Automatic transfer system of adjustable loading tray for final sterilized product

An automated system and adjustable technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of multi-turnaround sterilization trays, increased deformation and damage of sterilization trays, and limited number of sterilization trays. Achieve the effect of reducing fixed asset investment, convenient, efficient and high-quality transshipment, orderly and safe working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

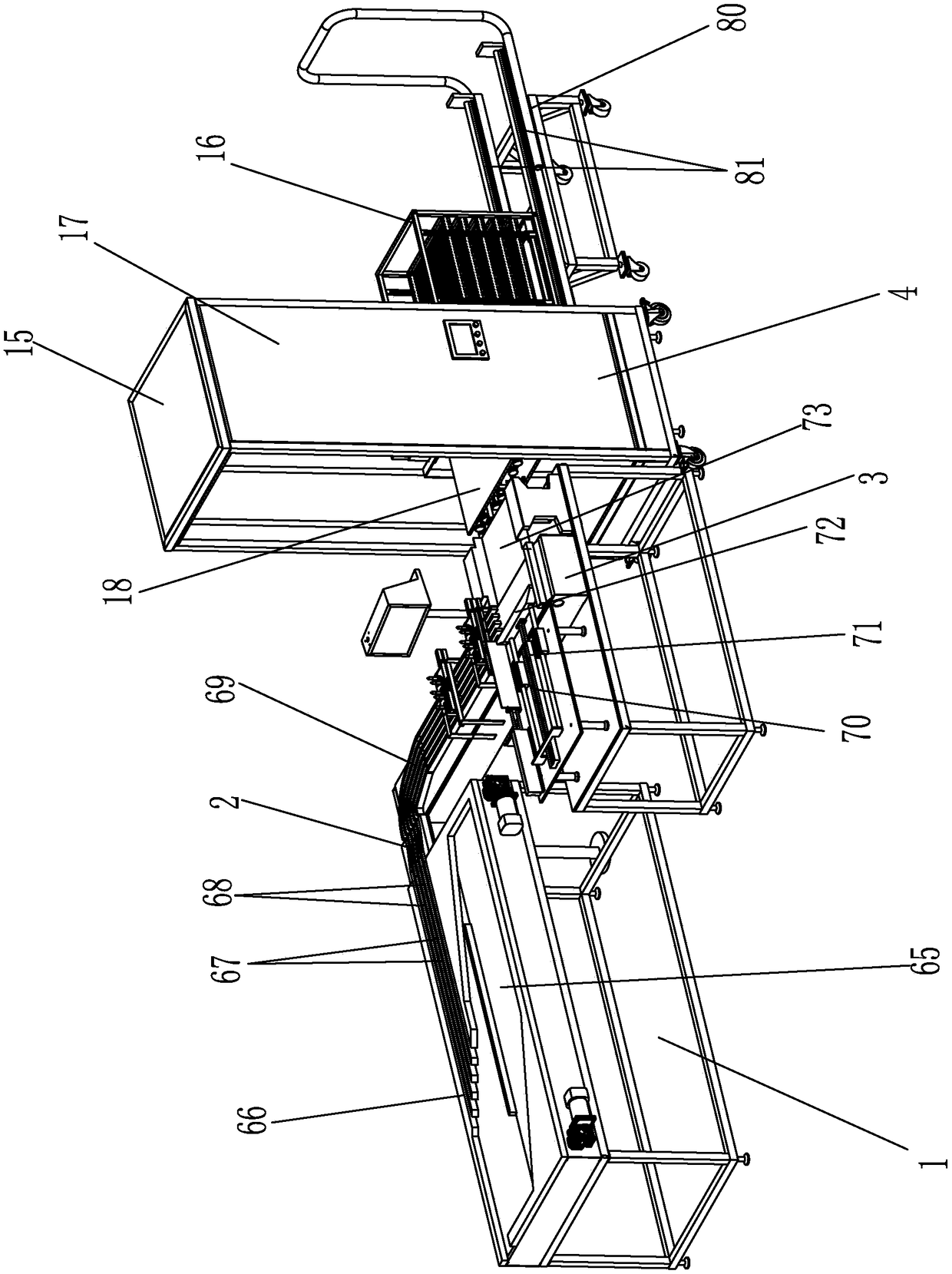

