Automatic dust blowing method for jeans

A jeans and automatic technology, applied in the direction of chemical instruments and methods, cleaning methods and utensils, textiles and papermaking, etc., can solve problems such as poor working environment, great health hazards for staff, and low work efficiency, and achieve good consistency and avoid The effect of large movement and stable pocket position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing:

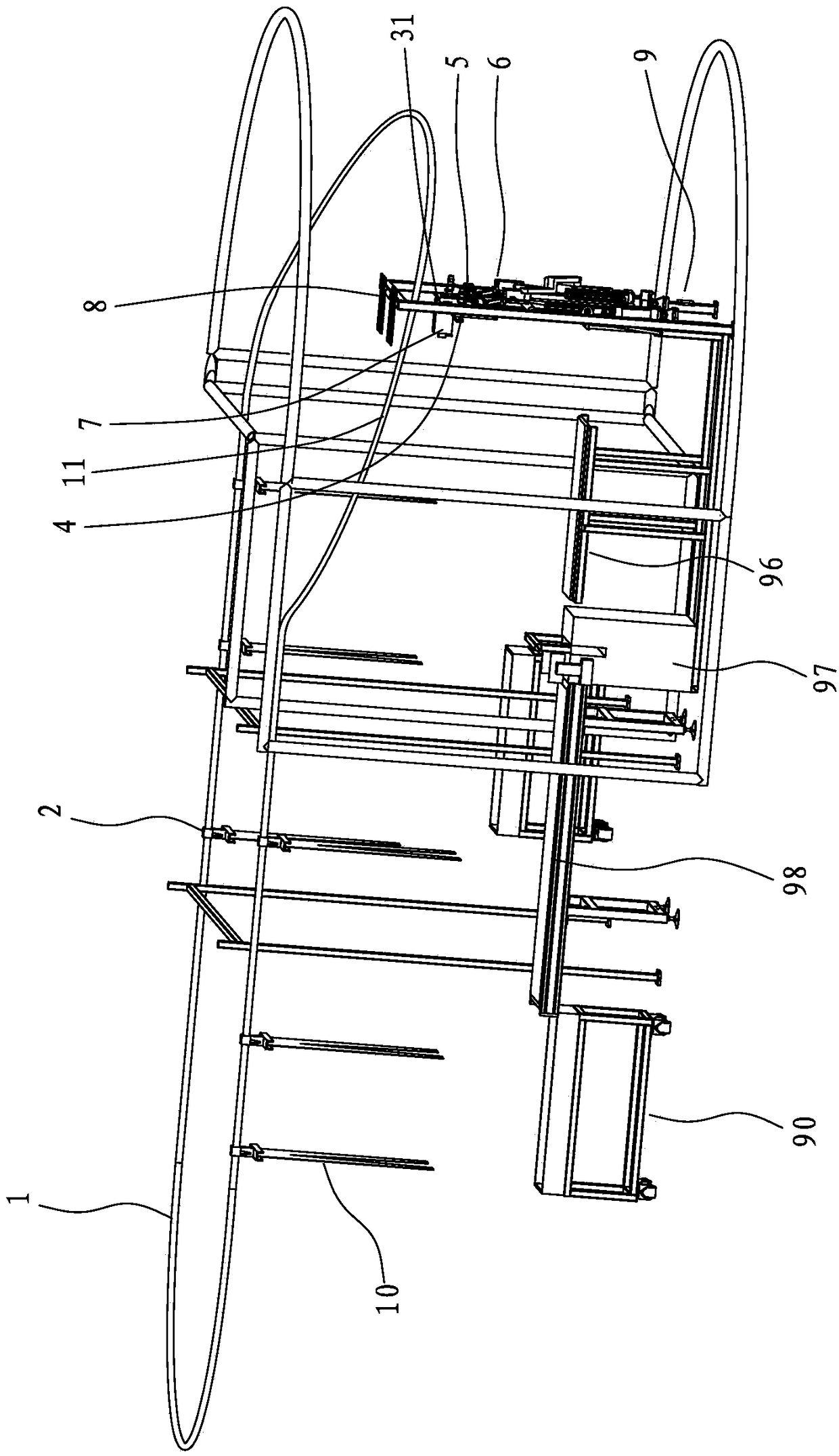

