Assembling device for water pipe connector

A technology for assembly devices and water pipe joints, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of manual assembly is not smooth, consumes a lot of time, and achieves the effect of avoiding labor intensity and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

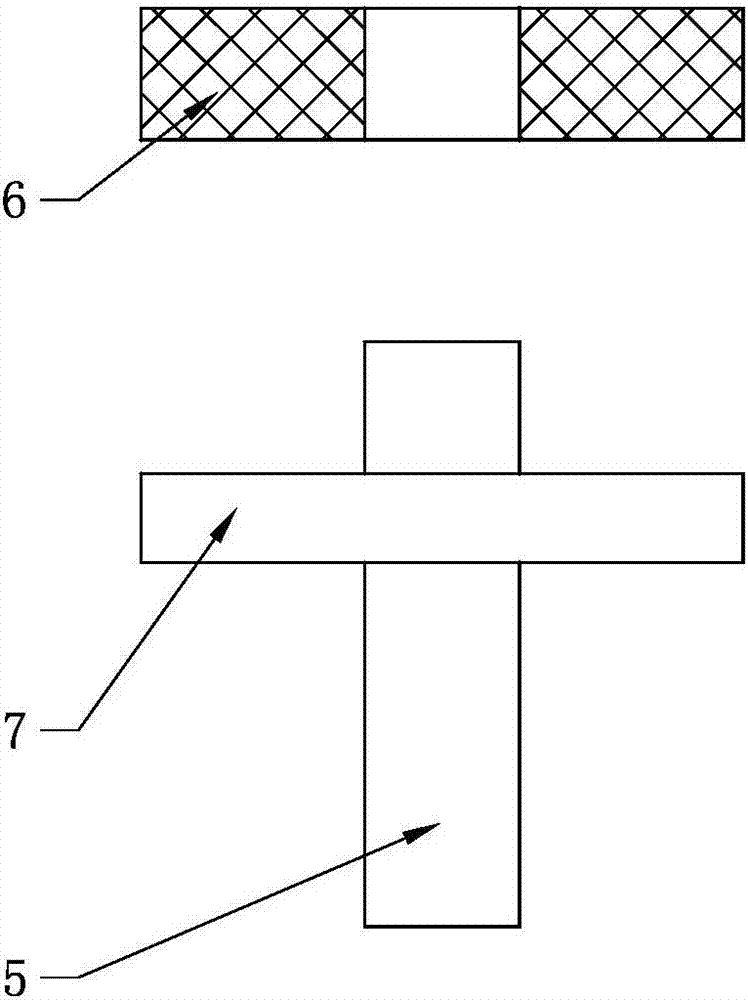

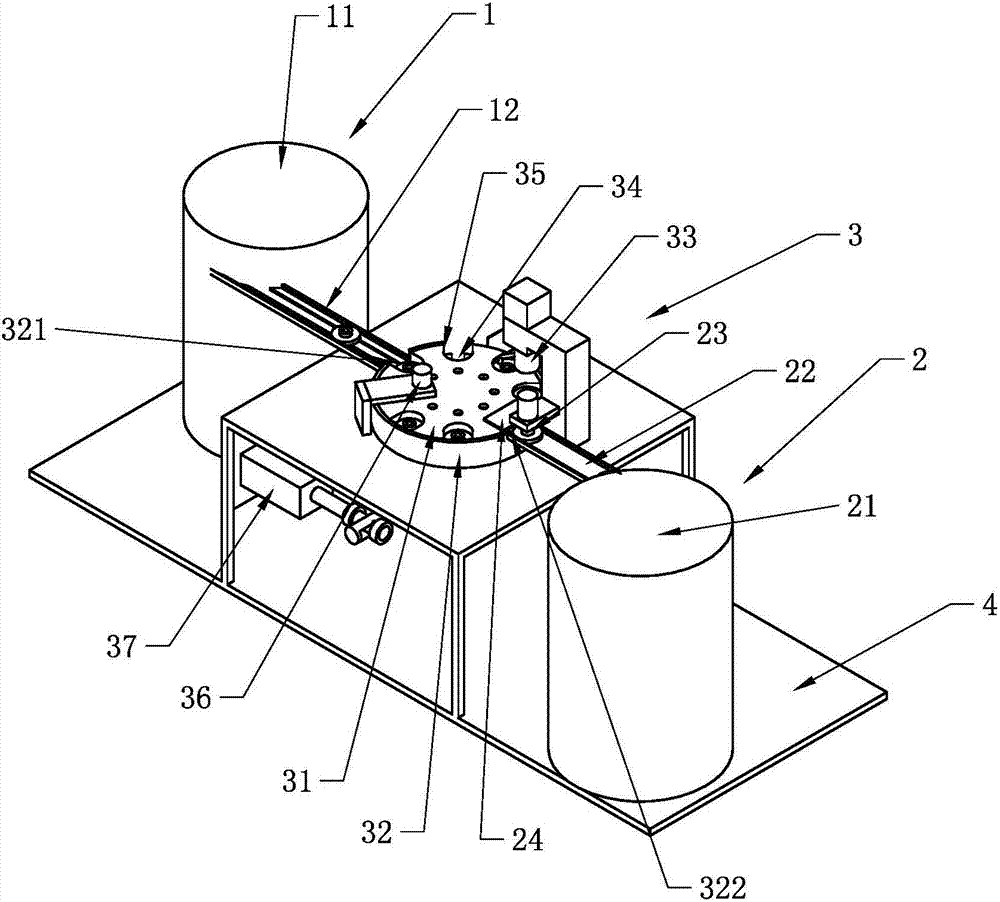

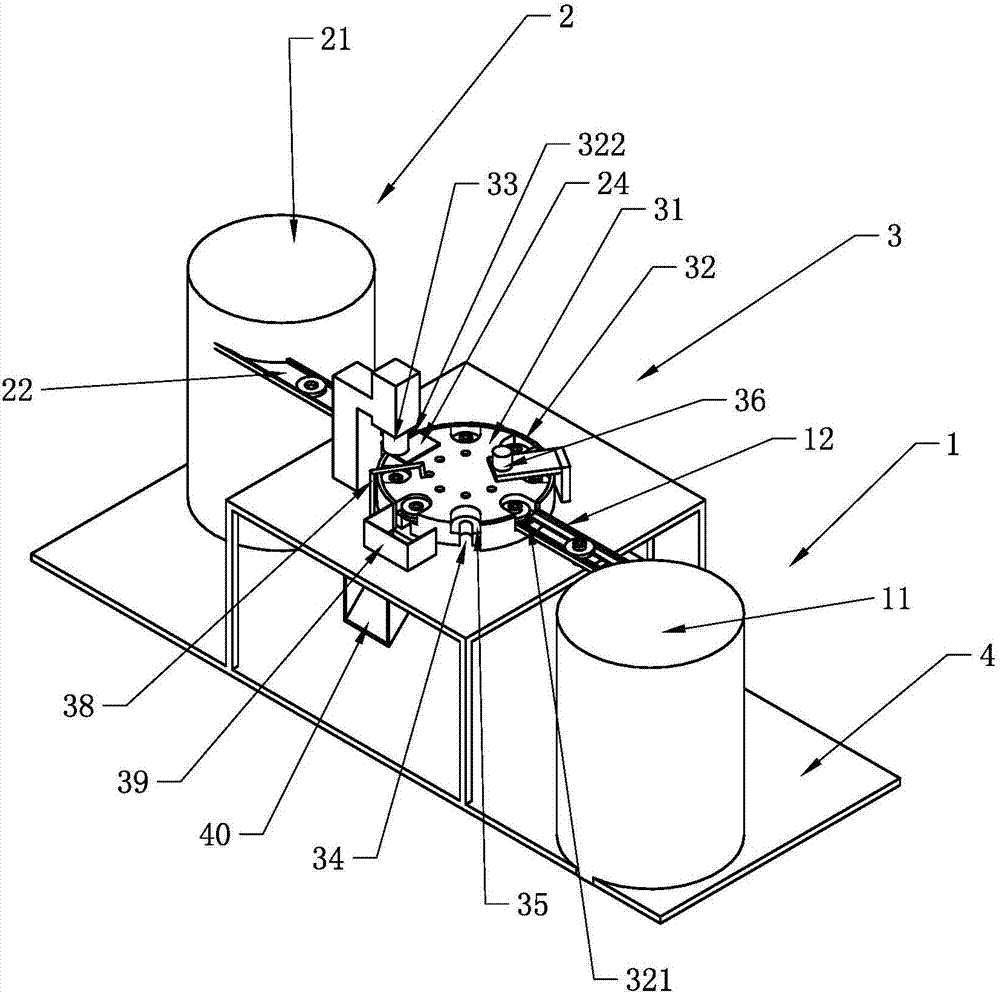

[0024] Such as figure 2 , image 3 As shown, an assembly device for a water pipe joint includes a frame 4, the frame 4 is provided with an assembly mechanism 3, a first conveying mechanism 1 for conveying an inner core 5 and a ring 7, and a second conveying mechanism 2 for conveying a gasket 6, The assembly mechanism 3 is arranged between the first conveying mechanism 1 and the second conveying mechanism 2 .

[0025] The assembly mechanism 3 includes a turntable 31 arranged horizontally, a limit plate 32 arranged along the circumference of the turntable 31, a first lifting rod 33 arranged on the top of the turntable 31 for press-fitting the gasket 6 to the inner core 5, and a limit plate 32 Connect with the first elevating rod 33 and the frame 4, the radial edge of the turntable 31 is uniformly provided with several first openings 34 for accommodating the inner core 5 to be placed vertically, and the top of the side wall of the first opening 34 is provided with an accommodat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com