Patents

Literature

34results about How to "Improve brick making efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System of making bricks by utilizing construction waste and method of making bricks by utilizing construction waste

InactiveCN109201702AQuality improvementImprove efficiencyConstruction waste recoverySolid waste disposalBrickArchitectural engineering

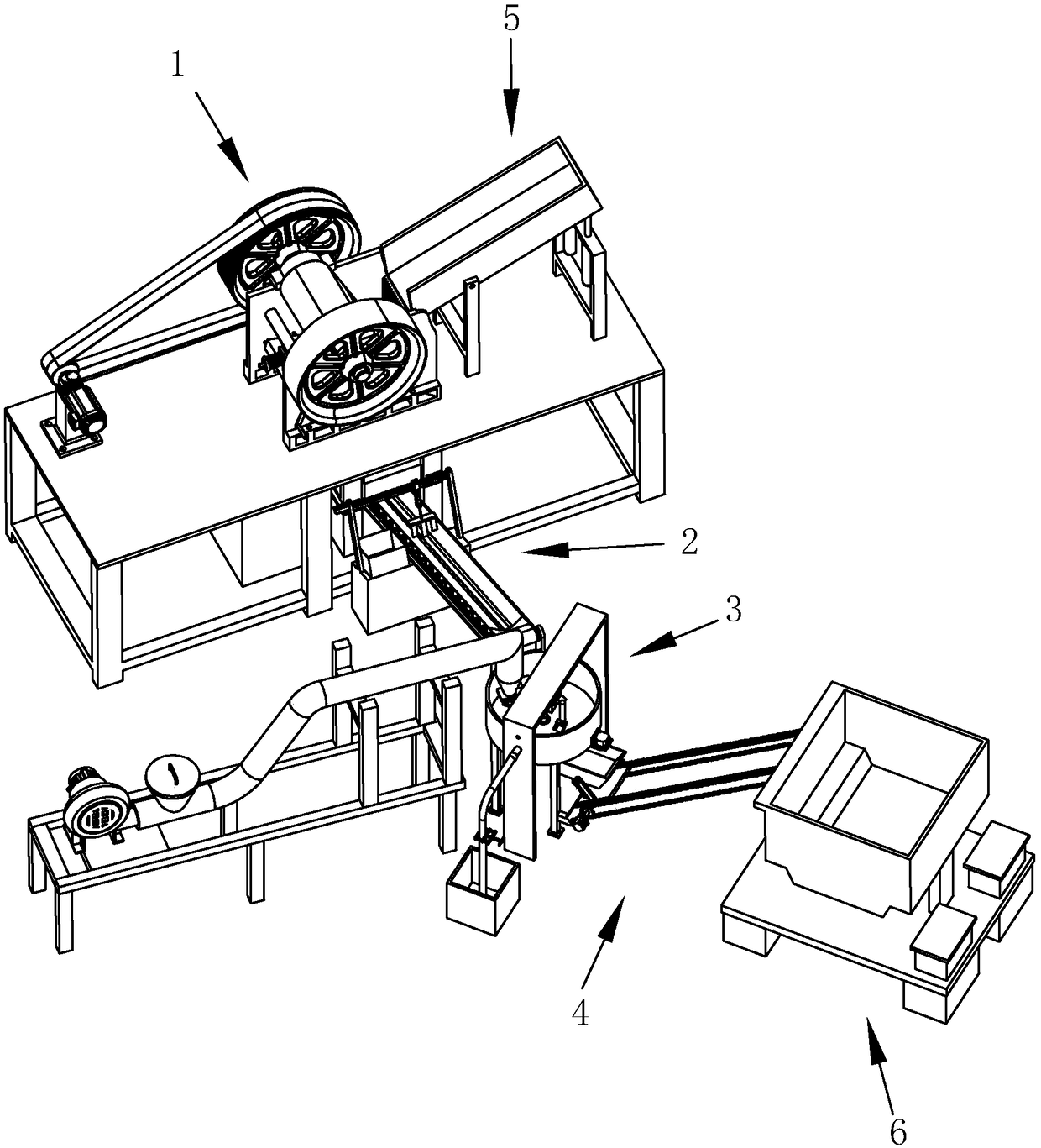

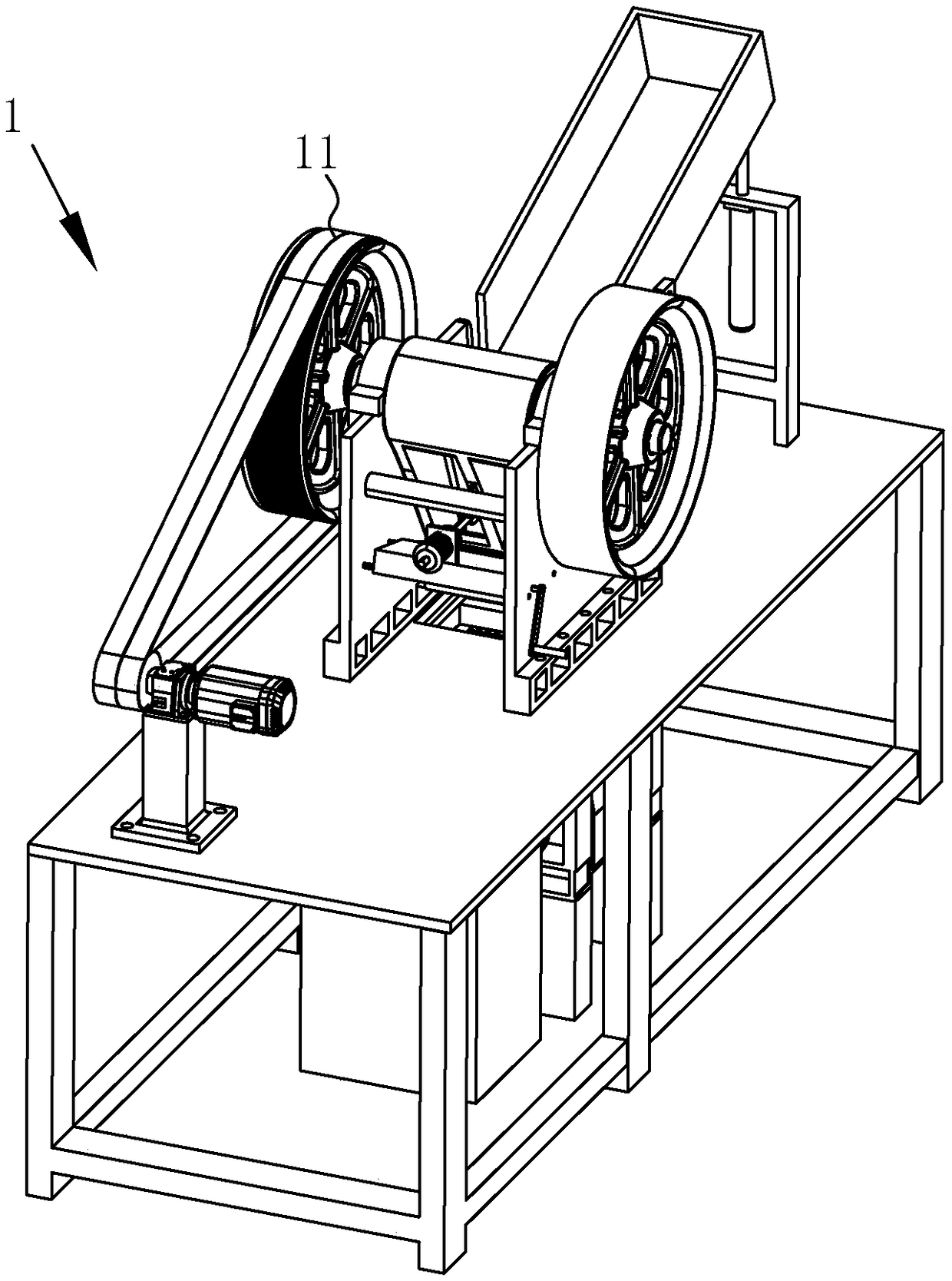

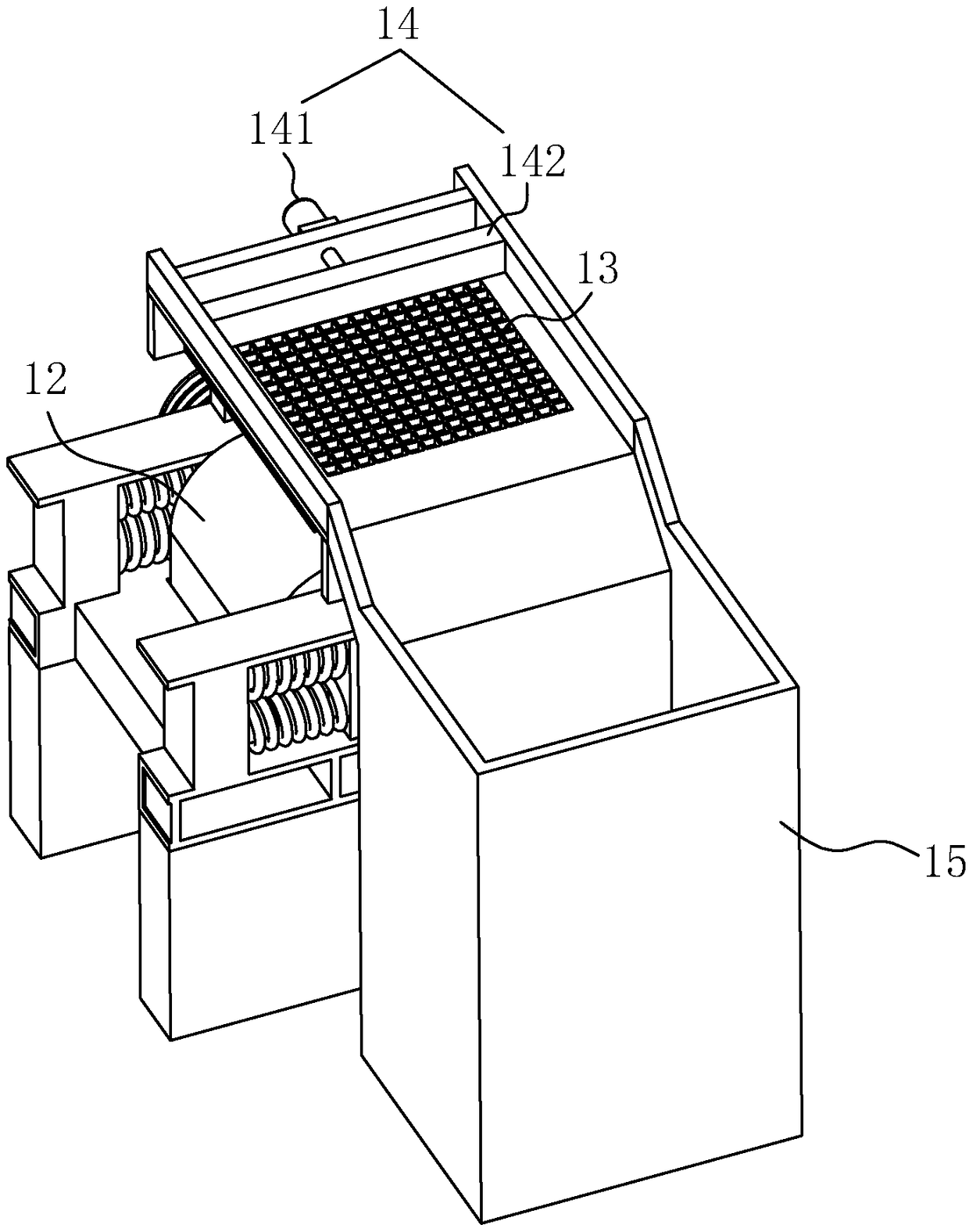

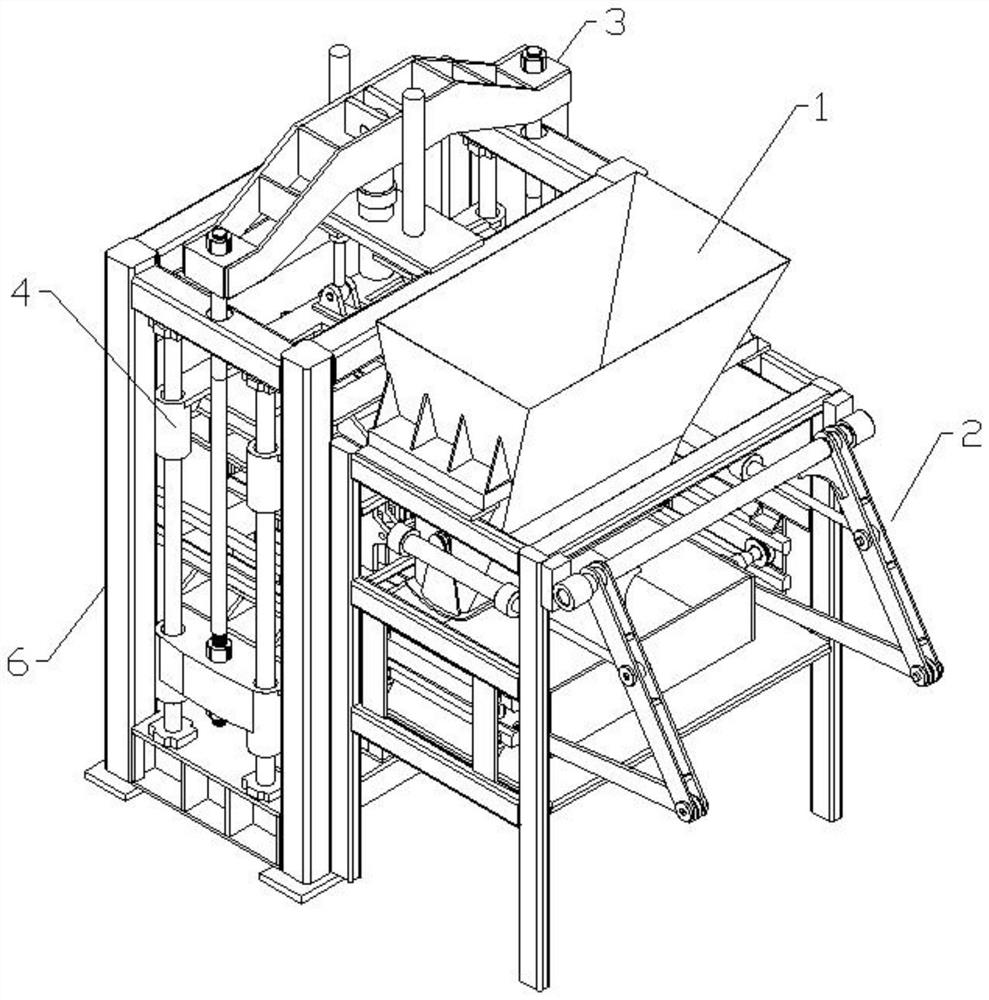

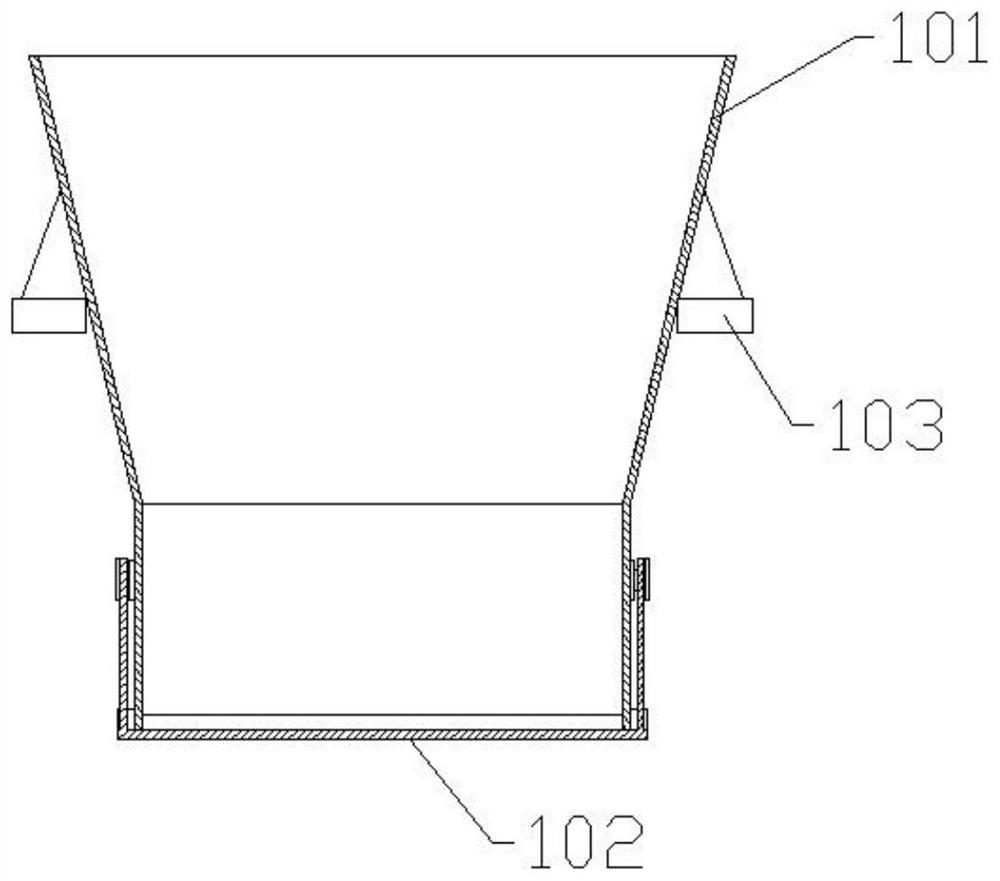

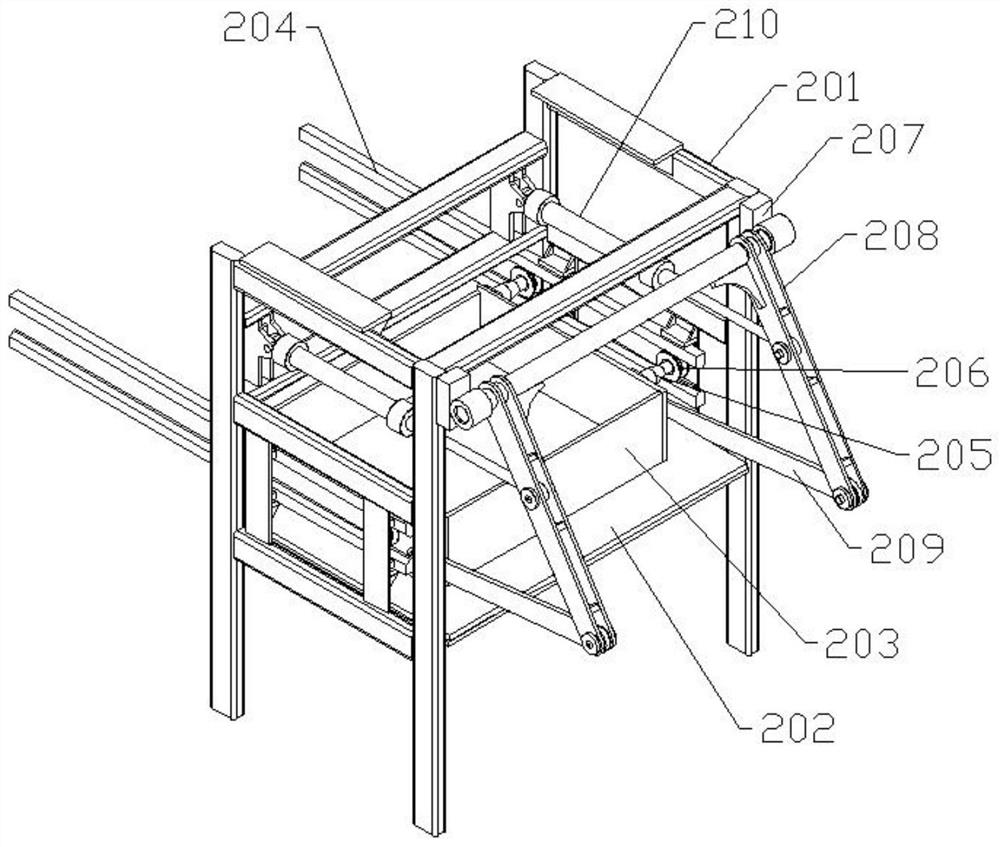

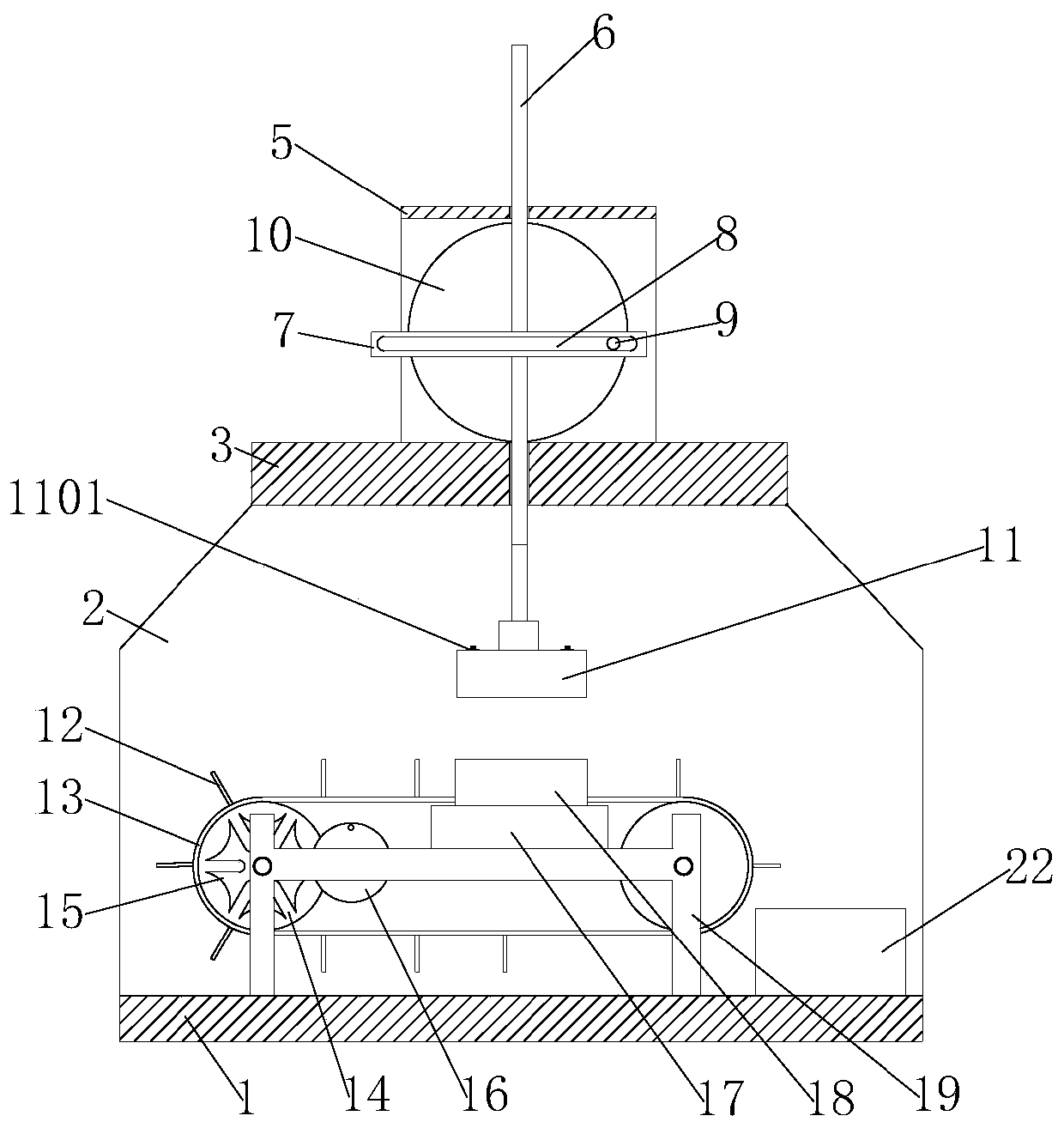

The invention discloses a system of making bricks by utilizing construction waste. The system is used for solving the problem that the construction waste cannot be utilized. According to the technicalscheme, the system is characterized by comprising a material inlet hopper, a breaking device, a screening device, a stirring device, a feeding device and a brick making machine. The material inlet hopper is used for receiving the large construction waste. The breaking device is used for breaking the large construction waste into coarse materials and fine materials. The screening device is used for separating irony impurities in the fine materials from the fine materials. The stirring device is used for stirring the screened fine materials to form construction raw materials. The feeding deviceis used for conveying the construction raw materials. The brick making machine is used for pressing the construction raw materials to form bricks. The purpose that the construction waste is processedto form the bricks is achieved.

