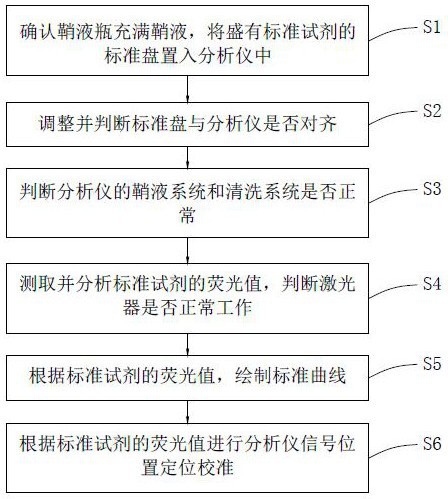

A quality control detection method and standard plate of a liquid phase chip analyzer

A liquid phase chip and detection method technology, applied in the direction of analysis of materials, material excitation analysis, individual particle analysis, etc., can solve problems such as no technical solutions, easy pollution, and improper display position of fluorescence value of test results, etc., to ensure Accuracy, accurate detection, and the effect of avoiding distortion of experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

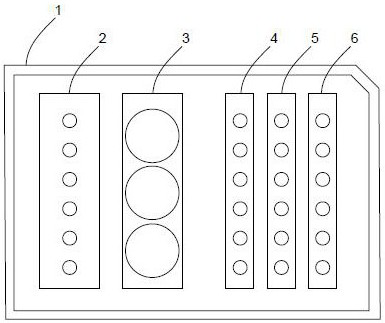

[0097] Configure standard reagents using PCR tubes as containers for quality control testing, each standard reagent is at least 100 μl, and put them into the standard wells on the tray body 1 .

[0098] Among them, the first microsphere reagents labeled with two different dyes are placed in the two standard wells of the calibration area 2, respectively numbered 110 and 120;

[0099] The two standard holes in the laser detection area 4 are respectively placed in the third microsphere reagents labeled with two different dyes that are consistent with those in the calibration area 2, and are also numbered 110 and 120 respectively;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com