Roller press combination grinding device

A combination of grinding and roller press technology, applied in grain processing, etc., can solve the problems of affecting system operation rate, increasing maintenance workload, and inconvenient regulation, and achieves the effects of avoiding excessive dehydration, eliminating wear and tear, and controlling product temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

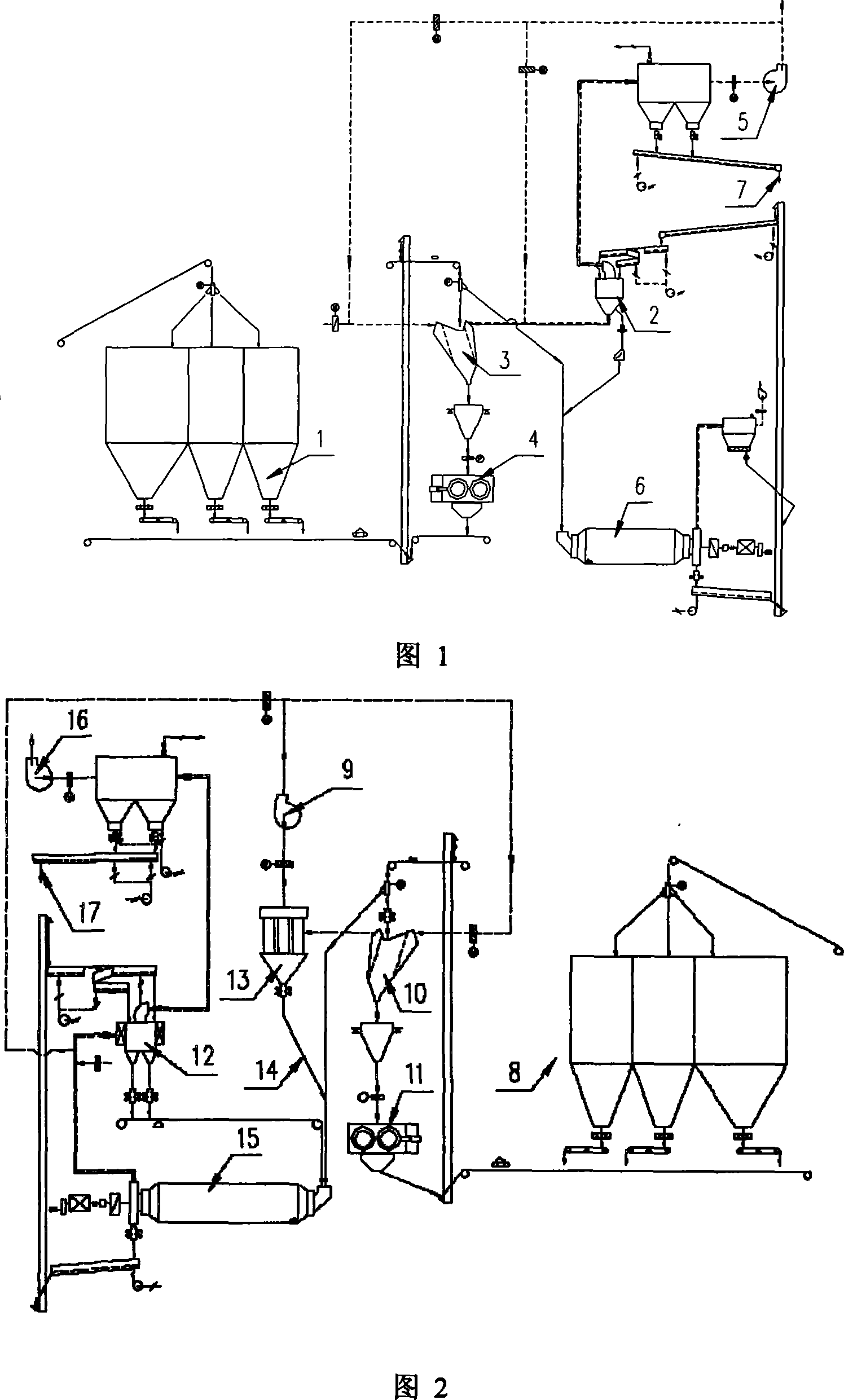

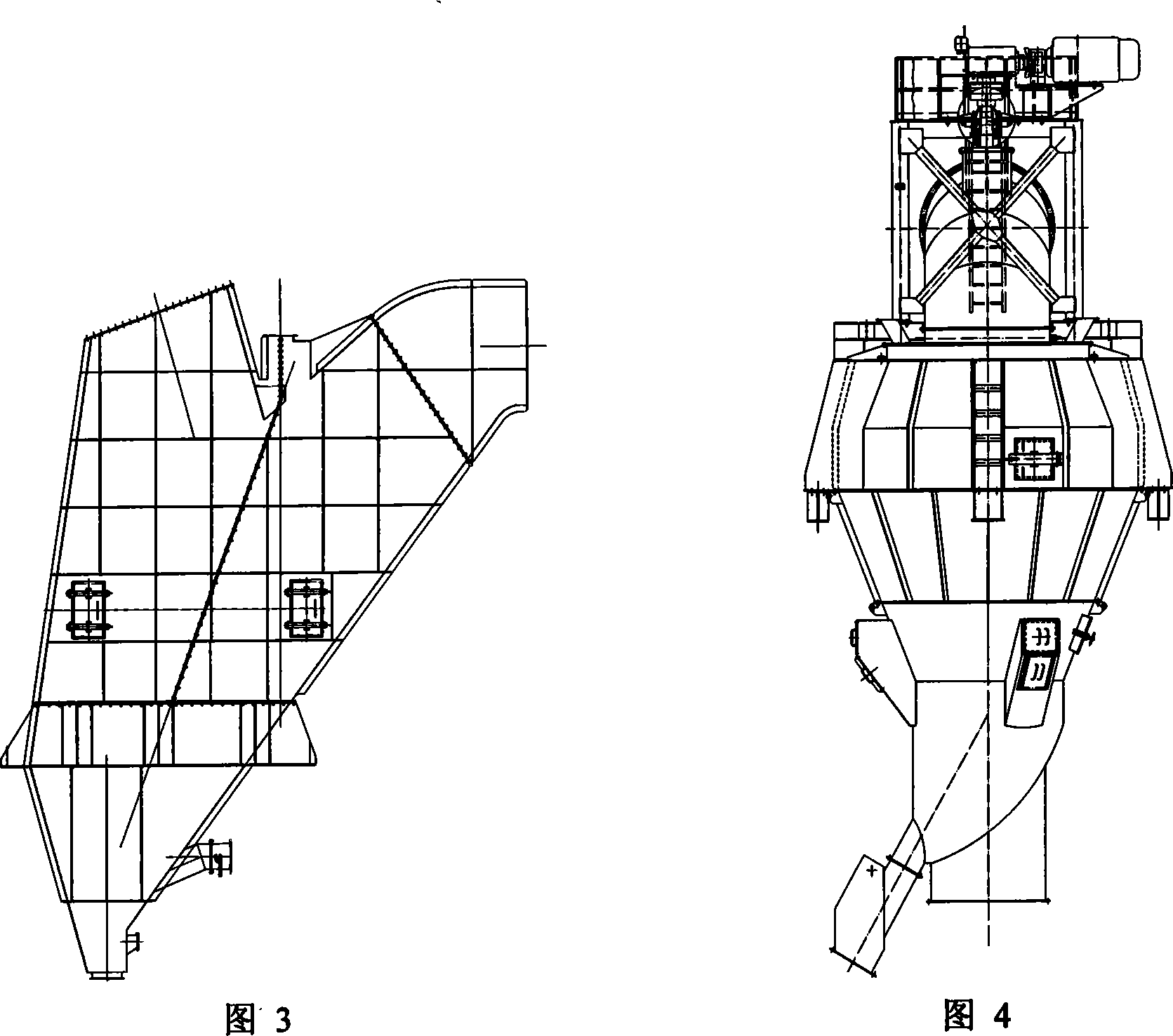

[0032] With reference to accompanying drawing 1, Fig. 2, Fig. 3 and Fig. 4.

[0033] A roller press combined grinding device, including material lifting and conveying equipment, a roller press and a ball mill, the material is lifted and transported, squeezed by the roller press and ground by the ball mill, and the qualified product is collected by the bag dust collector, and its ingredients are The new material matched by the mechanism 1 and the material squeezed by the roller press 4 are fed into the V-type powder separator 3 through the elevator and the belt conveyor, and the V-type powder separator 3 is sorted, and the coarse material falls into the roller press. The load bin above the machine 4 is then fed into the roller press 4 for extrusion, and the fine material is brought into the combined powder separator 2 by the gas from the bottom through the pipeline. The V-type powder separator 3 and the combined powder separator 2 are connected to one system. The coarse powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com