Owner:广东合韵达建筑工程有限公司

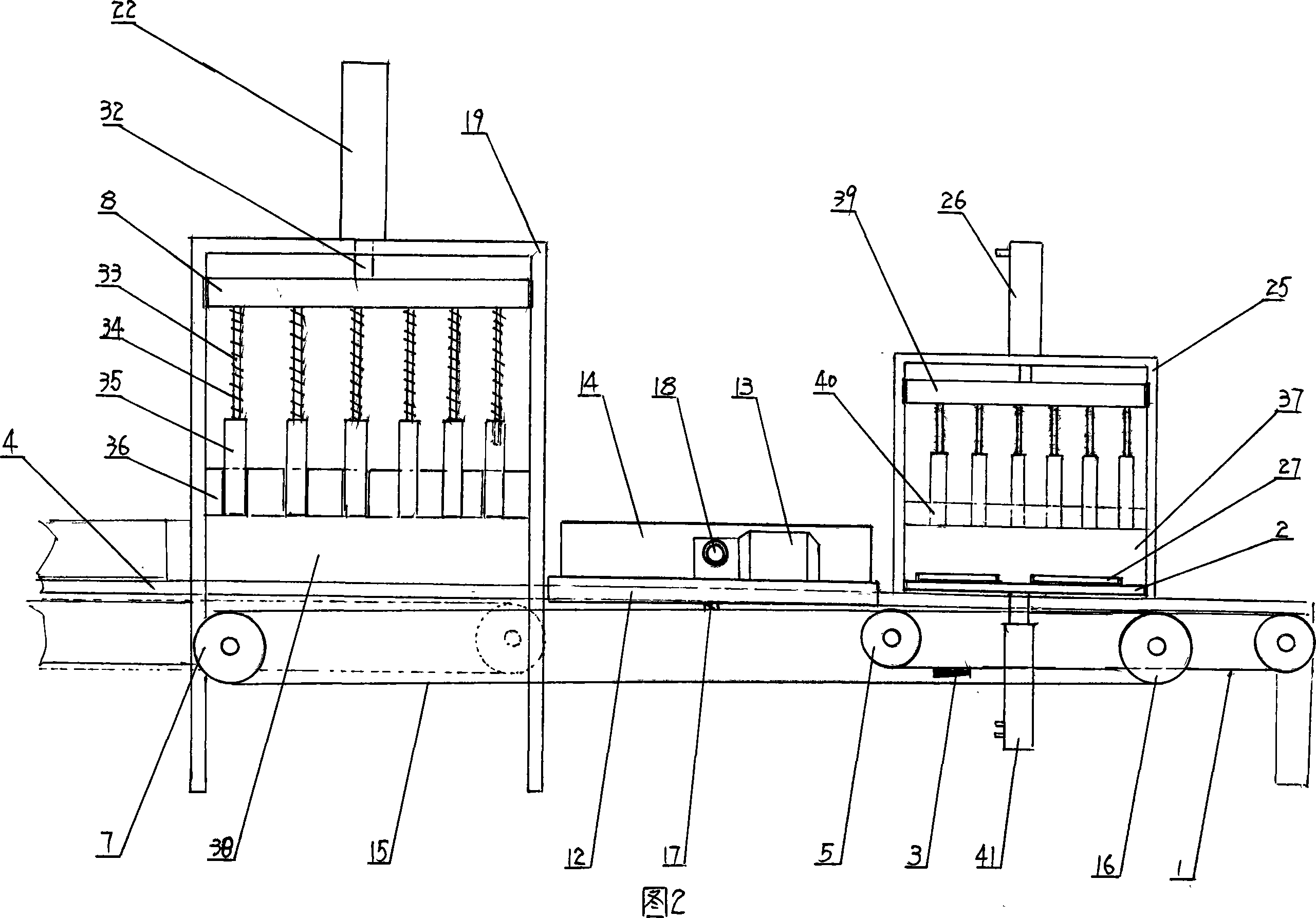

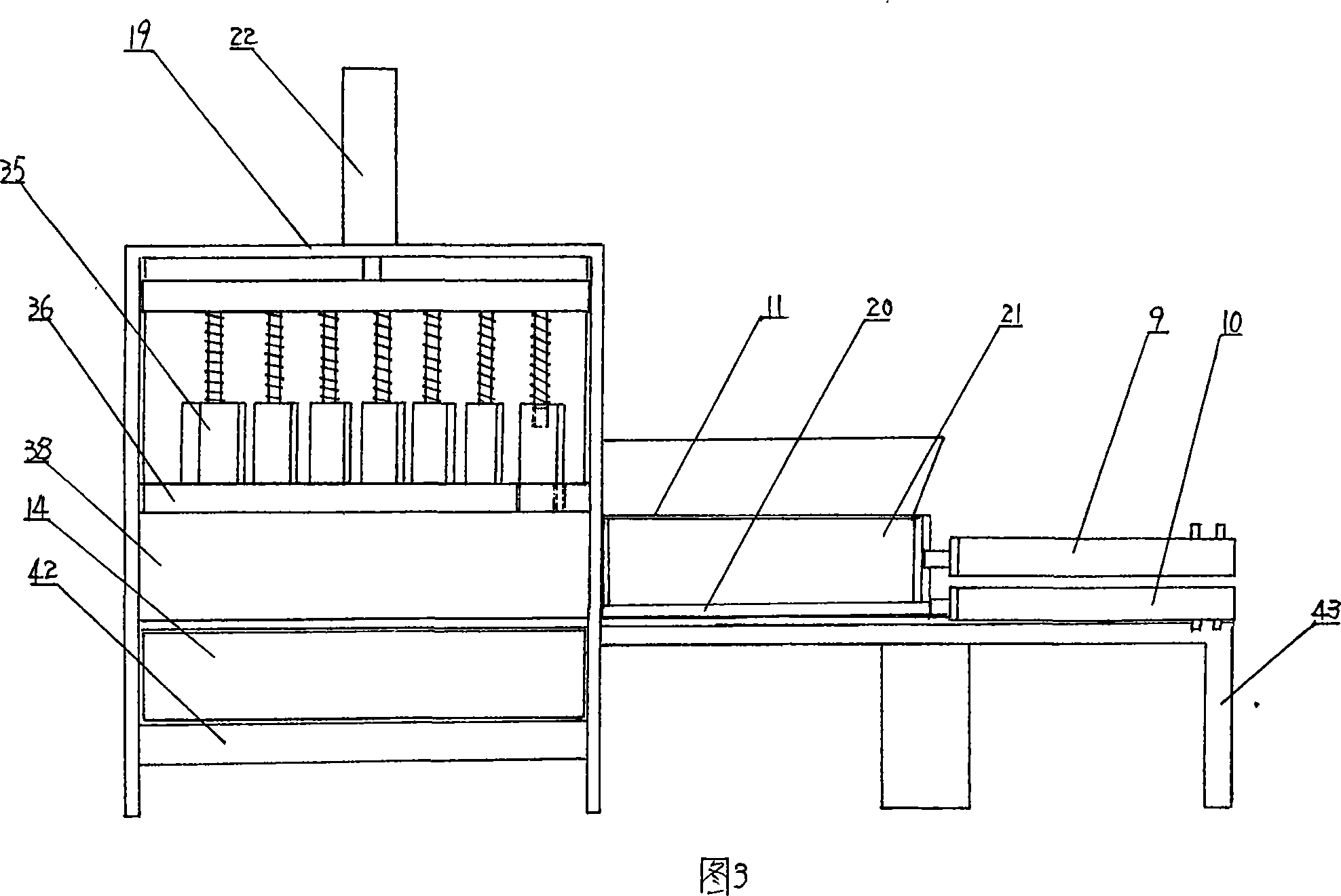

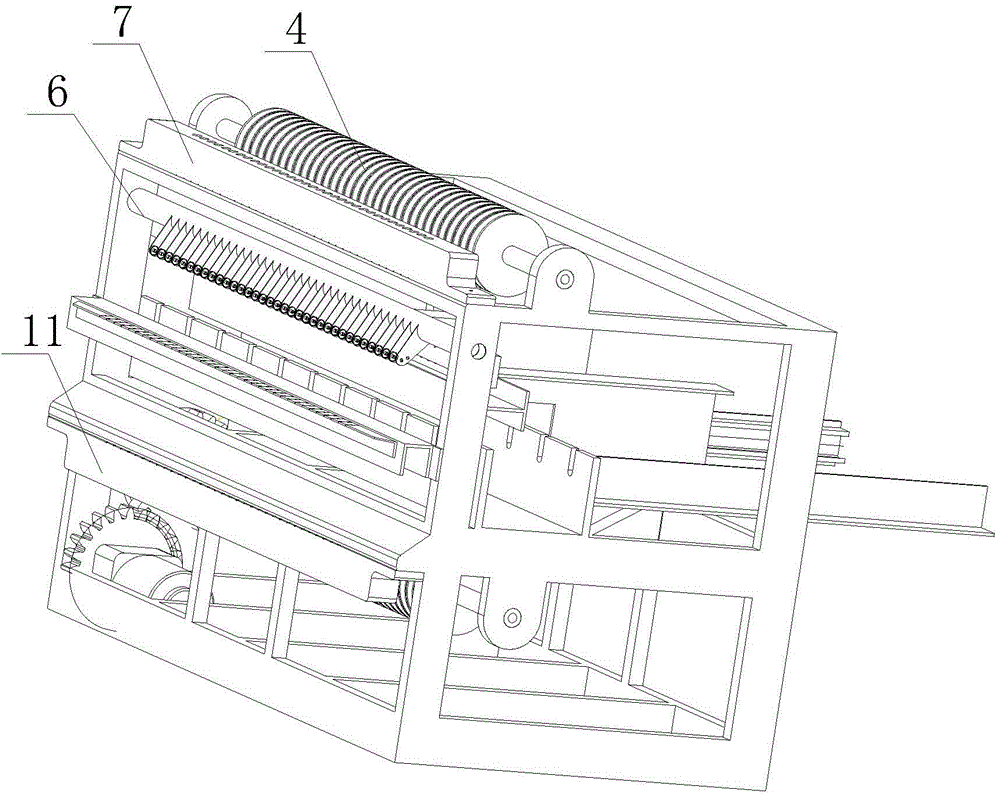

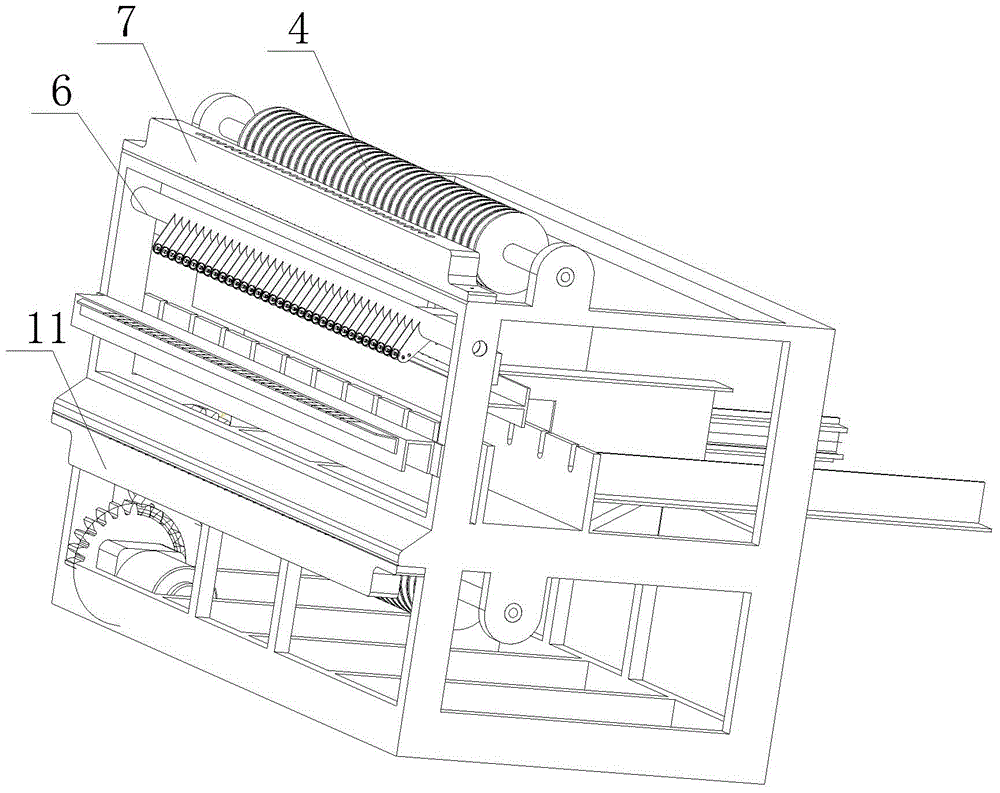

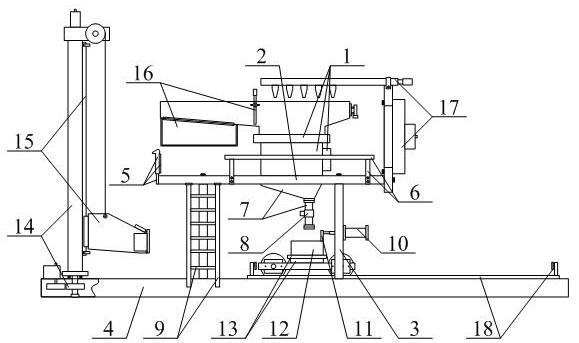

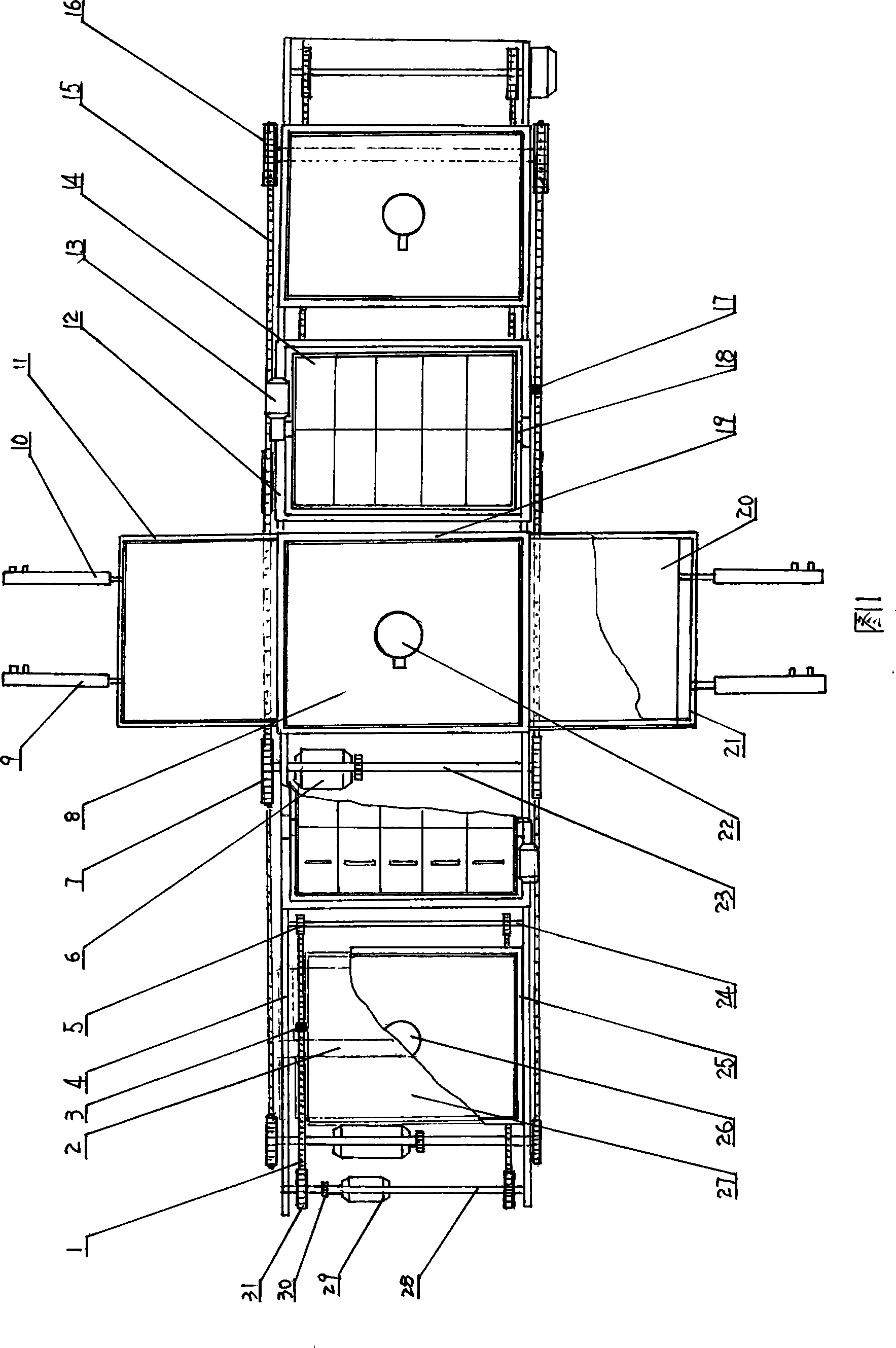

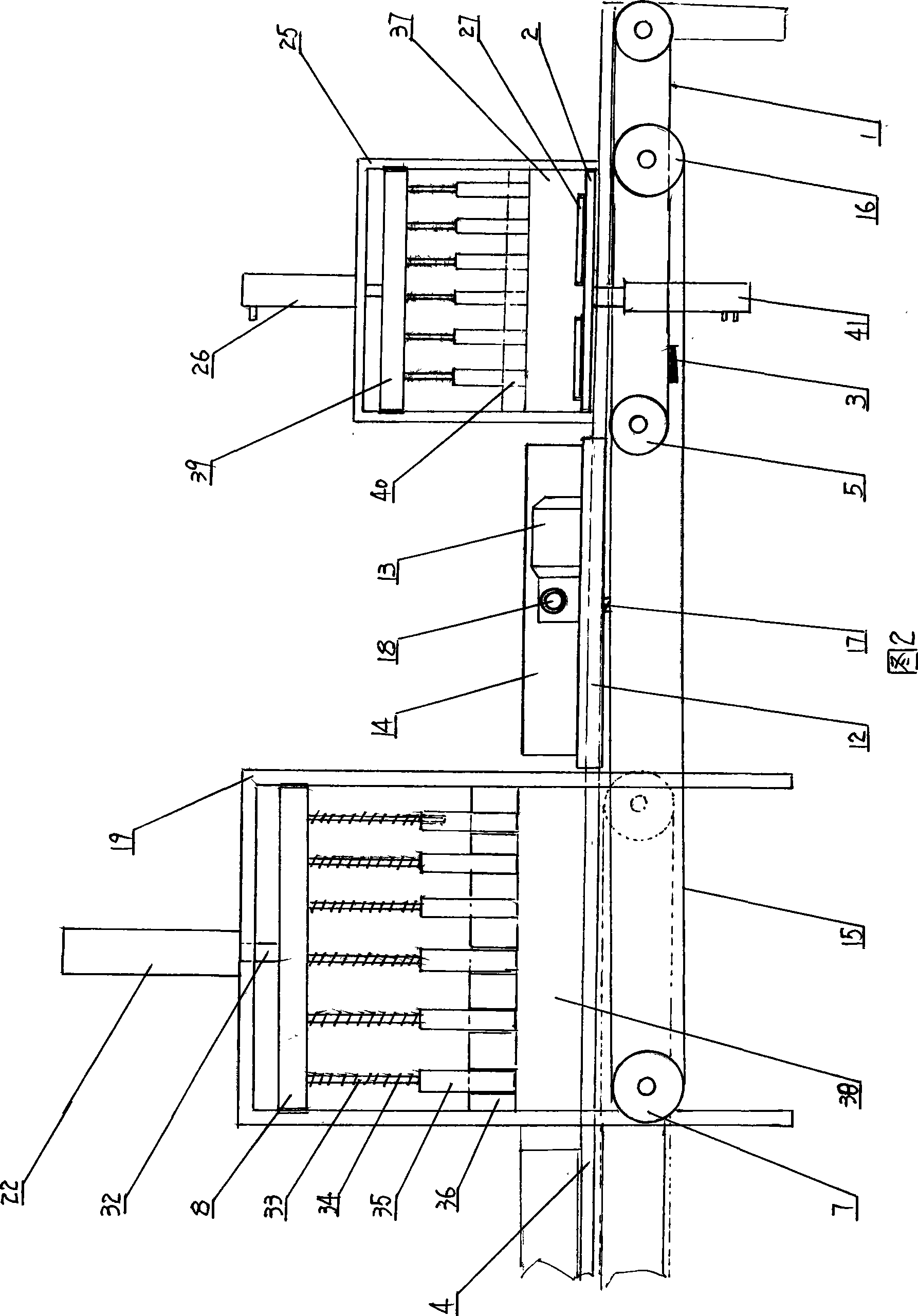

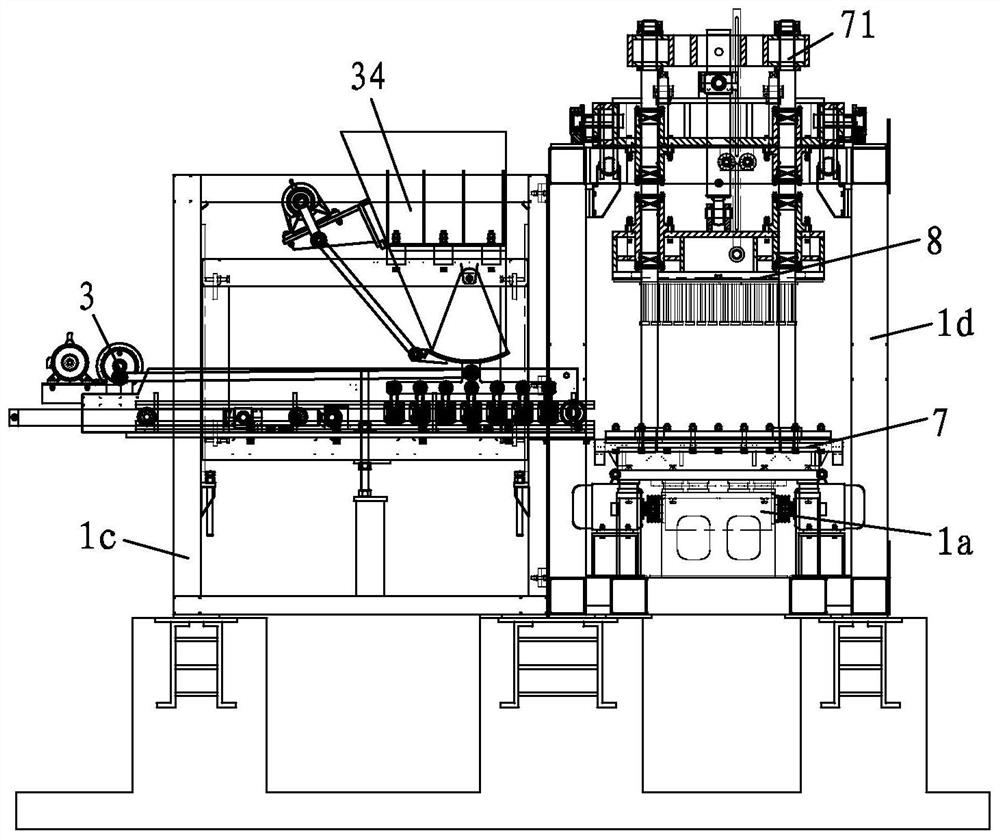