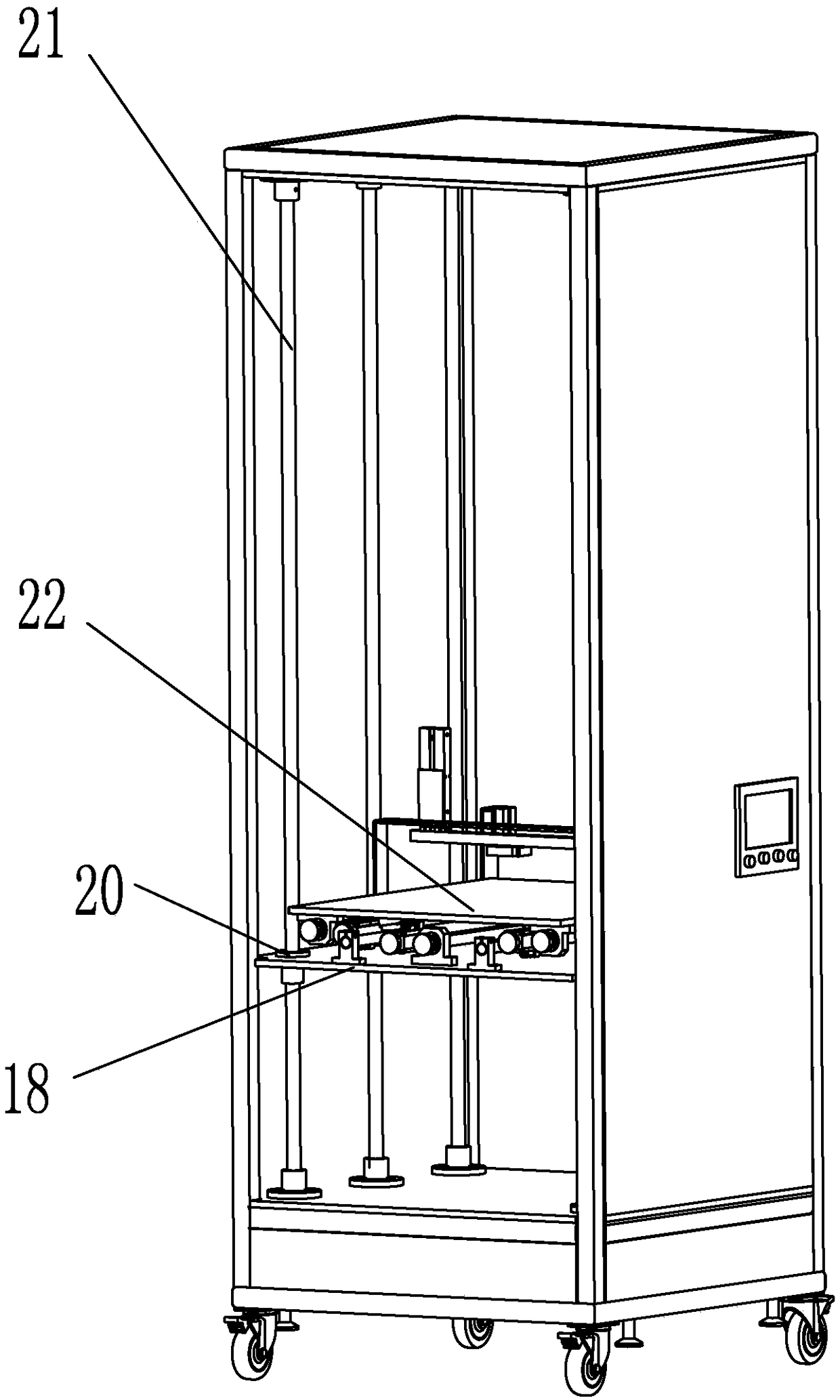

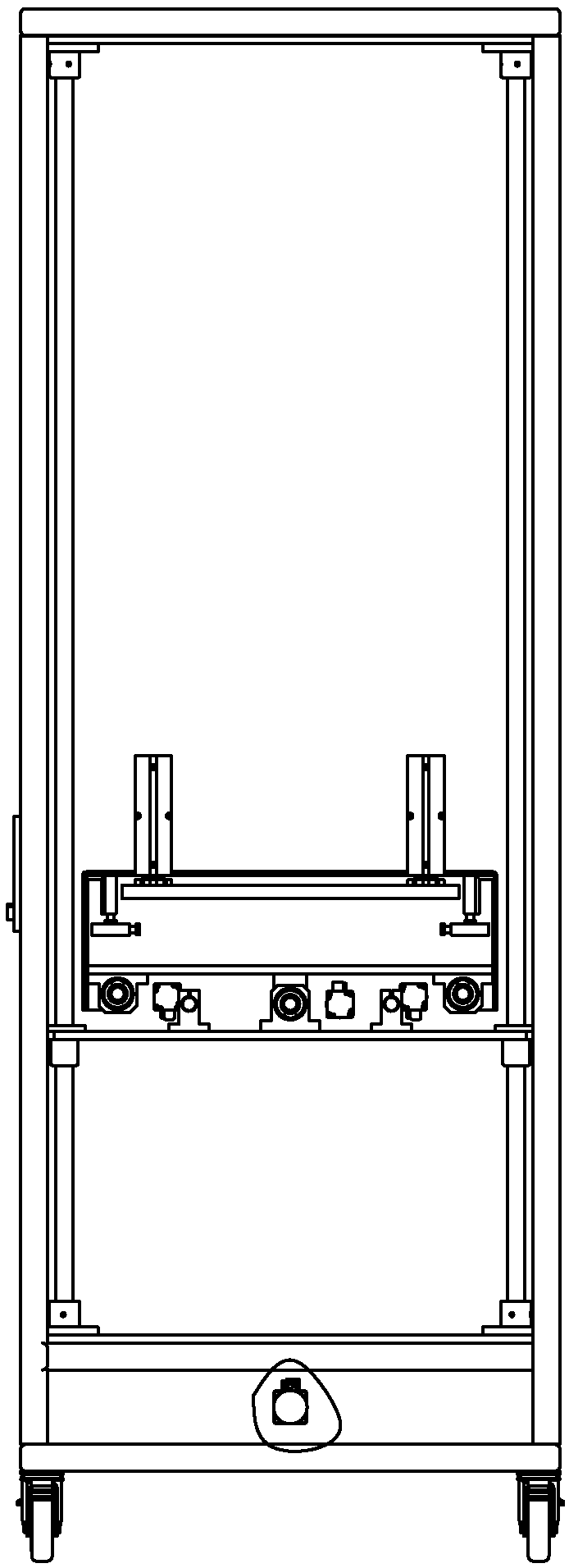

[0028] according to Figure 1-14 , an adjustable loading tray transfer automation system for terminally sterilized products, characterized in that the machine includes a multi-track feeding device 1, a multi-track bottle picking device 2, a multi-track alignment machine 3, a receiving and transferring device 4 and Feeding transfer device 5, the multi-track bottle picking device 2 includes a bottle picking box 6 and a bottle picking filter plate 7 fixedly connected with the bottle picking box 6 upper ends, and the bottle picking filter plate 7 includes a bottom plate 8, a first Fixed plate 9 and the second fixed plate 10, between described first fixed plate 9 and the second fixed plate 10, be provided with several bottle picking guide rails 11 identical in structure, between described first fixed plate 9 and pick bottle guide rail 11 Between the bottle picking guide rail 11 and the bottle picking guide rail close to the bottle picking guide rail and between the second fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com