Patents

Literature

34results about How to "Reduce the cost of brick making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing sludge autoclaved aerated concrete building block

InactiveCN101850574AHigh porosityMeet production requirementsSludge treatment by de-watering/drying/thickeningSolid waste managementBrickSludge

The invention belongs to the technical field of environmental engineering, and particularly relates to a process for preparing a sludge autoclaved aerated concrete building block. The process mainly comprises the following steps of: (1) quickly stirring and mixing spare dried sludge, water and lime, coal ash, cement, gypsum and aluminum powder with physical and chemical properties meeting the brick making requirements in a certain ratio and in turn; (2) feeding the mixture obtained in the step (1) into a die, and putting the die into a thermostatic curing box of 40 DEG C or 60 DEG C to perform foaming and curing for 4 hours; (3) putting the blank foamed and cured in the step (2) into an autoclave, and curing the blank for over 8 hours by adopting a stepwise buck-boost curing mode; and (4) piling the product discharged from the autoclave outdoors for over 2 days. The process can reach hazard-free and recycling treatment of urban sludge, save clay resources and save the brick making cost, and has remarkable economic, social and environmental benefits.

Owner:HUNAN UNIV OF SCI & TECH

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

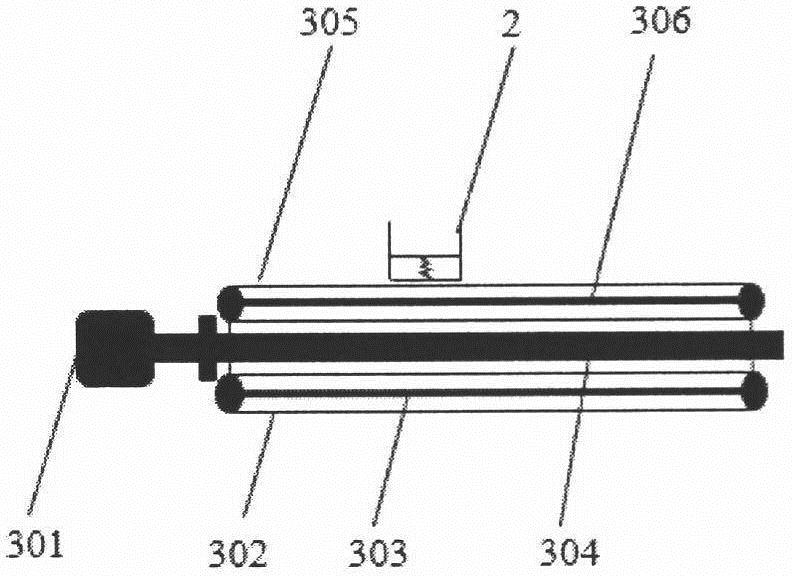

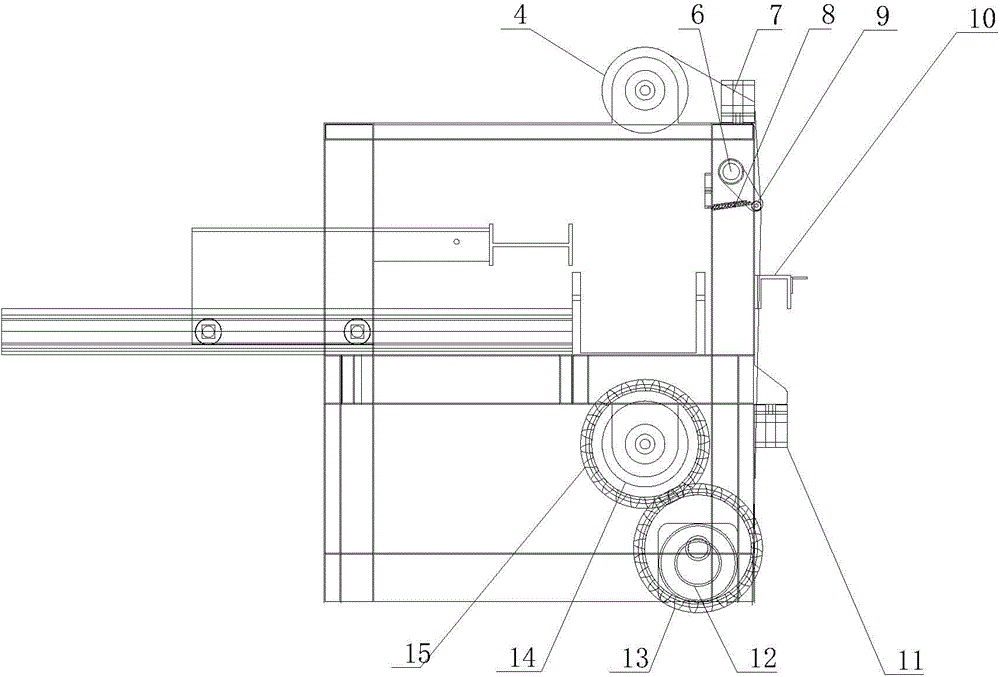

Operation method of carbon dioxide carbonized brick body manufacturing device

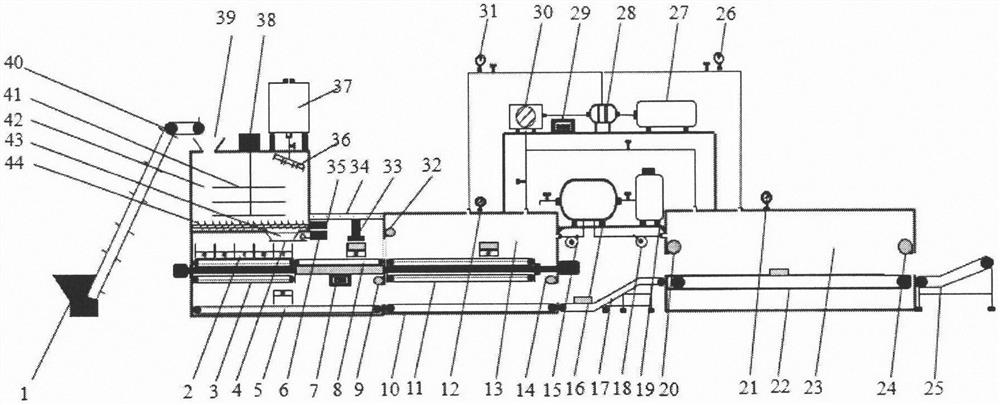

The invention discloses an operation method of a carbon dioxide carbonized brick body manufacturing device, and belongs to the field of civil engineering brick manufacturing. The two processes of pre-carbonization and secondary carbonization are specially set, so that after the shape and the strength of a brick body are temporarily stabilized, demolding is smoothly completed, and the strength is rapidly increased. All systems in the device work coordinately and orderly according to the method, so that charging, compaction forming and brick mold conveying are conducted at the same time, brick material adding and uniform mixing are conducted in the pre-carbonization process, and the brick body manufacturing and conveying efficiency is greatly improved; an upper conveying belt and a lower conveying belt rotate through a rotating shaft, brick bodies are demolded through spring limiters in brick molds, and brick body demolding and efficient cyclic utilization of the empty brick molds are achieved through electromagnet adsorption and releasing and conveying of the conveying belts. According to the brick manufacturing method, low-concentration carbon dioxide and construction waste are utilized, the carbon dioxide in a carbonization cavity can be pumped into a storage bin through an exhaust fan after carbonization, carbon dioxide gas is recycled, tail gas emission is reduced, environmental protection is facilitated, and the brick manufacturing cost is reduced.

Owner:NANJING FORESTRY UNIV

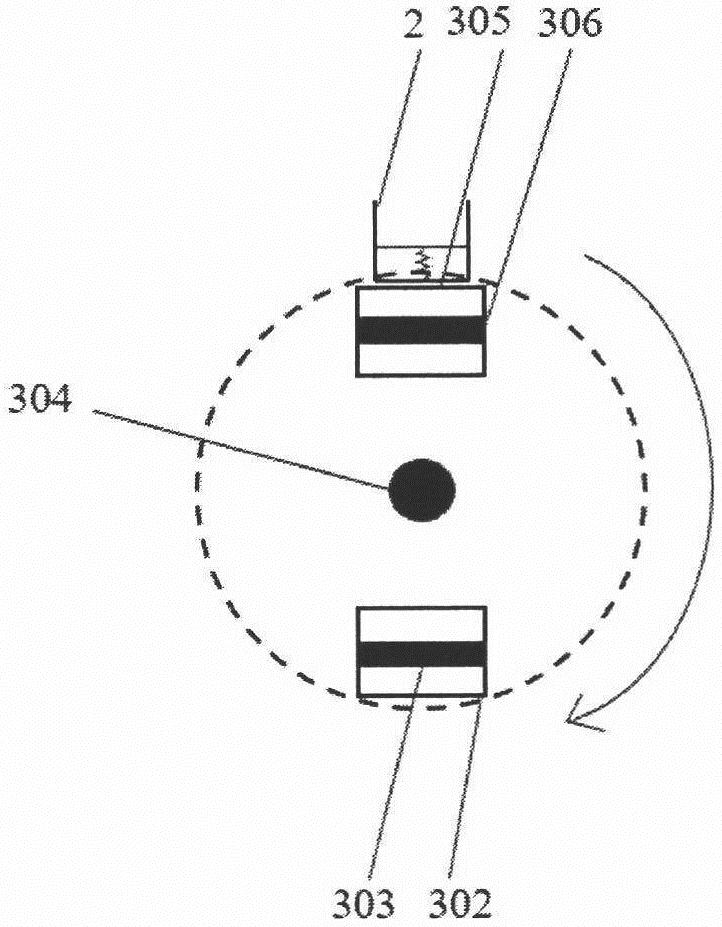

Al2O3-SiC-C refractory brick for torpedo ladle produced by utilizing waste Al2O3-C and preparation method of Al2O3-SiC-C refractory brick

InactiveCN107555970AExtended service lifeHigh degree of densificationMelt-holding vesselsBrickMaterials science

The invention belongs to the field of refractory matters for ferrous metallurgy and in particular relates to an Al2O3-SiC-C refractory brick for a torpedo ladle produced by utilizing a waste Al2O3-C material and a preparation method of the Al2O3-SiC-C refractory brick. The Al2O3-SiC-C refractory brick comprises the following raw materials in percentage by weight: 10-40% of special grade bauxite clinker particles with the particle size of 3-5mm, 10-30% of special grade bauxite clinker particles with the particle size of 1-3mm, 5-20% of alundum particles with the particle size of 0.088-1mm, 5-20% of corundum fine powder with the particle size of less than 0.088mm, 2-8% of silicon carbon particulates with the particle size of 0.088-1mm, 2-8% of silicon carbon fine powder with the particle size of less than 0.088mm, 10-25% of waste Al2O3-C material fine powder with the particle size of less than 0.088mm, 5-15% of alumina micro powder with the particle size of less than 0.088mm, 3-10% of binding clay fine powder with the particle size of less than 0.088mm, 1-10% of crystalline flake graphite powder with the particle size of less than 0.088mm, 0.5-5% of asphalt powder with the particle size of less than 0.088mm, and 4-8% of additional phenolic resin.

