Drive piston and foot valve seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

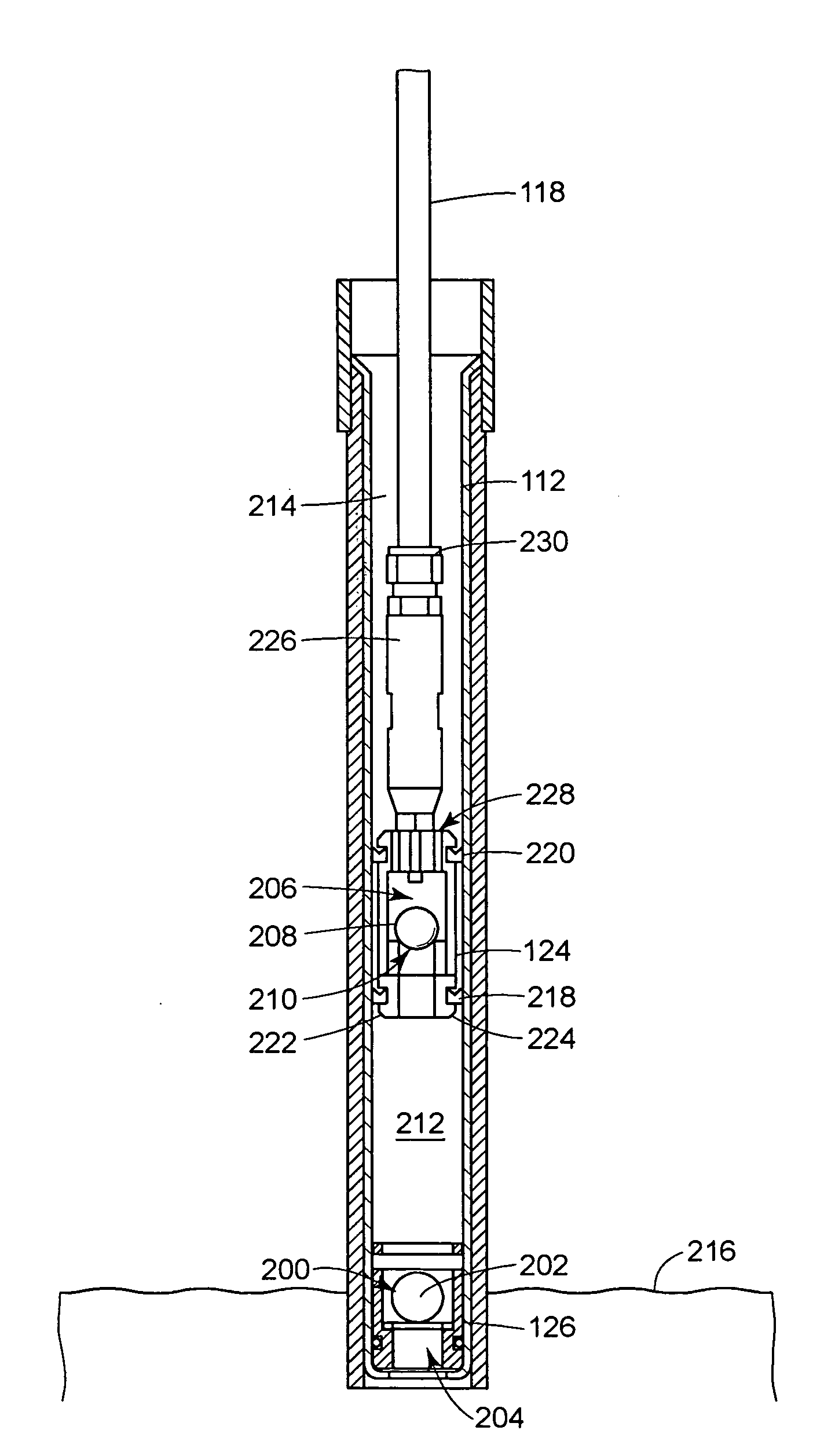

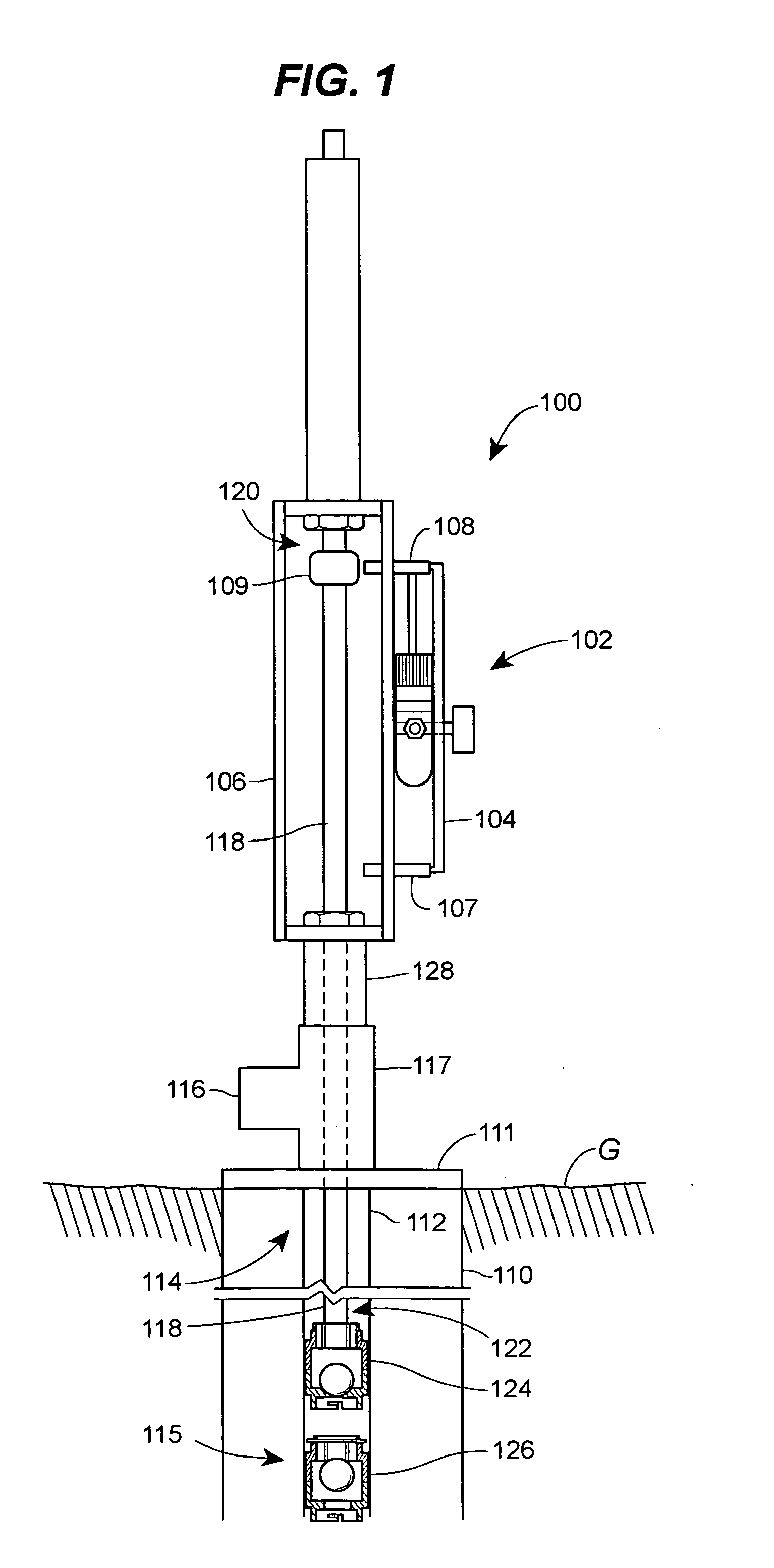

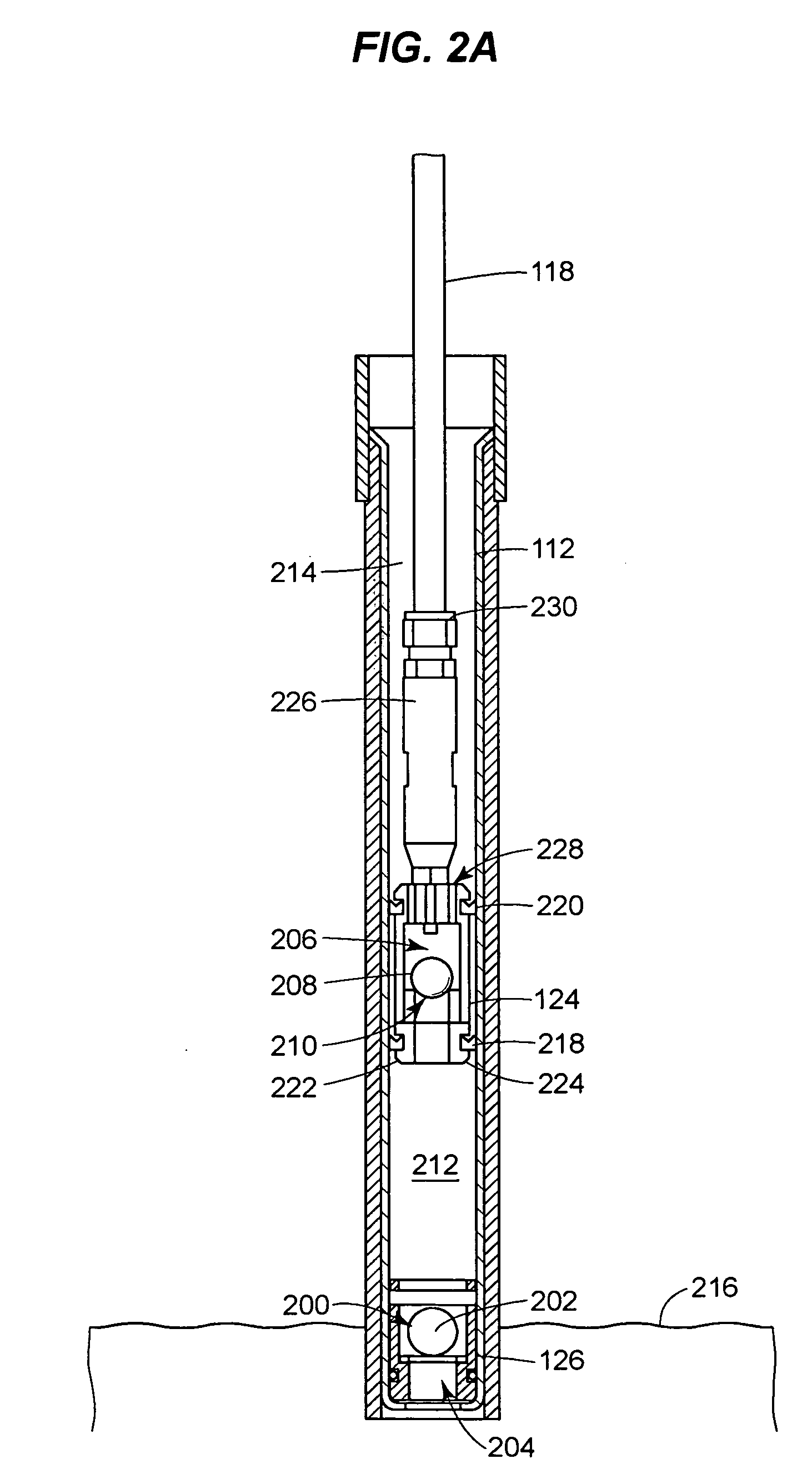

[0024]FIG. 1 illustrates a pumping system 100 that may be useful in pumping liquid, such as groundwater, hydrocarbons, tar, oil, chemicals or landfill leachate, through a well in a landfill or other geological site, for example, for collection analysis, consumption or disposal of the liquid. The system 100, of the illustrated example, has a drive motor assembly 102 having a piston pump actuator 104 mounted to a frame 106 (illustrated partially uncovered to display the inside) and with two limit switches 107, 108 for detecting a trigger element 109 for controlling operation of the drive motor 102. The drive motor assembly 102 is mounted to a drilled well casing 110 (illustrated partially uncovered to display the inside), via a well head 111, shown at the top surface (G) of a geological site. By way of example not limitation, the casing 110 may be formed of an organic polymer, such as polyvinyl chloride (PVC) or high density polyethylene (HDPE). Depending on the temperatures of the ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com