Application of household refuse pyrolytic gasification combustible gas in shale sintered brick process

A technology of pyrolysis gasification and domestic waste, which is applied in applications, petroleum industry, household appliances, etc., and can solve problems such as affecting soil and polluting water sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

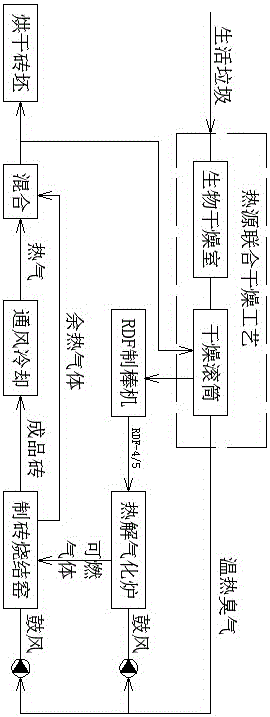

[0027] Embodiment one: A domestic waste pyrolysis gasification combustible gas is used in the shale sintered brick process, such as figure 1 As shown, it includes the following steps: 1) The domestic waste is processed by the heat source combined drying process, and the processed material is sent to the RDF rod making machine to make RDF solid fuel (for details about the heat source combined drying process, see another article named Patent application for "a domestic waste heat source combined drying process"); 2) Send RDF solid fuel into the pyrolysis gasifier for pyrolysis and gasification to obtain combustible gas; 3) Send the combustible gas into the brick sintering kiln, Burn finished bricks; while disposing of domestic waste, use the heat generated by the waste to burn bricks to achieve the purpose of comprehensive utilization of resources, reduce environmental pollution, reduce brick-making costs, and increase economic benefits; 4) For bricks that have completed step 3...

Embodiment 2

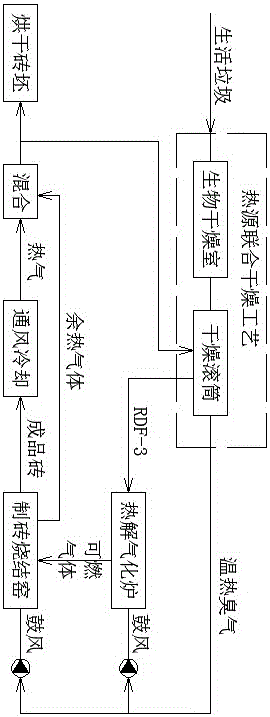

[0028] Embodiment two: A domestic waste pyrolysis gasification combustible gas is used in the shale sintered brick process, such as figure 2 As shown, it includes the following steps: 1) The domestic waste is subjected to heat source combined drying process; 2) The domestic waste treated in step 1) is directly sent to the pyrolysis gasifier for pyrolysis and gasification to obtain combustible Gas; 3) Send combustible gas into the brick-making sintering kiln, burn the finished bricks, and discharge waste heat gas; 4) Ventilate and cool the finished bricks in the brick-making sintering kiln after completing step 3), and extract the heat generated by cooling; 5) Send the combustible gas into the brick kiln for combustion in step 3) and combine the exhausted waste heat gas with the hot gas generated by cooling in step 4); 6) combine part of the gas after step 5) Pass into the drying kiln of the brick factory to dry the bricks; the other part passes into the drying drum used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com