Biogas production method

A production method and biogas technology, applied in biological sludge treatment, waste fuel, fermentation, etc., can solve problems such as system paralysis, blockage of pipelines, obstacles, etc., to prevent large-scale production, prevent material crusting, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

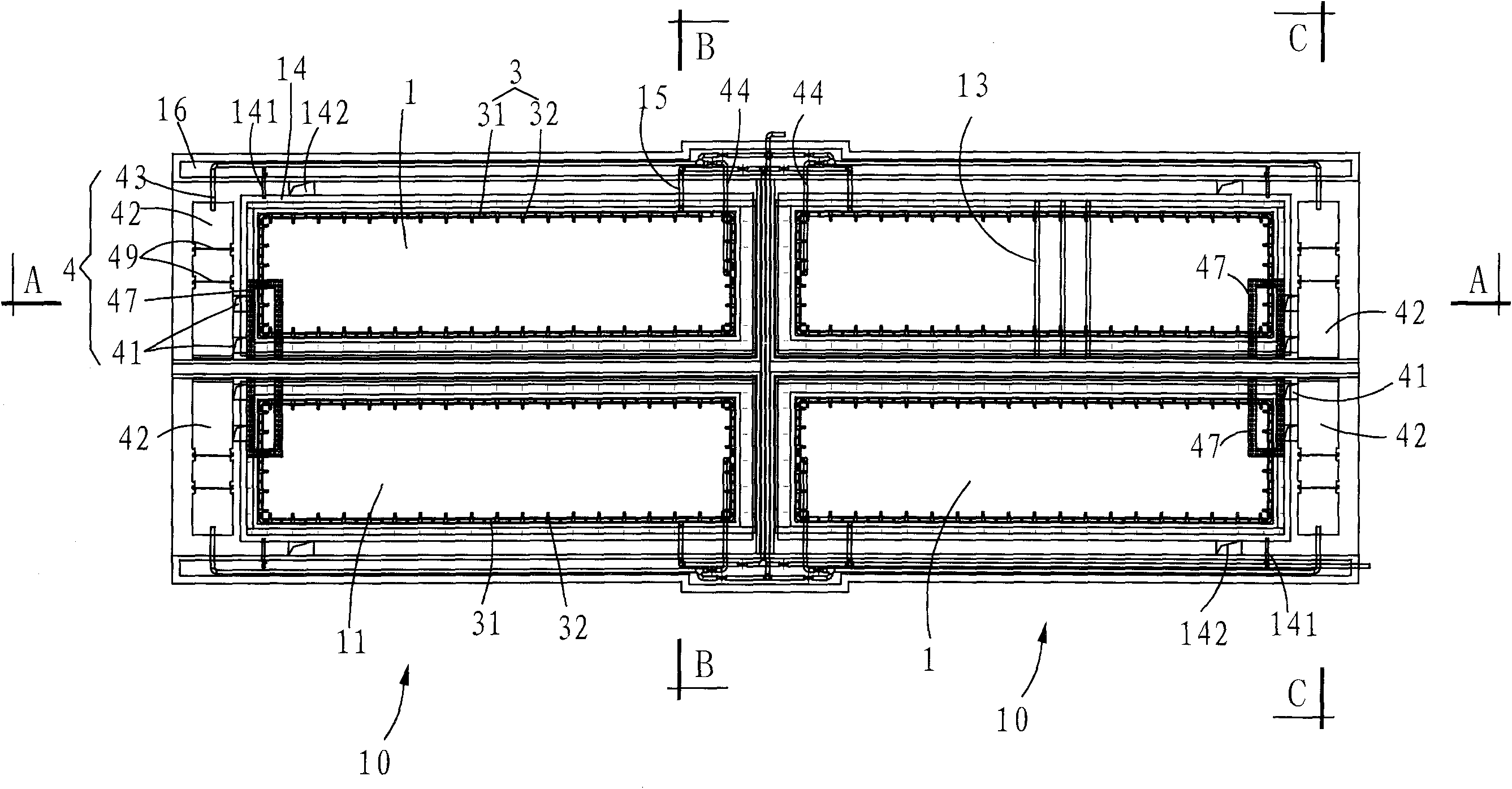

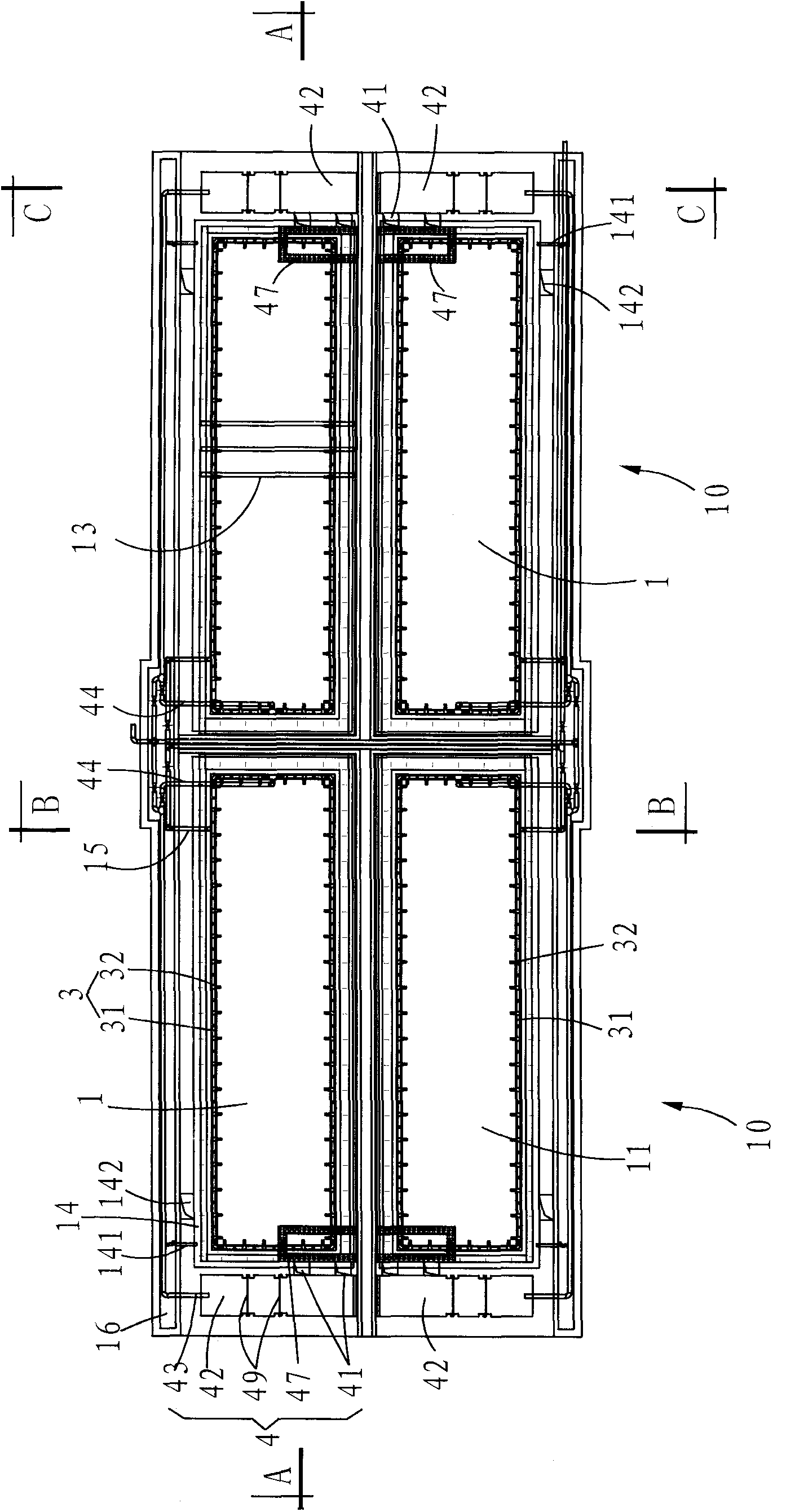

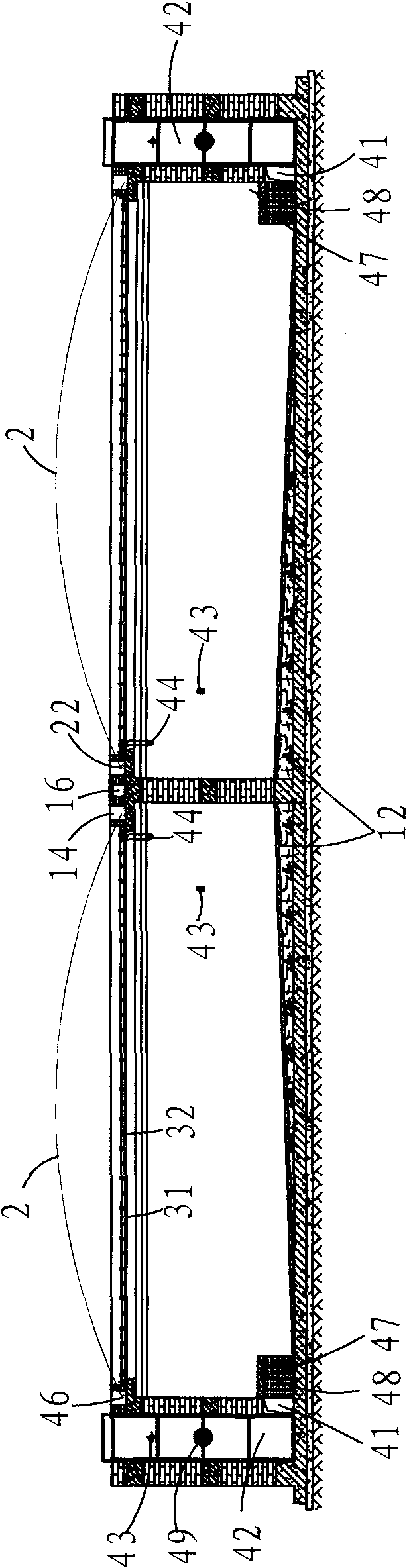

Image

Examples

Embodiment 1

[0031] Step 100: Feed through the large opening 11 of the anaerobic tank 1, and pretreat the material. The raw material is at least one of dry or fresh crop straw, animal manure, and biological waste, and the material does not need to be chopped Or pulverize and directly add inoculum or conditioning agent and mix and stack retting in anaerobic tank 1 until the fibers of the mixed material soften, partially decompose material wax, pectin, and reach a certain temperature; material and inoculum or conditioning agent For layered mixing, the stacking retting time is controlled within 7 days, the moisture content of the mixed material is controlled within the range of 60% to 65%, and the