An operation method for making bricks by using a carbon dioxide carbonization device

A carbon dioxide and carbonization device technology, applied in chemical instruments and methods, supply devices, clay preparation devices, etc., to achieve the effects of improving brick-making efficiency, reducing environmental protection, and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

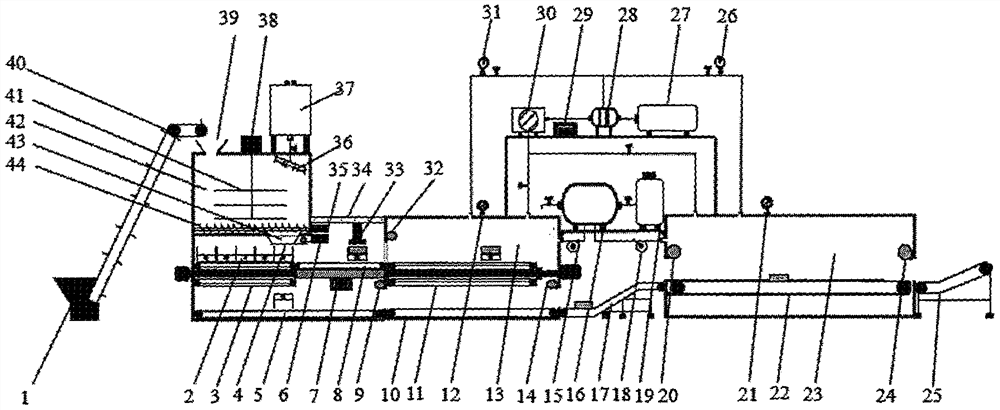

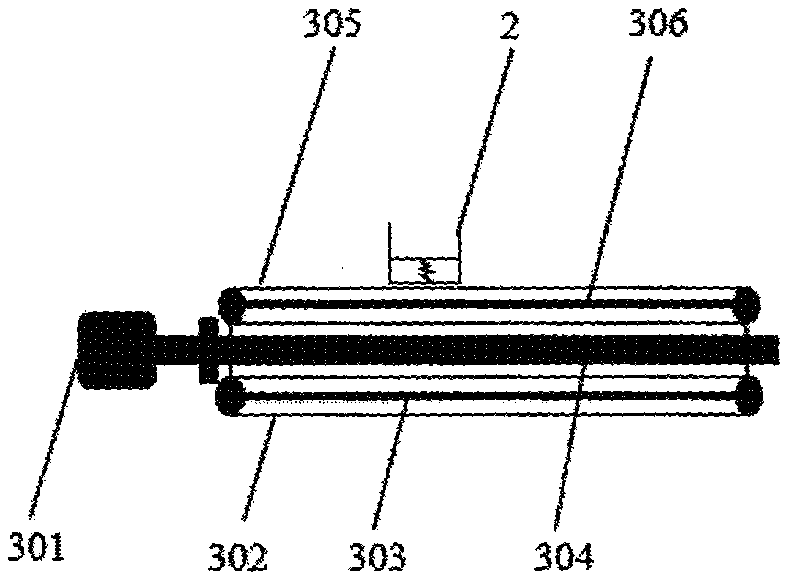

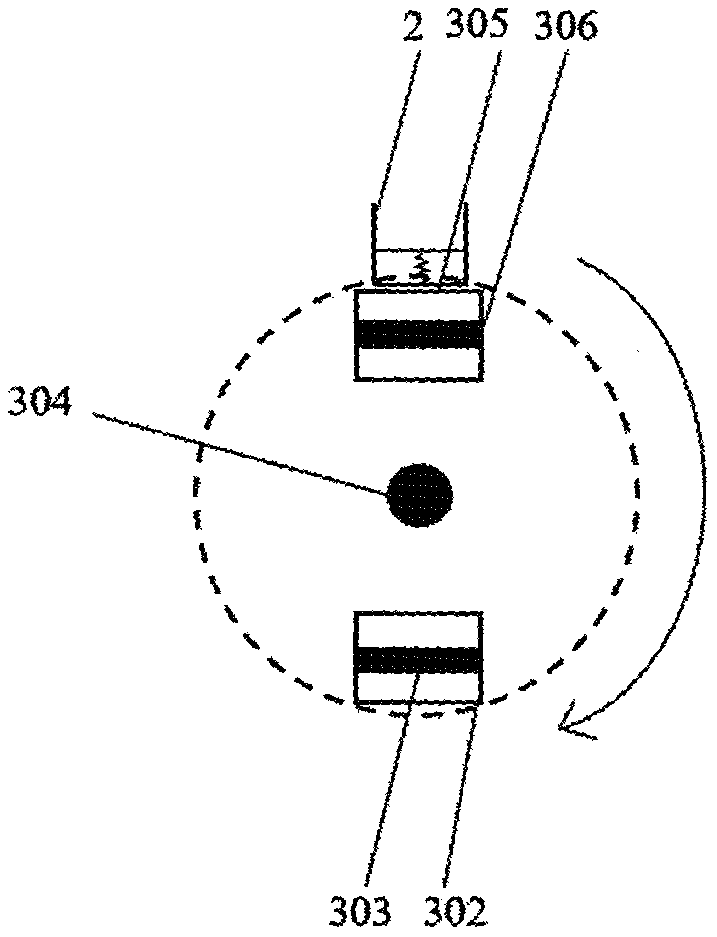

[0056] In order to more clearly demonstrate the operation method and working principle of the brick making device of the present invention, on the basis of the aforementioned brick making device and operating steps, further supplementary examples are carried out. Assuming that the brick mold 2 used in this method is an iron material, there are 5 brick molds 2 on the conveyor belt with spring stoppers and sensors, the inner size of the brick mold 2 is 240mm*115mm*120mm, and the thickness of the brick body is prefabricated The length and width of the pressure head of the hydraulic device 33 are 240mm*115mm. Assuming that the brick mold 2 is 220mm high, the distance between the lower conveyor belt 302 and the conveyor belt C10 is 400mm.

[0057] Its working principle: when working, clay brick fines and magnesium hydroxide solution are mixed in the mixing chamber 42 after a certain period of time and then stirred evenly. The discharge machine 44 works with the cutting plate 4 to o...

Embodiment 2

[0059] A carbon dioxide brick body carbonization device with embodiment 1, the difference is that the thickness of the prefabricated brick body is 53mm, the inner size of the brick mold 2 is 240mm*115mm*100mm, the height of the brick mold is 200mm, and the lower conveyor belt is 302 mm. The distance from the conveyor belt C10 is 350mm, the carbonization time of the first carbonization chamber 13 is 1h, and the ventilation pressure is 50kPa, the carbonization time of the second carbonization chamber 23 is 12h, and the ventilation pressure is 100kPa, and other working principles are the same as in Example 1.

Embodiment 3

[0061] The same carbon dioxide brick body carbonization device as in Embodiment 1, the difference is that the thickness of the prefabricated brick body is 90mm, the inner size of the brick mold 2 is 240mm*240mm*120mm, and the length and width of the pressure head are 240mm* 240mm, the carbonization time of the first carbonization chamber 13 is 3h, the ventilation pressure is 100kPa, the carbonization time of the second carbonization chamber 23 is 24h, the ventilation pressure is 300kPa, and other working principles are the same as the first example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com