Hydraulic self-running inclined-hole ordinary-state concrete casting trolley

A self-propelled and trolley technology, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of heavy formwork trolley, backward sliding construction, unstable driving, etc. Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

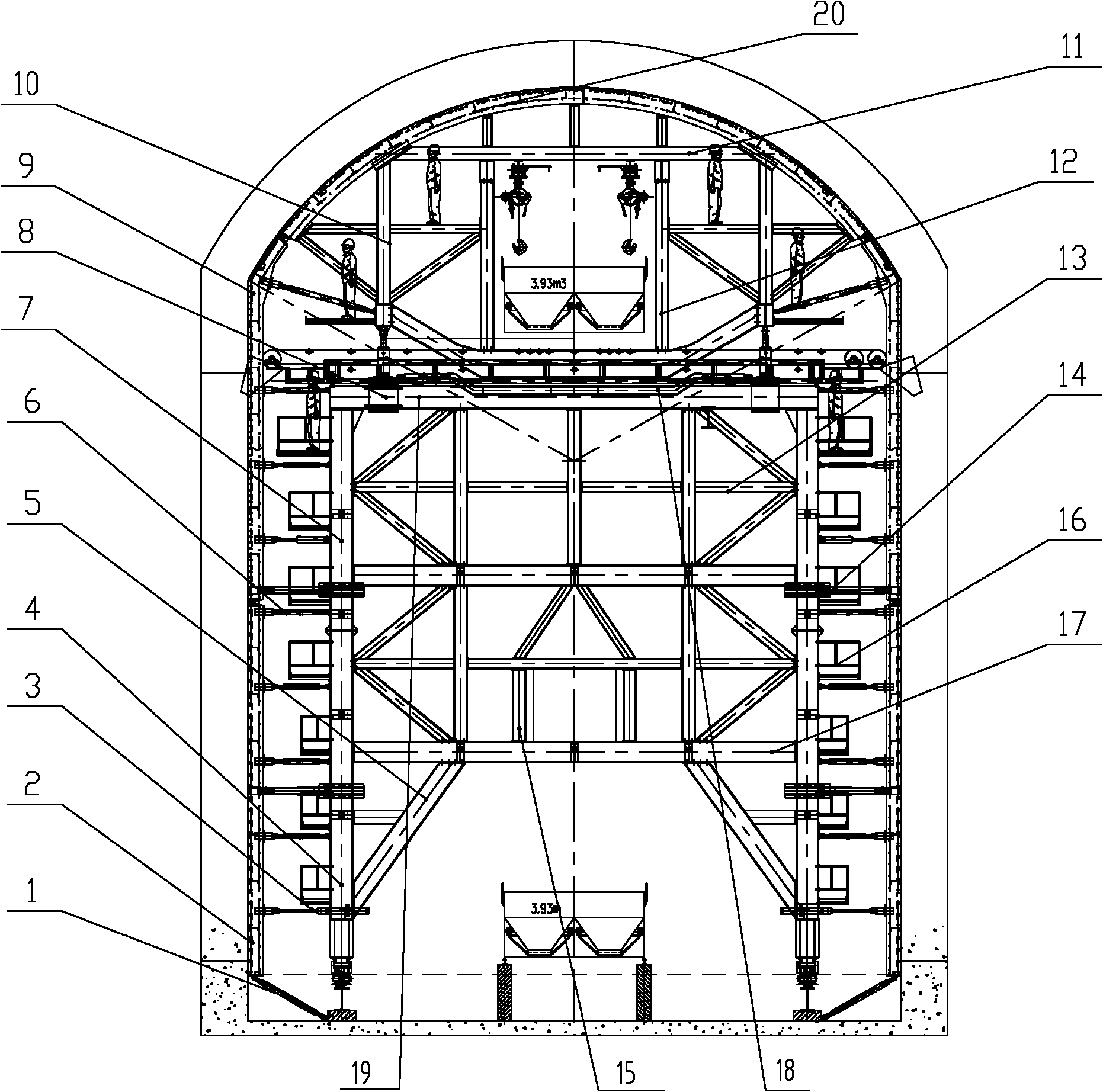

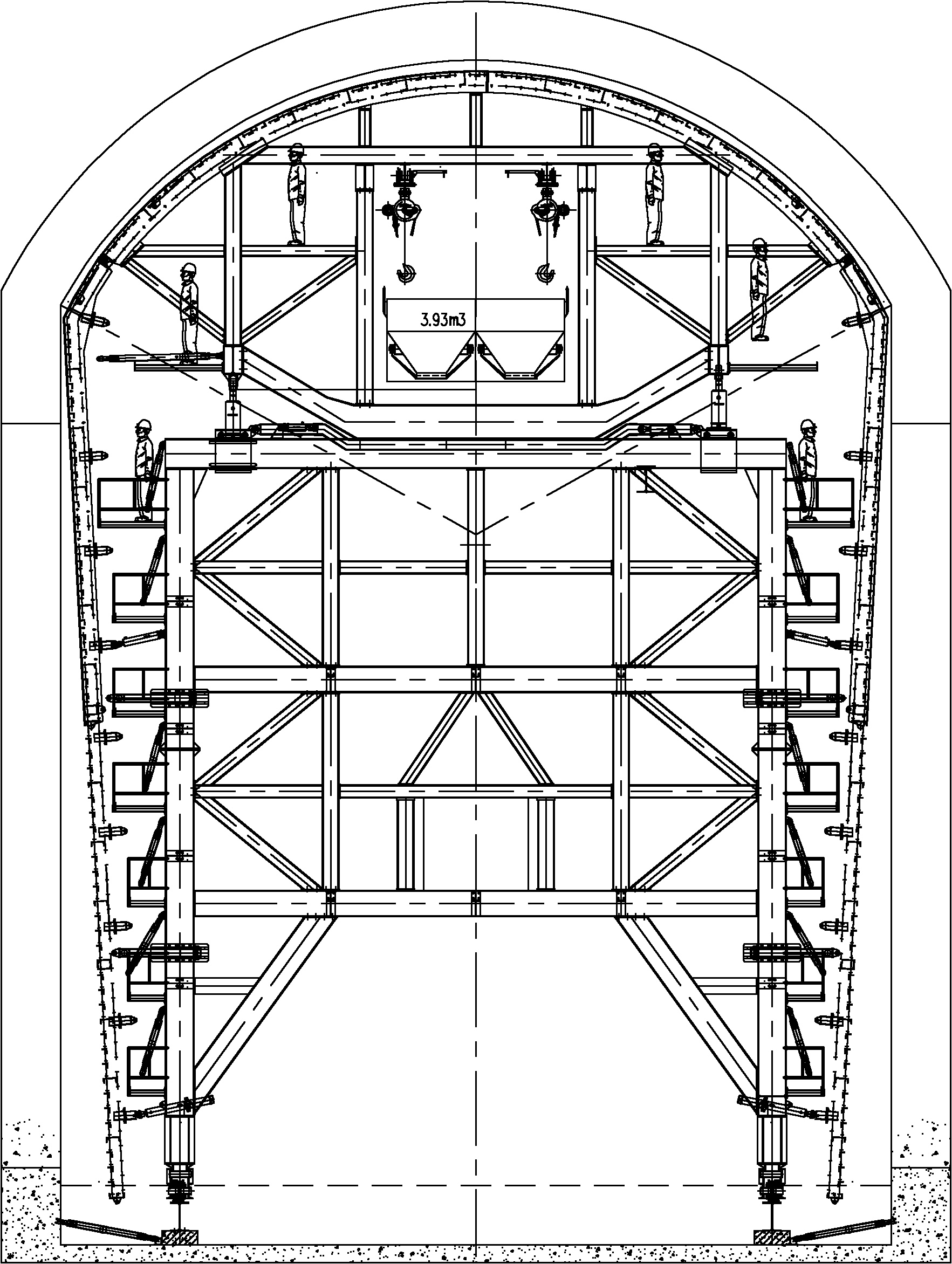

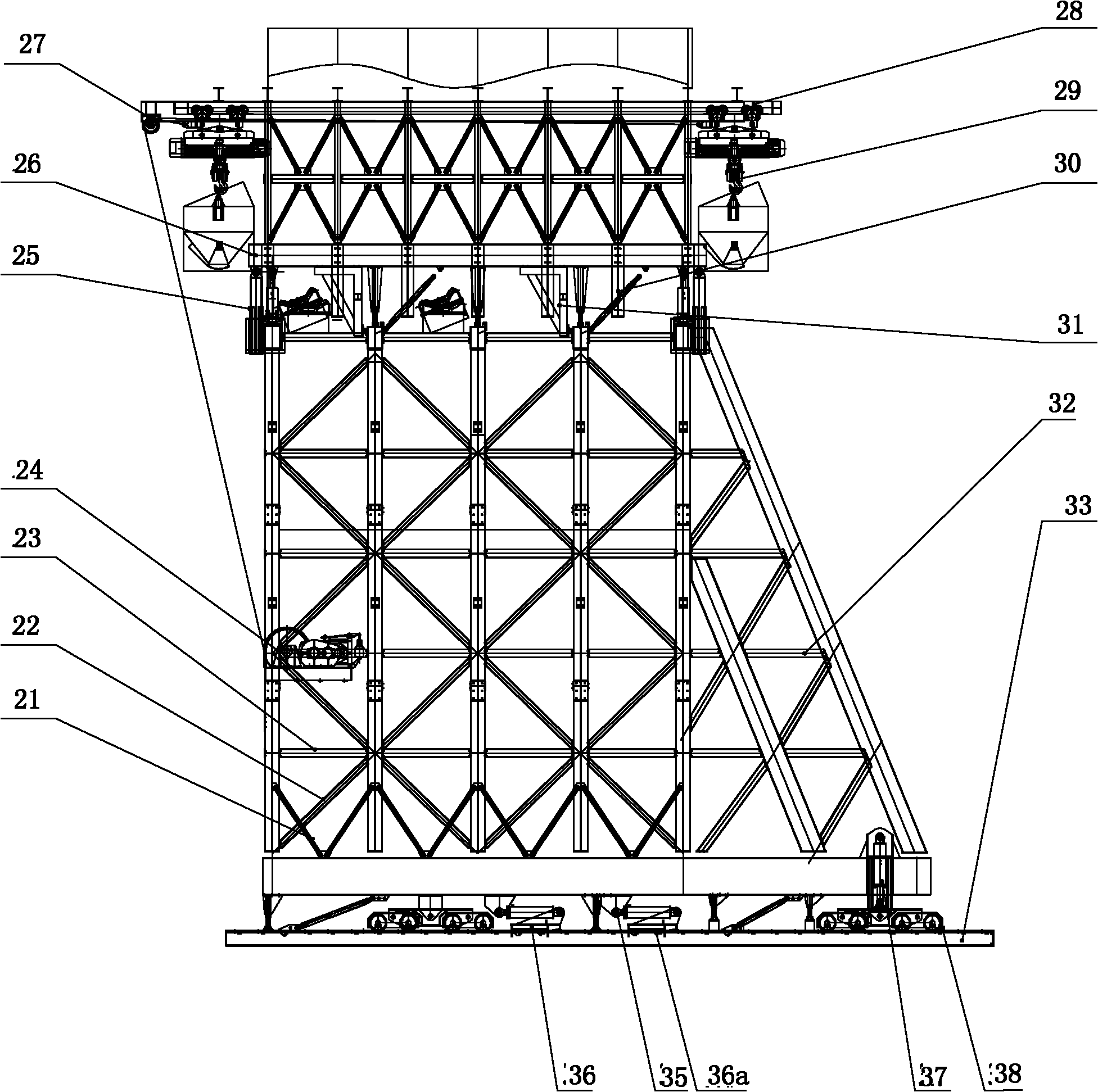

[0035] figure 1 It is a structural schematic diagram of the trolley of the present invention in the tunnel cross section when the concrete is poured, figure 2 It is a structural schematic diagram of the trolley of the present invention in the cross section of the tunnel when it is in a moving state, image 3 It is a schematic diagram of the side structure of the trolley of the present invention.

