Bearing receiving device

A technology of a receiving device and a discharging device, which is applied in the field of bearing transportation, can solve the problems of increasing the labor intensity of the staff and not being better, and achieve the effects of simple structure, improved production efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

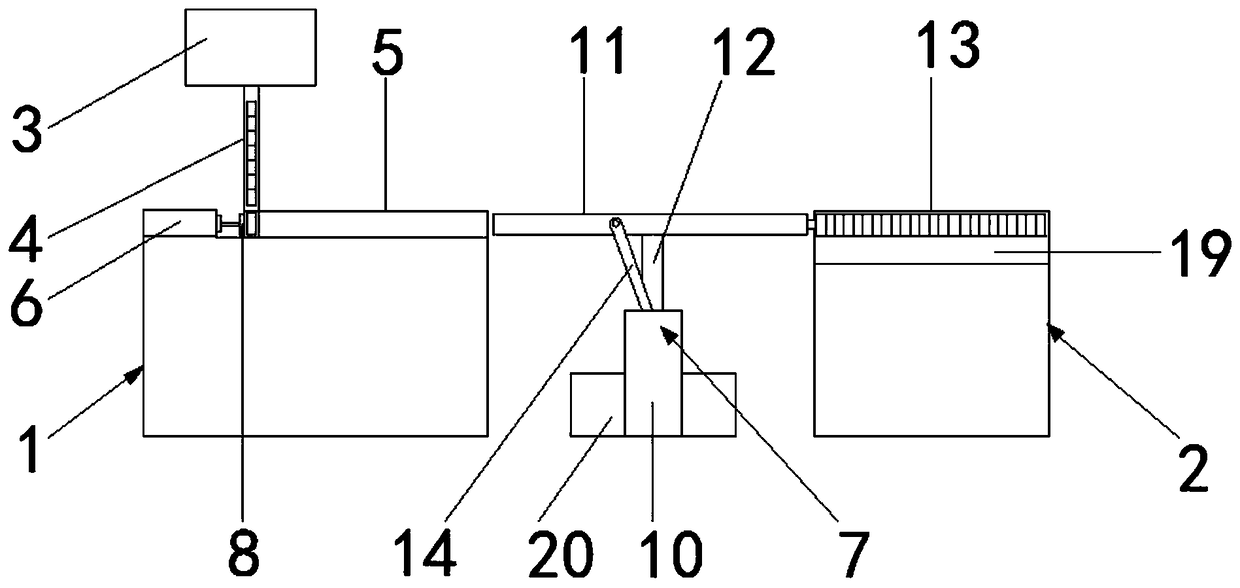

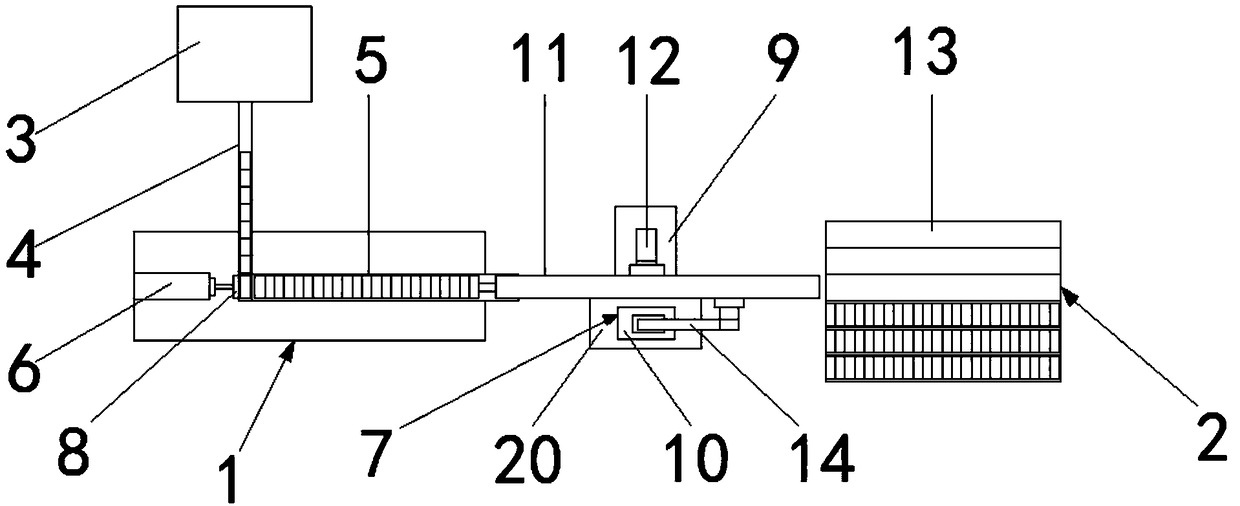

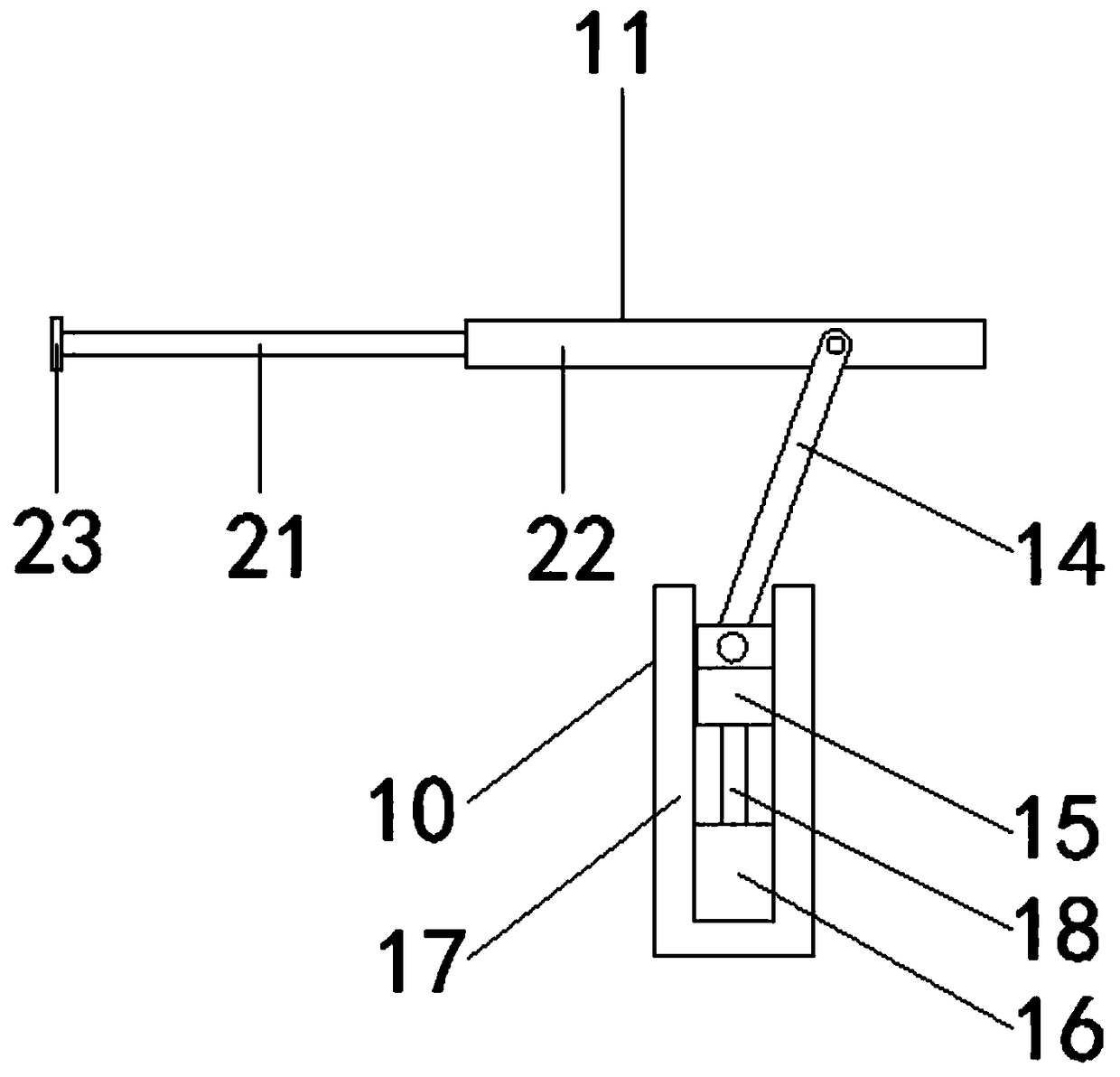

[0020] Such as figure 1 As shown, a bearing receiving device includes a pushing mechanism 1 and a stacking mechanism 2. The pushing mechanism 1 is adjacent to a discharge device 3, and the discharge device 3 passes through a discharge channel arranged obliquely downward. 4 is connected to the pusher mechanism 1, and the pusher mechanism 11 is provided with a horizontal first stacking chute 5 at the junction of the discharge channel 4, and one end of the first stacker 5 is adjacent to the discharge channel 4. The electro-hydraulic push rod 6 is provided with a transmission mechanism 7 adjacent to the other end, and the front end of the electro-hydraulic push rod 6 is provided with a product push plate 8, and the transmission mechanism 7 includes a base 9, a rocker drive mechanism 10, an electric telescopic rod 11. The base 9 is fixedly connected with a support rod 12, and the support rod 12 articulates the electric telescopic rod 11, and the other side of the electric telescopi...

Embodiment 2

[0024] Such as figure 1 As shown, a bearing receiving device includes a pushing mechanism 1 and a stacking mechanism 2. It is characterized in that: the pushing mechanism 1 is adjacent to a discharge device 3, and the discharge device 3 is arranged obliquely downward The discharge passage 4 is connected with the push mechanism 1, and the push mechanism 11 is provided with a horizontal first stacking chute 5 at the junction of the discharge passage 4, and the first stack trough 5 is adjacent to the discharge passage 4 One end is provided with an electro-hydraulic push rod 6, and the other end is adjacent to a transmission mechanism 7, and the front end of the electro-hydraulic push rod 6 is provided with a product push plate 8, and the transmission mechanism 7 includes a base 9, a rocker drive mechanism 10 , electric telescopic rod 11, described base 9 is fixedly connected with support rod 12, and described support rod 12 articulates described electric telescopic rod 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com