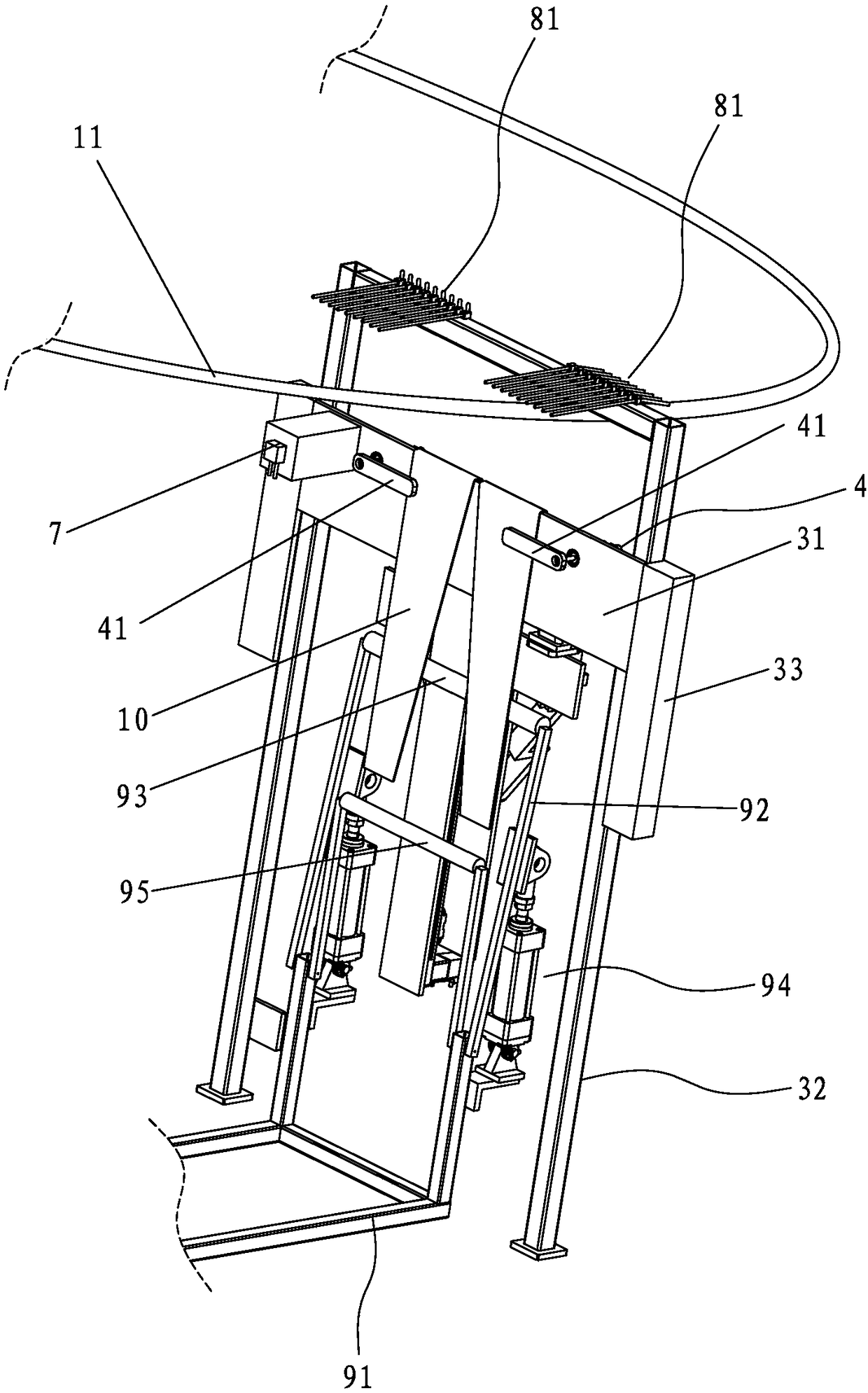

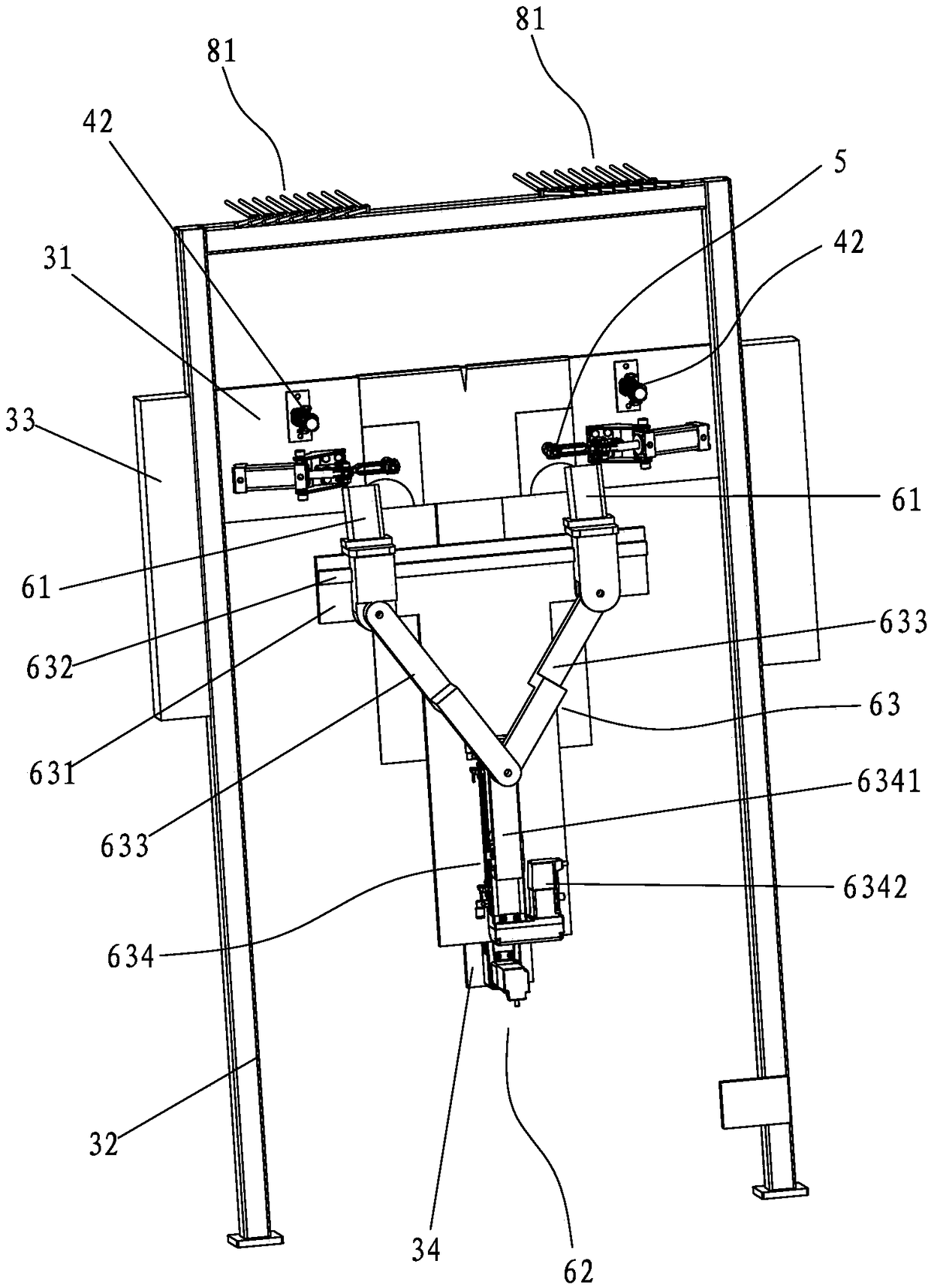

[0055] like Figure 1 to Figure 9 The shown automatic sootblowing equipment for jeans includes a circulation line 1 capable of reciprocating motion, and the circulation line 1 is provided with a hanging device 2 for hanging the jeans 10 from the upper part of the jeans. When hanging, the Hang the trousers top of the jeans upwards on the hanging device 2, and the side of the pocket that needs to be blown is facing backwards. Below the flow line 1, there is a pair of jeans that can pass through when the jeans move forward along the flow line 1. The baffle 31 blocked from the middle of the jeans, the baffle 31 is set upwards and the baffle 31 is provided with a pressing device 4 for pressing the jeans blocked by the rear side of the baffle 31 on the baffle 31, the hanging After the hanging device 2 passes through the baffle 31 and continues to move forward, the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com