Owner:UNIV OF SCI & TECH LIAONING

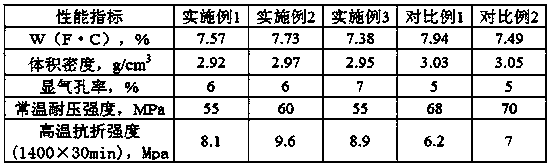

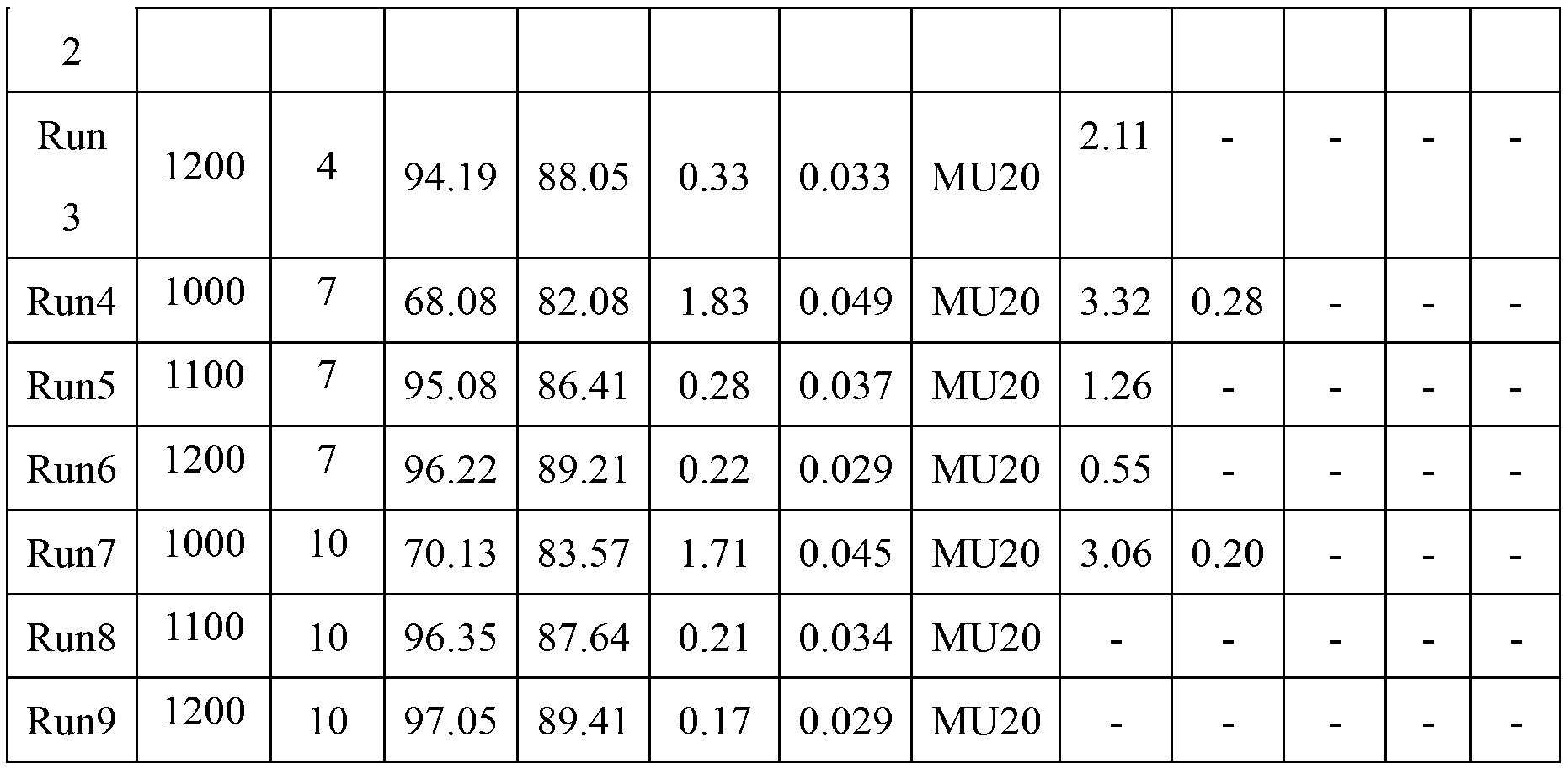

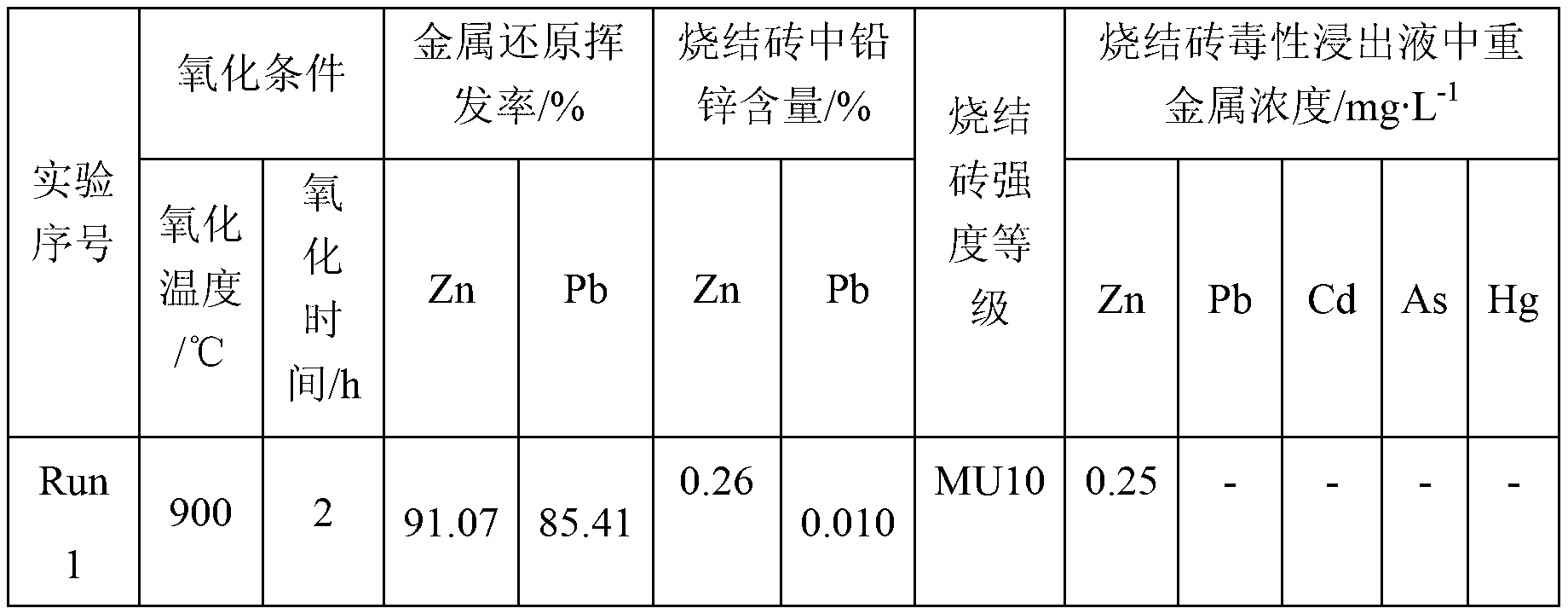

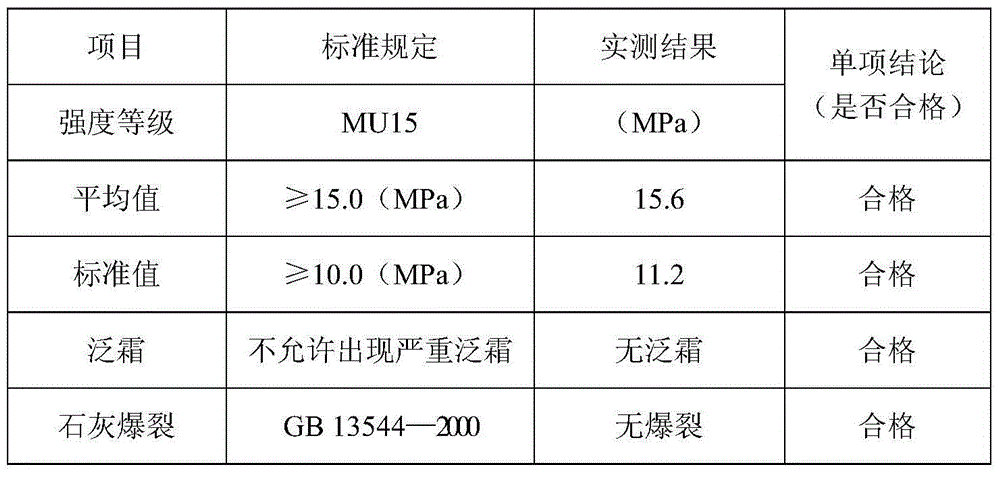

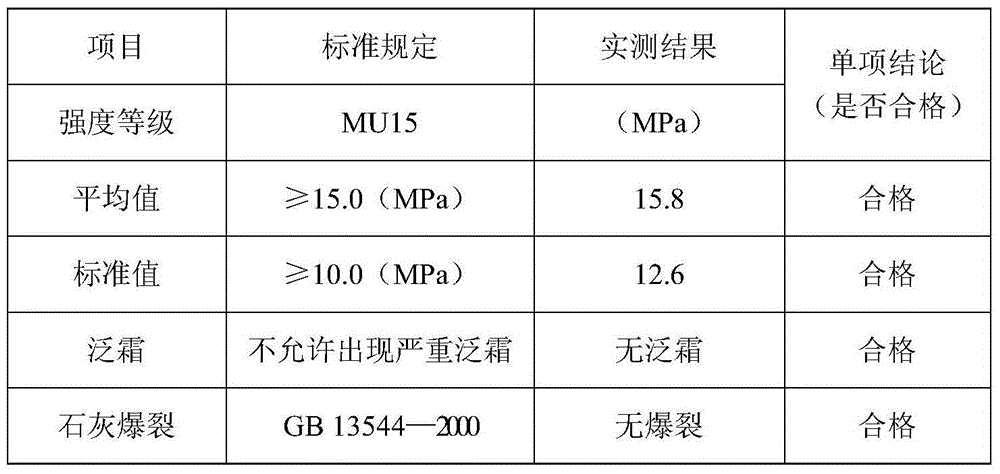

Recycling method for zinc-containing waste residue and urban domestic sludge

The invention relates to a recycling method for zinc-containing waste residue and urban domestic sludge. The recycling method comprises the following steps of: a, crushing and sieving the indigenous zinc-smelting waste residues; b, uniformly mixing 40%-80% (in percentage by weight) of the indigenous zinc-smelting waste residues with 20%-60% of urban domestic sludges, and ageing the mixture under the normal temperature; c, pressing and forming the aged mixture, an drying the pressed and formed mixture to obtain a dry body; d, reducing and volatilizing the dry body in a high-temperature sealed furnace, and collecting the volatile component to obtain the zinc-enriched smoke dust, wherein the reducing temperature is 1000 DEG C to 1200 DEG C and the reducing time is 6 hours to 10 hours; and f, ventilating air to the high-temperature sealed furnace for oxidizing and roasting, wherein the oxidizing and roasting temperature is 900 DEG C to 1100 DEG C and the oxidizing time is 2 hours to 8 hour, and cooling with the furnace to obtaine a sintered brick.

Owner:CENT SOUTH UNIV +1

Biogas slurry sintered brick and preparation method thereof

InactiveCN104086159AReduce labor intensityHigh degree of automationCeramic materials productionClaywaresBrickThree stage

The invention provides a biogas slurry sintered brick and a preparation method thereof. The biogas slurry sintered brick is prepared from the following components in percentage by weight: 75-85% of clay, 14-24% of coal gangue and 0.5-2% of biogas slurry. The preparation method of the biogas slurry sintered brick comprises the following steps: carrying out three-stage crushing on clay and coal gangue by adopting a jaw type crusher, a hammer crusher and a fine crushing double roll crushing machine, then adding biogas slurry, stirring by adopting a double-shaft mixer, then aging uniformly mixed materials in an ageing warehouse so that raw materials are fully homogenized, then conveying the homogenized raw material to a forming shop, carrying out extrusion molding by virtue of an extruder to obtain a green body, and finally drying the green body in a tunnel drying room, thus obtaining the biogas slurry sintered brick finished product. The preparation method of the biogas slurry sintered brick has the advantages that the biogas slurry obtained by carrying out anaerobic fermentation on organic ingredients in household garbage in a garbage treatment process and carrying out solid-liquid separation on residual waste is taken as a raw material of the sintered brick, recycling of urban and rural waste is realized, harmless, reduction and recycling treatment of garbage is guaranteed, and brick making cost is greatly reduced, and strength of the sintered brick is improved.

Owner:新密市环新生活垃圾处理有限公司

Residue soil baking-free brick and preparation method thereof

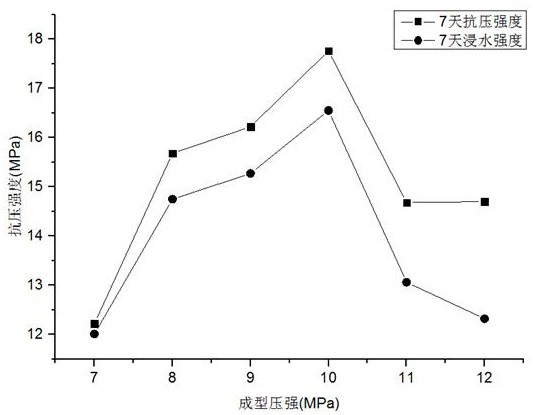

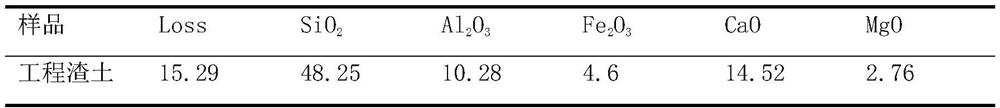

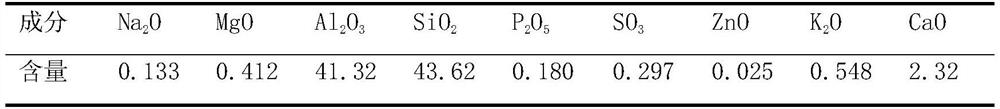

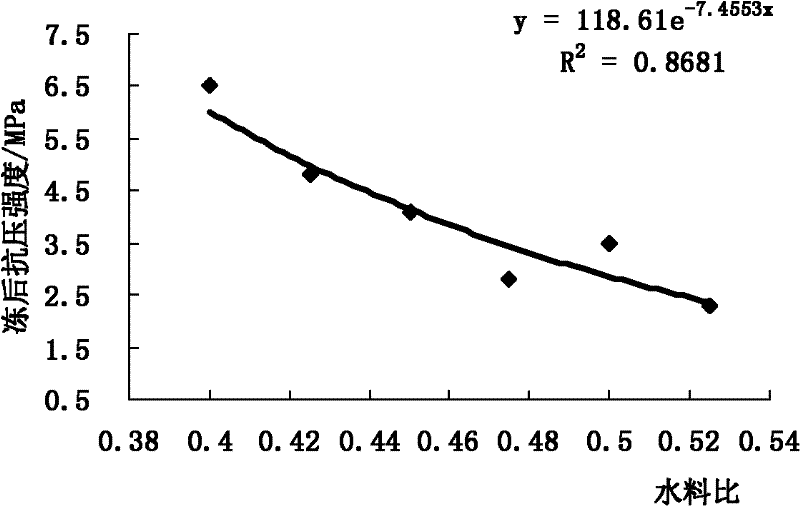

PendingCN112521096AGuaranteed compressive strengthIncrease the proportionCompressive resistanceBrick

The invention discloses a residue soil baking-free brick and a preparation method thereof, and relates to the technical field of baking-free bricks. The baking-free brick is formed by pressing 40-60%of muck, 10-20% of fly ash, 10-20% of cement, 10-20% of brick-concrete construction waste and 0.5-2% of lime as raw materials, a soil curing agent does not need to be doped any more, the specific gravity of solid waste in the raw material components reaches 78% or above, particularly, the 7-day strength of the baking-free brick is larger than 15 MPa, and the softening coefficient is larger than 0.8. The problems of high production cost, poor water stability and small specific gravity of solid wastes of the muck baking-free brick in the prior art are solved, the doping amount of the solid wastes such as muck, fly ash and construction wastes is increased on the premise of ensuring the compressive strength of the baking-free brick, the production cost is reduced, and the method is more economical and environment-friendly.