total solid content is controlled within the range of 35% to 40%, so that the fiber softening of the mixed material can proceed smoothly. It can also partially decompose the wax and pectin of the material, which increases the temperature of the mixed material. The inoculum or conditioning agent is a...

Embodiment 2

[0036] Step 100: Feed through the large opening 11 of the anaerobic tank 1, and pretreat the material. The raw material is at least one of dry or fresh crop straw, animal manure, and biological waste, and the material does not need to be chopped Or pulverize and directly add inoculum or conditioning agent and mix and stack retting in anaerobic tank 1 until the fibers of the mixed material soften, partially decompose material wax, pectin, and reach a certain temperature; material and inoculum or conditioning agent For layered mixing, the stacking time is 15 days, the moisture content of the mixed material is controlled within the range of 65% to 70%, and the total solid content is controlled within the range of 30% to 35%, which can make the fiber softening of the mixed material go smoothly. It can also partially decompose the wax and pectin of the material, which increases the temperature of the mixed material. The inoculum or conditioning agent is at least one of livestock an...

Embodiment 3

[0041] Step 100, feeding through the large opening 11 of the anaerobic tank 1, and pretreating the material, the raw material is dry or fresh cyanobacteria, directly adding inoculum or conditioning agent without chopping or pulverizing and Mixed retting is carried out in the oxygen tank 1 until the fiber of the mixed material is softened, the wax and pectin of the material are partially decomposed, and a certain temperature is reached; the material and the inoculum or conditioner are layered and mixed, and the fermentation temperature of the stacked retting material is Above 42°C, the stacking retting time is controlled within 2 days, the moisture content of the mixed material is controlled within the range of 50% to 60%, and the total solid content is controlled within the range of 40% to 50%, which can make the fiber softening of the mixed material go smoothly. It can also partially decompose the wax and pectin of the material, which increases the temperature of the mixed mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com