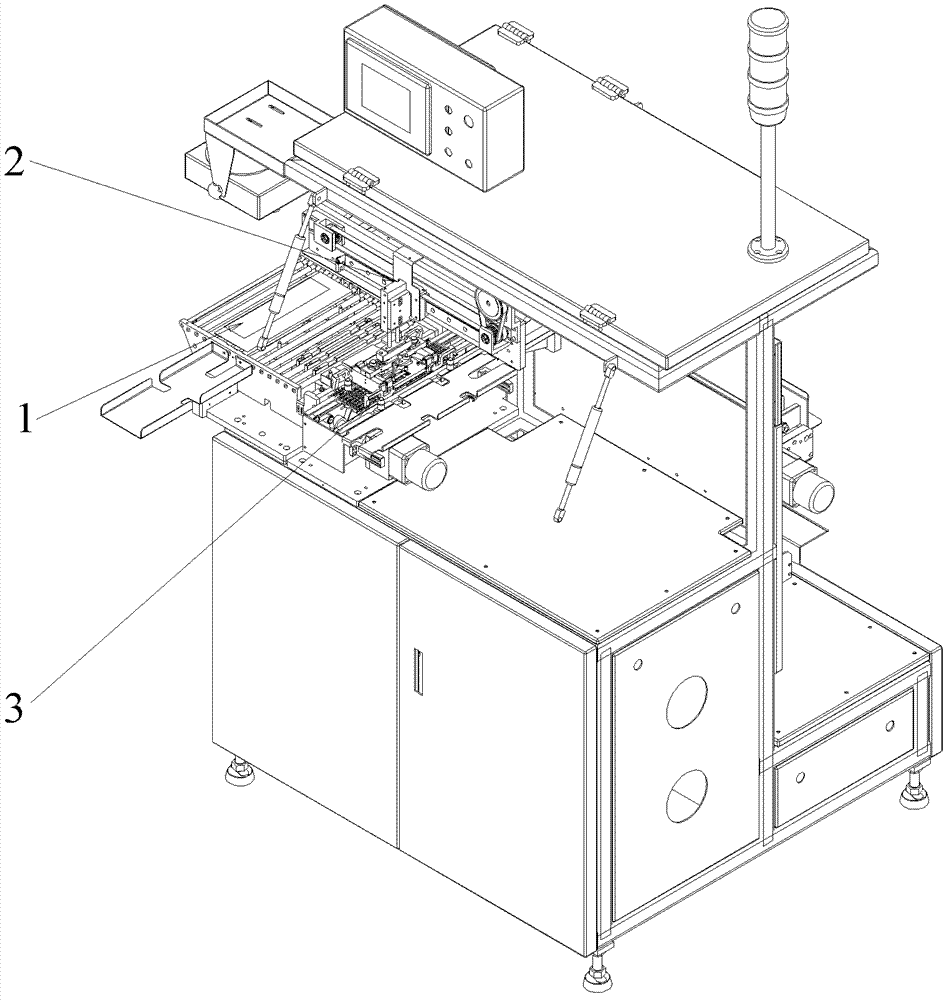

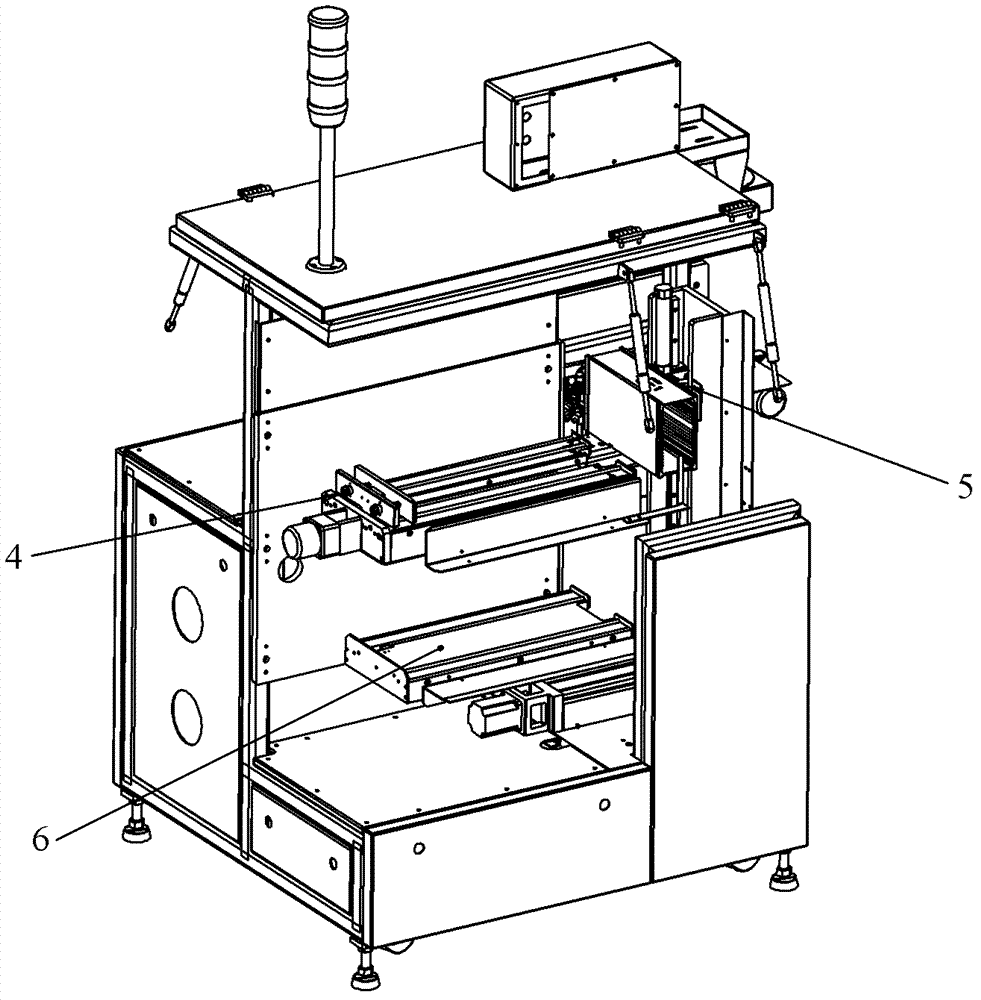

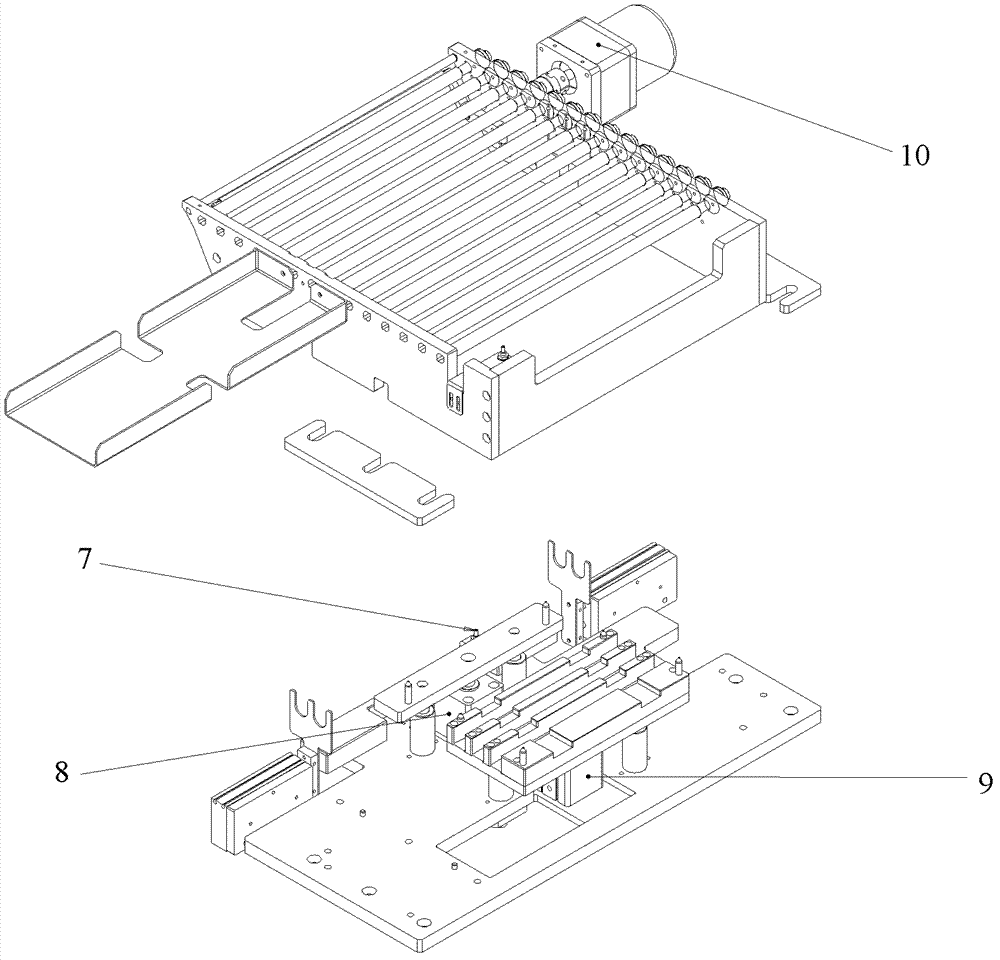

[0024] Such as figure 1 with figure 2 As shown, the automatic receiving machine of the present invention includes a whole material mechanism 1, a material strip picking and placing mechanism 2, a material strip conveying mechanism 3, a first magazine conveying mechanism 4, a magazine grasping mechanism 5, and a second magazine conveying mechanism 6 , the monolithic mechanism 1 is located below the material strip pick-and-place mechanism 2, the material strip conveying mechanism 3 is located on one side of the monolithic mechanism 1, and the first magazine conveying mechanism 4 is located below the magazine grasping mechanism 5 and conveyed with the material strip The mechanism 3 is arranged oppositely, and the second magazine conveying mechanism 6 is located below the first magazine co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com