Owner:西安市政道桥建设集团有限公司

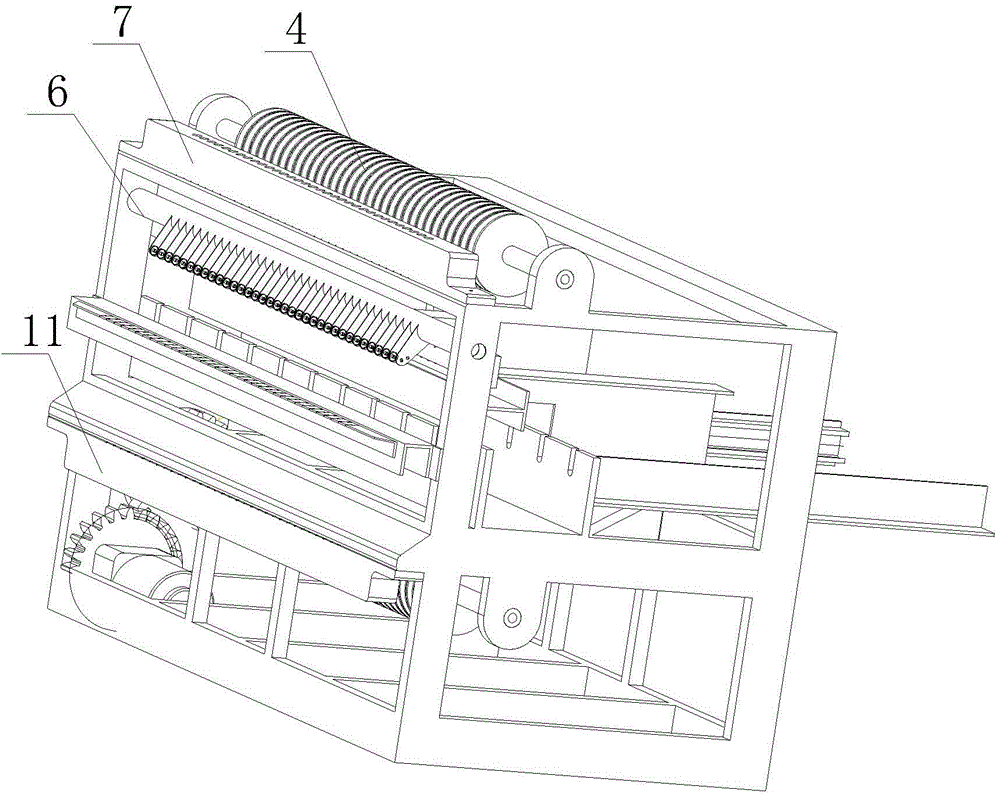

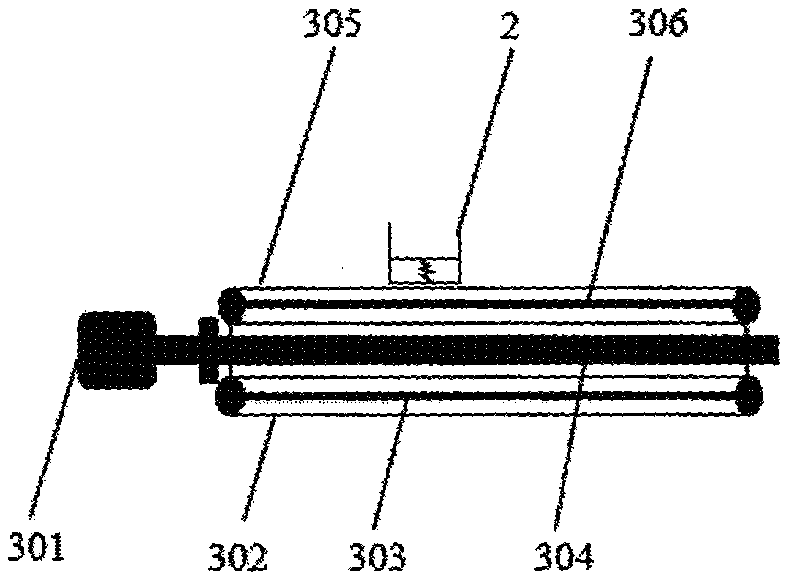

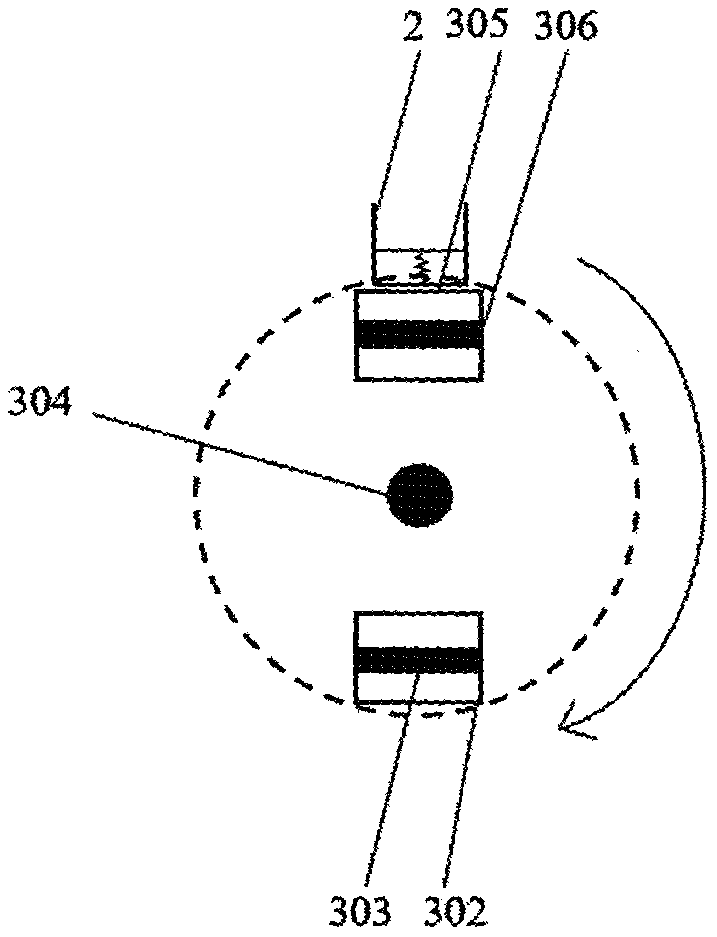

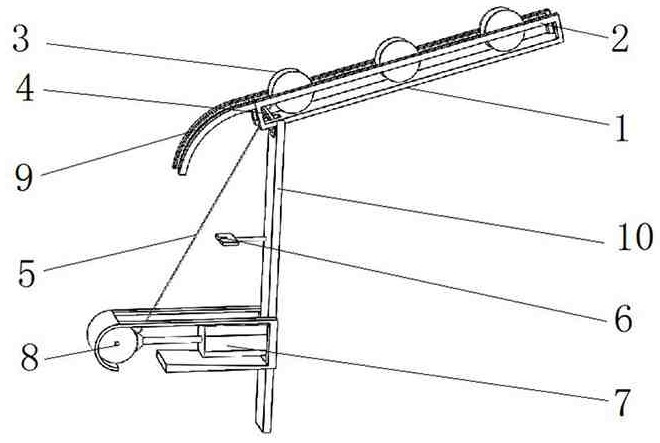

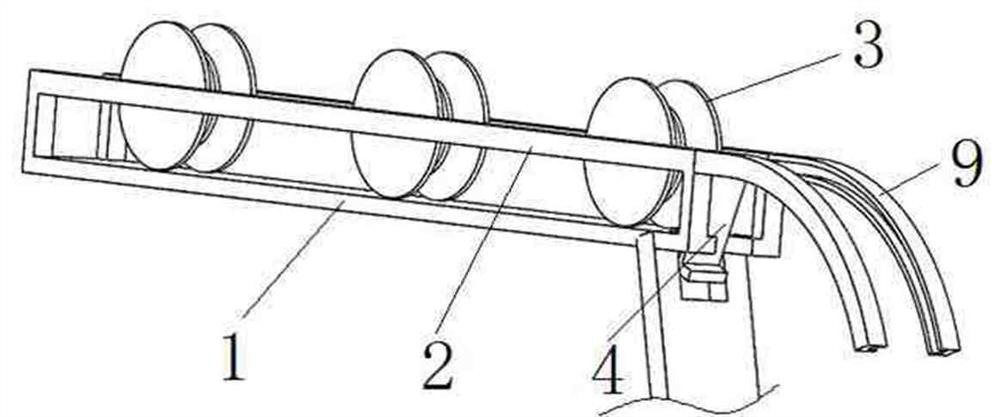

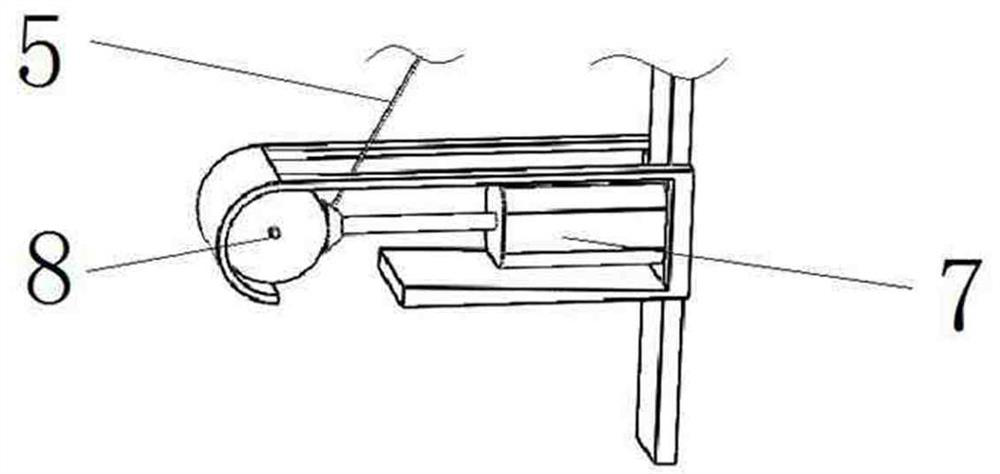

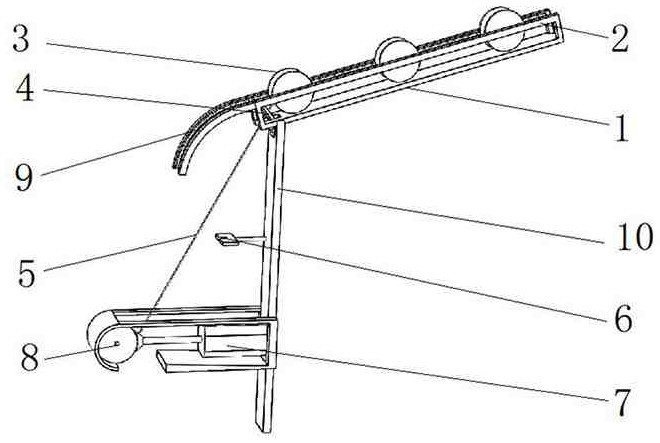

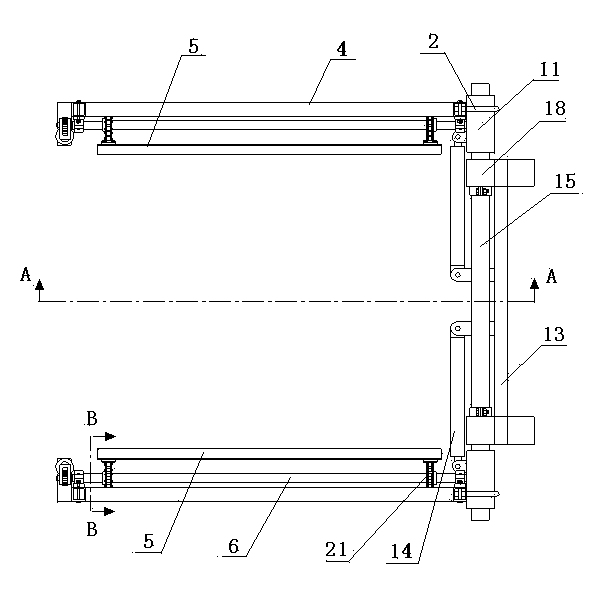

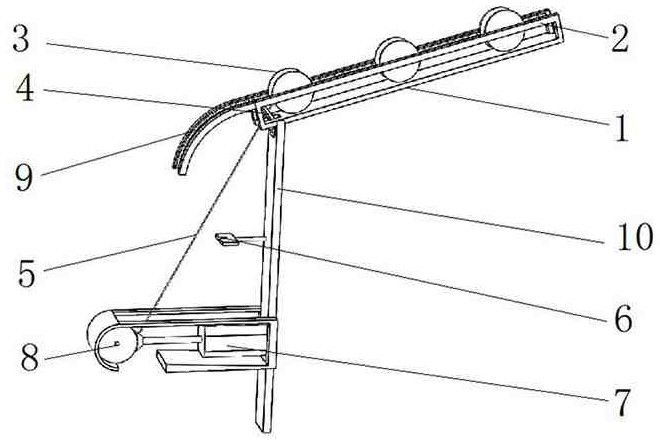

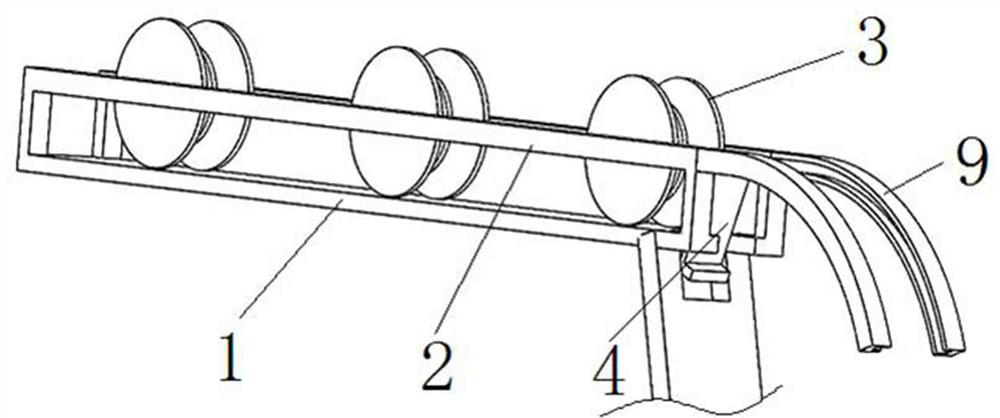

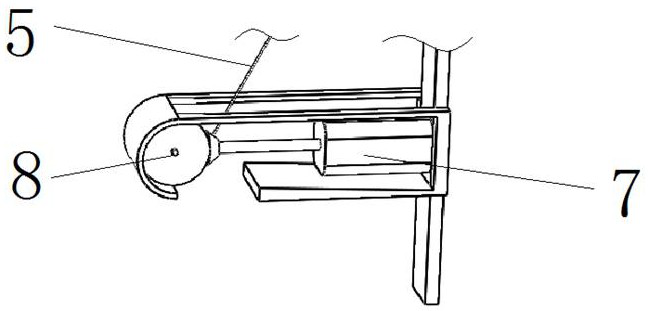

Steel wire automatically replacing device for raw brick cutting machine

ActiveCN104626344AAvoid fatigueImprove brick making efficiencyCeramic shaping apparatusBrickEngineering

The invention provides a steel wire automatically replacing device for a raw brick cutting machine. The steel wire automatically replacing device comprises a rack, one side of the rack is provided with a raw brick cutting table, a first steel wire rope winding shaft is arranged over the raw brick cutting table and a second steel wire rope winding shaft is arranged under the raw brick cutting table, and the upper and lower sides of the raw brick cutting table are provided with a first steel wire rope holding device and a second steel wire rope holding device respectively; a steel wire rope is wound on the second steel wire rope winding shaft from the first steel wire rope winding shaft through first steel wire rope holding device, the second steel wire rope holding device in sequence, the raw brick cutting table and the second steel wire rope holding device. During working, the first steel wire rope holding device and the second steel wire rope holding device each tightens the steel wire rope; when the steel wire rope is replaced, the first steel wire rope holding device and the second steel wire rope holding device are made to release the steel wire rope, the second steel wire rope winding shaft rotates by a certain angle to let the steel wire wind, a steel wire rope which reaches fatigue strength leaves away from the raw brick cutting location, and a new steel wire rope arrives at the raw brick cutting location, and tensile failure of the steel wire rope caused by fatigue can be avoided. By means of the steel wire automatically replacing device, the raw brick cutting machine can work without stop around the clock, the efficiency of making bricks is greatly improved, and the cost of making the bricks is saved.

