Ink jetting and supplying device of unit type intaglio press

A gravure printing machine and ink supply device technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as knife lines, lowered quality of printed products, ink tray ink overflowing ink skin, etc., to avoid ink lines and Color difference, reduce fatigue speed, prevent ink skinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

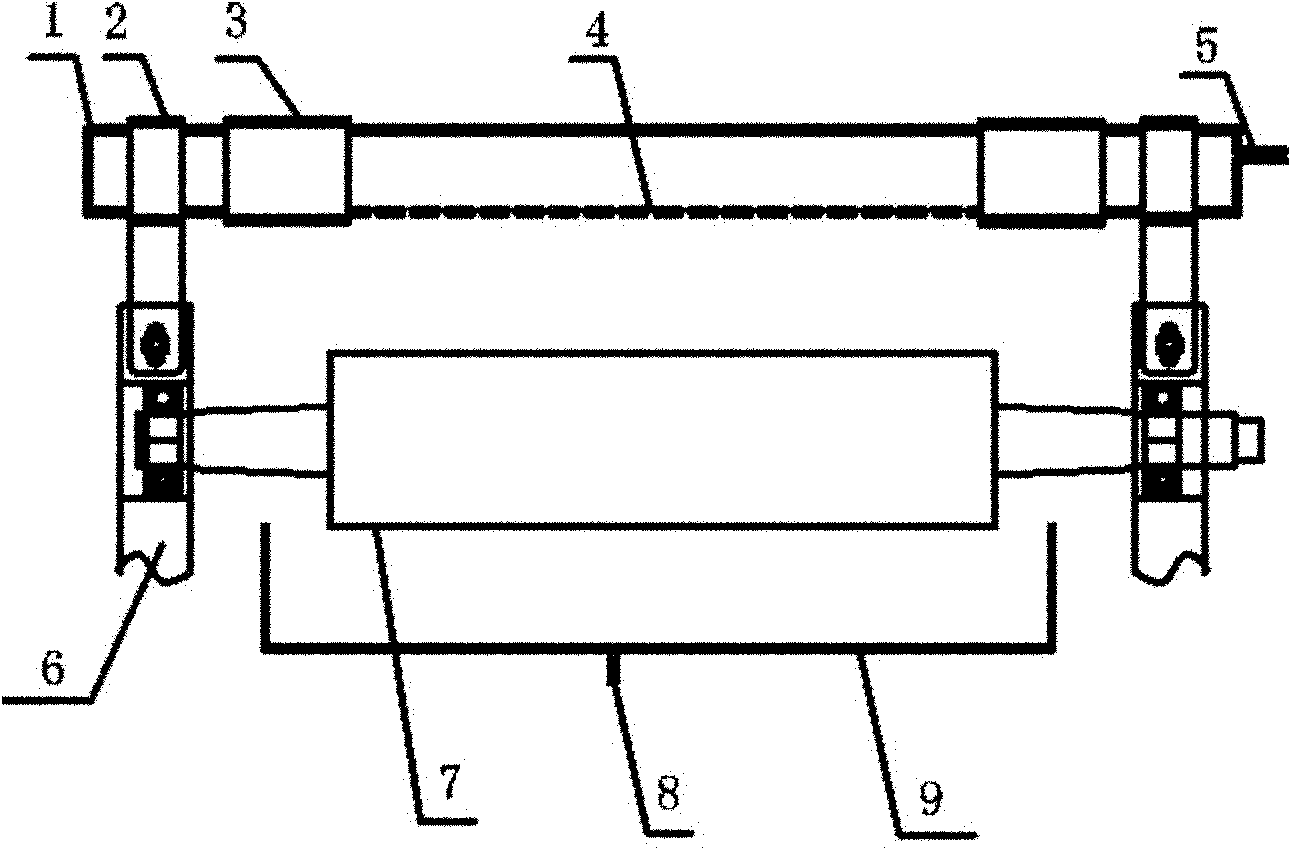

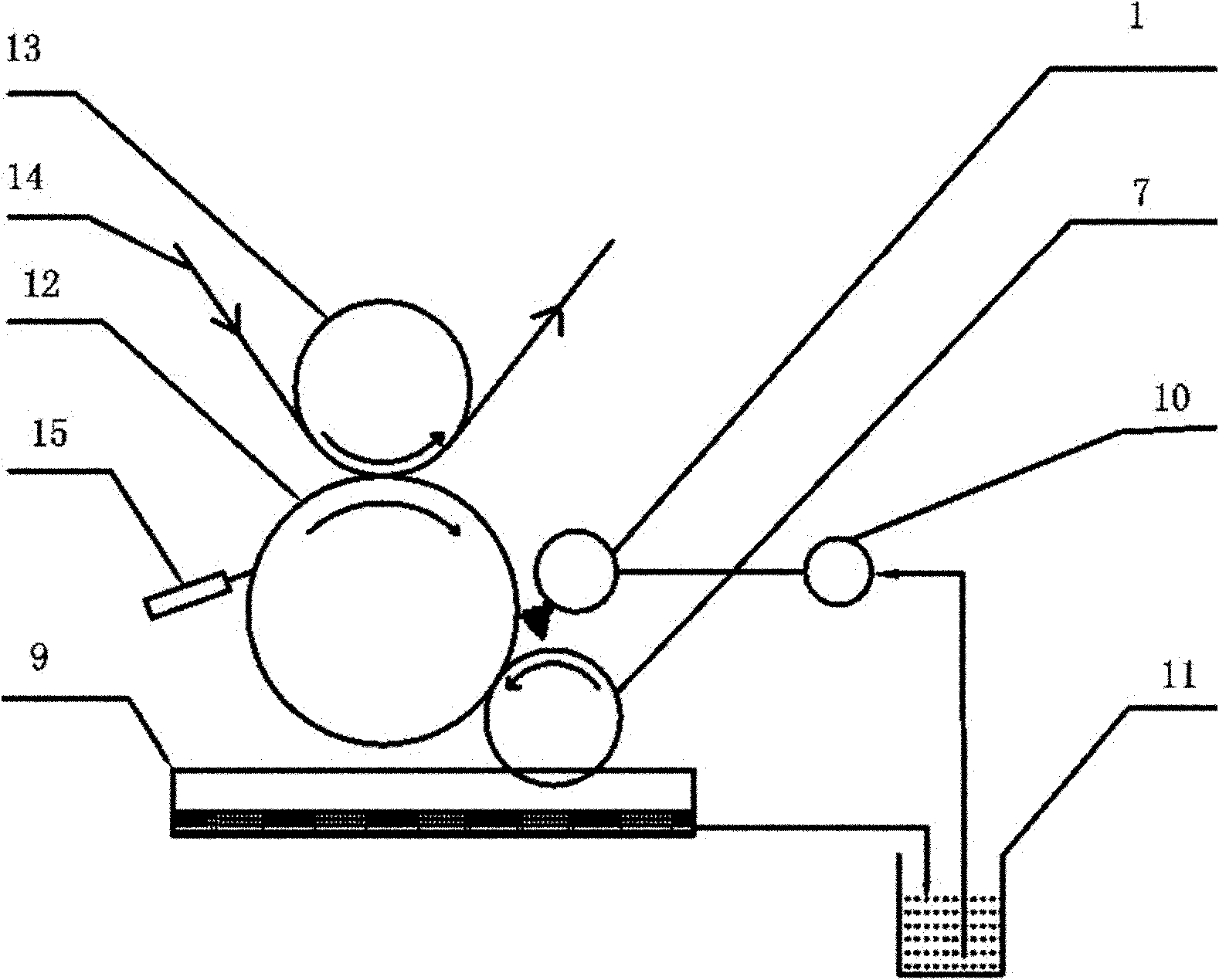

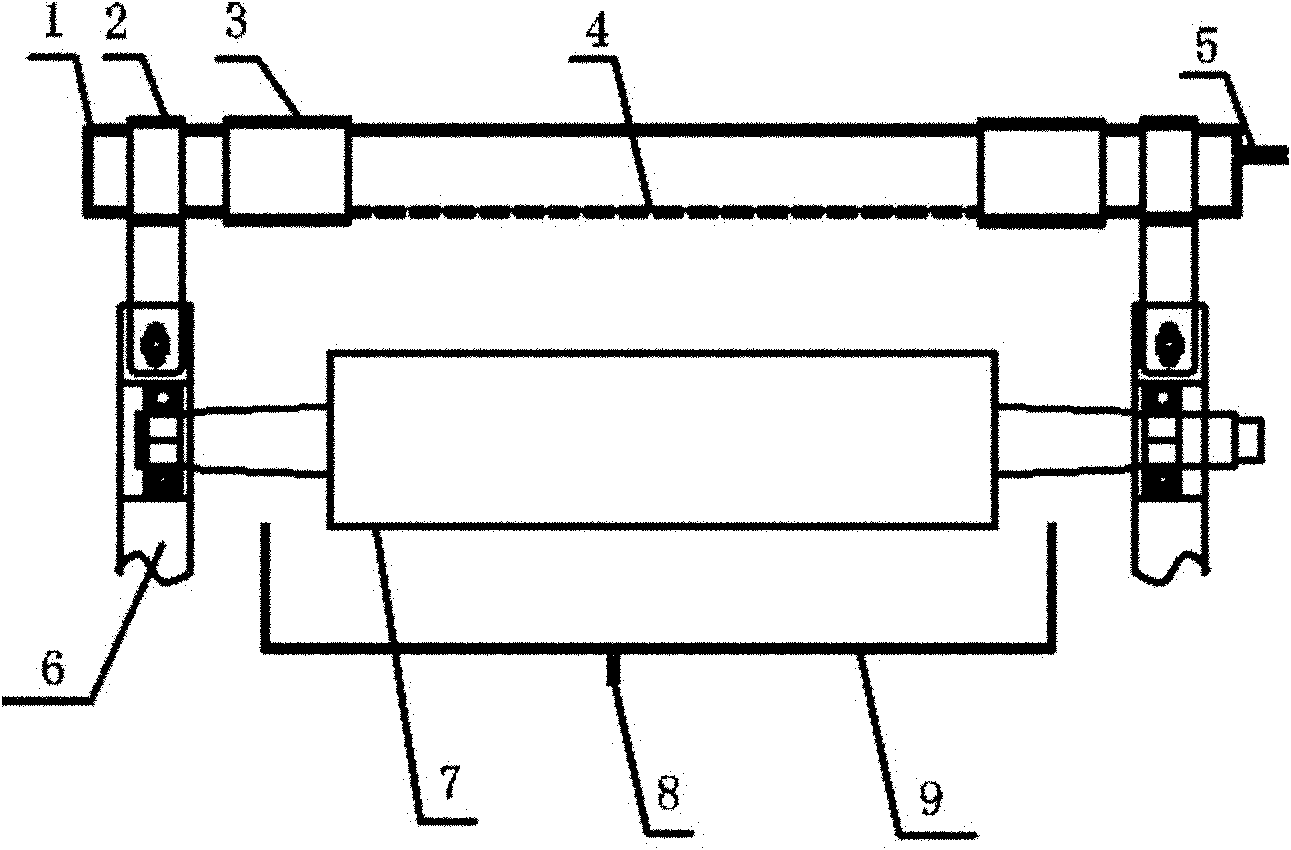

[0011] Such as figure 1 As shown, a unit-type gravure printing machine inkjet ink supply device includes an inkjet tube assembly, a circulation pump 10, an ink tank 9 and an ink delivery roller assembly, the ink tank 9 is provided with an ink return hole 8, and the ink jet tube assembly Including inkjet tube 1, fixed bracket 2 and adjustment ring 3, inkjet tube 1 is fixed on the ink transfer roller swing arm 6 above the ink transfer roller 7 through the fixed bracket 2, and the distance angle is adjustable, and the adjustment ring 3 is installed on the fixed On the inkjet tube 1 inside the bracket 2, one side of the inkjet tube 1 is provided with an ink inlet hole 5. The ink hole 4, the ink jet hole 4 faces the tangential position of the printing plate roller 12 and the ink transfer roller 7, the ink transfer roller assembly includes the ink transfer roller 7 and the ink transfer roller swing arm 6, and the ink transfer roller 7 is fixed on the ink transfer roller through a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com