[0036] Such as figure 1 , figure 2 , image 3 As shown, the hydraulic self-propelled inclined tunnel normal concrete pouring trolley includes a frame and a side wall pouring mechanism, and also includes a top arch pouring mechanism, and a hydraulic traveling mechanism hinged with the trolley frame and arranged at the bottom of the frame.

[0037] The vehicle frame consists of gantry columns 4, 7, gantry diagonal braces 5, gantry struts 13, gantry vertical braces 15, gantry cross braces 17, gantry beams 19, gantry diagonal stays 21, 22, gantry horizontal Pull bar 23 etc. parts ...

Embodiment 2

[0052] to combine figure 1 , figure 2 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 .

[0053] The other mechanisms are the same as in Embodiment 1, but the different structures are: the trolley hydraulic traveling device consists of a traveling track fixed on the track bolster, a traveling mechanism moving on the traveling track, the traveling mechanism is hinged to the bottom beam of the trolley frame, and the other end Hinged with the hydraulic cylinder, the hydraulic cylinder is connected with the locking mechanism, the locking mechanism can be fixed on the track bolster and detachable, and the hydraulic cylinder provides the moving power of the trolley.

[0054] As shown in the figure, the moving track includes track b1, track bolster b2, and track foundation. Track b1 is first fixed on track bolster b2 by conventional methods. There is a track fixing buckle at the front joint of b2, and the track fixing buckle and track b1 are welded and fixed tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com