Production process of anti-pill combed woolen sweater

A production process and sweater technology, which is applied in biochemical fiber processing, textiles and papermaking, fiber processing, etc., can solve the problems of increased pilling, low warp and weft density, large dispersion of length and fineness, etc., and achieve reduction Fiber damage, tight and smooth structure, and the effect of maintaining style characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

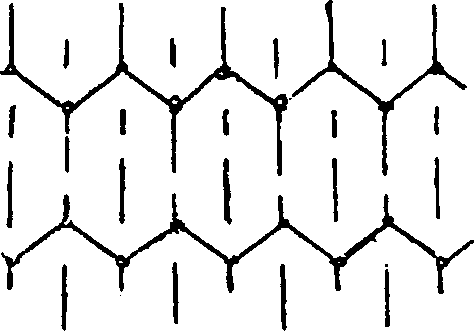

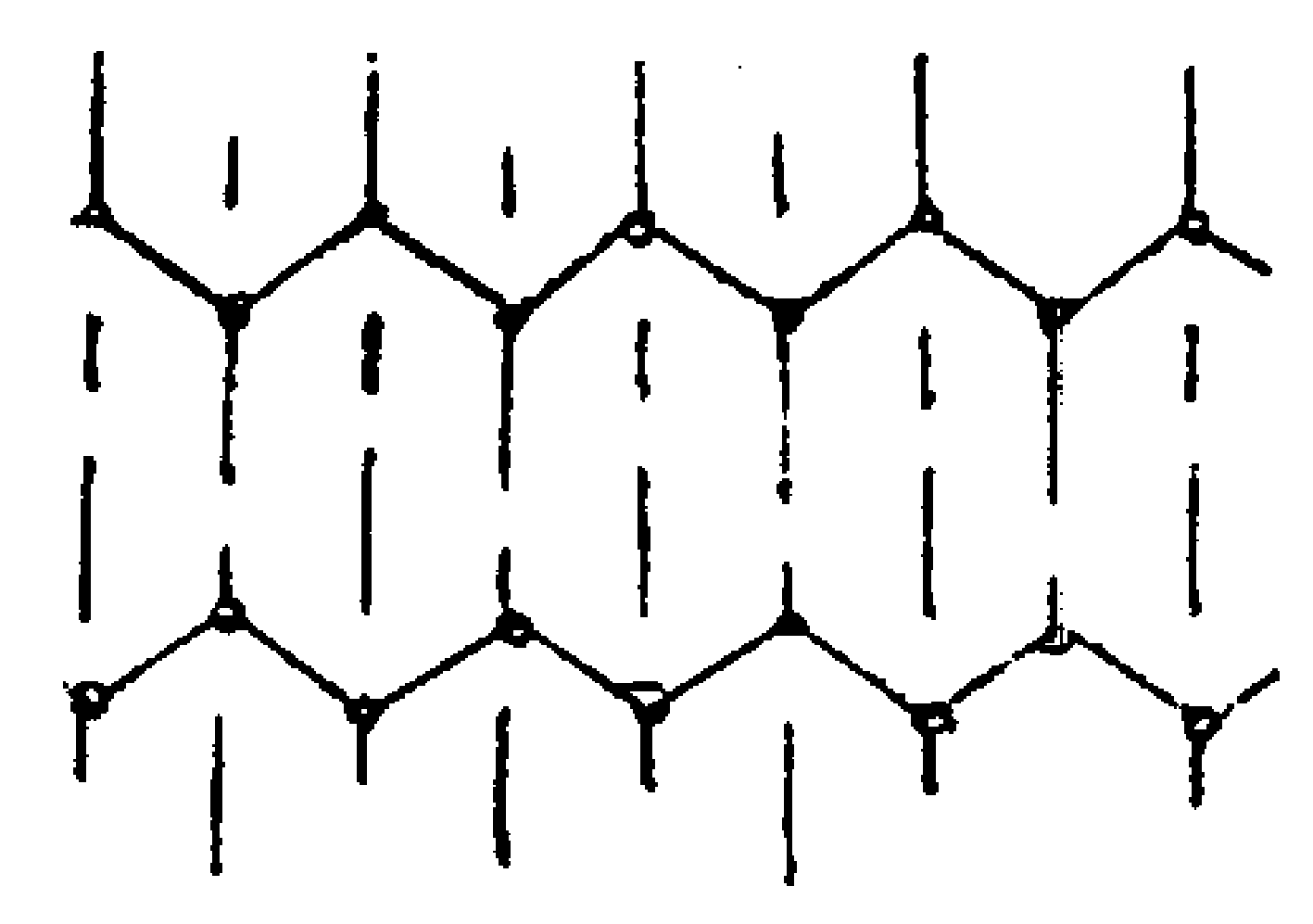

Method used

Image

Examples

Embodiment 1

[0016] The re-combing process of wool tops adopts the process of merging 20 pieces, outputting one piece, drafting multiple of 20, and sliver weight of 20g / m, so as to control the average length of fibers in the top ≥ 90mm, the length of the main body ≥ 110mm, and the length dispersion ≤ 30 %, short hair rate ≤ 2.5% under 30mm.

Embodiment 2

[0018] The production of woolen sweaters with raw yarns of 40 metric counts has a single yarn twist coefficient of 95 and a twist of 600 twists / m.

Embodiment 3

[0020] The protease used in the alkaline protease treatment process before wool yarn dyeing is Novo Lan. The bath ratio of the treatment solution is 1:20, the pH value of the treatment solution is 8, the treatment temperature is 45° C., and the treatment time is 45 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com