Owner:NANTONG UNIVERSITY

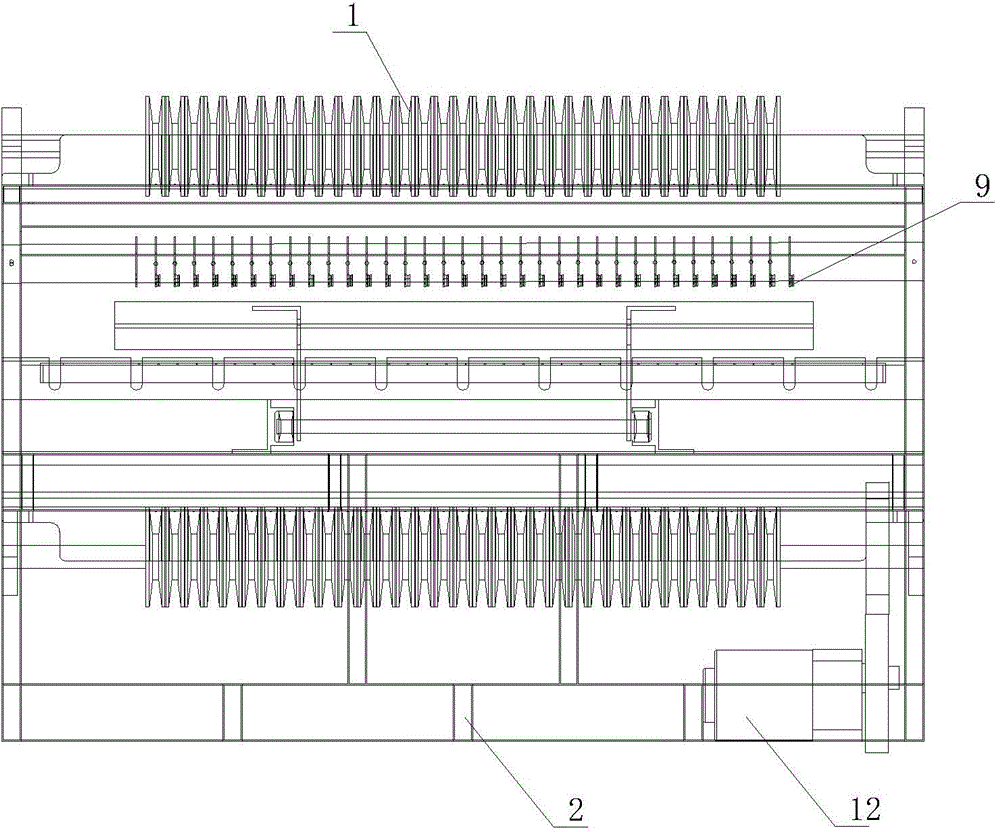

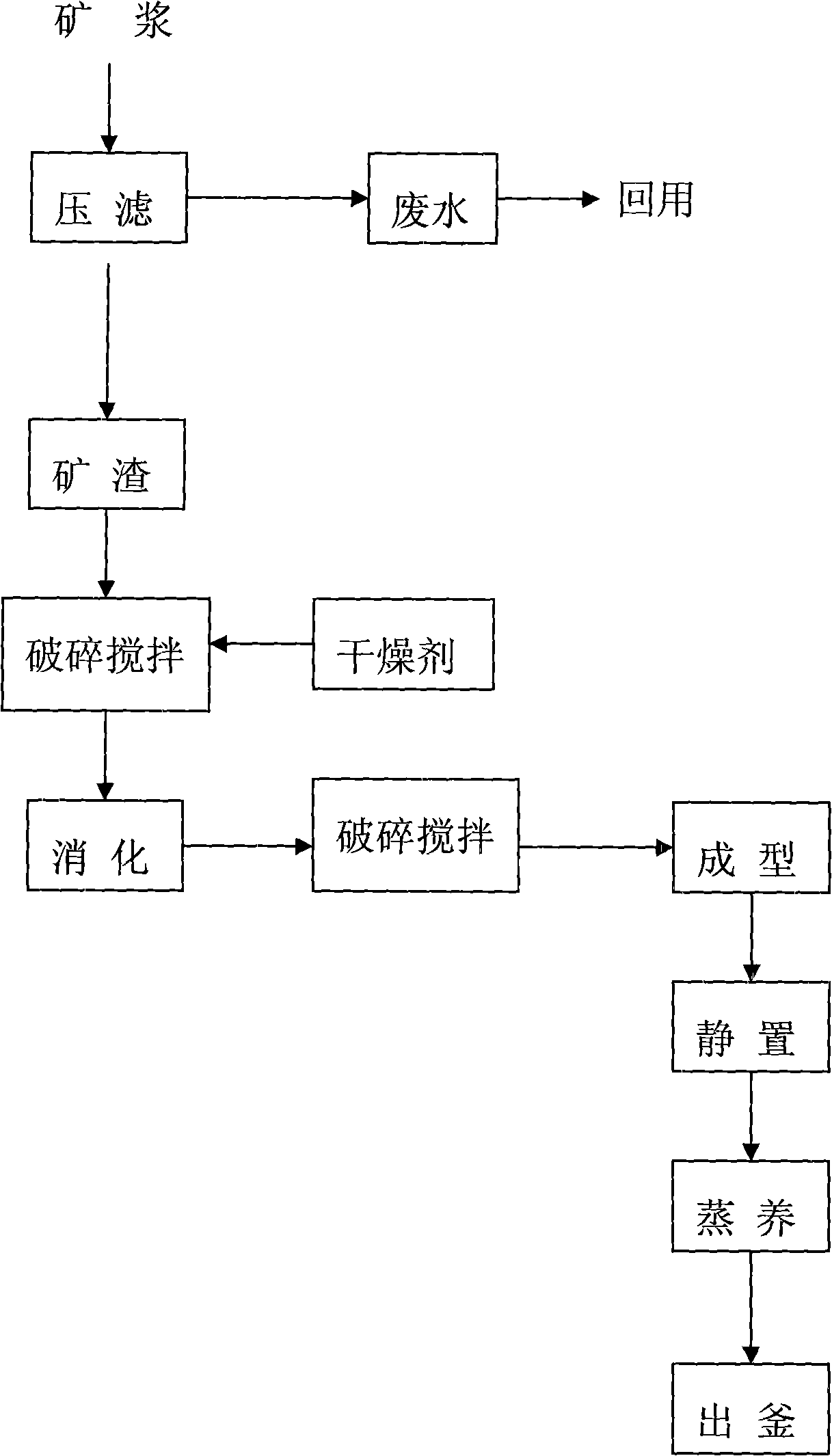

Comprehensive treatment method for mine tailing

InactiveCN101293751AReduce pollutionImprove the ecological environmentSolid waste managementSolid waste disposalBrickMining engineering

The invention relates to the technical field of comprehensive using of mine tailings, in particular to a method for comprehensively treating the mine tailings. The invention solves the problems of high cost, unstable quality and having potential safety hazard in the process of preparing bricks by the mine tailings and nonideal comprehensive treatment effect existing in the prior art; the technical scheme provided by the invention is a comprehensive treat method for the mine tailings, comprising the following steps sequentially: 1. pulp processing; 2. slag pretreatment; 3. steaming nourishing and making bricks. Compared with the prior art, the method for comprehensively treating the mine tailings has the following advantages: 1. solving a plurality of problems existing in the mine tailings radically; 2. saving large funds; 3. saving vast resources; 4. simple technological method; 5. safe, reliable and environmental protection products; 6. low cost; 7. good comprehensive treatment effect, which has significant practical meaning.

Owner:王颖

Reclamation method for hexavalent chromium contaminated soil

ActiveCN105665436ALow mobilityEffectively fixedSolid waste managementSolid waste disposalChromium contaminationBrick

The invention provides a reclamation method for hexavalent chromium contaminated soil. The reclamation method comprises the processes of reducing hexavalent chromium in the contaminated soil and preparing building bricks with the soil as raw materials. According to the content of the hexavalent chromium in the soil, the hexavalent chromium is reduced to trivalent chromium with low toxicity with ferrous sulfate as a reducing agent, and then the trivalent chromium is used for preparing the bricks. According to the reclamation method for the hexavalent chromium contaminated soil, not only is the leaching concentration of the hexavalent chromium in the soil reduced, but also the soil is taken as one of the raw materials for preparing the bricks. The prepared bricks are used as building materials and thus harmless disposal and reclamation of the hexavalent chromium contaminated soil are achieved.

Owner:UNIV OF JINAN

Method of automatically replacing steel wire for raw brick cutting machine

ActiveCN104626345AAvoid fatigueImprove brick making efficiencyCeramic shaping apparatusBrickEngineering

The invention provides a method of automatically replacing a steel wire for a raw brick cutting machine. According to the method, when a steel wire rope on a raw brick cutting table meets a replacing condition, a first steel wire rope holding device and a second steel wire rope holding device are controlled to release the steel wire rope, and a second steel wire rope winding shaft is driven to wind until a new steel wire rope is located on the raw brick cutting table; then the first steel wire rope holding device and the second steel wire rope holding device are driven in sequence to tighten the new steel wire rope, and the tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device. By means of the scheme, the raw brick cutting machine can work without stop around the clock, the efficiency of making bricks is greatly improved, and the cost is saved. The tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device, and the new steel wire rope can be tensioned exactly.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

