Foam glass and preparation method thereof

A technology of foam glass and desulfurized gypsum, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., and can solve problems such as solid waste accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

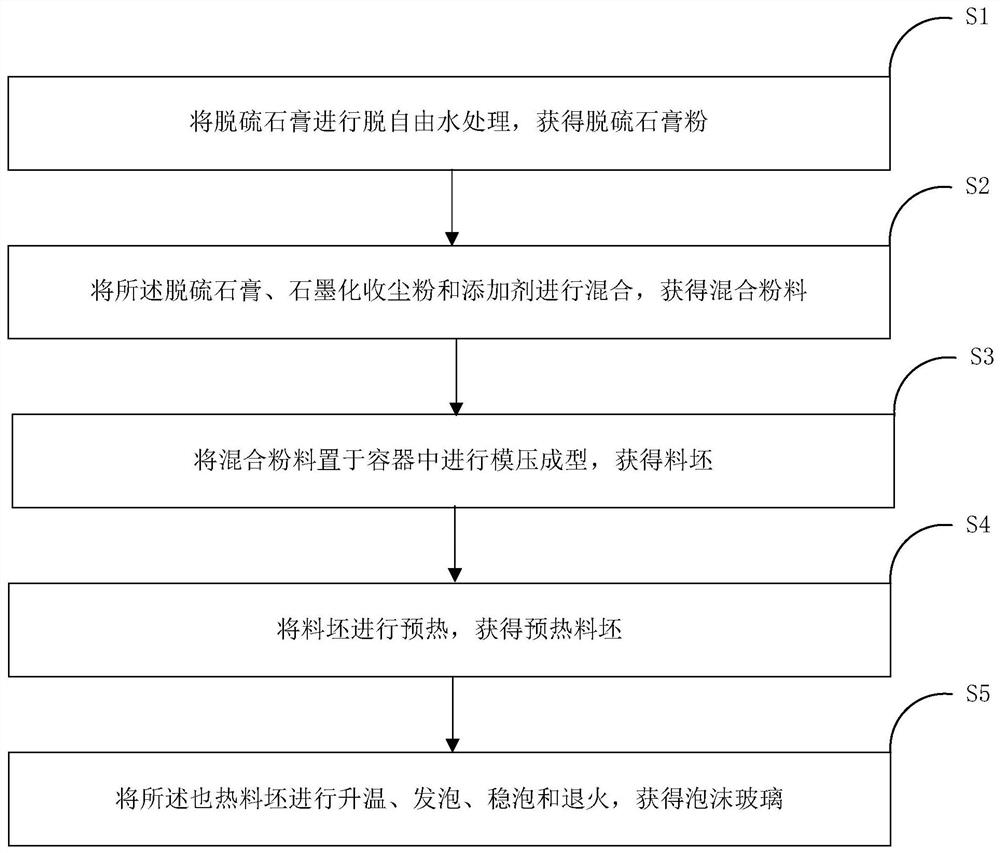

[0035] According to a typical embodiment of the present invention, a kind of preparation method of cellular glass is provided, and described method comprises:

[0036] S1. Desulfurization gypsum is subjected to free water treatment to obtain desulfurization gypsum powder;

[0037] As an optional embodiment, the dehydration treatment should ensure that the desulfurized gypsum powder becomes uniform. Generally speaking, the water content of the desulfurized gypsum powder is less than or equal to 3% by mass.

[0038] S2. Mix the desulfurized gypsum, graphitized dust-collecting powder and additives to obtain a mixed powder. In order to ensure uniform foaming, the mixed material must be uniform; in parts by mass, the composition of the mixed powder includes: 2-6 parts of desulfurized gypsum, 89-97 parts of graphitized dust collection powder and 1-5 parts of additives;

[0039] The role of graphitized dust collection powder is as a raw material for preparation, controlling 89-97 pa...