Flip-flop forming machine for heat preservation building module blocks

InactiveCN101049712AEasy to manufactureEasy to useCeramic shaping apparatusHydraulic cylinderEngineering

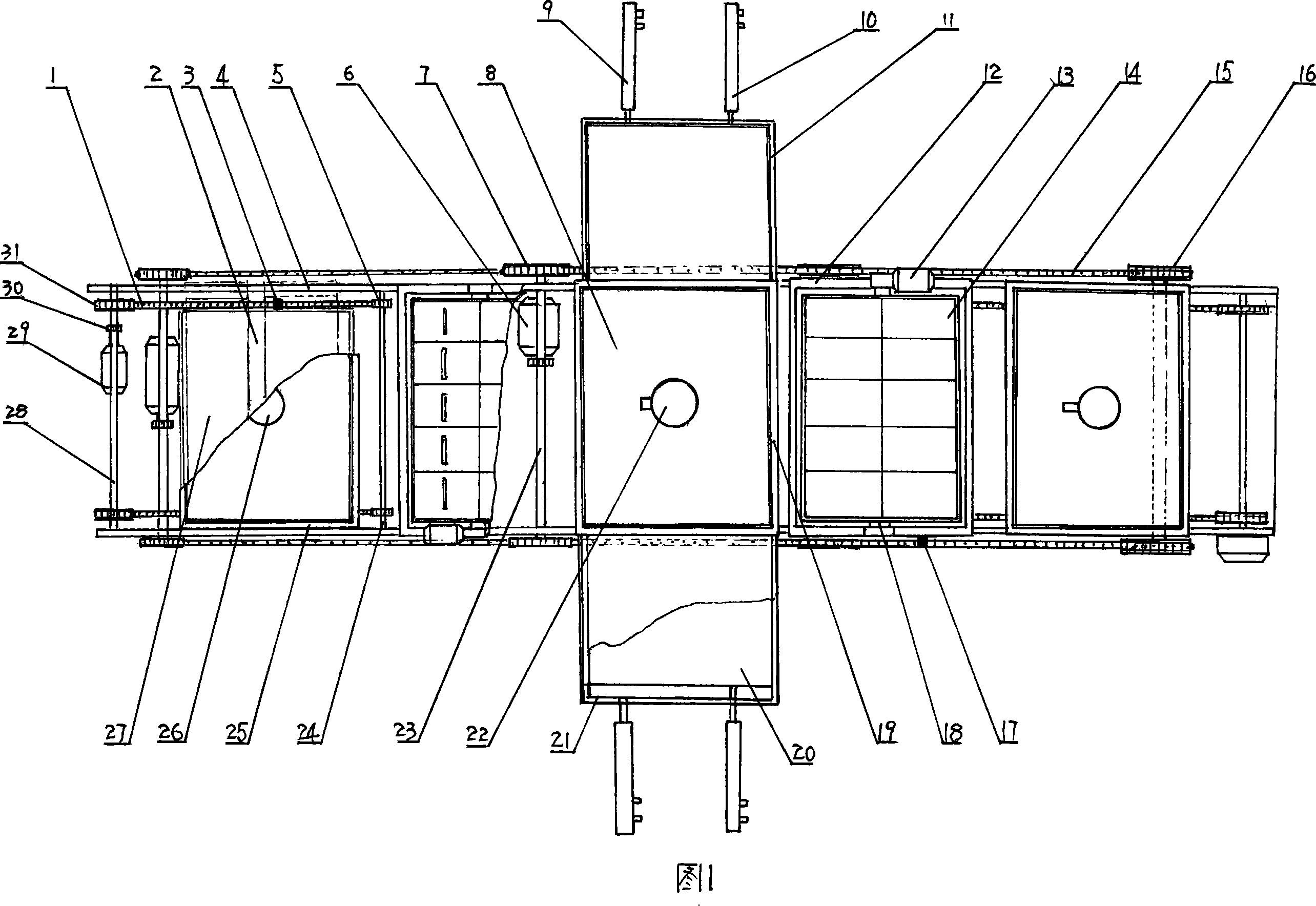

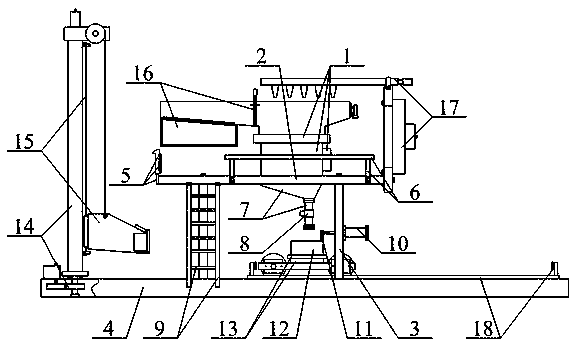

A turning-over and shaping machine for manufacturing the insulating building blocks with different shapes is composed of a feeding unit, a material pressing unit, a turnover mould unit and a demoulding unit. The turnover mould of said turnover mould unit is driven by master motor via master chain to move on track to the material pressing unit and demoulding unit. The movable feeding box is driven by the feeding hydraulic cylinder and the hydraulic cylinder of base plate to the material pressing unit. Said turnover mould is turned over on its holder.