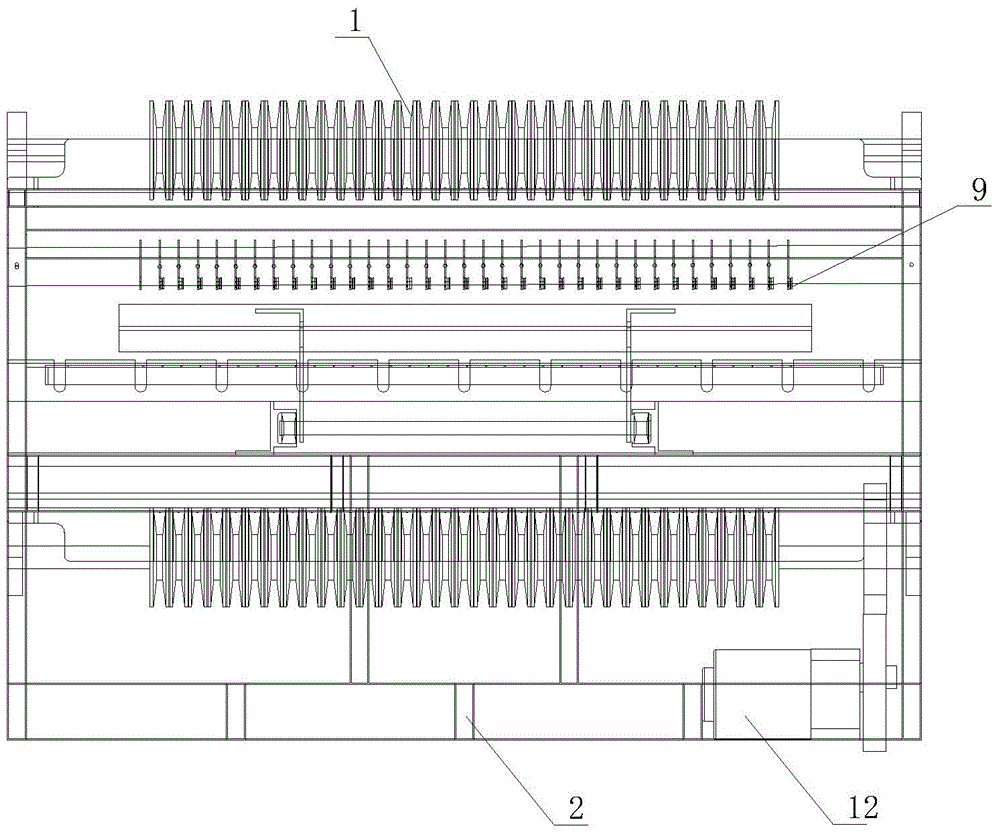

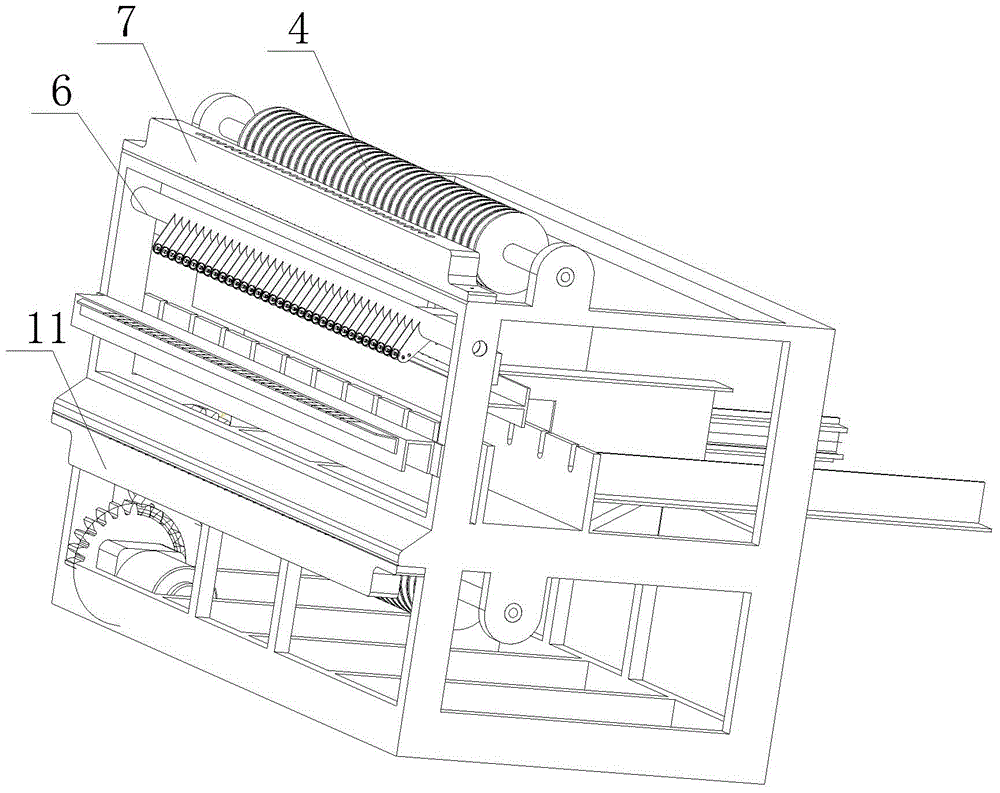

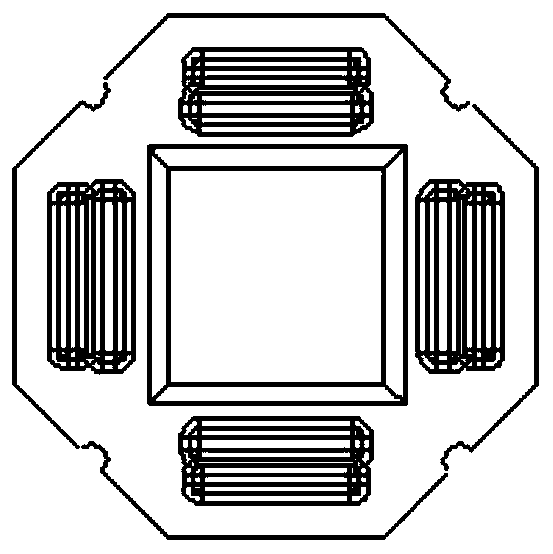

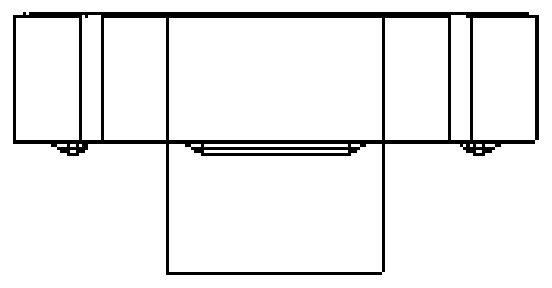

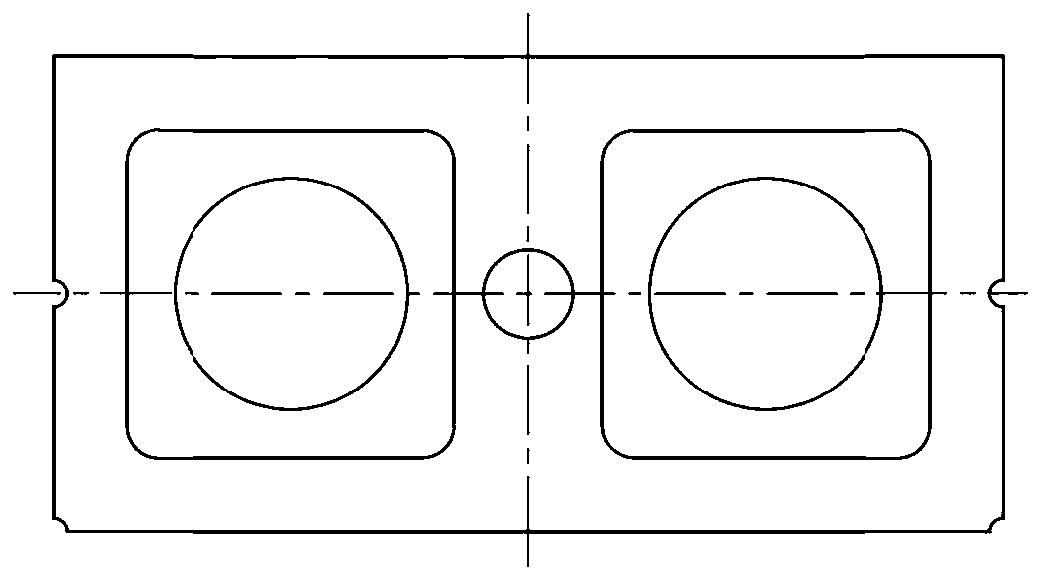

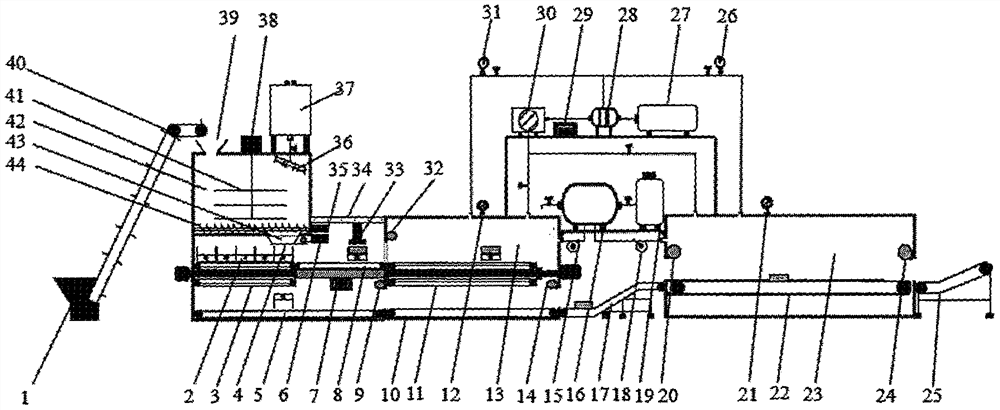

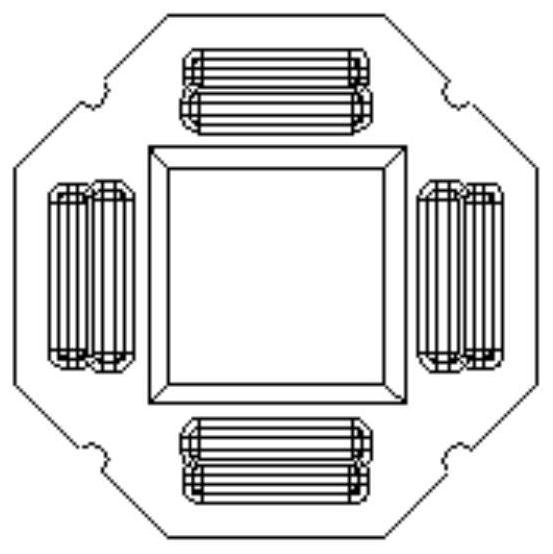

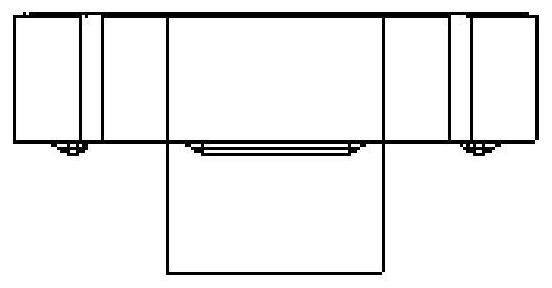

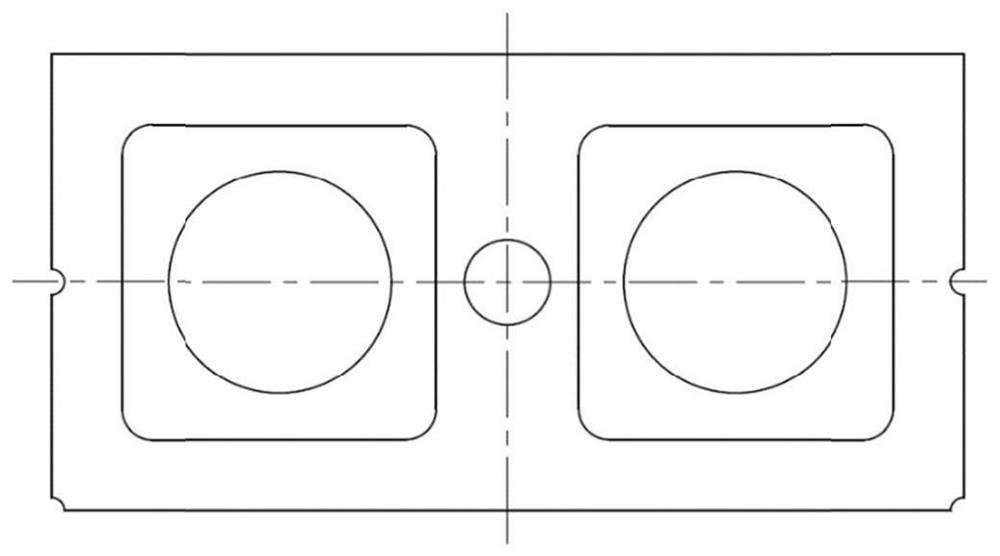

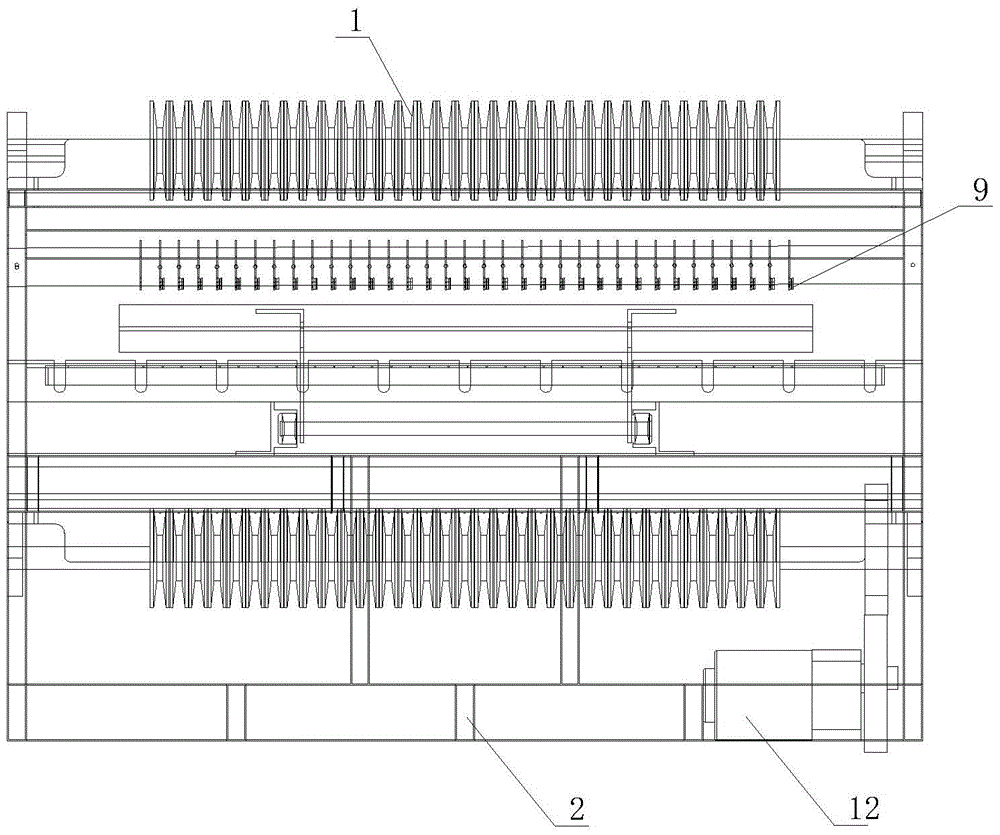

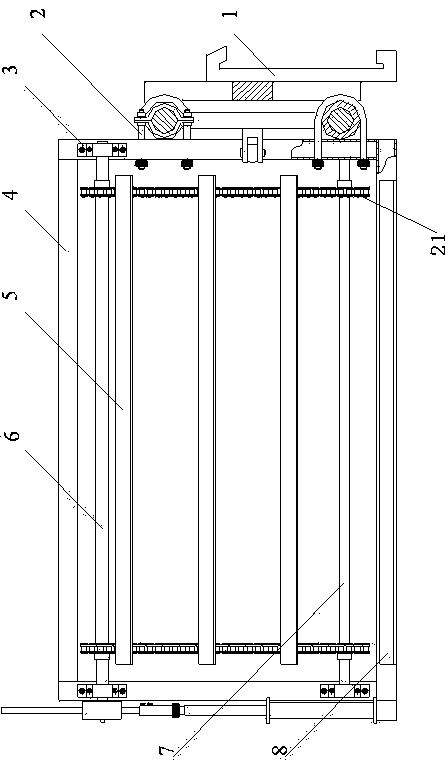

Hydraulic brick making machine and brick making method

ActiveCN110434983AMeet productionExtended service lifeDischarging arrangementFeeding arrangmentsBrickEngineering

The invention relates to a hydraulic brick making machine and a brick making method. An upper fixing beam of the brick making machine is fixedly installed on a guide upright post, a connecting deviceis positioned between the upper fixing beam and a base, a distributing mechanism is installed on the connecting device, and a mould frame fixing piece for fixing a mould frame is detachably arranged on the connecting device; an upper die assembly is mounted on the upper fixing beam; a lower die assembly is mounted on the base; and a die frame assembly is detachably mounted on the lower die assembly. During use, a lower die and a die frame synchronously move upwards to a first position, and the die frame is continuously moved upwards to form a first filling cavity; and primary material distribution is performed, the lower die moves downwards, and secondary material distribution is performed. According to the hydraulic brick making machine and the brick making method, secondary distributioncan be realized, and the manufacture of brick bodies with different structures can be met; adjustment is carried out according to different types of brick making requirements, different configurationscan be selected according to required functions, different brick type requirements are met, the brick making cost is reduced, and the service life of the brick making machine is effectively prolonged.

Owner:CRRC DALIAN CO LTD

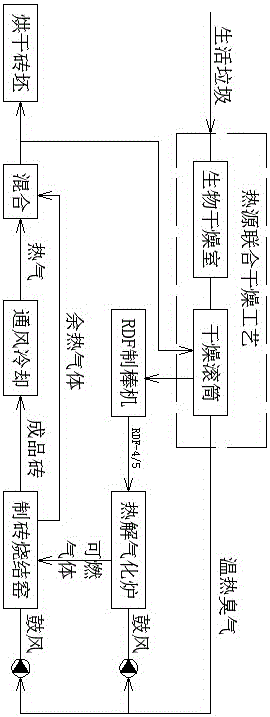

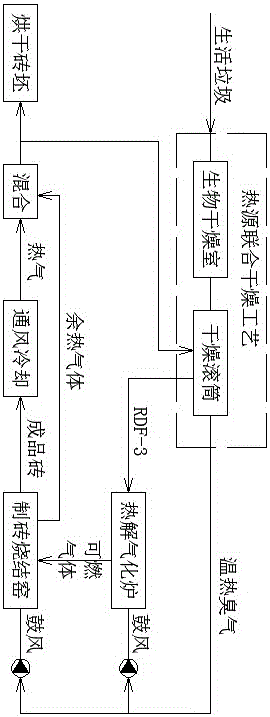

Application of household refuse pyrolytic gasification combustible gas in shale sintered brick process

InactiveCN106147813AReduce pollutionNo emissionsEnergy inputSpecial form destructive distillationThermal energyRefuse-derived fuel

The invention discloses application of household refuse pyrolytic gasification combustible gas in shale sintered brick process, including the steps of treating household refuse with combined heat drying process to produce RDF (refuse derived fuel), and performing pyrolytic gasification to obtain combustible gas; delivering the combustible gas into a brick-producing sintering kiln to sinter finished bricks; exhausting waste heat gas produced by cooling of finished bricks; mixing waste heat gas produced by combustion in the brick-producing sintering kiln and hot gas produced by cooling; introducing part of mixed gas into a brickyard drying kiln to dry green bodies; introducing the other part into a drying cylinder that is used in the drying process to dry refuse; introducing gas that is produced by drying the refuse into a brickyard blower and a pyrolytic gasifier blower. Heat produced by the refuse is utilized to sinter bricks during domestic refuse treatment, so that heat is made full use; stinking gas produced by drying the refuse is introduced into the brickyard blower and the pyrolytic gasifier blower and is combusted, thereby being discharged.

Owner:FUJIAN ZHENGREN ENVIRONMENTAL PROTECTION

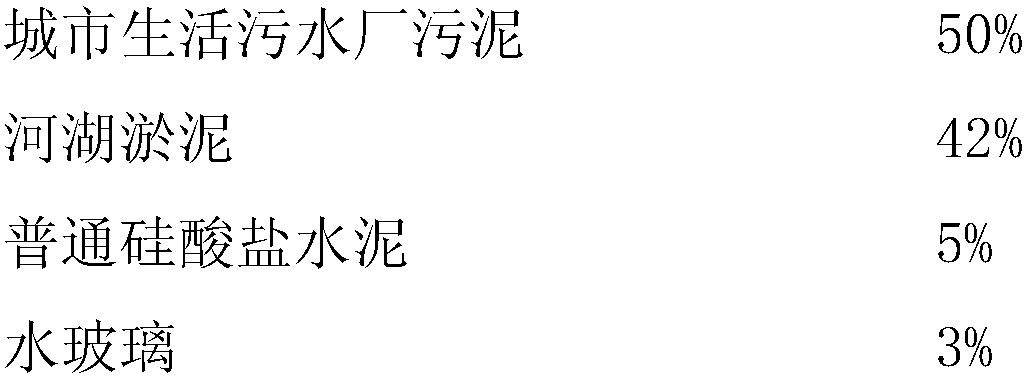

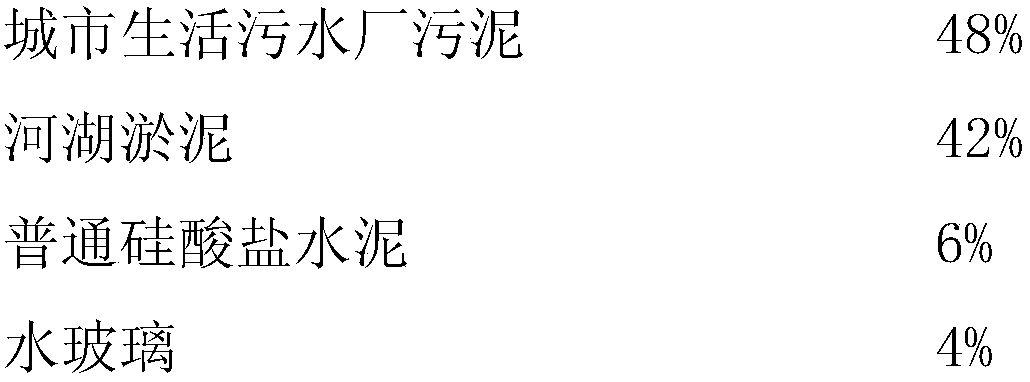

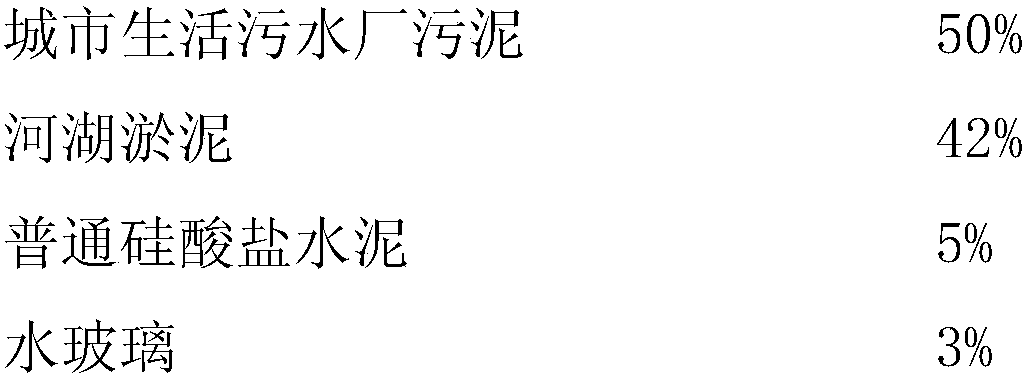

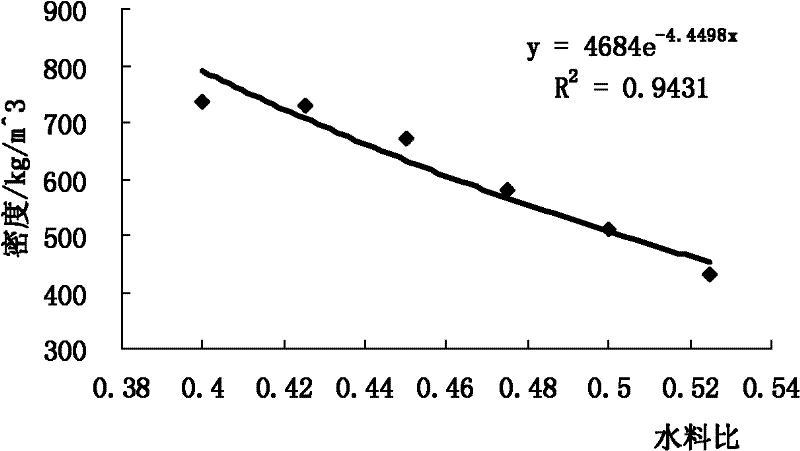

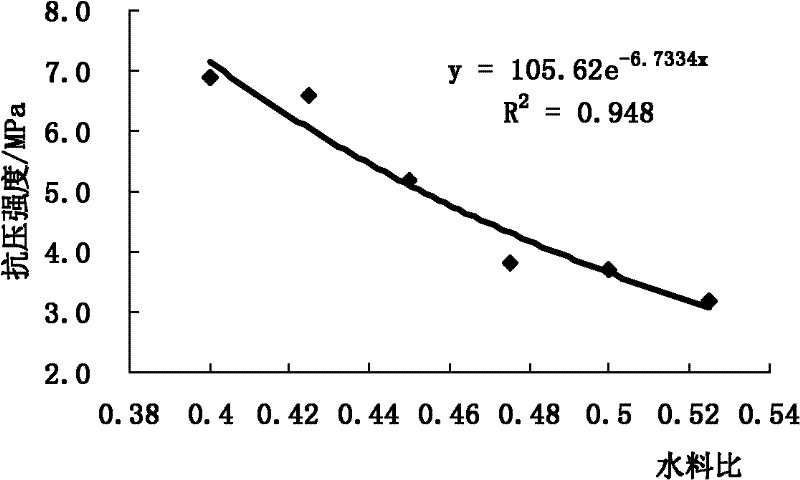

A method for firing sponge bricks using sludge and silt

ActiveCN106187092BHigh strengthHigh porosityCeramic materials productionCeramicwareBrickRoom temperature