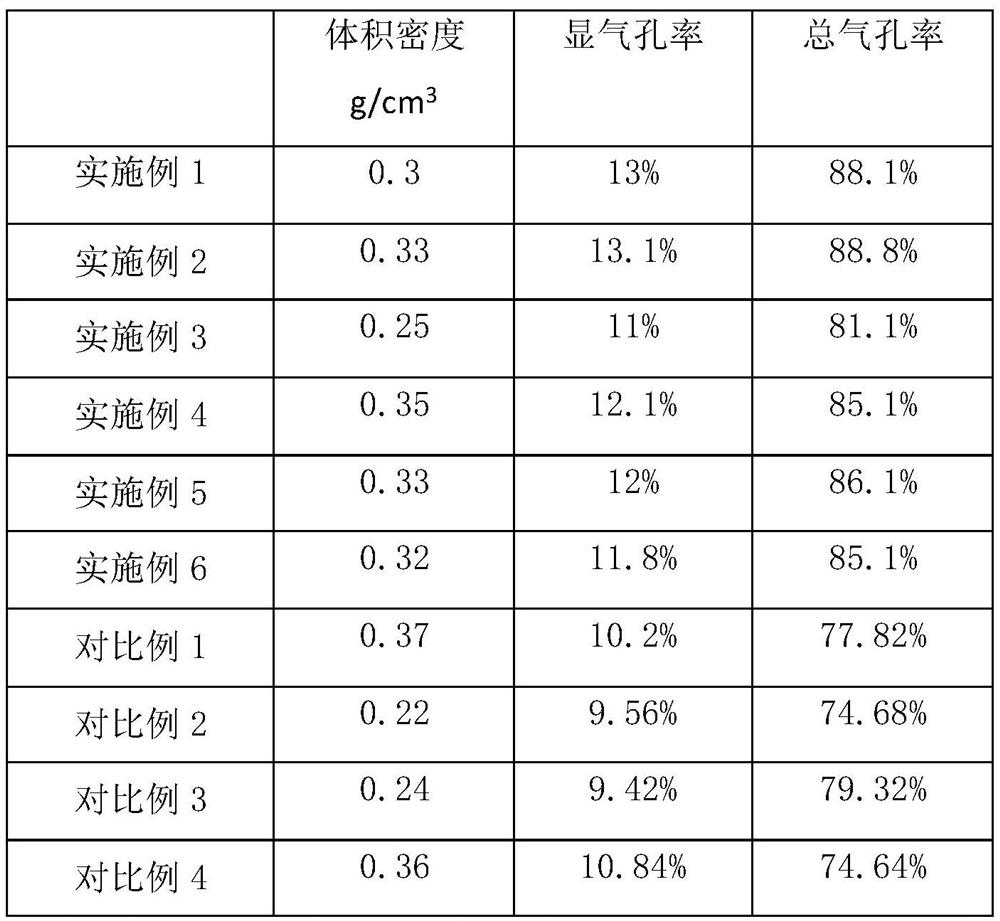

Embodiment 1

[0055] A preparation method of cellular glass, the method comprising:

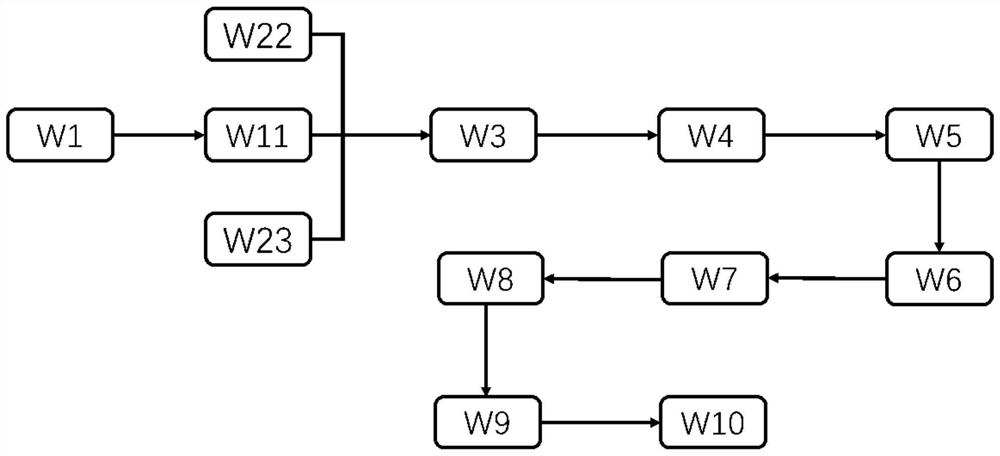

[0056] The desulfurization gypsum W1 is dehydrated to become anhydrous desulfurization gypsum W11. Mix dust collection powder W22, anhydrous desulfurized gypsum W11 and additive W23 according to 2 parts, 96 parts and 2 parts; uniformly mix in a mixer to obtain a mixture W3, and put the mixed material in a mold for preliminary compression molding , and then put it into a corundum crucible coated with vaseline or other volatile organic substances and carbon powder. Slowly raise the temperature to 450°C at a rate of 5-7°C / min for preheating to obtain hot mix W5, and keep it warm for 1h. The temperature is raised at a heating rate of 15°C / min, and the foaming stage is carried out at 1250°C for about 1 hour. Rapidly cool down to 600°C at a speed of 10°C / min to stabilize the foam, keep warm for 30 minutes, turn off the power, and cool to room temperature with the furnace for annealing.

Embodiment 2

[0058] A preparation method of cellular glass, the method comprising:

[0059] The desulfurization gypsum W1 is dehydrated to become anhydrous desulfurization gypsum W11. Mix dust collection powder W22, anhydrous desulfurized gypsum W11 and additive W23 according to 3 parts, 95 parts and 2 parts; uniformly mix in a mixer to obtain a mixture W3, and put the mixed material in a mold for preliminary compression molding , and then put it into a corundum crucible coated with vaseline or other volatile organic substances and carbon powder. Slowly raise the temperature to 500°C at a rate of 5-7°C / min for preheating to obtain hot mix W5, and keep it warm for 1h. The temperature is raised at a heating rate of 15°C / min, and the foaming stage is carried out at 1350°C for about 1 hour. Rapidly cool down to 650°C at a speed of 10°C / min to stabilize the foam, keep warm for 30 minutes, turn off the power, and cool to room temperature with the furnace for annealing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com