Owner:付振顶

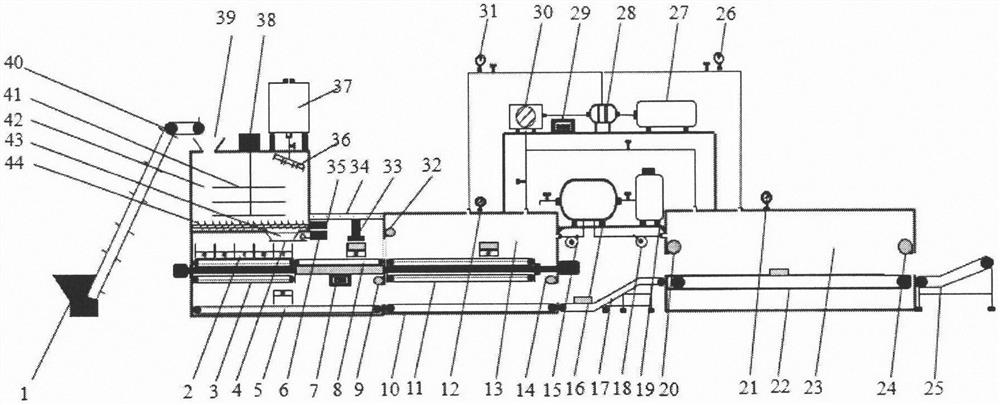

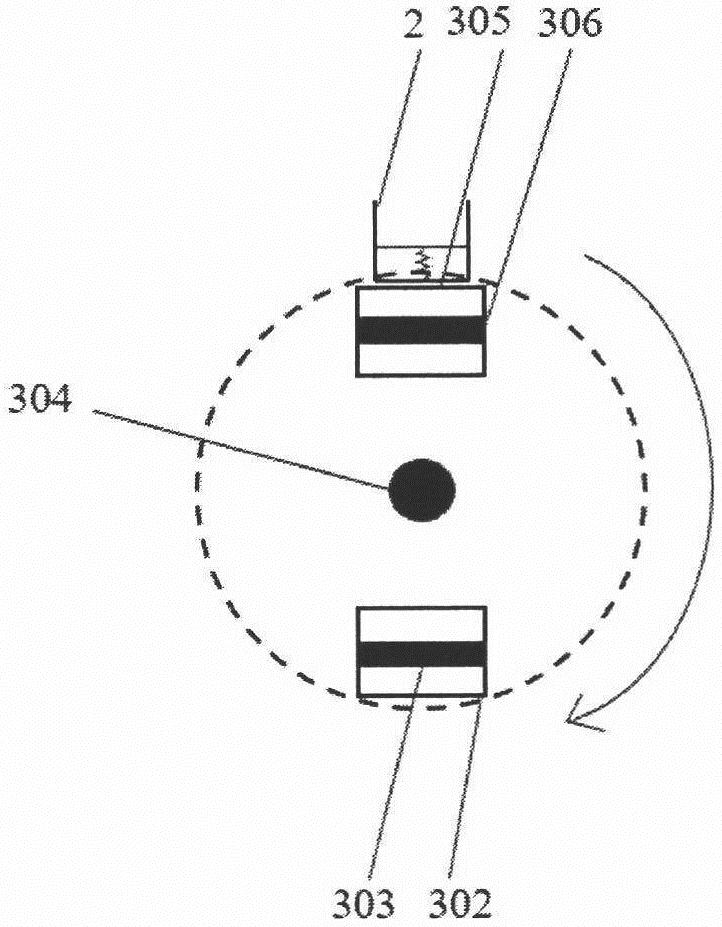

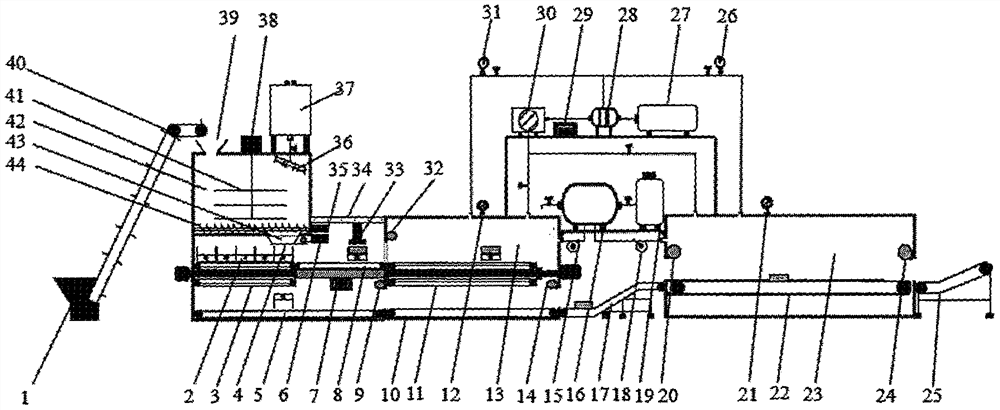

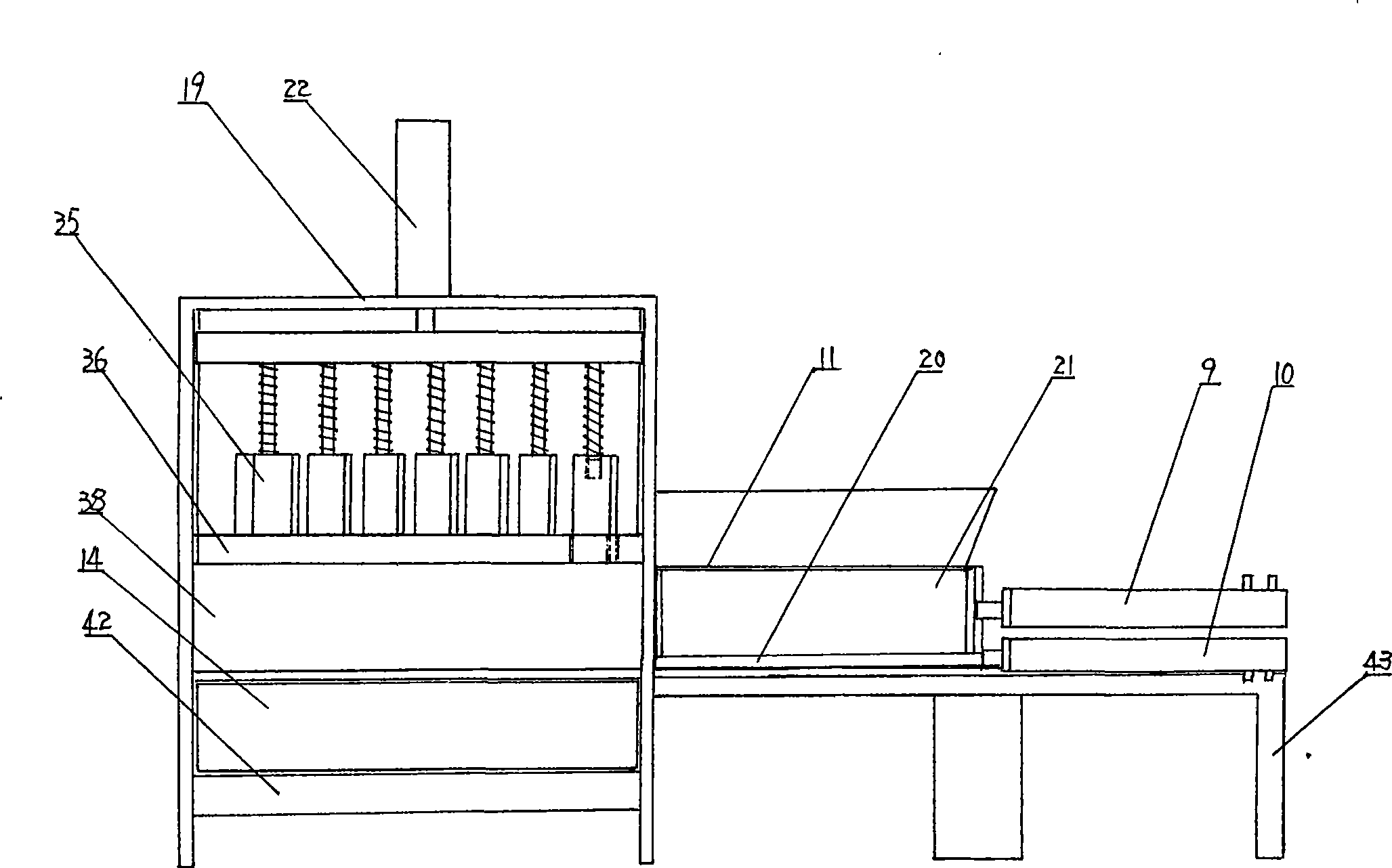

Operation method of carbon dioxide carbonized brick body manufacturing device

The invention discloses an operation method of a carbon dioxide carbonized brick body manufacturing device, and belongs to the field of civil engineering brick manufacturing. The two processes of pre-carbonization and secondary carbonization are specially set, so that after the shape and the strength of a brick body are temporarily stabilized, demolding is smoothly completed, and the strength is rapidly increased. All systems in the device work coordinately and orderly according to the method, so that charging, compaction forming and brick mold conveying are conducted at the same time, brick material adding and uniform mixing are conducted in the pre-carbonization process, and the brick body manufacturing and conveying efficiency is greatly improved; an upper conveying belt and a lower conveying belt rotate through a rotating shaft, brick bodies are demolded through spring limiters in brick molds, and brick body demolding and efficient cyclic utilization of the empty brick molds are achieved through electromagnet adsorption and releasing and conveying of the conveying belts. According to the brick manufacturing method, low-concentration carbon dioxide and construction waste are utilized, the carbon dioxide in a carbonization cavity can be pumped into a storage bin through an exhaust fan after carbonization, carbon dioxide gas is recycled, tail gas emission is reduced, environmental protection is facilitated, and the brick manufacturing cost is reduced.

