Solvent casting device and solvent casting method

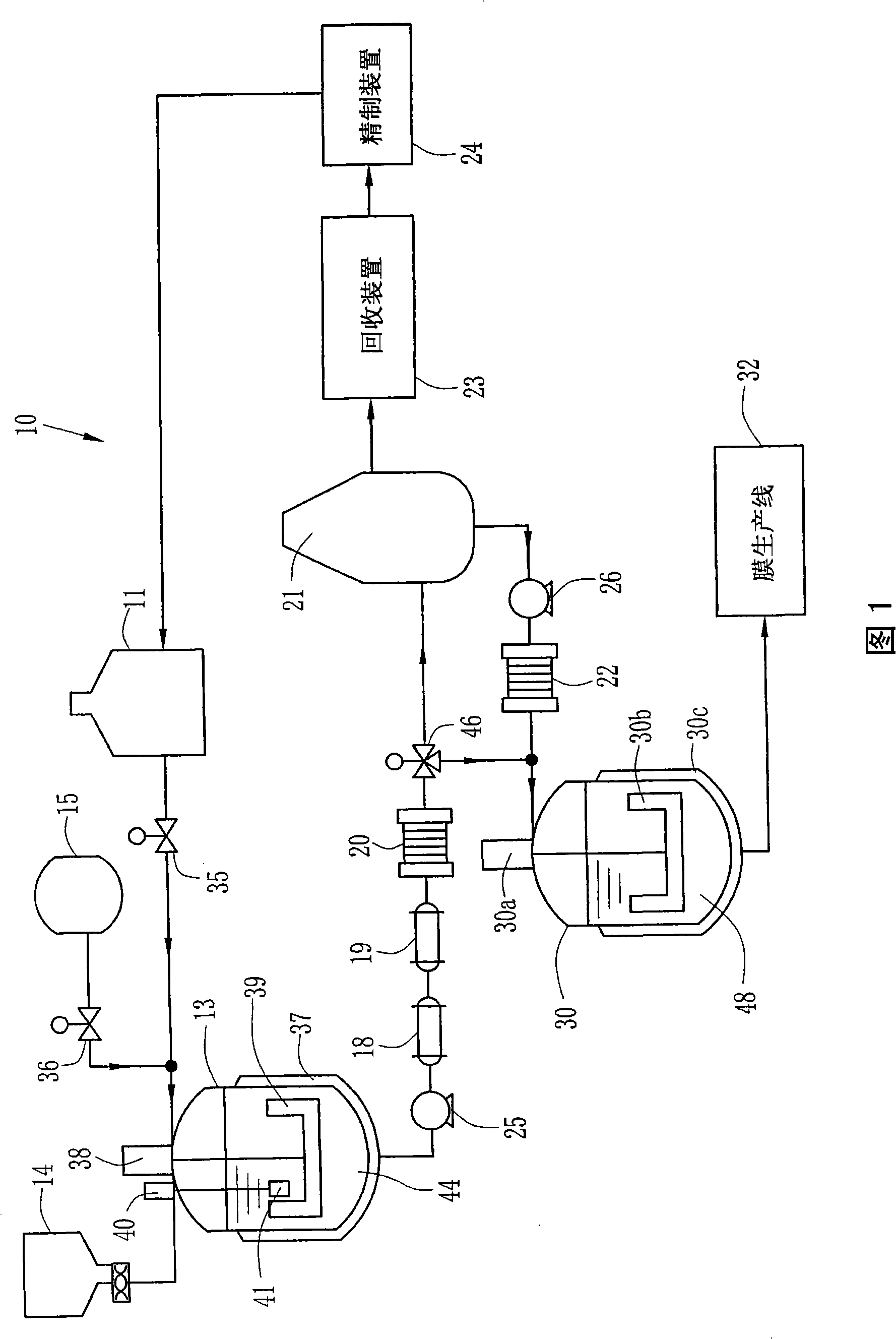

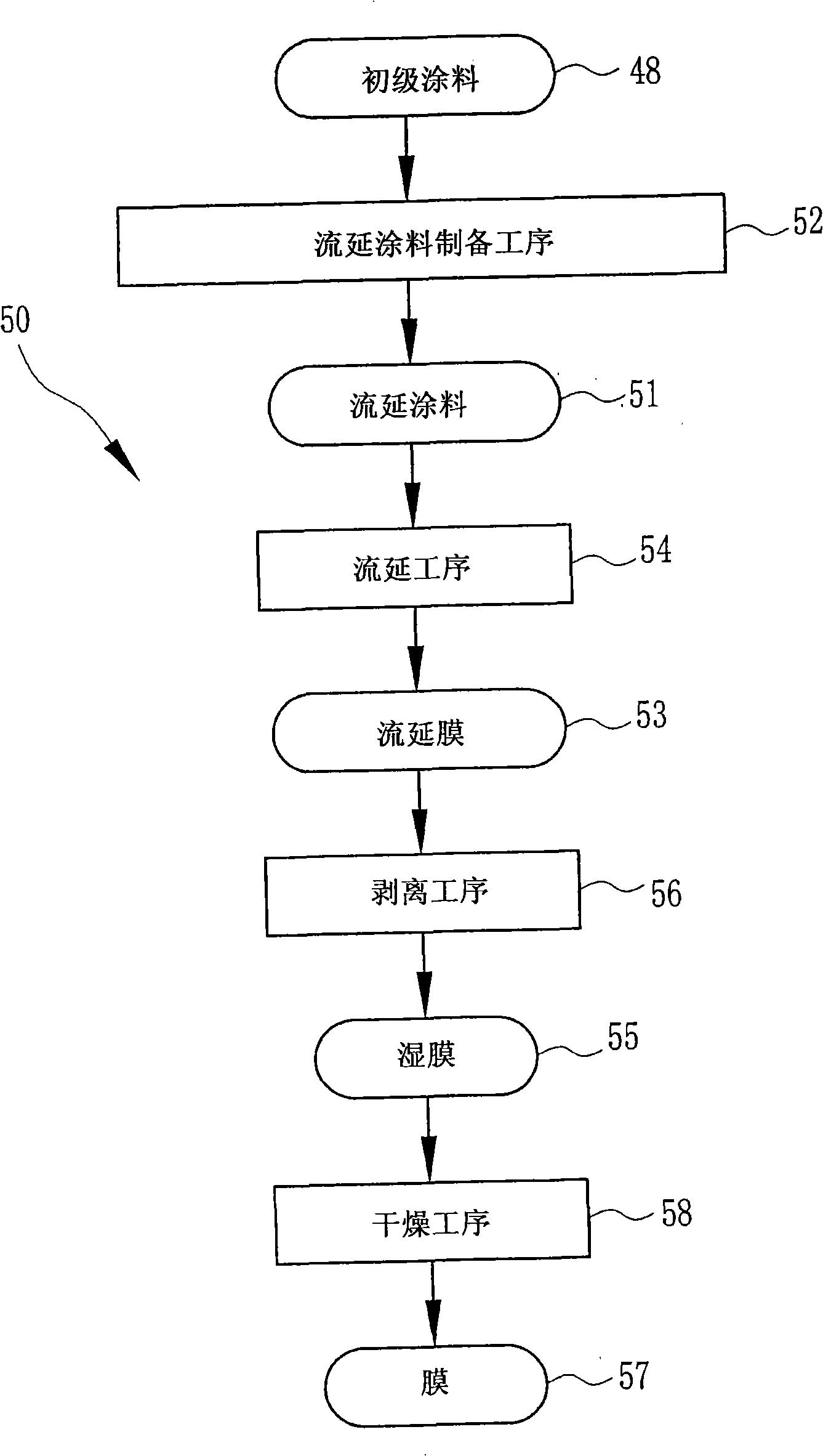

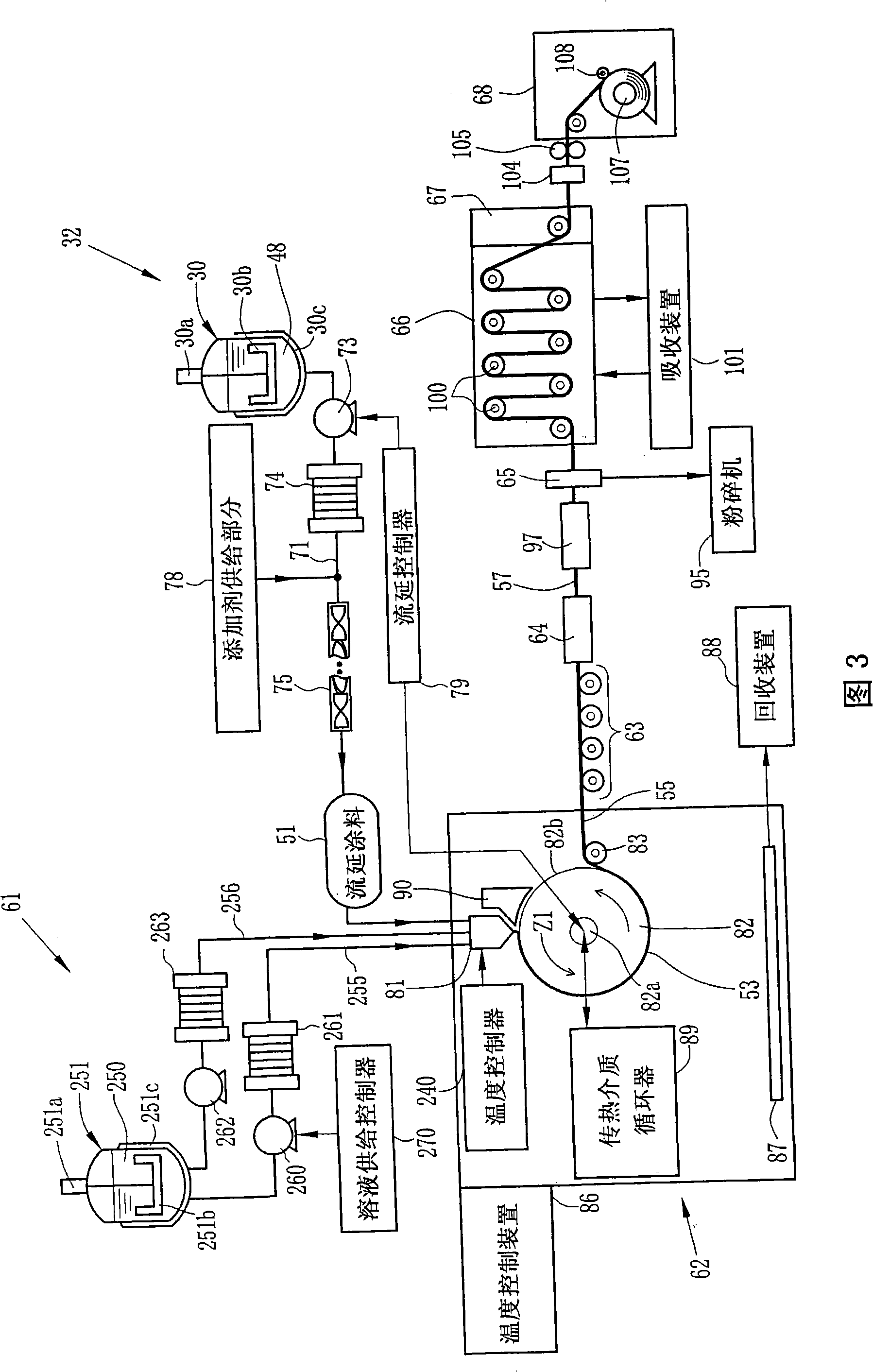

A solution and equipment technology, applied in the field of solution casting equipment, can solve problems such as reducing productivity, and achieve the effects of reducing the generation of skinning, preventing skinning, preventing peeling defects and the dispersion of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0186] In Example 1, Experiments 1-16 were performed. Experiments 5, 8, 9, 13, 14 are comparisons of the invention and the others are embodiments of the invention. The description of Experiment 1 will be carried out in detail, and the description of the same case will be omitted in the description of Examples 2-16.

[0187] [Experiment 1]

[0188] Now proceed to the description of Experiment 1. The composition used to prepare the coating for film production was as follows:

