Full-automatic material delivery system

A fully automated and automatic material receiving technology, applied in the field of fully automated material distribution system, can solve the problems of slow efficiency and low bending accuracy, and achieve the effect of speeding up efficiency and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

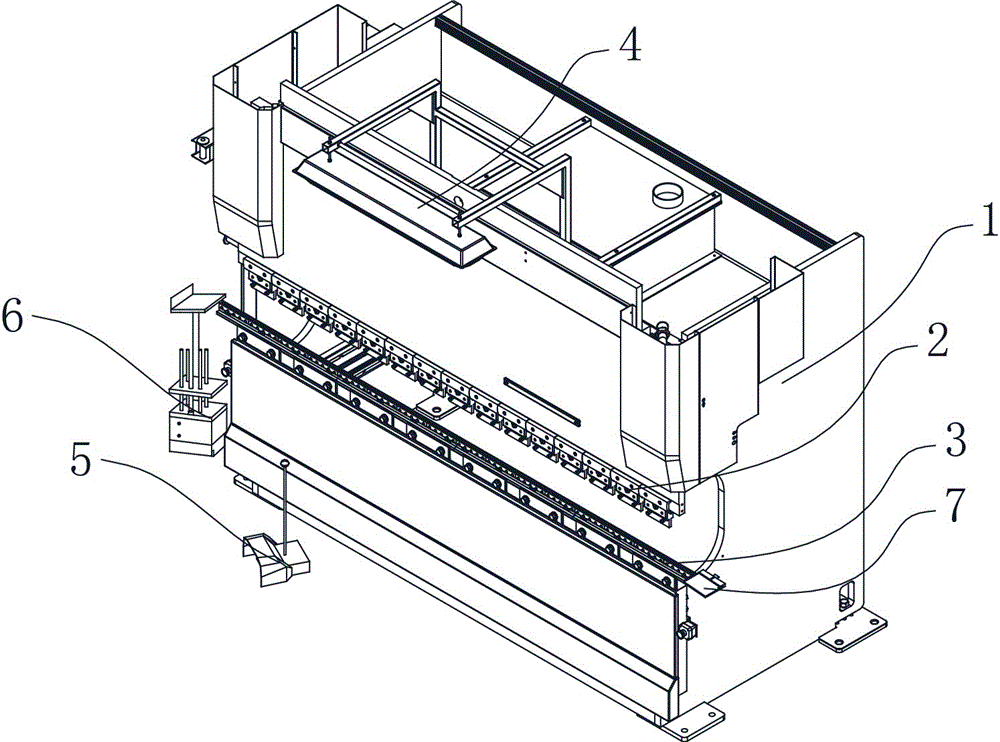

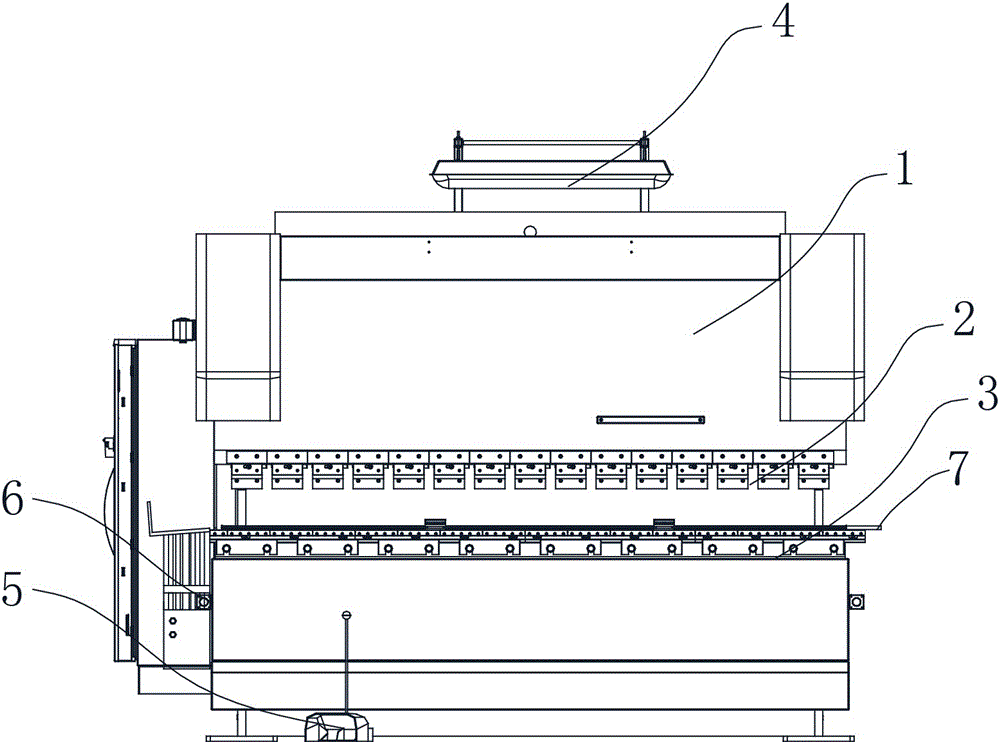

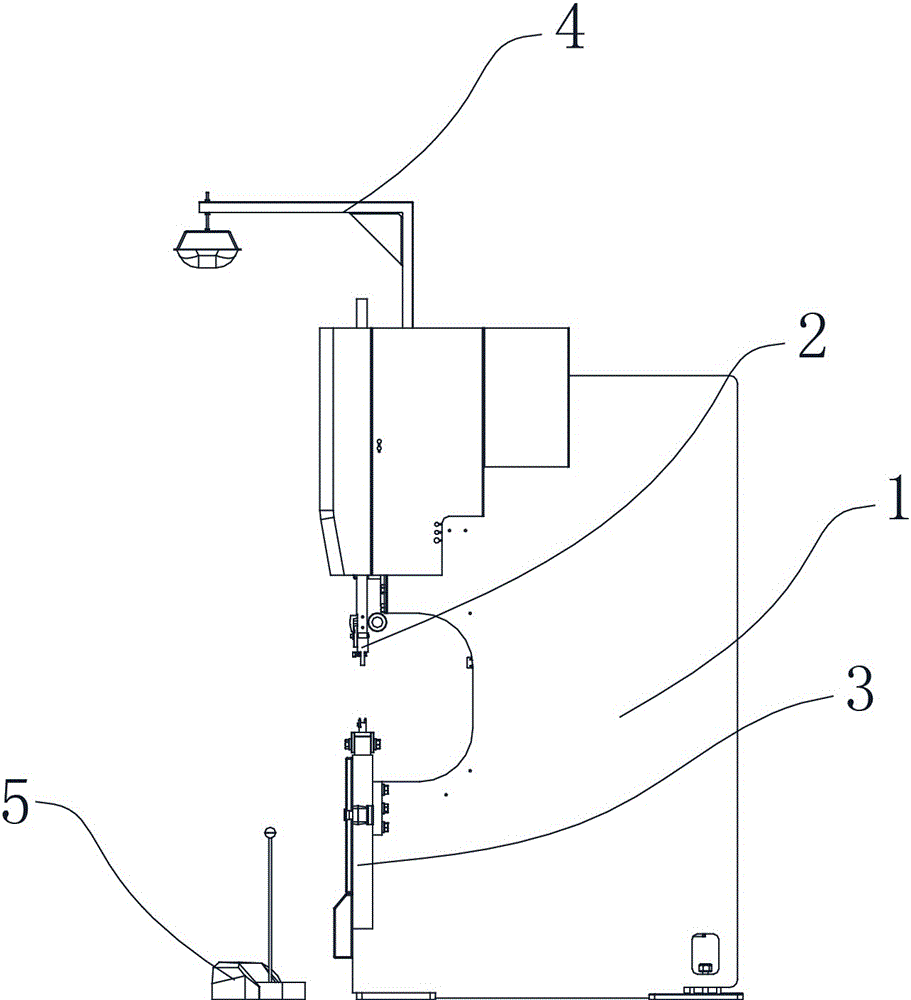

[0026] A fully automated material distribution system, comprising a box body 1, an upper mold 2 and a lower mold 3 cooperating with the upper mold 2 are arranged on the box body 1, a groove is arranged in the middle of the lower mold 3, and the The two sides of the box body 1 are provided with a material inlet and a material outlet, the described material inlet is provided with a positioning plate 7 for controlling the position of the material plate, and the described material outlet is provided with an automatic material receiving mechanism 6 , the two sides of the groove are provided with a plurality of rollers 31, the rollers 31 are evenly spaced on the gear belt 32, and the gear belt 32 is provided with a plurality of conveying gears 33, the conveying The bottom of the gear 33 is provided with a cross frame 34, one support of the cross fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com