Owner:NANJING FORESTRY UNIV

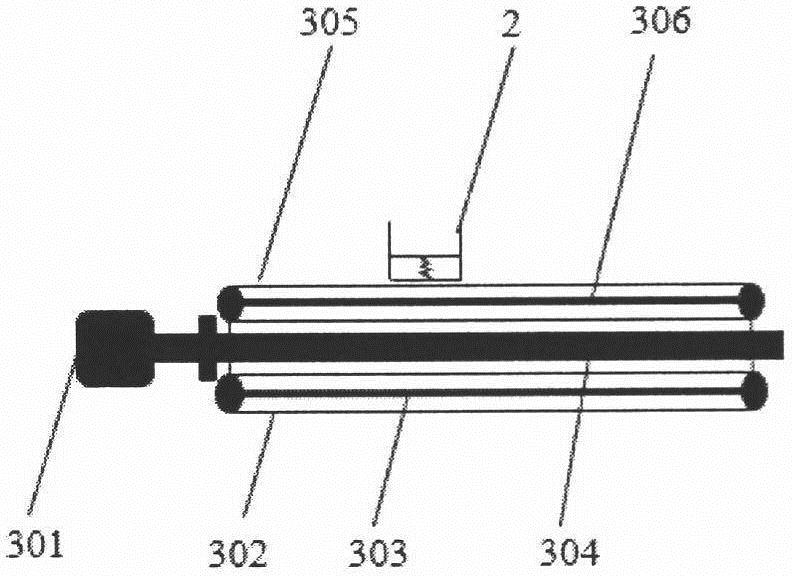

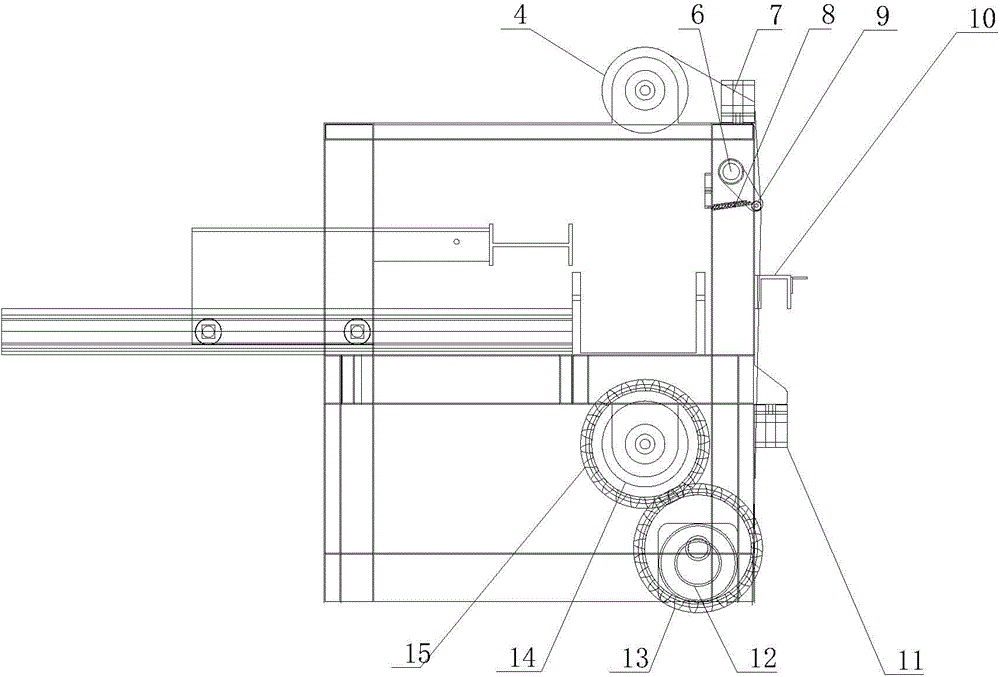

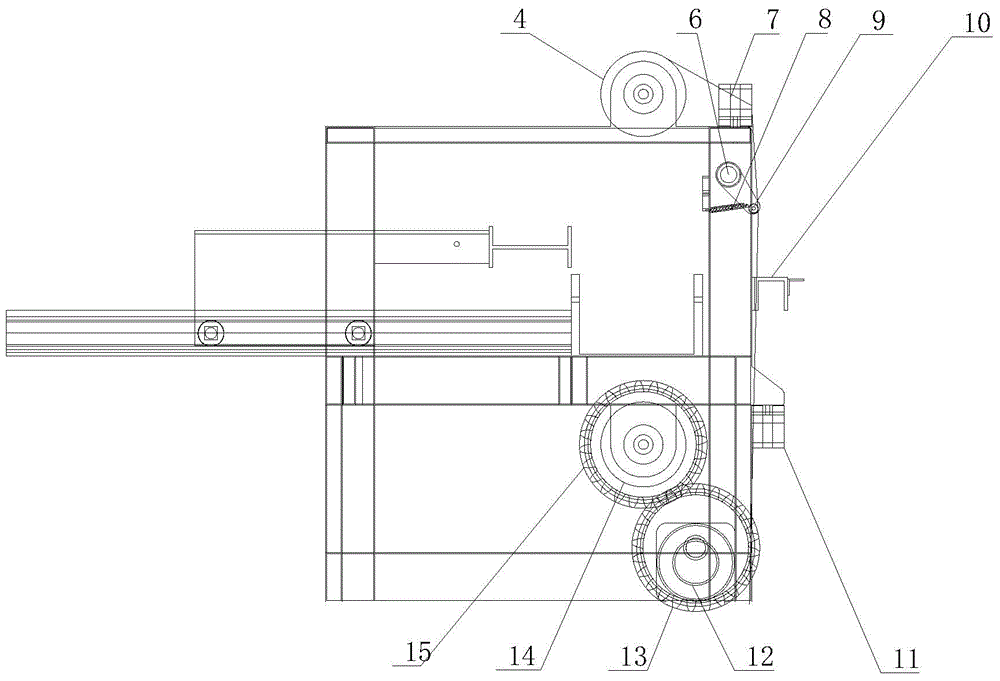

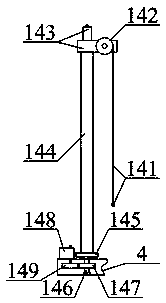

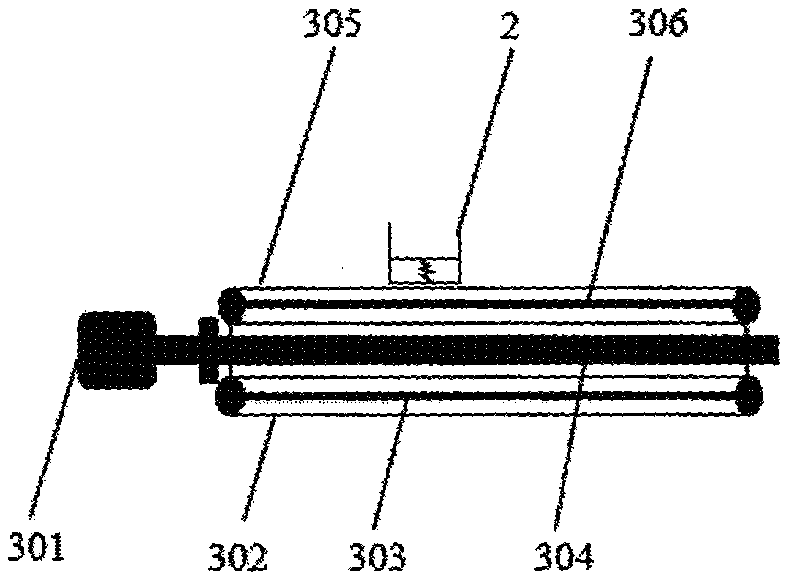

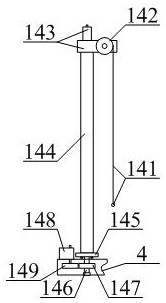

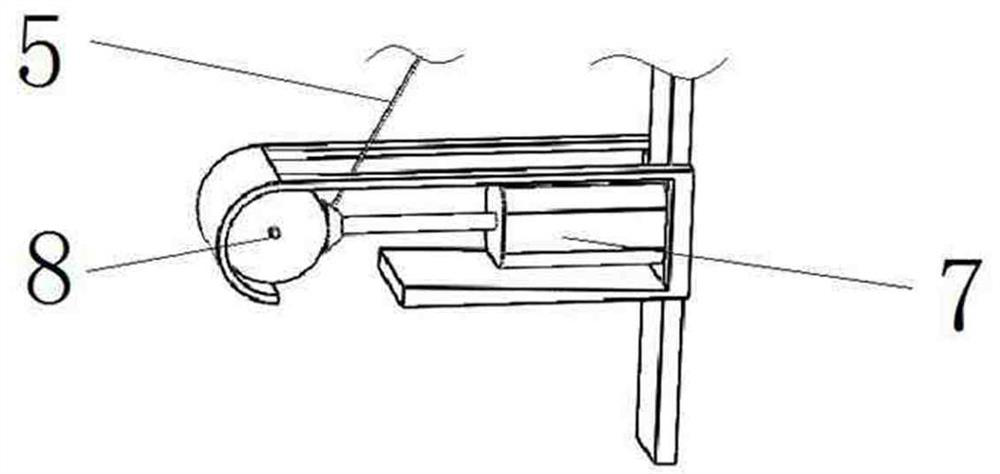

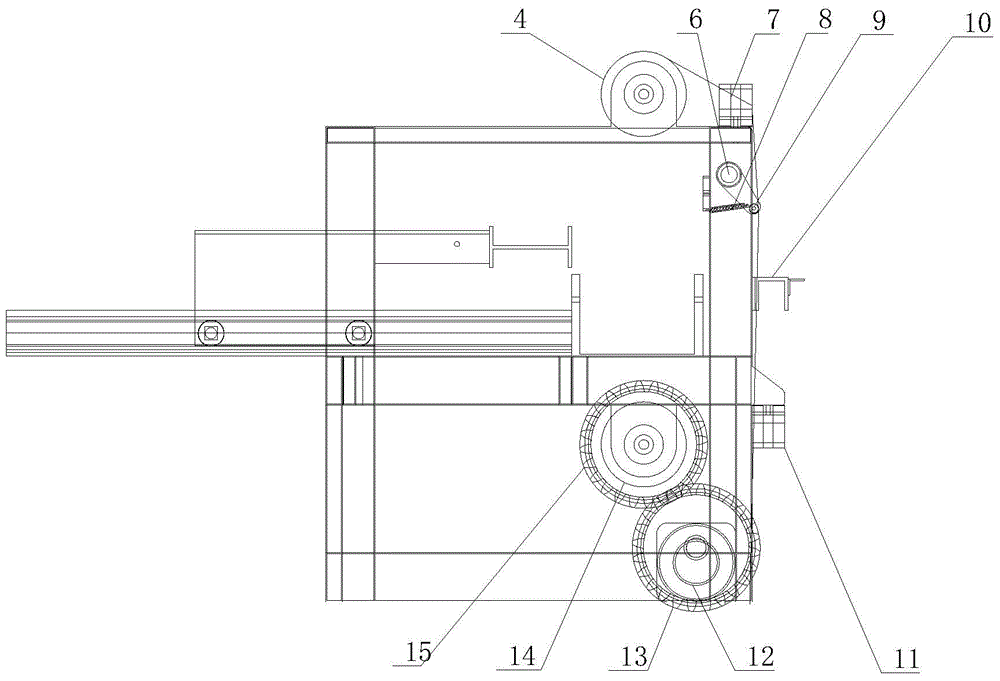

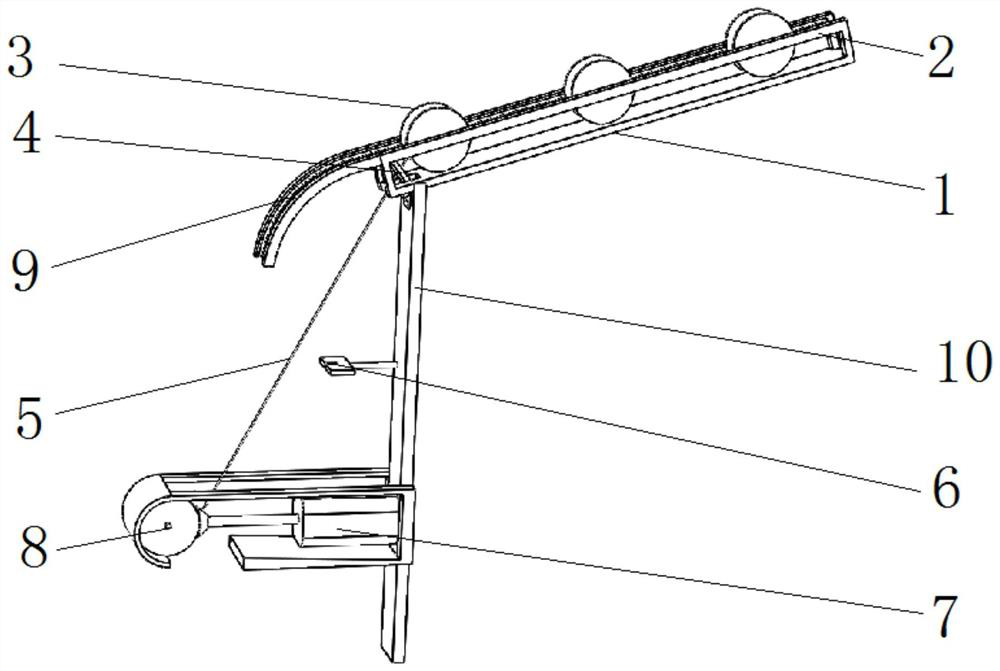

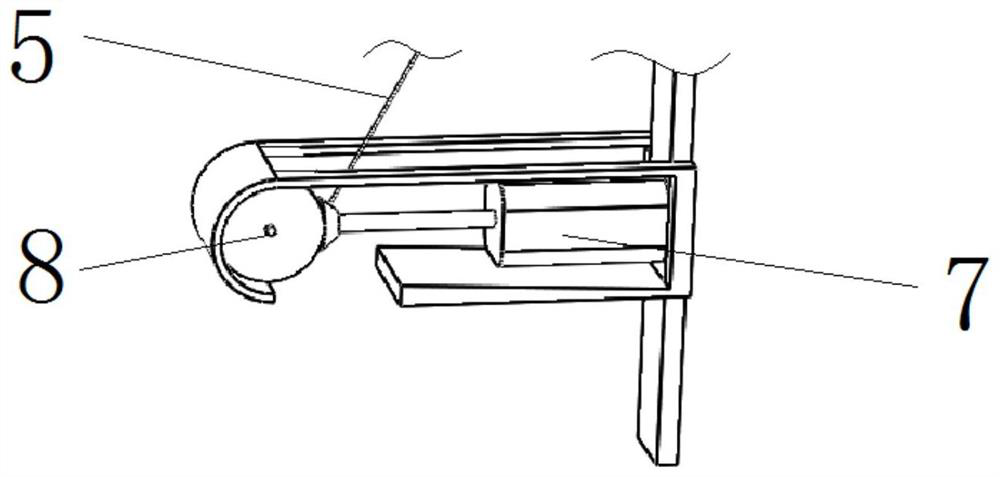

Steel wire automatically replacing device for raw brick cutting machine

ActiveCN104626344AAvoid fatigueImprove brick making efficiencyCeramic shaping apparatusBrickEngineering

The invention provides a steel wire automatically replacing device for a raw brick cutting machine. The steel wire automatically replacing device comprises a rack, one side of the rack is provided with a raw brick cutting table, a first steel wire rope winding shaft is arranged over the raw brick cutting table and a second steel wire rope winding shaft is arranged under the raw brick cutting table, and the upper and lower sides of the raw brick cutting table are provided with a first steel wire rope holding device and a second steel wire rope holding device respectively; a steel wire rope is wound on the