[0189]

[0190] Cellulose triacetate 89.3% by weight

[0191] (degree of substitution, 2.8)

[0192] Plasticizer A (triphenyl phosphate) 7.1% by weight

[0193] Plasticizer B (biphenyl diphenyl phosphate) 3.6% by weight

[0194]

[0195] Dichloromethane (first solvent component) 87% by weight

[0196] Methanol (second solvent component) 12% by weight

[0197] n-Butanol (third solvent component) 1% by weight

[0198] The solvent used for the coating contains the first solvent component and the ...

Embodiment 2

[0280] [Experiment 1]

[0281] The cellulose triacetate used in Example 10 was synthesized from cellulose obtained from wood, and the Ca content in the cellulose was 5 ppm. Furthermore, as UV absorber A, 2-(3-tert-butyl-5-methyl-2-hydroxyphenyl)-5-chlorobenzotriazole was used. Other conditions are the same as Experiment 1 of Example 1.

[0282] [Experiment 2-16]

[0283] UV Absorber A is the same as in Experiment 1 of Example 2. Other conditions of Examples 2-16 were the same as in Experiments 2-16 of Example 1, respectively.

Embodiment 3

[0285] In Example 3, methanol was used instead of n-butanol used to prepare mixed solvents A-E. Other conditions were the same as in Examples 1 and 2 to conduct experiments 1-16 in Example 3.

[0286] Furthermore, in Examples 2 and 3, in a similar manner to Example 1, evaluations were performed in terms of skinning generation and film smoothness. The evaluation results of Experiments 1-16 of each of Examples 2 and 3 were the same as in Experiments 1-16 of Example 1, respectively.

[0287]Even after continuous and long-term driving, the solution casting method and solution casting apparatus of the present invention can reduce the occurrence of skinning. Therefore, a film can be produced efficiently without cleaning several parts and devices in the casting chamber 62 such as a casting die, a casting drum, and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com