Electrode plate wrapping method

A pole plate and wrapping technology, which is applied to the field of wrapping battery plates, can solve the problems of workers' health hazards, low work efficiency, errors in subsequent processes, etc., so as to save labor costs, improve production efficiency and improve accuracy. The effect of reliable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

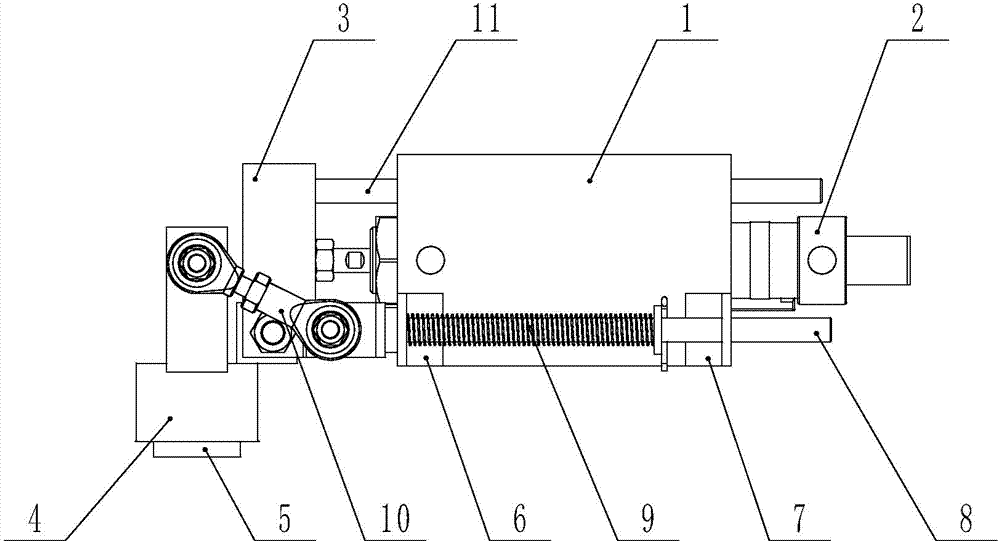

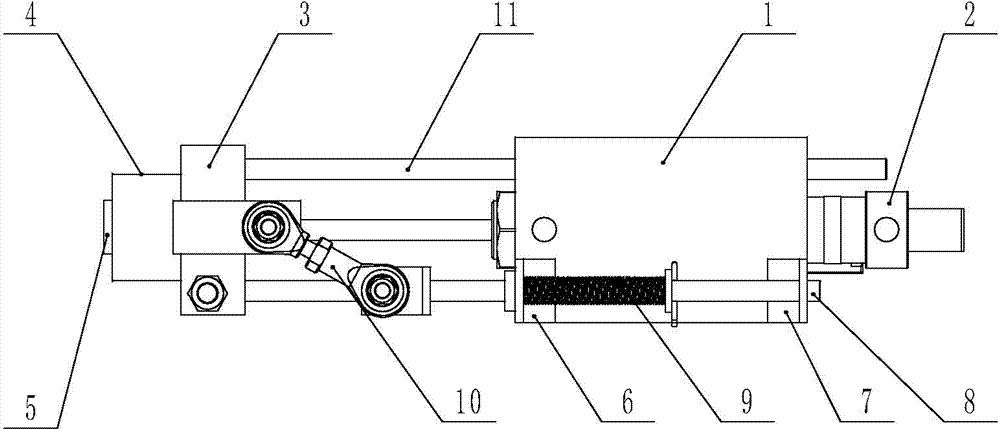

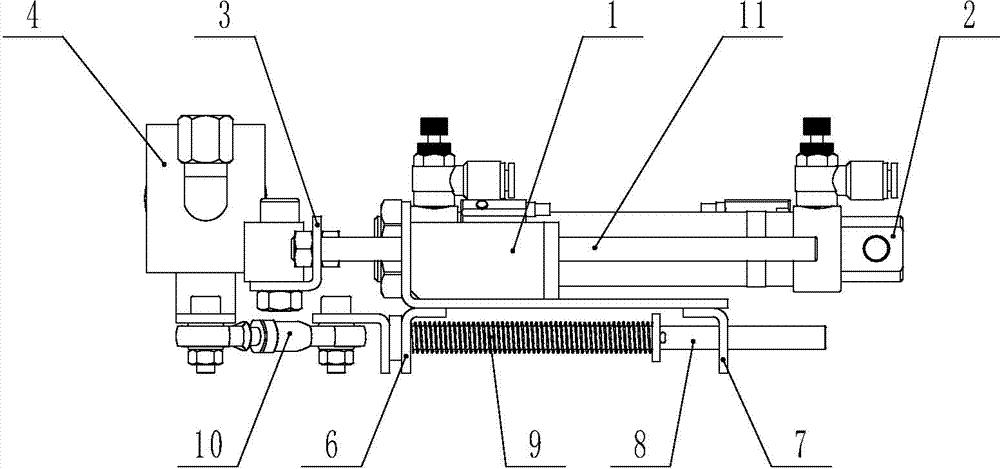

Image

Examples

Embodiment Construction

[0026] Hereinafter, the electrode plate wrapping method of the present invention will be further described in detail through specific embodiments.

[0027] The method of plate packing includes the following steps: firstly, the positive plate and the negative plate are arranged vertically in the plate bin, and then the material is taken by the reclaiming device. First, a suction cup is used to horizontally suck a positive plate to attract the positive electrode. After the plate is turned down 90°, the positive plate is placed in the trough, and the material is moved by the material moving device. The positive plate placed in the trough is moved forward by one station, and the separator paper is moved from top to bottom. After being cut by a cutter, the positive plate is vertically set on the trough. The positive plate continues to move forward by one station. During the movement, the front end of the positive plate contacts the middle of the separator paper. As the positive plate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com