The invention discloses a method for firing a sponge brick from sludge and silt. The method comprises the following steps: S1. uniformly stirring dewatered sludge, silt, cement and water glass; S2. sending the uniformly stirred mixture into a brick making machine, and pressing to obtain a green brick; S3. curing the green brick at room temperature, and drying; and S4. putting the dried green brick into a kiln, and carrying out sintering to obtain the sponge brick. The sponge brick is prepared from 30-70 wt% of dewatered sludge, 10-50 wt% of silt, 3-10 wt% of cement and 1-5 wt% of water glass. According to the method, the sponge brick is prepared by mainly firing municipal sewage plant dewatered sludge and dredging silt, has favorable water permeability, can satisfy the requirement for sidewalk roadbed strength, and has the functions of moisture retention and heat reduction.

Owner:HOHAI UNIV

Process for preparing sludge autoclaved aerated concrete building block

InactiveCN101850574BHigh porosityMeet production requirementsSludge treatment by de-watering/drying/thickeningSolid waste managementBrickSludge

Owner:HUNAN UNIV OF SCI & TECH

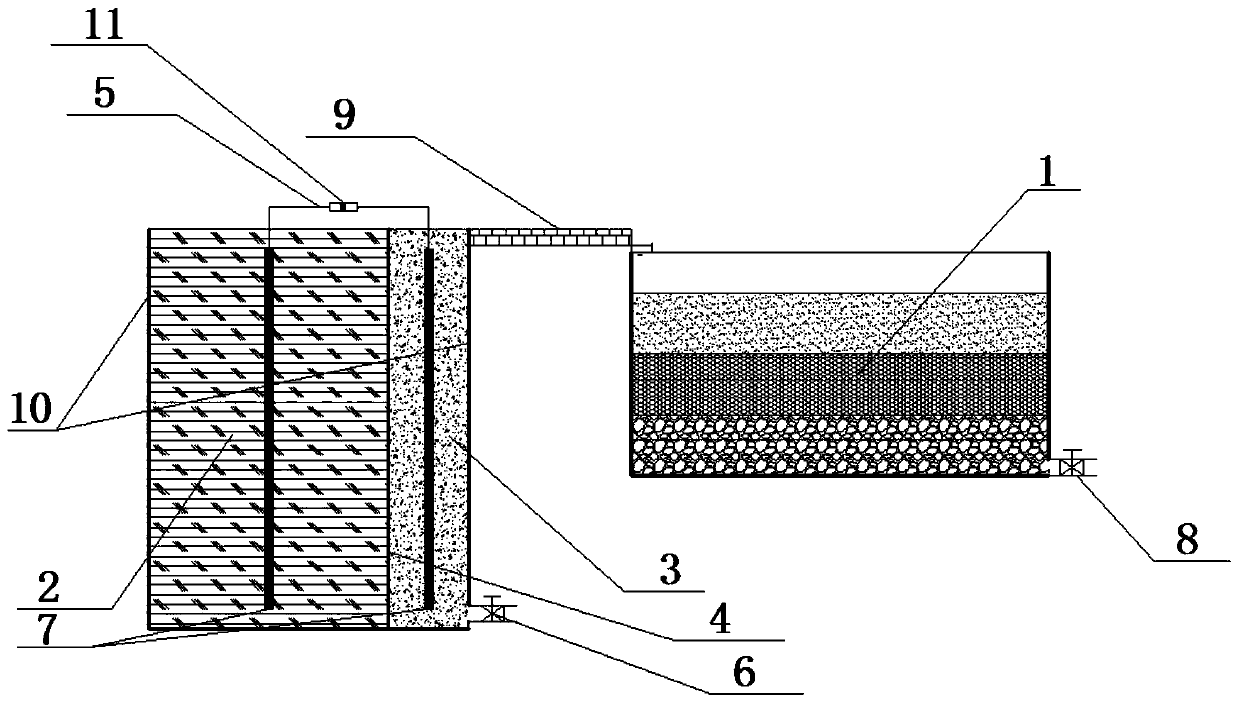

Microbial fuel cell taking straws and sludge as matrixes, construction method and sludge treatment method

ActiveCN110854420AIncrease dissolved oxygen contentImprove processing efficiencyBiochemical fuel cellsBiological sludge treatmentMicrobial fuel cellFuel cells

The invention discloses a microbial fuel cell taking straw and sludge as matrixes, a construction method and a sludge treatment method, and belongs to the field of environmental engineering. The microbial fuel cell comprises a filter wetland, an anode chamber, a cathode chamber, a proton exchange membrane and a circuit system. The anode chamber and the cathode chamber are isolated by the proton exchange membrane. A current generated by proton exchange is stored in the circuit system. Effluent obtained after purification of the microbial fuel cell is discharged under the action of the filter wetland. The matrix of the anode chamber is a straw and sludge stirring mixture, and the matrix of the cathode chamber is sludge. The novel microbial fuel cell is integrally formed by considering the chemical characteristics of straw and sludge and the action characteristics of microbial fuel cells. Organic matters in sludge are removed, the water content of sludge is reduced, and the power generation efficiency of microbial fuel cells is improved. An environment-friendly building is achieved. The novel microbial fuel cell has the advantages of simple structure, reasonable design and convenienceof dredging.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST +1

Aerated concrete block and preparation method thereof

InactiveCN108178604AReduce usageReduce the cost of brick makingCeramicwareSodium silicateIndustrial waste

The invention discloses an aerated concrete block and a preparation method thereof. The aerated concrete block is prepared from raw materials in parts by mass as follows: 20-30 parts of slag, 30-35 parts of tailings, 20-30 parts of phosphogypsum, 10-20 parts of fly ash, 1-2 parts of graphite, 1-3 parts of concentrated high foamer, 0.5-1 part of vermiculite and 7-10 parts of sodium silicate. The aerated concrete block can be produced in a factory in a large batch manner with the traditional aerated concrete block production process, the strength of the aerated concrete block also meets certainstandard, by means of industrial waste residues discharged by a chemical enterprise, industrial refuse produced by the chemical enterprise is used to the greatest extent, use rate of lime and cement is reduced, brick manufacture cost is reduced greatly, and foaming capacity can be controlled effectively by changing various parameters of the production process.

Owner:安徽建鑫新型墙材科技有限公司

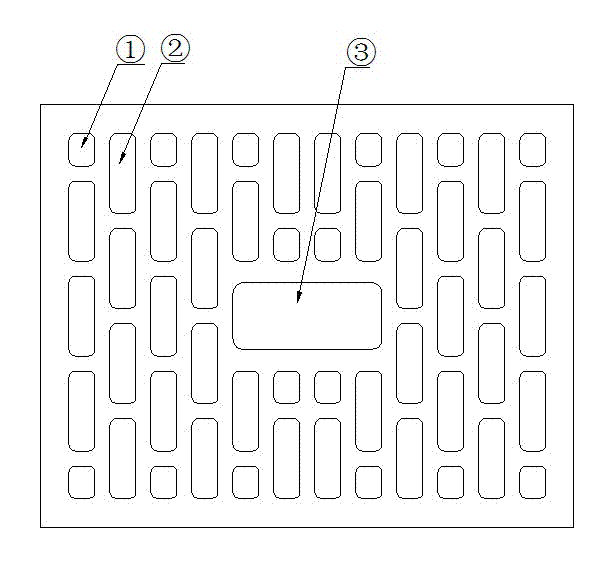

Preparation method of novel self-insulation perforated brick

The invention relates to a preparation method of a novel self-insulation perforated brick. The method comprises the steps of evenly mixing illite shale, coal gangue, glass beads and additives according to the mass ratio of (3-4) to (1-2) to (0.1-0.3) to (0.01-0.1), aging the materials for 3-7 days after water is added to the materials according to technological requirements, extruding the materials to form an air brick by a two-stage vacuum extruder, drying the air brick for 3-5 days at 40+ / -5 DEG C, slowly heating a dried air brick in an annular kiln to 1000+ / -10 DEG C, and sintering the dried air brick for 5 hours at over 900 DEG C, thus obtaining the novel self-insulation perforated brick, wherein the sintering period is 50 hours.

Owner:HUNAN UNIV OF TECH

An operation method for making bricks by using a carbon dioxide carbonization device

The invention discloses an operation method for making a brick body by using a carbon dioxide carbonization device, and belongs to the field of civil engineering brick making. In the present invention, two processes of pre-carbonization and secondary carbonization are ad hoc, and after temporarily stabilizing the shape and strength of the brick body, demoulding and rapid strength growth are successfully completed. All systems in the device work in an orderly manner according to this method, so that loading, compaction and brick mold transmission are carried out at the same time, and brick materials are added and mixed in the pre-carbonization process, which greatly improves the brick production and transmission efficiency; up and down The conveyor belt rotates through the rotating shaft, and the brick body is demoulded through the spring stopper in the brick mould, and is absorbed and released by the electromagnet and conveyed by the conveyor belt, so as to realize the demoulding of the brick body and the efficient recycling of the empty brick mould. This brick-making method utilizes low-concentration carbon dioxide and construction waste. After carbonization, the carbon dioxide in the carbonization chamber can be pumped into the storage bin by the exhaust fan, and the carbon dioxide gas can be recycled to reduce tail gas emissions, which is beneficial to environmental protection and reduces production costs. brick cost.

Owner:NANJING FORESTRY UNIV

Method for producing bricks from silt and sludge

InactiveCN101830687BWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primarystirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

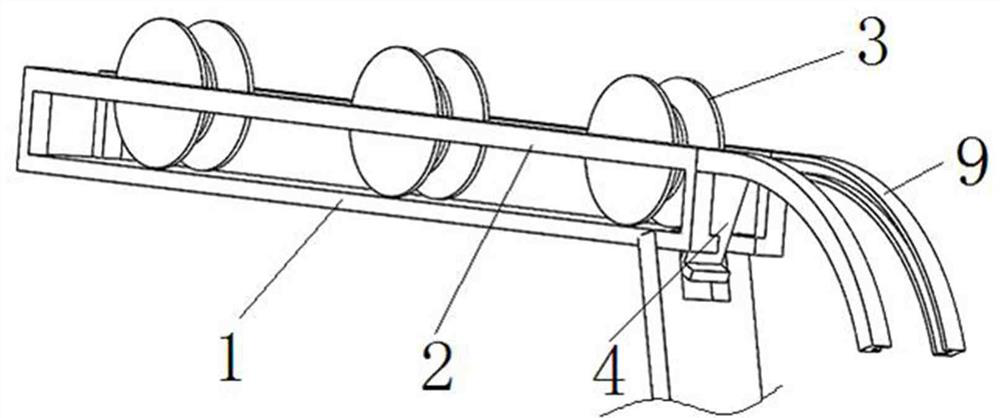

A method for intelligently exchanging billet steel wire

ActiveCN111775289BReduce labor intensityNo manual operationAuxillary shaping apparatusBrickWire wheel

The invention belongs to the technical field of brick and tile production equipment. The invention discloses an intelligent method for exchanging billet steel wires, including the following process: S1. Pneumatic stopper blocks the leftmost upper wire wheel, pneumatic clamp clamps the lower wire wheel, infrared The sensing device detects the state of the steel wire between the upper wire wheel and the lower wire wheel in real time; S2, the infrared sensing device detects that the steel wire is broken; S3, the pneumatic stopper and pneumatic clamp will be released at the same time, and the lower wire wheel will fall and be discarded. The upper wire wheel on the side slides down to the position of the lower wire wheel along the pre-stored track and the guide track; the second upper wire wheel on the left on the pre-stored track slides to the position of the leftmost upper wire wheel at the beginning; at this time, the pneumatic The stopper and the pneumatic clamp are clamped simultaneously, and the steel wire is straightened again. The device or method for intelligently exchanging blank cutting steel wires of the present invention realizes intelligent steel wire replacement without manual operation, and can realize 24-hour uninterrupted work of the blank cutting machine, thereby greatly improving brick-making efficiency and saving brick-making costs.

