Polyester plasticizer for leading glass fiber to form felt and preparation method of polyester plasticizer

A polyester plasticizer and glass fiber technology, applied in the direction of adhesive additives, polymer adhesive additives, etc., can solve the problems of unsuitability for glass fiber mats, poor compatibility of adhesives, and narrowing of the scope of use. To achieve the effect of improving the scope of application, good bonding strength and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

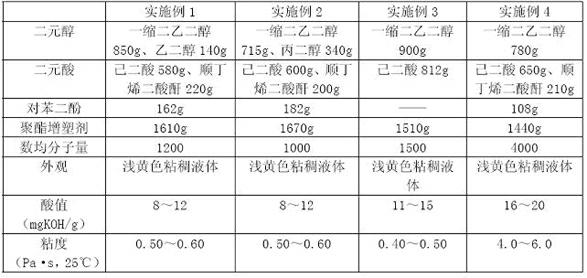

[0018] The polyester plasticizer for glass fiber matting in this embodiment is made of diethylene glycol, ethylene glycol, adipic acid and maleic anhydride, with a number average molecular weight of 1200 and a viscosity of 0.50 to 0.60 (Pa·s, 25°C).

[0019] The preparation method of this polyester plasticizer has the following steps:

[0020] ①Add 850g of diethylene glycol, 140g of ethylene glycol, 580g of adipic acid, and 220g of maleic anhydride into the reactor, feed in nitrogen gas and stir to gradually raise the temperature to 210°C. After the reaction system becomes uniform and transparent, Keep the temperature and continue the reaction until the measured acid value is less than 12 mgKOH / g.

[0021] ② Cool down to 190°C, add 162g of hydroquinone, then cool to 0°C-40°C, filter, and the filtrate is polyester plasticizer with a weight of 1610g and a number average molecular weight of 1200. Its appearance is light yellow viscous liquid, the acid value is 8-12 mgKOH / g, and...

Embodiment 2)

[0023] This embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

Embodiment 3)

[0025] Step 1. in the preparation method of the present embodiment is basically the same as Example 1, and step 2. is as follows:

[0026] ②Cool to 0℃~40℃, filter, and the filtrate is the ester plasticizer. Its appearance is light yellow viscous liquid. See Table 1 for the rest of the differences.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com