Intermittent cooling heat pump drying device and method

A heat pump drying and drying equipment technology, applied in lighting and heating equipment, heating to dry solid materials, drying solid materials, etc., can solve the problems of moisture gradient and internal stress, different moisture diffusion rates, etc. Cost saving and drying rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

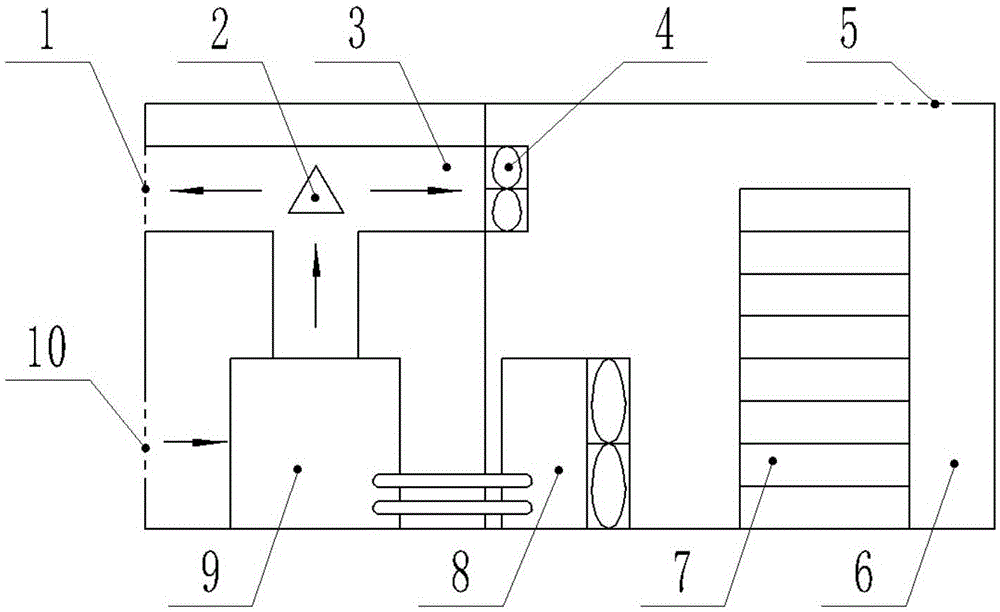

[0018] Honeysuckle is dried using intermittent cooling heat pump drying equipment and method. The details are as follows: ① pick the fresh honeysuckle and carry out pretreatment, and then load it into the heat pump drying equipment to prepare for drying; ② start the heat pump drying equipment, and the ambient air enters the heat pump external unit (9) through the air inlet (10), and is absorbed by the heat pump external unit. (9) After absorbing the heat, it turns into cold air and enters the exhaust pipe (3), and is discharged into the environment through the exhaust port (1) under the control of the control valve (2), and at the same time, the heat of the ambient air is absorbed by the heat pump external unit (9) Finally, it is transferred to the heat pump internal unit (8) placed inside the drying chamber (6) through the pipeline to heat the material, raising the drying temperature to 45°C, and the drying time lasts for about 3 hours; ③ Change the control mode, the ambient a...

Embodiment 2

[0020]Chrysanthemums are dried using intermittent cooling heat pump drying equipment and methods. The details are as follows: ① Pick fresh chrysanthemums and carry out pretreatment, then put them into the heat pump drying equipment and prepare for drying; (9) After absorbing the heat, it turns into cold air and enters the exhaust pipe (3), and is discharged into the environment through the exhaust port (1) under the control of the control valve (2), and at the same time, the heat of the ambient air is absorbed by the heat pump external unit (9) Finally, it is transferred to the heat pump internal unit (8) placed inside the drying chamber (6) through the pipeline to heat the material, raising the drying temperature to 40°C, and the drying time lasts for about 2 hours; ③Change the control mode, the ambient air It enters the heat pump external unit (9) from the air inlet (10), and after being absorbed by the heat pump external unit (9), it turns into cold air and enters the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com