Owner:江苏科磊半导体有限公司

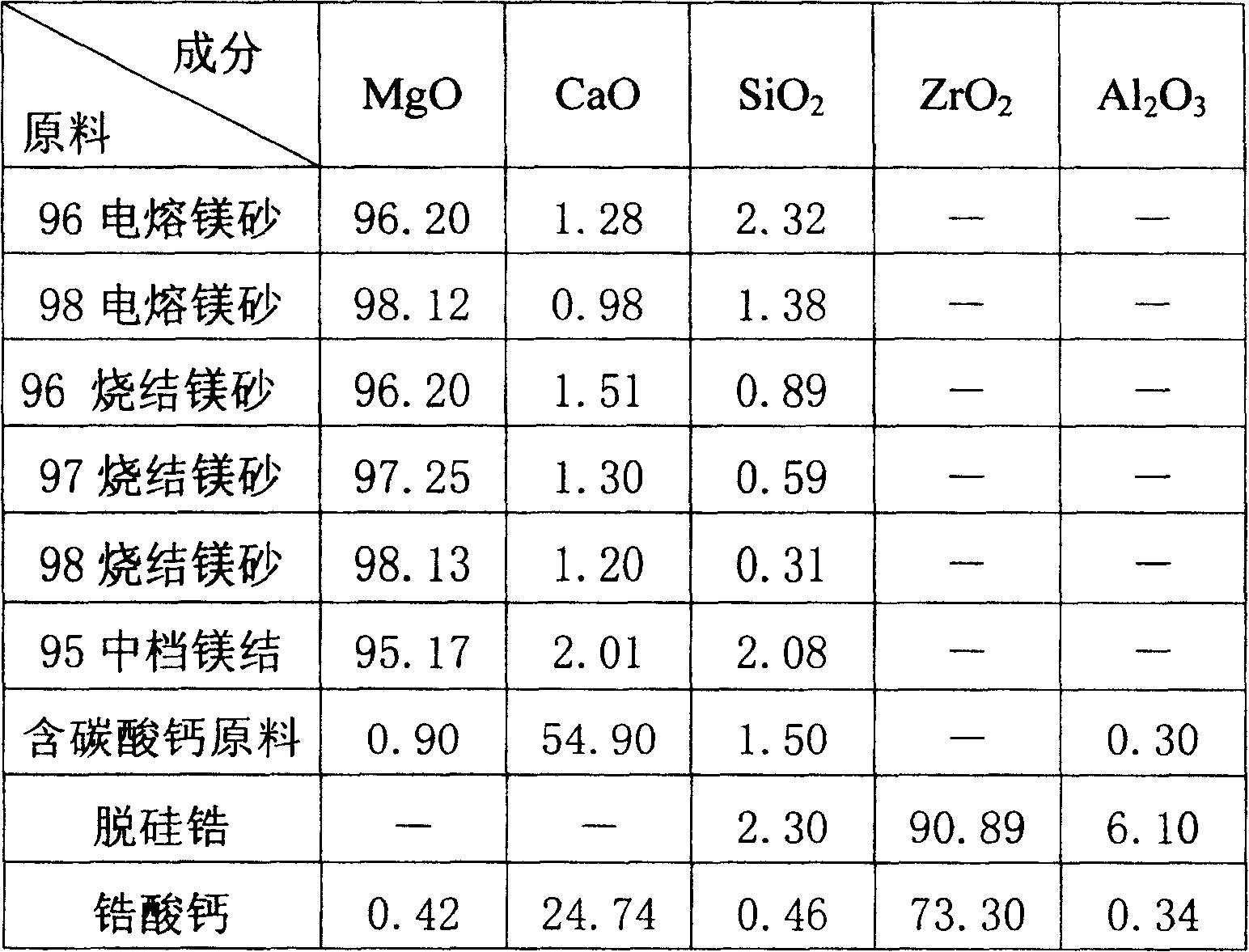

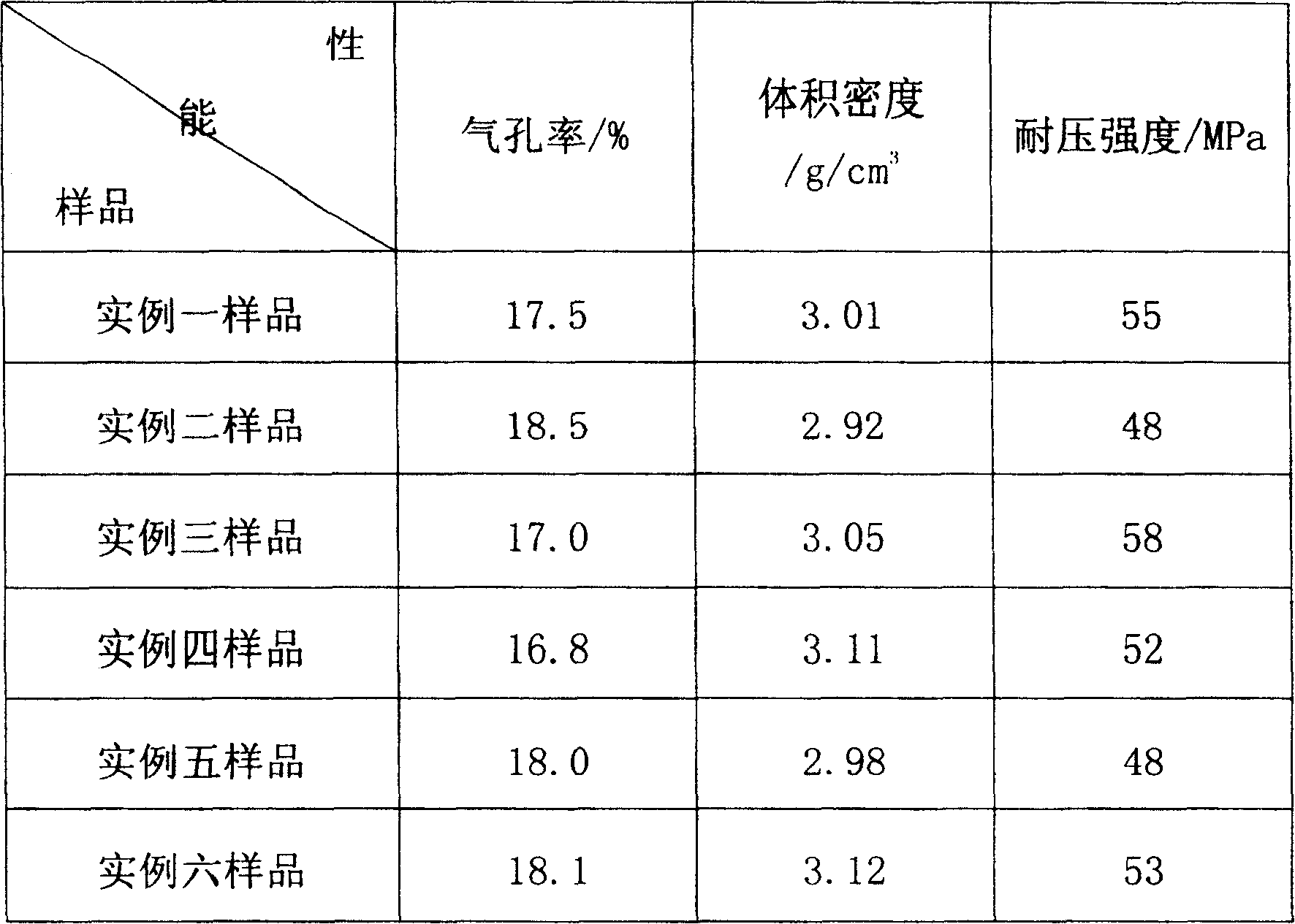

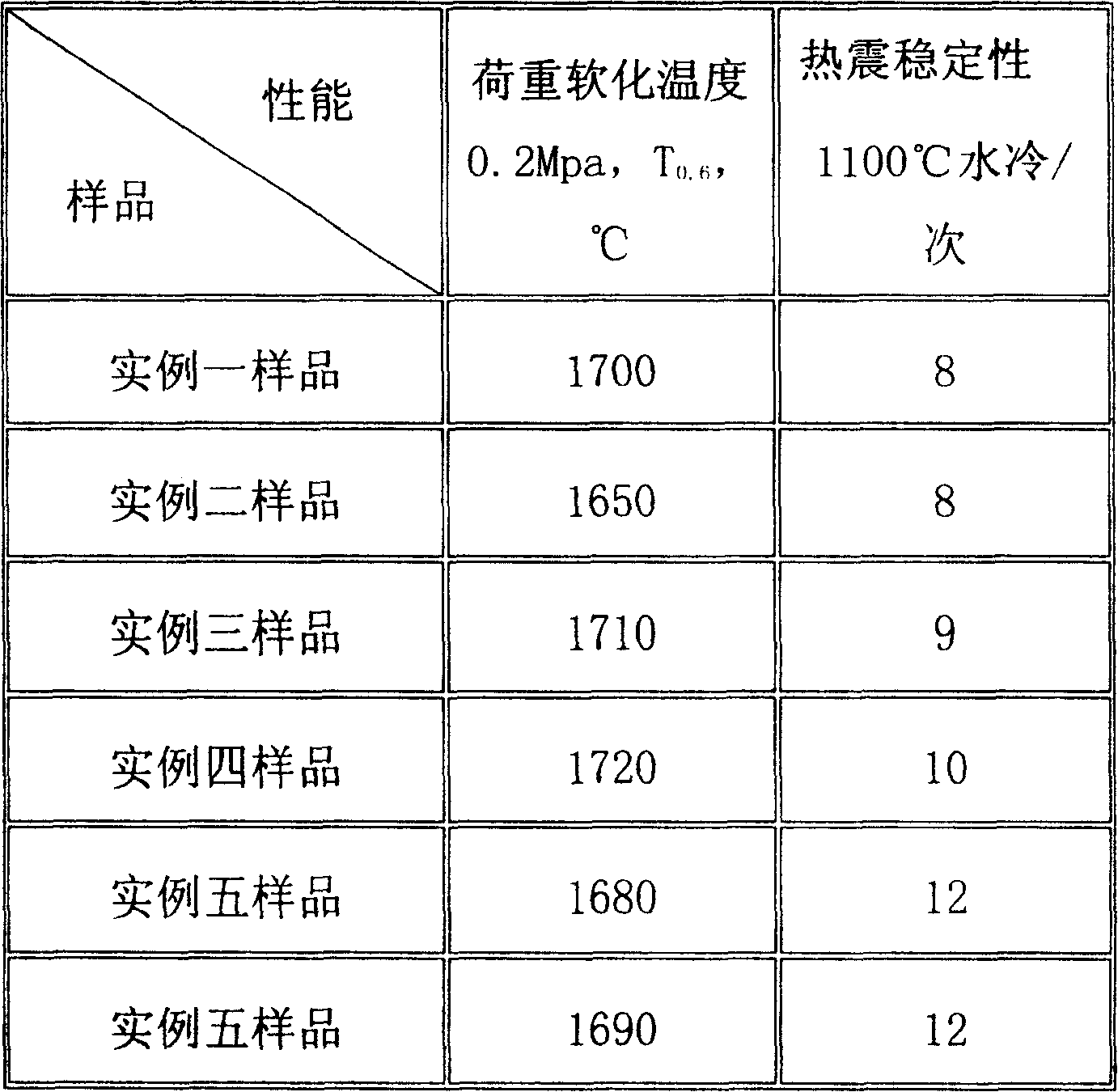

MgO-CaO-ZrO2 brick for cement kiln high-temperature zone and its preparation method

The invention discloses MgO-CaO-ZrO2 bricks for cement kiln hot zones, wherein the components include magnesite clinker or fused magnesia sand containing 94-99% of magnesium oxide 75-85%, light calcium carbonate 3-13%, zirconium dioxide 2-10% or calcium zirconate 2-6%, iron-oxide red as addition agent 1-4%, and balancing sulfite black liquor as binder bonding agent. The invention also discloses a process for making the MgO-CaO-ZrO2 bricks.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of resource recovery method of hexavalent chromium polluted soil

ActiveCN105665436BLow mobilityEffectively fixedSolid waste managementSolid waste disposalBrickPollution

The invention provides a resource recovery method of hexavalent chromium polluted soil, which includes the reduction of hexavalent chromium in the polluted soil and the preparation process of building bricks using soil as raw material. According to the content of hexavalent chromium in the soil, ferrous sulfate is used as a reducing agent to reduce hexavalent chromium to trivalent chromium with low toxicity, and then used for the preparation of bricks. The resource recovery method of hexavalent chromium-contaminated soil of the present invention not only reduces the leaching concentration of hexavalent chromium in the soil, but also uses the soil as one of the raw materials for the preparation of bricks, and the prepared bricks are used as building materials, realizing The harmless treatment and resource utilization of hexavalent chromium-contaminated soil were discussed.

Owner:UNIV OF JINAN

Hydraulic brick making machine and brick making method

ActiveCN110434983BMeet productionExtended service lifeDischarging arrangementFeeding arrangmentsBrickEngineering

A hydraulic brick making machine and a brick making method. The upper fixed beam of the brick making machine is fixedly installed on the guide column, the connecting device is located between the upper fixed beam and the base, the material distributing mechanism is installed on the connecting device, and the connecting device is detachably A mold frame fixture for fixing the mold frame is provided; the upper mold assembly is installed on the upper fixing beam; the lower mold assembly is installed on the base; the mold frame assembly is detachably installed on the lower mold assembly. When in use, the lower mold and the mold frame are moved up to the first position synchronously, and the mold frame continues to be moved up to form the first filling cavity; for the first time of material distribution, the lower mold is moved down for the second time of material distribution. The invention can realize secondary material distribution to meet the production of bricks with different structures; it can be adjusted according to the requirements of different types of bricks, and different configurations cannot be selected according to the required functions, so as to meet the needs of different brick types, reduce the cost of bricks, and effectively improve the production efficiency. The service life of the brick machine.

Owner:CRRC DALIAN CO LTD

Method for Automatically Changing Steel Wires of Blank Cutting Machine

ActiveCN104626345BAvoid fatigueImprove brick making efficiencyCeramic shaping apparatusBrickEngineering

The invention provides a method of automatically replacing a steel wire for a raw brick cutting machine. According to the method, when a steel wire rope on a raw brick cutting table meets a replacing condition, a first steel wire rope holding device and a second steel wire rope holding device are controlled to release the steel wire rope, and a second steel wire rope winding shaft is driven to wind until a new steel wire rope is located on the raw brick cutting table; then the first steel wire rope holding device and the second steel wire rope holding device are driven in sequence to tighten the new steel wire rope, and the tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device. By means of the scheme, the raw brick cutting machine can work without stop around the clock, the efficiency of making bricks is greatly improved, and the cost is saved. The tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device, and the new steel wire rope can be tensioned exactly.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

