Double-layer tundish covering agent

A technology of tundish and covering agent, which is applied in the field of metallurgy, can solve problems such as molten steel pollution, easy crusting on the slag surface, and adverse effects on the performance of the covering agent, so as to prevent secondary pollution, ensure heat preservation, and prevent slag surface from forming shell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Application of double-layer tundish covering agent of the present invention in continuous casting cast steel slab

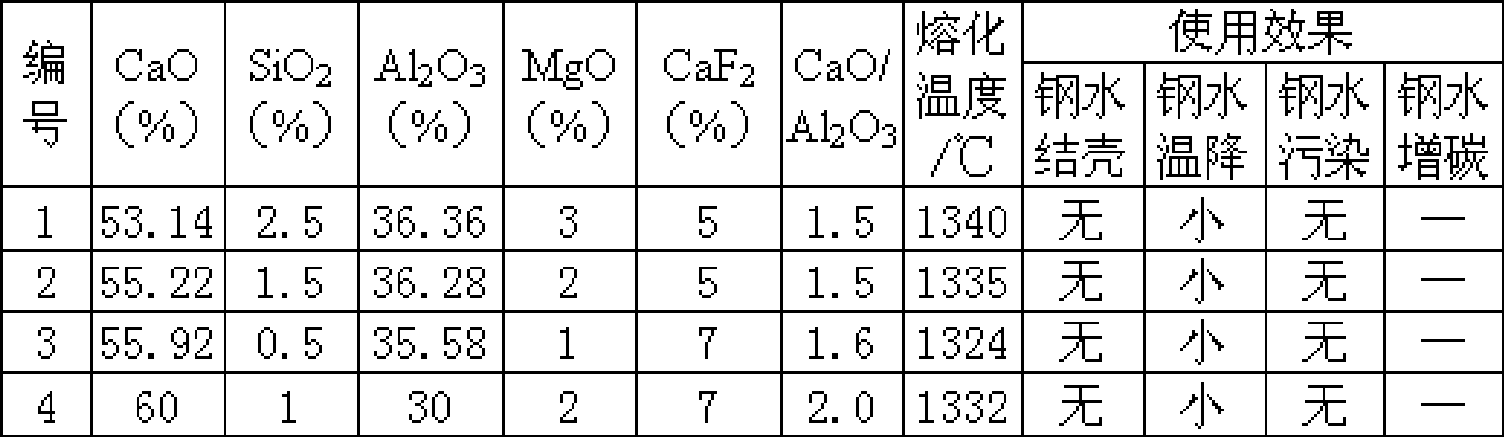

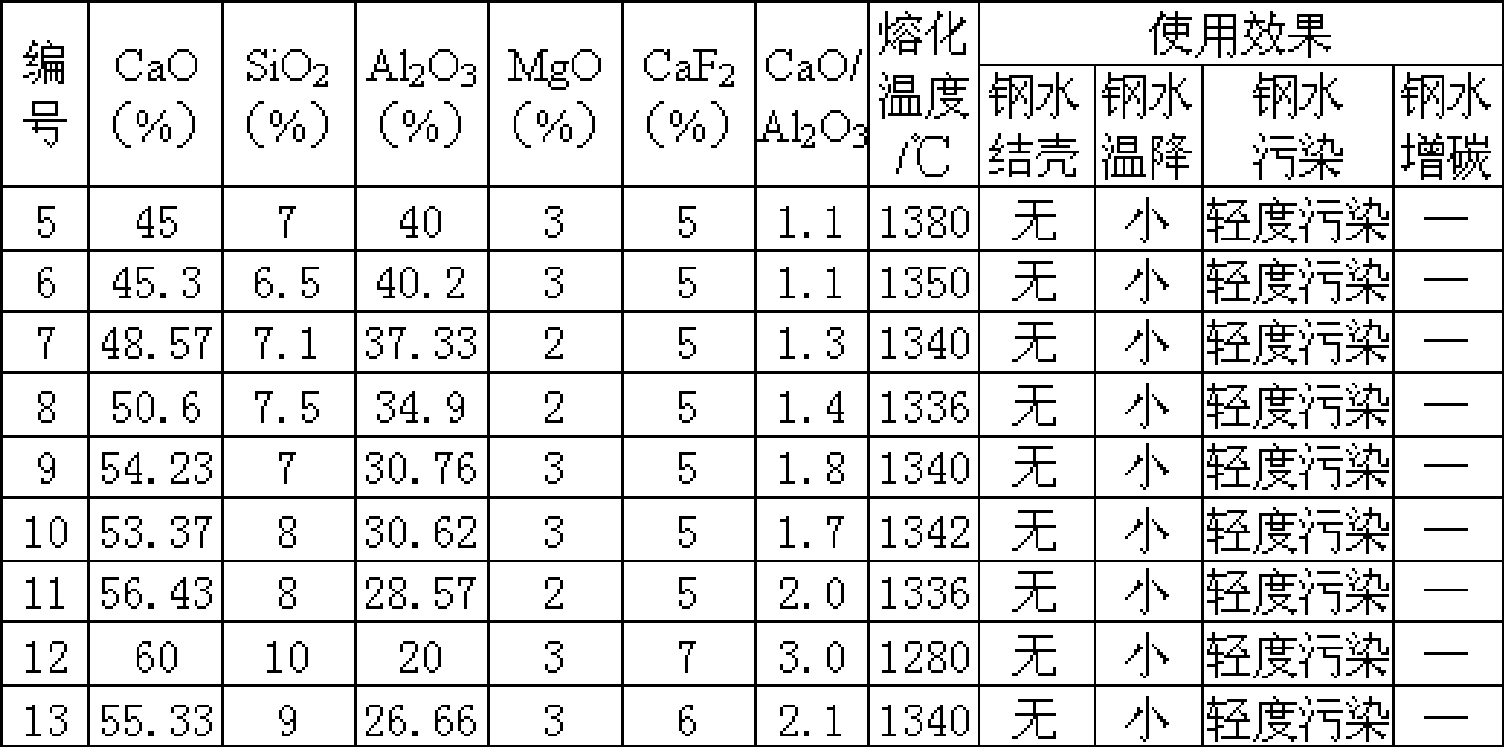

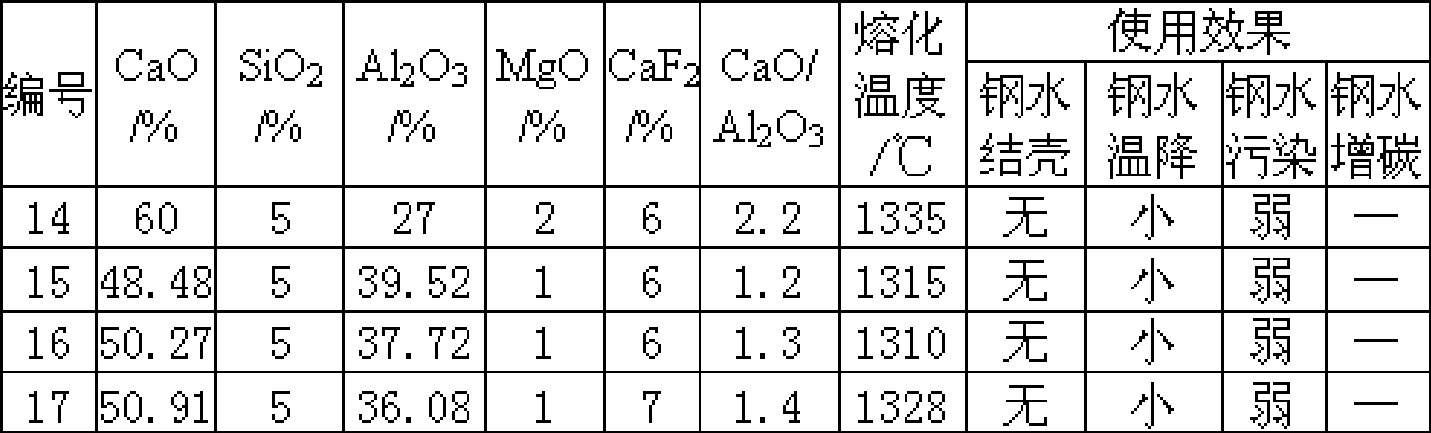

[0024] The double-layer tundish covering agent of the present invention is used to coat molten steel and cast steel slabs. See Table 1 for the chemical composition (wt%) of the poured steel grades.

[0025] The chemical composition (weight wt %) of the steel grade of table 1 pouring

[0026] steel

kind

C

Si

mn

P

S

Cr

Mo

als high aluminum

steel 0.35

~0.42 0.20

~0.45 0.30

~0.60 ≤0.035 ≤0.035 1.35

~1.65 0.15

~0.25 0.7

~1.10 the gear

steel 0.17

~0.23 0.17

~0.37 0.80

~1.10 ≤0.030 ≤0.030 1.00

~1.30 ≤0.15 / bearing

steel 0.95

~1.05 0.15

~0.35 0.25

~0.45 ≤0.025 ≤0.015 1.40

~1.65 ≤0.10 / Tube blank

steel 0.33

~0.38 0.25

~0.40 1.45

~1.70 ≤0.030 ≤0.030...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com