Homogenization pile metering checking device

A technology of equipment and metering devices, applied in the field of homogenizing reactor metering and checking equipment, can solve the problems of waste of manpower and material resources, difficulty in meeting the stable production requirements of rotary kilns, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

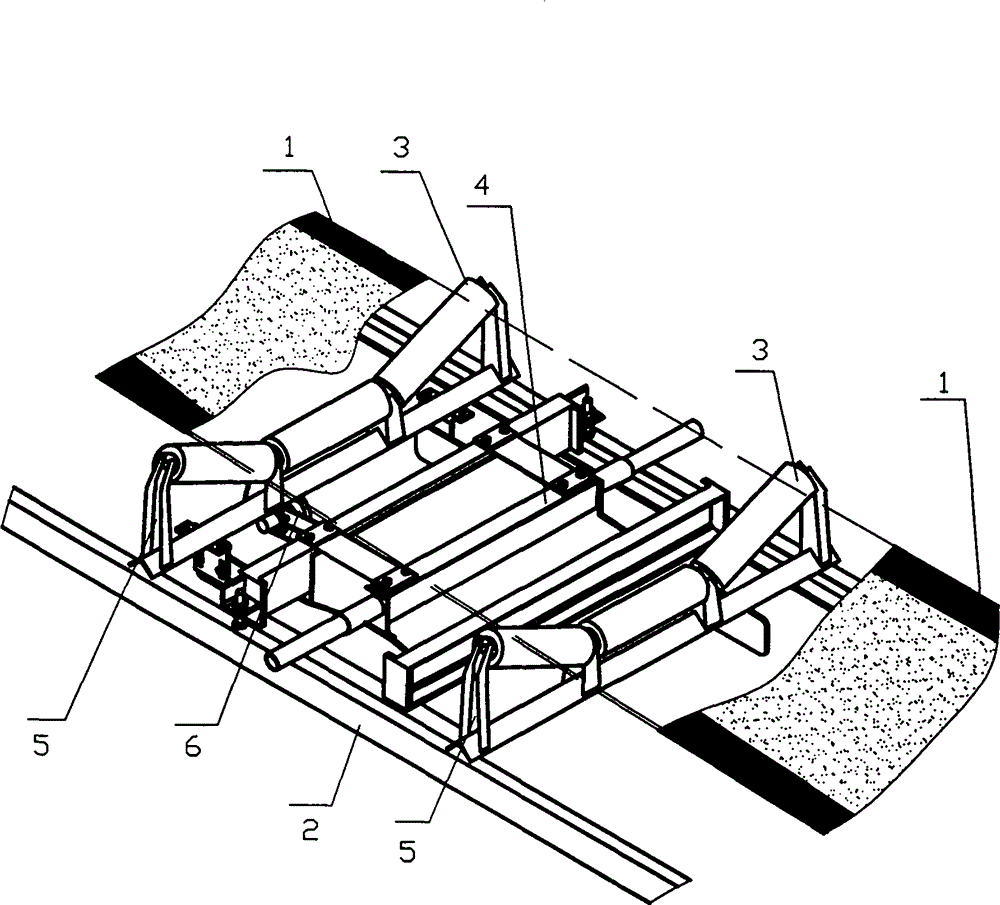

[0007] As shown in the figure, a homogenizing reactor measuring and checking equipment is composed of a belt 1, a conveyor beam frame 2, a supporting roller group 3, a measuring device 4, a supporting roller group bracket 5, and a speed measuring device 6; it is characterized in that: The conveyor beam 2 is equipped with several supporting roller set brackets 5. After each supporting roller set bracket 5 supports the supporting roller set 3, the belt 1 can run in a balanced manner on the supporting roller set 3, and the supporting roller set 3 can rotate normally ; On the conveyor beam 2 at the center between the supporting roller group 3 and the supporting roller group 3 is equipped with a metering device 4, the measuring device 4 is close to the supporting roller group 3 at the end of the supporting roller group bracket 5 bottom device is equipped with a speed measuring device 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com