Piston with venting device for hydraulic traction mechanism tensioner

A technology of traction mechanism and tensioning device, which is applied in the direction of transmission device, mechanical equipment, belt/chain/gear, etc., and can solve the problem of unreliable exhaust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

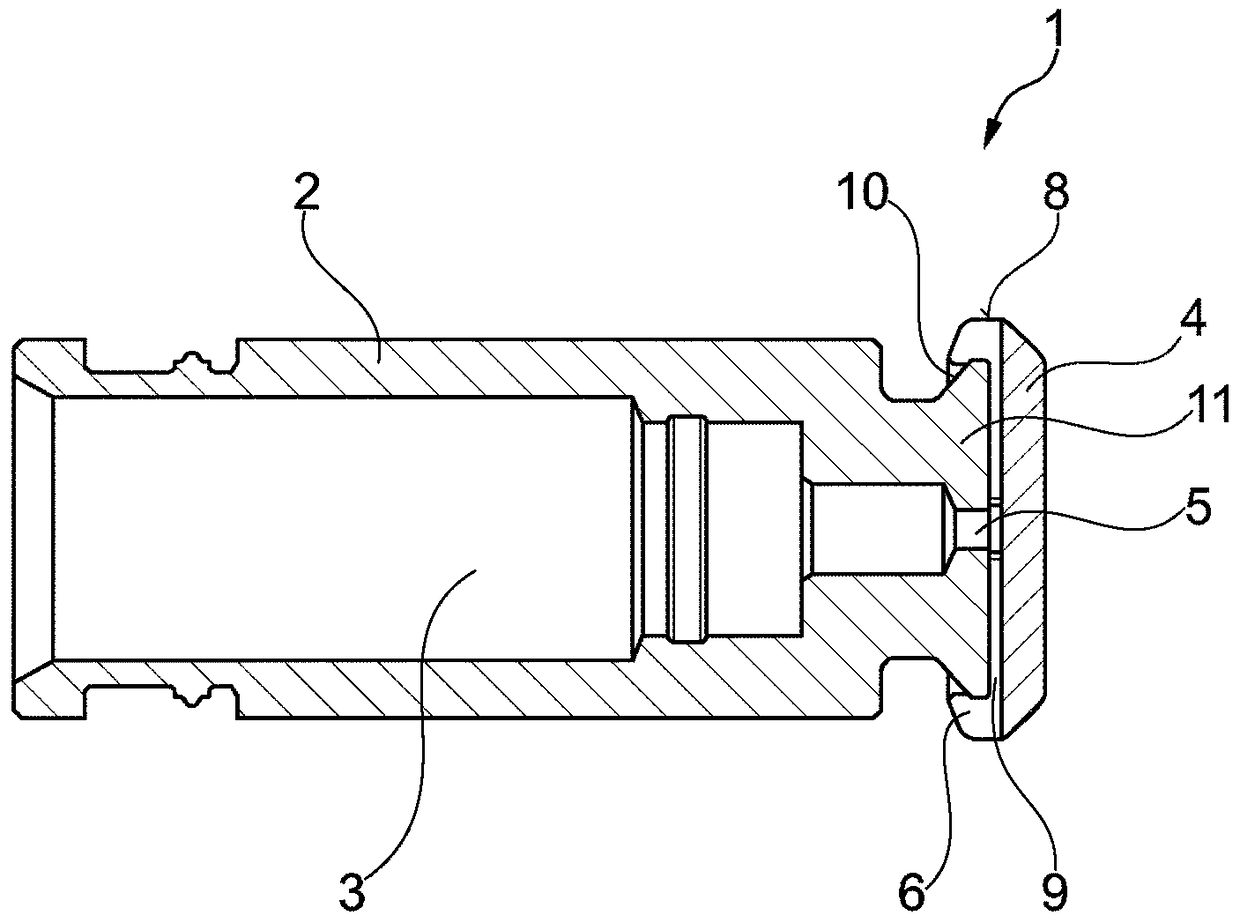

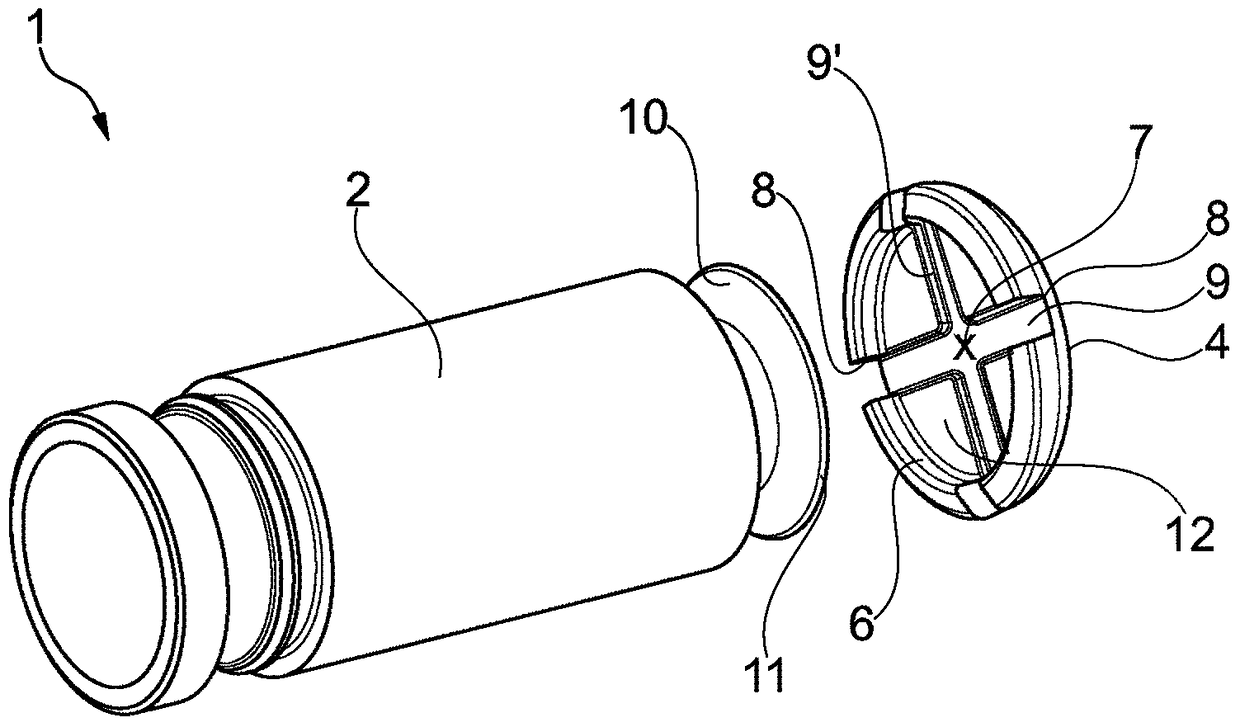

[0011] figure 1 A cross-section through a piston according to the invention is shown, which is provided for use in a hydraulic traction mechanism tensioning device. The piston 1 has a cylinder-shaped housing 2 with a hollow chamber 3 for receiving oil. The hollow chamber 3 is designed as a high-pressure chamber in which an oil pressure builds up. Since air has different compression properties than oil, it is desirable to divert the air contained in the hollow chamber. For this reason, through-holes are arranged in the top 11 of the housing 2 , through which air can escape from the hollow chamber 3 or the high-pressure chamber of the piston 1 . The piston 1 is usually made of steel or aluminum and rests on a tensioning rail, which is usually made of plastic or another lightweight material. During operation, the piston 1 presses against the tensioning rail, causing wear on the tensioning rail in the contact region due to the harder piston material. It is known to arrange a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com