Reel type take-up device in recording equipment

A technology of burning equipment and a material receiving device, which is applied in the directions of packaging, winding strips, thin material processing, etc., can solve the problems of low efficiency of material receiving, low degree of automation, failure to achieve fully automatic material receiving, etc. To achieve the effect of improving the efficiency of receiving materials and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

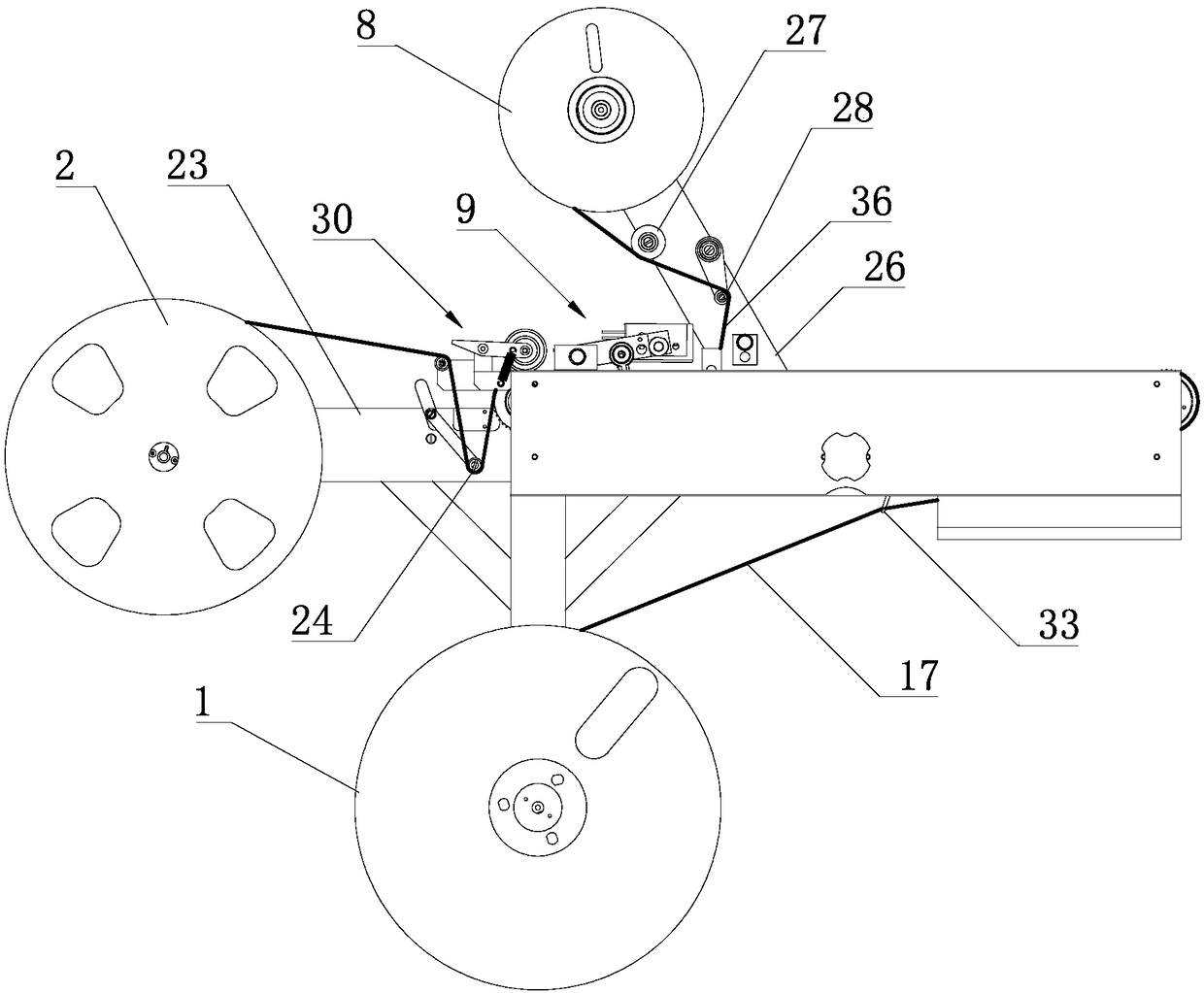

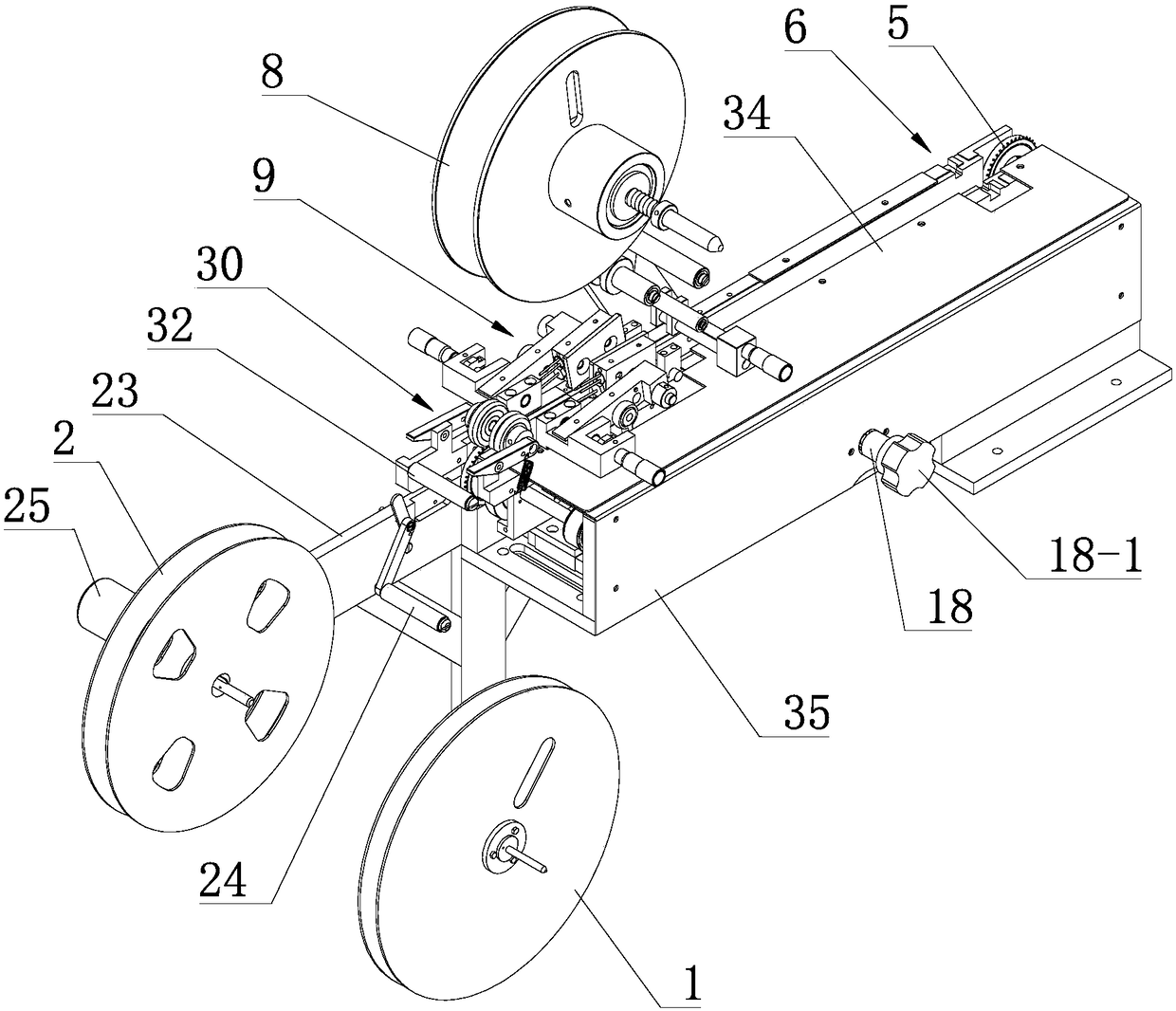

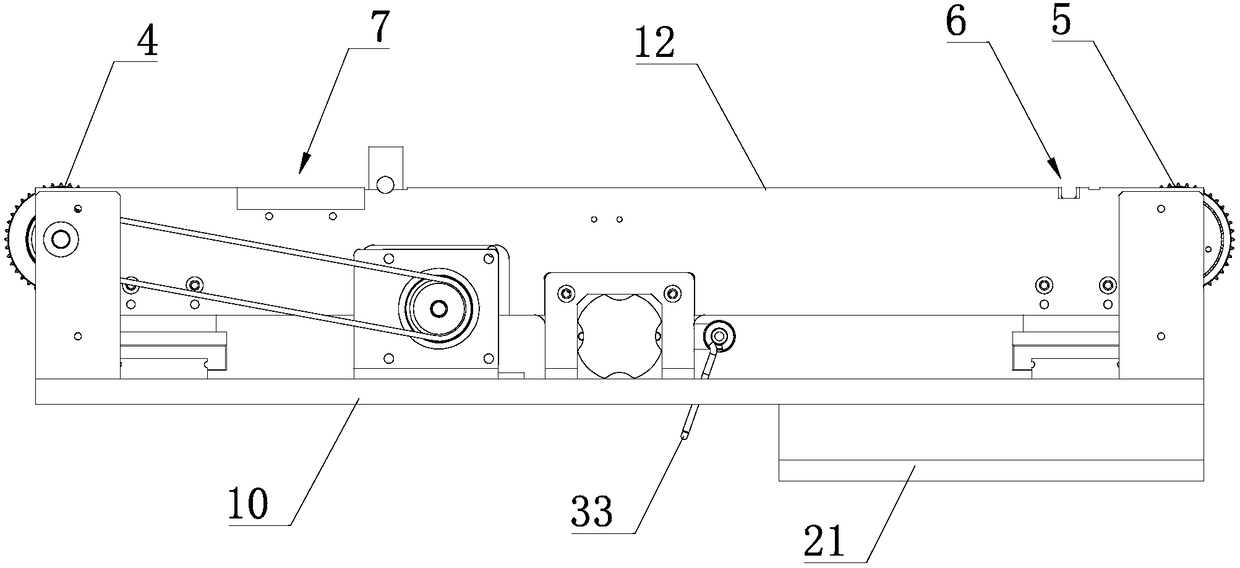

[0047] see Figure 1-5 , the reel-type receiving device in the burning equipment in the present embodiment, comprises the unwinding reel 1 that is used to place the unloaded chip belt 17, is used to collect the winding of the chip belt 17 that has burnt chip Disc 2, chip tape conveying mechanism and film covering mechanism; wherein, said chip tape conveying mechanism includes two supporting guide plates and a chip tape driving mechanism fixedly connected on the frame of burning equipment, and said chip tape driving mechanism includes Drive wheel and chip tape driver 3, the drive wheel includes a drive wheel 4 and a driven wheel 5 that are rotatably connected to the chip tape drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com