Anti-crusting biogas pool

A biogas digester and encrustation technology, which is applied in the field of biogas digesters, can solve problems such as explosion, labor and time-consuming, and users cannot use biogas normally, so as to improve the efficiency and safety of gas production and prevent scum and encrustation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

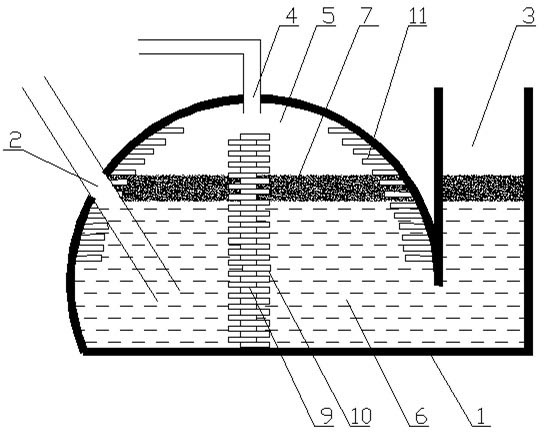

[0014] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

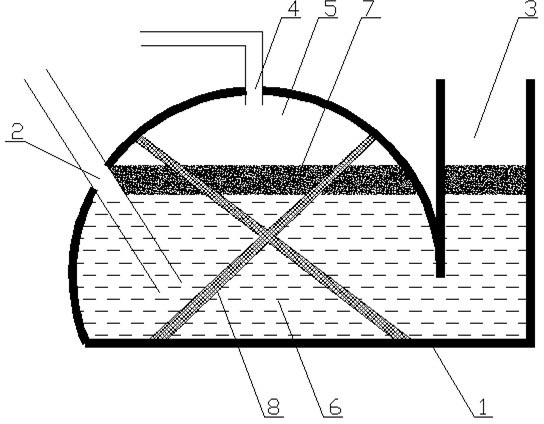

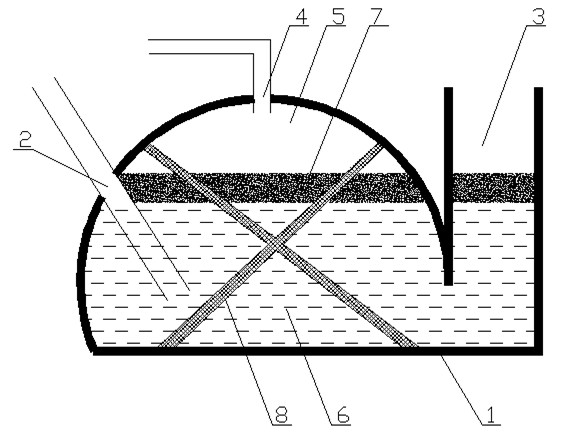

[0015] figure 1 It is a structural schematic diagram of Example 1 of the present invention, as shown in the figure, the crust-free biogas digester of the present invention includes a biogas digester body 1, and the biogas digester body 1 is provided with a feed inlet 2, a discharge outlet 3 and a biogas outlet 4 The upper part of the biogas digester body 1 is a gas storage chamber 5, the lower part is a fermentation chamber 6, and the discharge port 3 is a water pressure room. obstructive.

[0016] In this embodiment, the protrusion is a support rod 8 , one end of the support rod 8 is fixed at the bottom of the biogas tank body 1 , and the other end extends into the gas storage chamber 5 .

[0017] In this embodiment, the support rod 8 is X-shaped; the X-shaped support rod has a large cut when cutting through the scum, and the crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com