Anti-burst cement and preparation method of same

An anti-explosion cracking and cement technology, which is applied in cement production and other directions, can solve the problems of fast hydration speed, low tensile strength, and easy cracks, so as to reduce water demand and shrinkage rate, improve strength and stability, and benefit The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

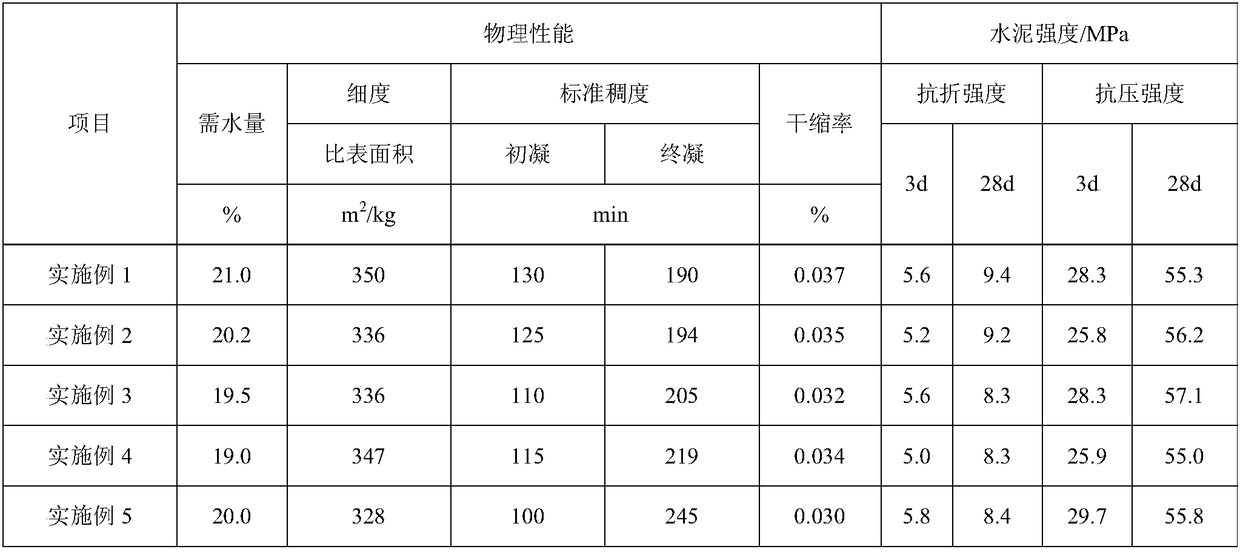

Examples

Embodiment 1

[0031] A kind of explosion-proof cement, made of the following raw materials in weight percentage:

[0032] Clinker 50%, phosphogypsum 2.5%, titanium gypsum 1.5%, water slag 29%, limestone 5%, black ash 7%, active silicon 2%, lignin fiber 0.2%, polypropylene fiber 0.3%, glass fiber 0.5% , 0.5% water reducer, 1% sodium polyacrylate, 0.5% sodium lauryl sulfate.

[0033] The clinker is ordinary Portland cement clinker. The chemical composition of the clinker is: SiO 2 20-25%, Al 2 o 3 3-8%, Fe 2 o 3 2~5%, CaO 60~70%, MgO≤1%, SO 3 ≤0.5%; loss on ignition ≤1%.

[0034] The water reducer is a high-efficiency sulfamate water reducer. The chemical composition of described black ash is: SiO 2 ≥90%, Al 2 o 3 ≤2.5%, Fe 2 o 3 ≤3%, CaO≤0.5%, MgO≤0.5%, SO 3 ≤0.5%; loss on ignition ≤5%.

[0035] The preparation method comprises the following steps:

[0036] (1) Take each raw material according to the above-mentioned weight ratio, mix clinker, water slag, limestone, phosphogyp...

Embodiment 2

[0040] A kind of explosion-proof cement, made of the following raw materials in weight percentage:

[0041]45% clinker, 2% phosphogypsum, 1% titanium gypsum, 32% water slag, 10% limestone, 6% black ash, 1% active silicon, 2% lignin fiber, 0.2% polypropylene fiber, 0.6 glass fiber %, water reducer 1%, sodium polyacrylate 0.5%, sodium lauryl sulfate 0.5%.

[0042] The clinker is ordinary Portland cement clinker. The chemical composition of the clinker is: SiO 2 20-25%, Al 2 o 3 3-8%, Fe 2 o 3 2~5%, CaO 60~70%, MgO≤1%, SO 3 ≤0.5%; loss on ignition ≤1%.

[0043] The water reducer is a polycarboxylate high-efficiency water reducer.

[0044] The preparation method is the same as in Example 1.

Embodiment 3

[0046] A kind of explosion-proof cement, made of the following raw materials in weight percentage:

[0047] Clinker 55%, phosphogypsum 2%, titanium gypsum 3%, water slag 20%, limestone 8%, black ash 7%, active silicon 1%, lignin fiber 0.1%, polypropylene fiber 0.3%, glass fiber 0.6% , 1% water reducer, 1% sodium polyacrylate, 1% sodium lauryl sulfate.

[0048] The clinker is ordinary Portland cement clinker. The chemical composition of the clinker is: SiO 2 20-25%, Al 2 o 3 3-8%, Fe 2 o 3 2~5%, CaO 60~70%, MgO≤1%, SO 3 ≤0.5%; loss on ignition ≤1%.

[0049] The water reducer is a composite of powdery naphthalene sulfonate high-efficiency water reducer and sulfamate high-efficiency water reducer.

[0050] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com