Dry process rotary kiln cement production line based facility and method for cooperatively processing electrolytic manganese residues

A technology of electrolytic manganese slag and synergistic treatment, applied in cement production, lighting and heating equipment, preheating costs, etc., can solve the problems of unsatisfactory comprehensive utilization of electrolytic manganese slag, no significant technical effect advantages, secondary pollution, etc. , to protect the social ecological environment and natural environment, reduce the skinning of the smoke chamber, and promote the effect of gasification combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

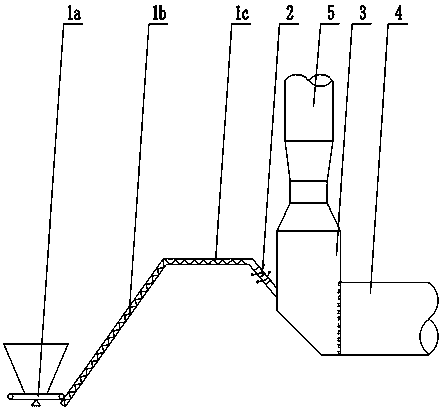

[0043] see figure 1 , the present embodiment is a kind of equipment based on the dry-process rotary kiln cement production line to co-process electrolytic manganese slag, mainly including quantitative feeder 1a, inclined screw conveyor 1b, horizontal screw conveyor 1c, air lock feeder 2, kiln tail Smoke chamber 3, rotary kiln 4, calciner 5. The discharge port of described quantitative feeder 1a is connected with the feed port of inclined screw conveyor 1b, and the discharge port of described inclined screw conveyor 1b is connected with the feed port of horizontal screw conveyor 1c, The discharge port of the horizontal screw conveyor 1c is connected with the feed port of the air lock feeder 2, and the discharge port of the described wind lock feeder 2 is connected with the feed port of the kiln tail smoke chamber 3 Communication, the flue gas outlet of the kiln tail smoke chamber 3 is connected with the air inlet of the calciner 5 through pipes, and the material outlet of the ...

Embodiment 2

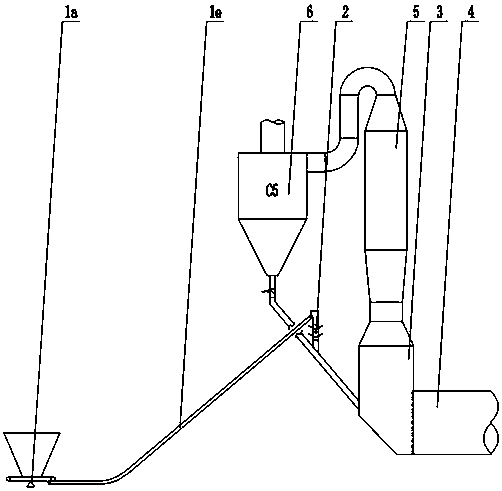

[0046] see figure 2 , a device based on the dry-process rotary kiln cement production line for co-processing electrolytic manganese slag, mainly including quantitative feeder 1a, belt conveyor 1e, air lock feeder 2, kiln tail smoke chamber 3, rotary kiln 4, decomposition Furnace 5, C5 level cyclone preheater 6. The discharge port of described quantitative feeder 1a is connected with the feed port of belt conveyor 1e, and the discharge port of described belt conveyor 1e is connected with the feed port of lock air feeder 2 , the discharge port of the air lock feeder 2 is connected with the lower end of the feeding pipe of the C5 grade cyclone preheater 6 (after the feeding pipe comes with a flap valve), and the C5 grade cyclone preheater The discharge port of the feeding pipe of 6 is connected with the feed port of the kiln tail smoke chamber 3, the air outlet of the kiln tail smoke chamber 3 is connected with the air inlet of the calciner 5 with a pipeline, and the kiln tail ...

Embodiment 3

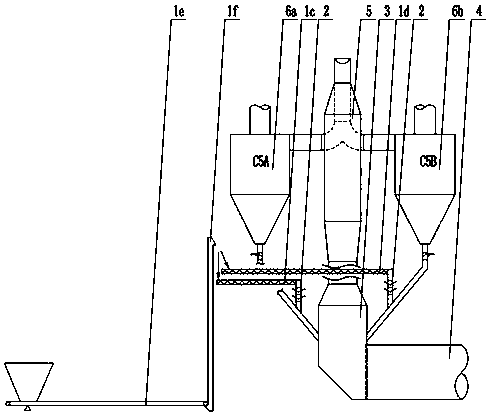

[0049] see image 3 , a device based on dry rotary kiln line co-processing electrolytic manganese slag, mainly including horizontal screw conveyor 1c, horizontal screw conveyor 1d, belt conveyor 1e, bucket elevator 1f, air lock feeder 2, Kiln tail smoke chamber 3, rotary kiln 4, calciner 5, C5A class cyclone preheater 6a, C5B class cyclone preheater 6b. The discharge port of the belt conveyor 1e is connected with the feed port of the bucket elevator 1f, and the discharge port of the bucket elevator 1f is connected with the horizontal screw conveyor 1c and the horizontal screw conveyor 1d respectively. The feed port of the horizontal screw conveyor 1c and the discharge port of the horizontal screw conveyor 1d are respectively connected with the feed port of the lock wind feeder 2, and the lock wind feeder corresponding to the horizontal screw conveyor 1c The first discharge port of the feeder 2 is connected with the lower end of the feeding pipe of the C5A-level cyclone prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com