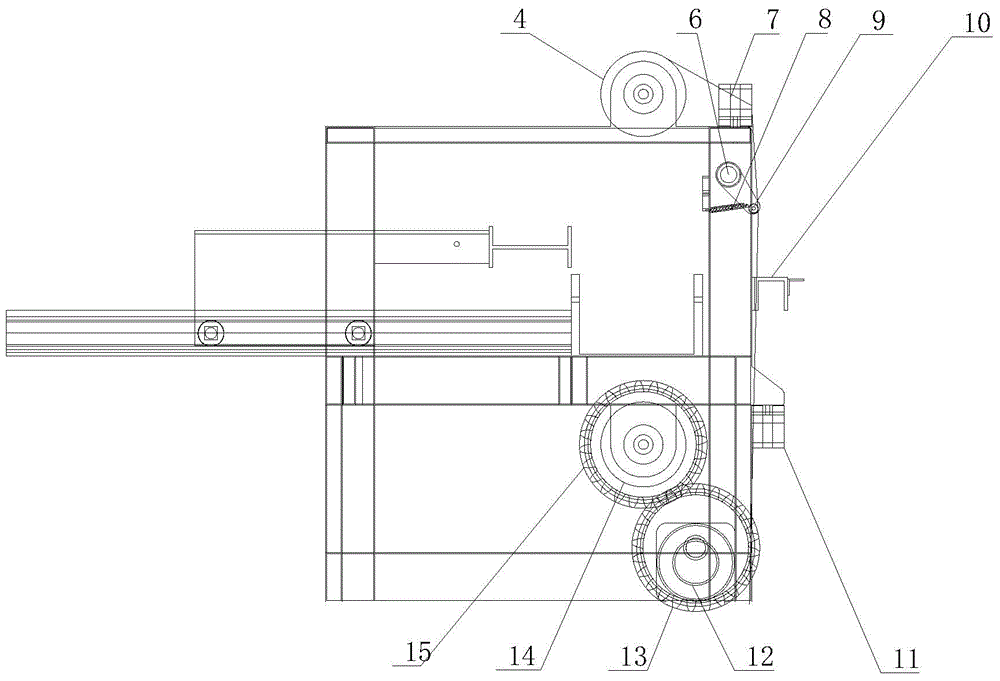

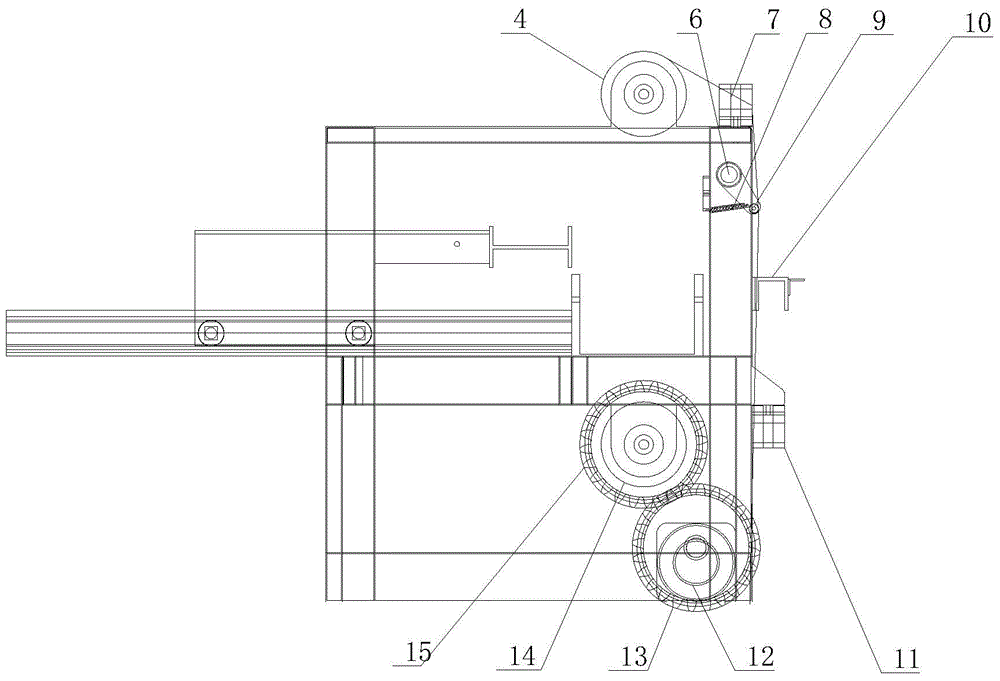

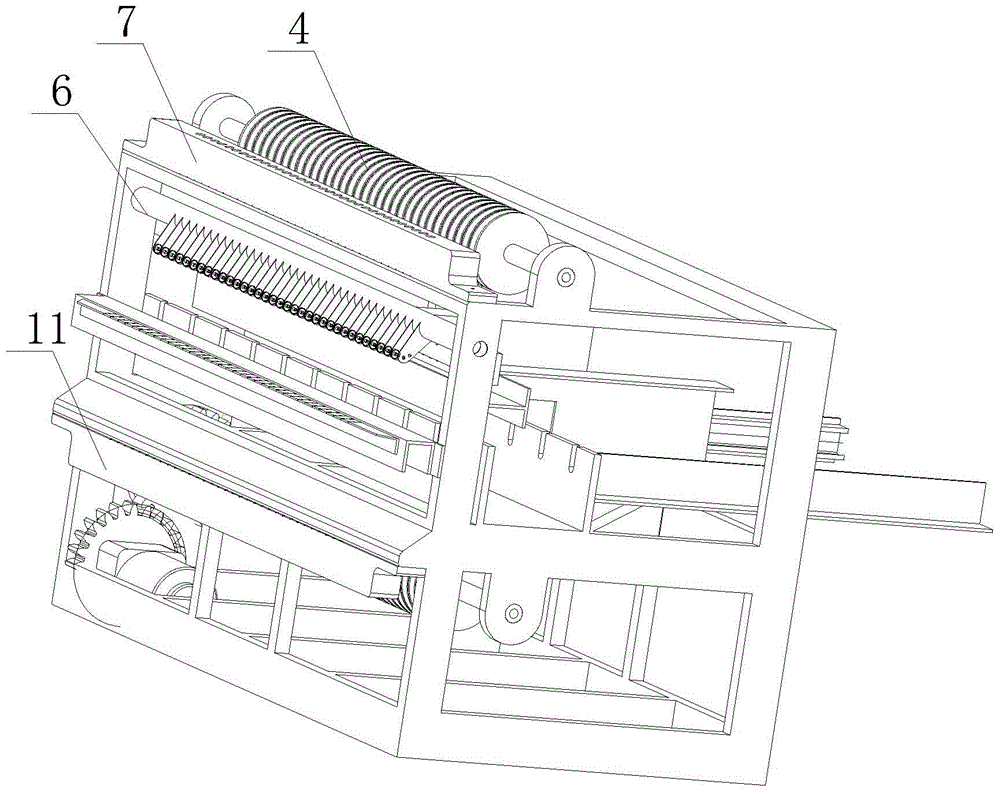

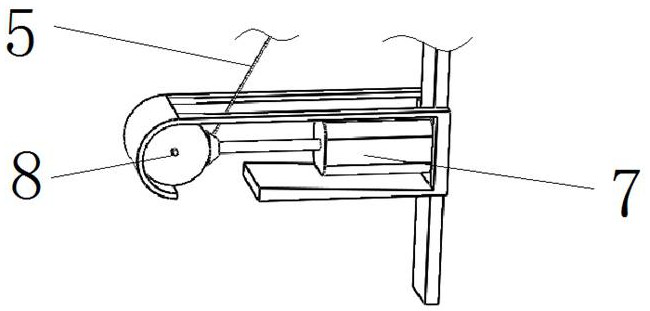

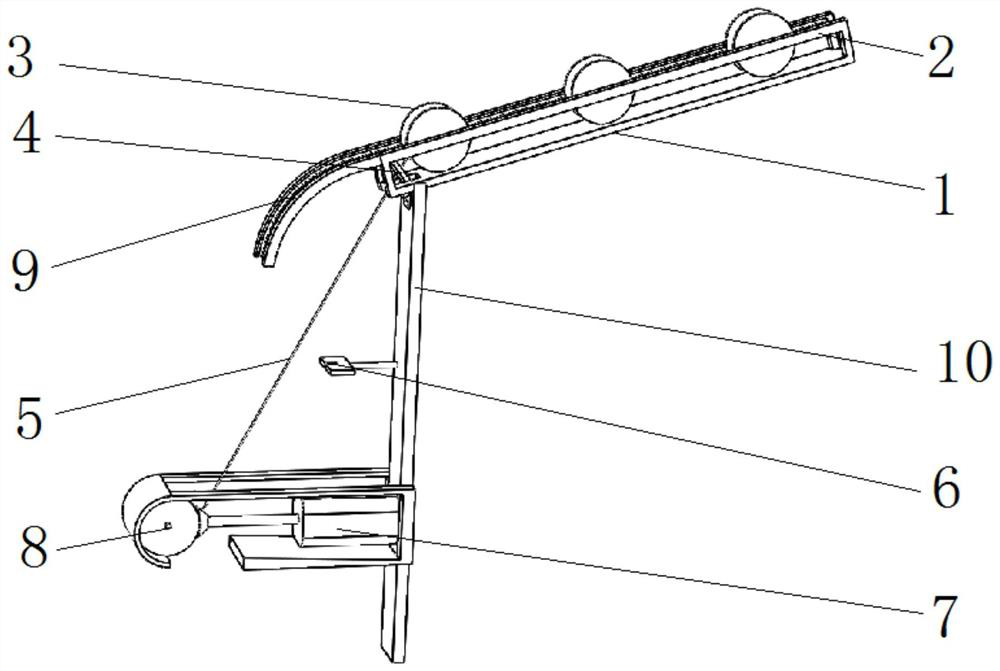

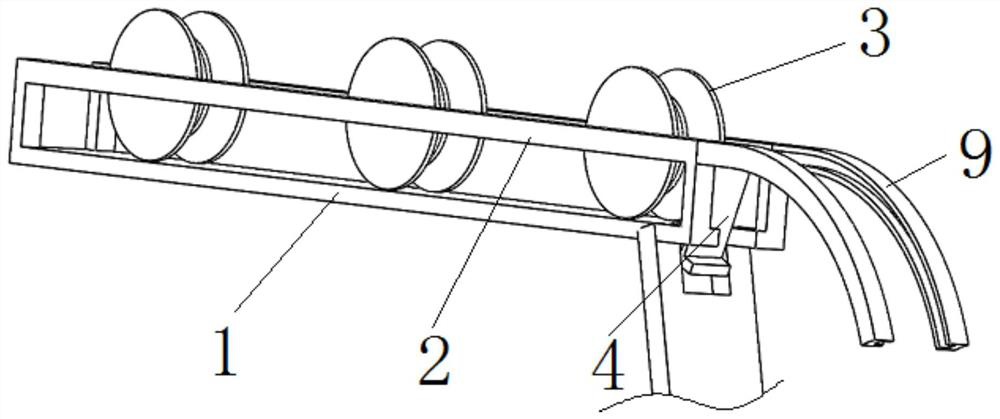

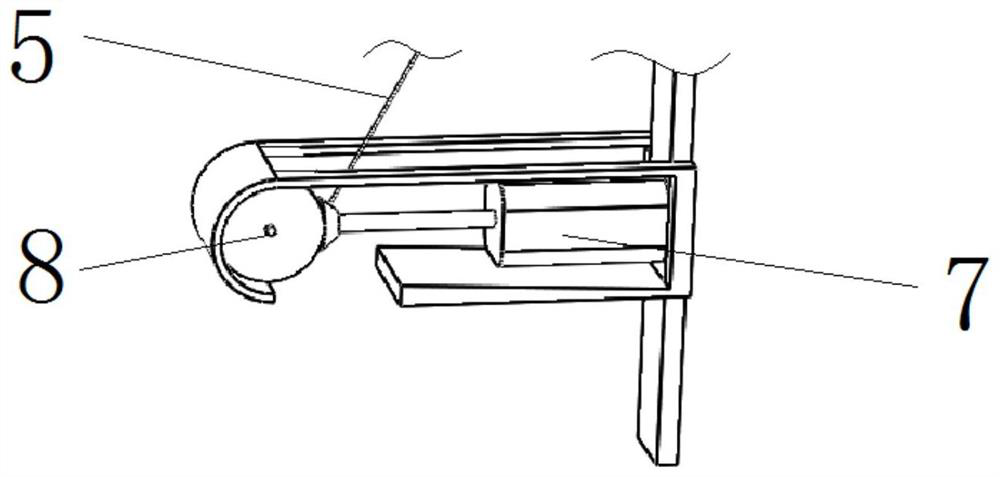

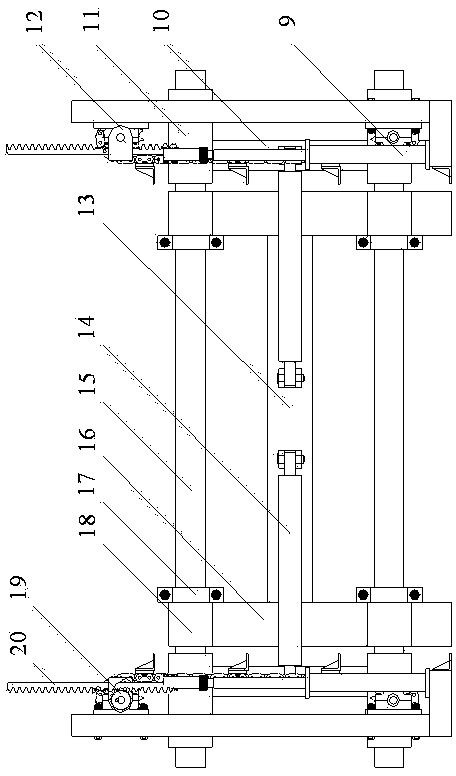

Smart device for steel wire exchanging and cutting

ActiveCN111775291AImprove brick making efficiencyReduce the cost of brick makingAuxillary shaping apparatusFixed frameElectrical and Electronics engineering

The invention relates to the technical field of brick and tile production devices. The invention discloses a smart device for steel wire exchanging and cutting. The device comprises a vertical fixed frame, a cutting rack, a pre-stored track, a plurality sets of upper wire wheels, a limit mechanism, a wire, a sensing device, a clamping mechanism and a lower wire wheel. The pre-stored track is fixedly connected with the upper of the cutting rack. The upper wire wheels are arranged on the pre-stored track. The limit mechanism is arranged at the leftmost of the pre-stored track, and limits a leftmost upper wire wheel. The lower wire wheel is clamped at the front end of the clamping mechanism. The sensing device is fixed to the vertical fixed frame and arranged at the upper end of the clampingmechanism. The sensing device is used to detect whether the wire between the upper wire wheels and the lower wire wheel is broken. The smart device for steel wire exchanging and cutting without manualoperation can realize the intelligent exchanging of steel wires, and can realize the 24-hour uninterrupted work of the cutting device. Therefore, the brick production efficiency is greatly improved and the brick production cost is saved.

Owner:NANTONG UNIVERSITY

Automatic replacing equipment for blank cutting steel wire

ActiveCN113370364ANo manual operationImprove brick making efficiencyAuxillary shaping apparatusBrickWire wheel

The invention belongs to the technical field of brick and tile production equipment, and discloses automatic replacing equipment for a blank cutting steel wire. The equipment comprises a vertical fixing frame, a blank cutting rack, a pre-storage track, a plurality of sets of upper steel wire wheels, a limiting mechanism, a steel wire, a sensing device, a clamping mechanism and a lower steel wire wheel. The pre-storage track is fixedly connected to the upper portion of the blank cutting rack, the several sets of upper steel wire wheels are placed on the pre-storage track, and the limiting mechanism is arranged at the leftmost position of the pre-storage track and limits the leftmost upper steel wire wheel. The lower steel wire wheel is clamped at the front end part of the clamping mechanism. The sensing device is fixed to the vertical fixing frame and arranged at the upper end of the clamping mechanism. The sensing device is used for detecting whether the steel wire between the upper steel wire wheels and the lower steel wire wheel is broken or not. According to the automatic replacing equipment for the blank cutting steel wire, manual operation is not needed, intelligent steel wire replacing is achieved, 24-hour uninterrupted work of a green brick cutting machine can be achieved, and therefore the brick making efficiency is greatly improved, and the brick making cost is saved.

Owner:NANTONG UNIVERSITY

Baking-free green brick loading and unloading and transporting device matched with fork lift truck

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Method for making cement bricks by using pulping alkali to recover green mud and boiler ash

The invention discloses a method for manufacturing cement bricks from green mud and boiler ash recycled by utilization of pulping alkali. The method is as follows: firstly, the following raw materials are weighed, by weight, 25-30% of green mud, 18-38% of boiler ash, 35-55% of limestone powder and 1-1.5% of cement, the above raw materials are mixed uniformly, and a mixture is obtained; secondly, the mixture is subjected to molding at a pressure of 40-50 MPa, and green bricks are obtained; thirdly, the green bricks are subjected to curing and cement bricks are obtained. The employed green mud does not need dewatering or alkalinity reduction, energy consumption is saved greatly, the brick manufacturing cost is lowered, the green mud doping amount is high, the cement doping amount is lowered than a conventional level, the waste utilization rate is raised greatly, the cement expense is saved, and the brick manufacturing cost is lowered further.

Owner:GUANGXI JINGUI PULP PAPER

An intelligent device for changing and cutting steel wire

ActiveCN111775291BNo manual operationImprove brick making efficiencyAuxillary shaping apparatusBrickWire wheel

The invention belongs to the technical field of brick and tile production equipment. The invention discloses an intelligent device for exchanging billet-cutting steel wires, which includes a vertical fixing frame, a billet-cutting frame, pre-stored tracks, several groups of upper wire wheels, a limit mechanism, steel wires, induction device, clamping mechanism and lower steel wire wheel; the pre-storage track is fixedly connected above the billet cutting frame, several sets of upper steel wire wheels are placed on the pre-storage track, and the limit mechanism is set at the leftmost position of the pre-storage track and the leftmost The upper steel wire wheel is used to limit the position; the lower steel wire wheel is clamped at the front end of the clamping mechanism; the sensing device is fixed on the vertical fixing frame and placed at the upper end of the clamping mechanism, and the sensing device is used to detect the upper wire wheel and the lower Whether the wire between the wire wheels is broken. The intelligent steel wire changing device of the present invention realizes intelligent steel wire changing without manual operation, and realizes the 24-hour uninterrupted work of the blank cutting machine, thereby greatly improving brick-making efficiency and saving brick-making costs.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com