CNC discharging disc inserting device for PCB tiny-drill groove forming

A technology of blanking and inserting disks, applied in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of cutting edge or thread angle gap, inconvenient manual operation, PCB micro-drilling easily hurting hands, etc. , to achieve the effect of increasing the rate of material collection, reducing energy consumption and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

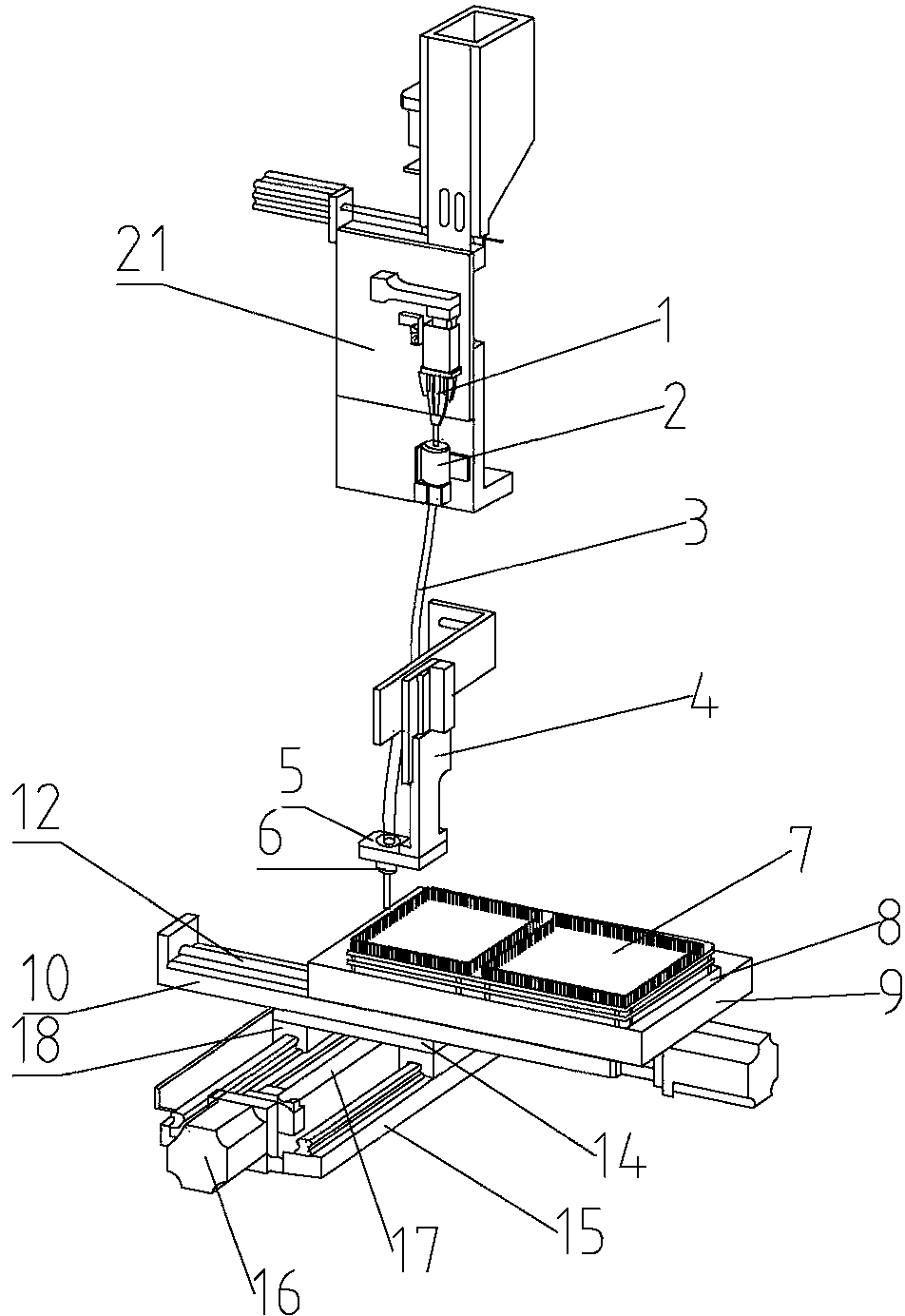

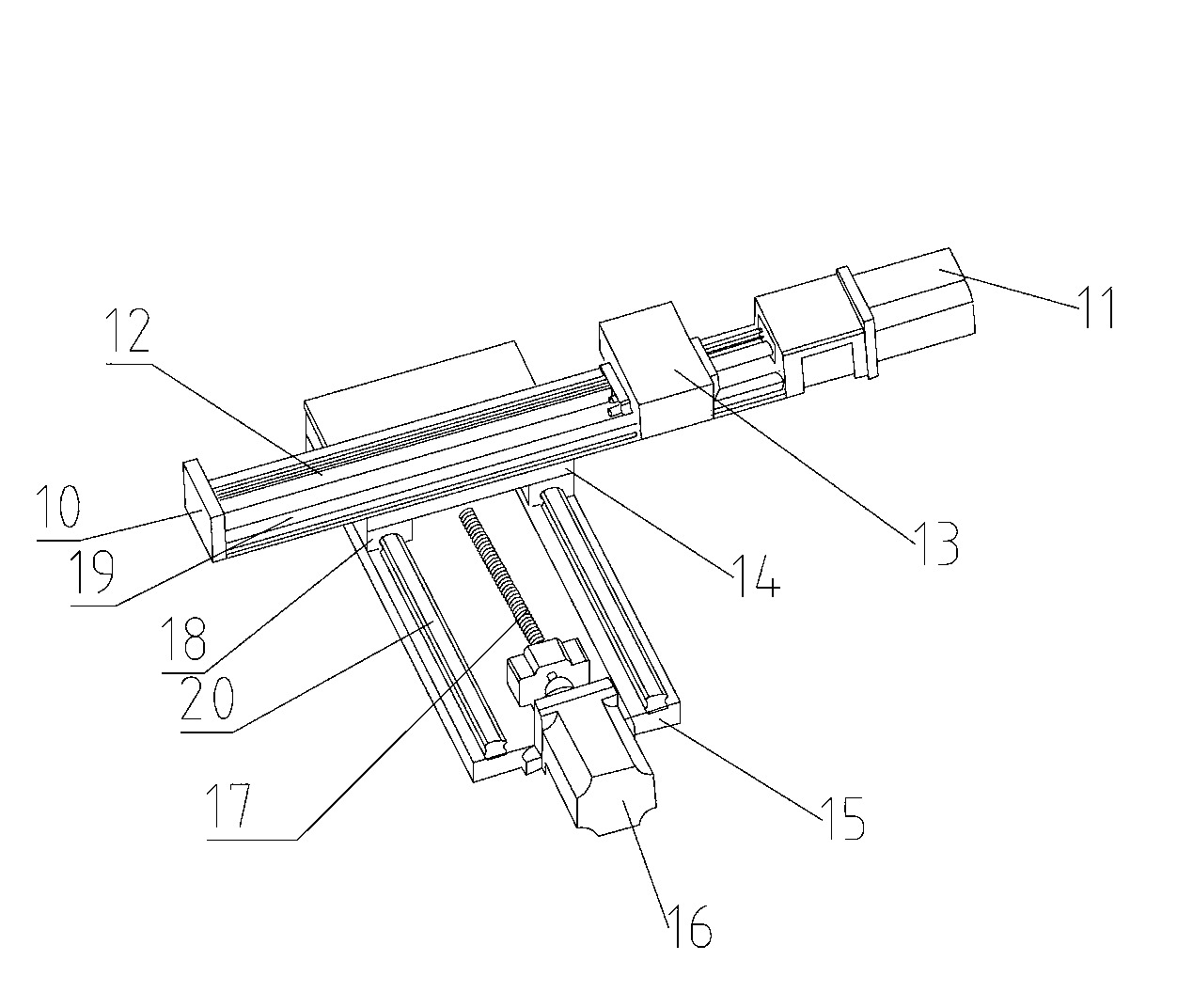

[0021] Such as figure 1 As shown, the CNC blanking device for slotting PCB micro-drilling includes a blanking mechanism and a receiving mechanism located below the blanking mechanism. The blanking mechanism includes a blanking frame 21, and the blanking frame 21 is installed There are feeding pneumatic finger 1 and receiving hopper 2. The receiving hopper 2 is below the pneumatic finger 1. The bottom end of the receiving hopper 2 is provided with a feeding port, and a feeding pipe 3 is installed at the feeding port; the above-mentioned receiving mechanism includes Receiving upper and lower cylinders 4, the XY moving device located under the receiving upper and lower cylinders 4, and the tray point plate 8 installed on the XY moving device for carrying the tray; the bottom of the receiving upper and lower cylinders 4 is equipped with a guide groove 6. A ring-shaped metal detection sensor 5 is arranged on the periphery of the material guide trough 6, and the bottom end of the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com