Automatic rotating device for spraying outer wall of nodular cast iron pipe socket

A technology of nodular cast iron and automatic rotation, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc. It can solve the problems of increasing the labor intensity of operators, affecting the appearance quality of pipes, and affecting production efficiency, so as to avoid artificial Cost and time-consuming, simple and practical structure, simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

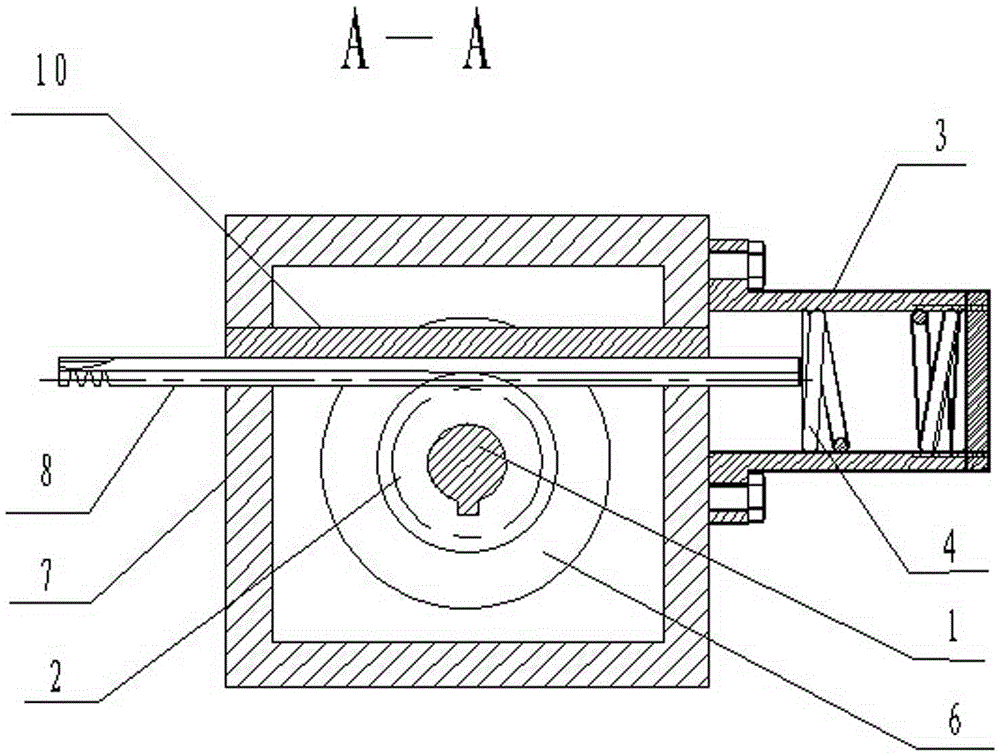

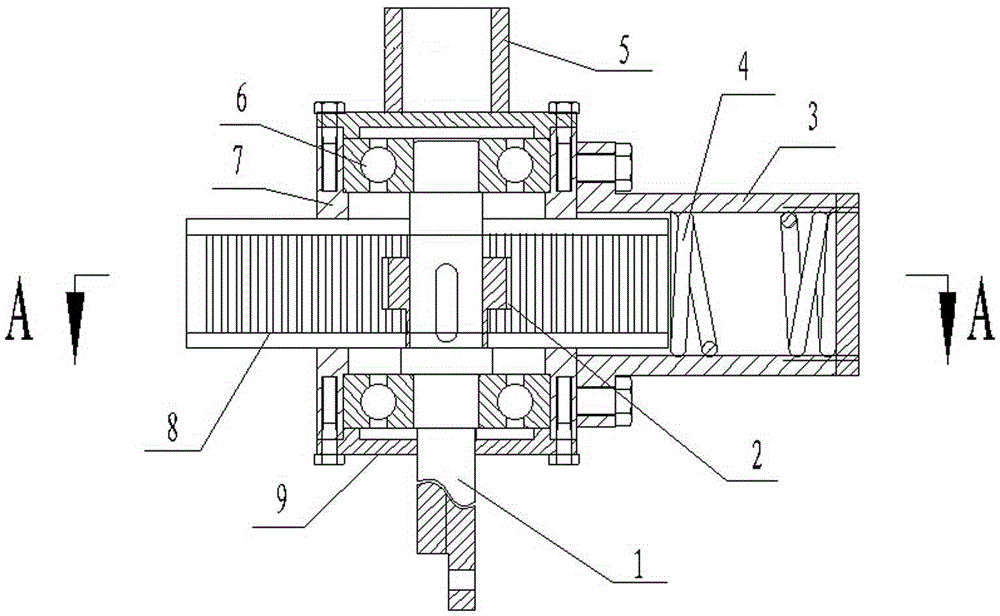

[0015] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0016] In the spraying process of ductile iron pipes, the motor drives the tops located at the two ports of the ductile iron pipes to rotate, and the tops drive the ductile iron pipes to rotate. The spraying trolley equipped with spray guns travels over the cast iron pipes from one end to the other, towards the bottom. The outer wall of the pipe is sprayed. When the spraying trolley walks to the socket end of the ductile iron pipe, if the spray gun is still sprayed in the original direction, a large part of the paint will be sprayed on the top of the top pipe and the ground, causing unnecessary material loss. And because the paint sprayed on the top and the ground at the same time due to the rotation of the top, the paint sprayed on the top is thrown onto the ductile iron pipe again, which not only needs to be cleaned up manually, which causes unnecessa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com