second steel wire rope winding shaft from the first steel wire rope winding shaft through first steel wire rope holding device, the second steel wire rope holding device in sequence, the raw brick cutting table and the second steel wire rope holding device. During working, the first steel wire rope holding device and the second steel wire rope holding device each tightens the steel wire rope; when the steel wire rope is replaced, the first steel wire rope holding device and the second steel wire rope holding device are made to release the steel wire rope, the second steel wire rope winding shaft rotates by a certain angle to let the steel wire wind, a steel wire rope which reaches fatigue strength leaves away from the raw brick cutting location, and a new steel wire rope arrives at the raw brick cutting location, and tensile failure of the steel wire rope caused by fatigue can be avoided. By means of the steel wire automatically replacing device, the raw brick cutting machine can work without stop around the clock, the efficiency of making bricks is greatly improved, and the cost of making the bricks is saved.

Owner:NANTONG UNIVERSITY

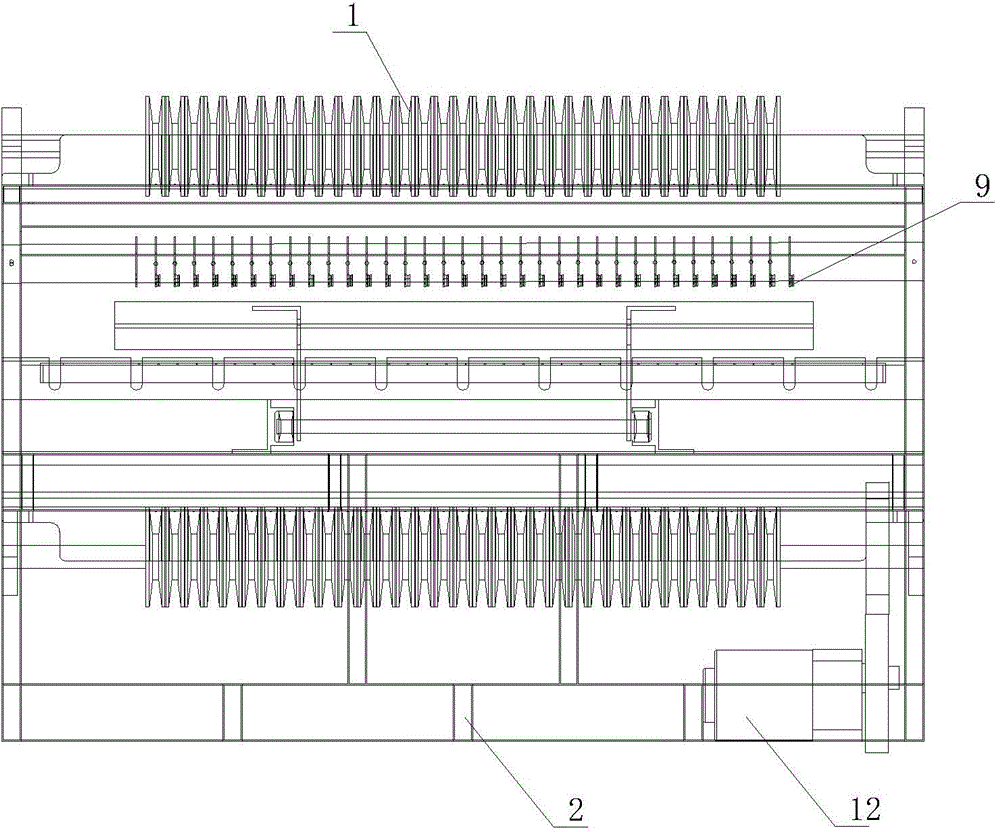

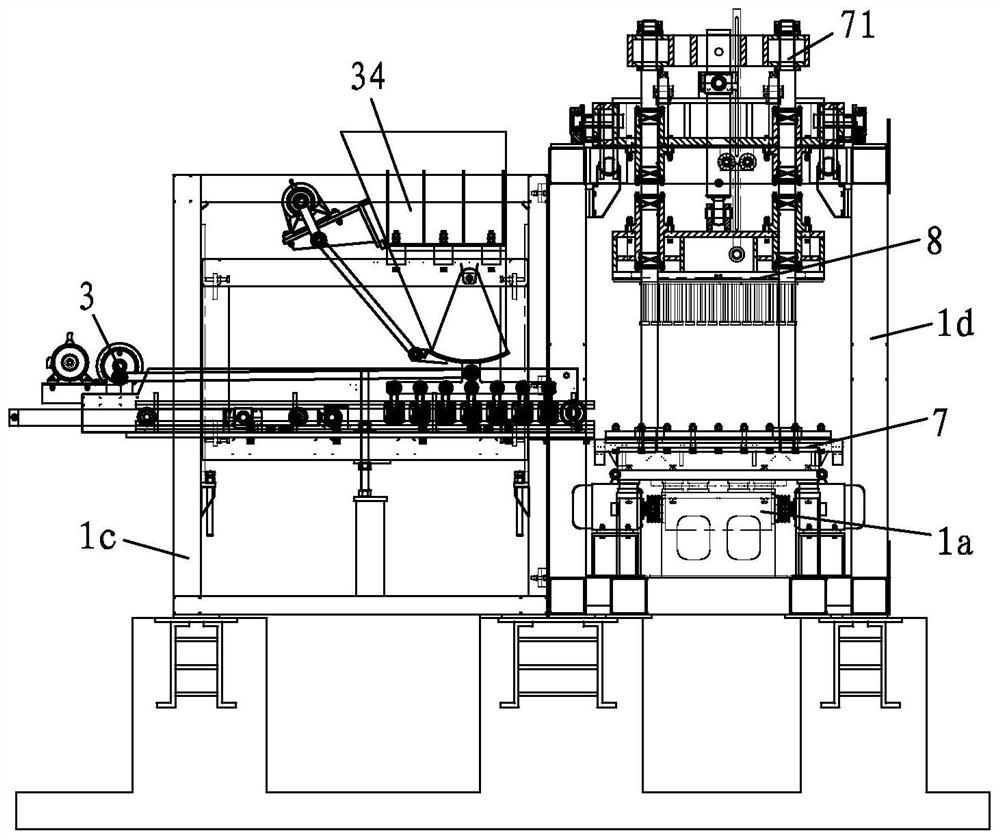

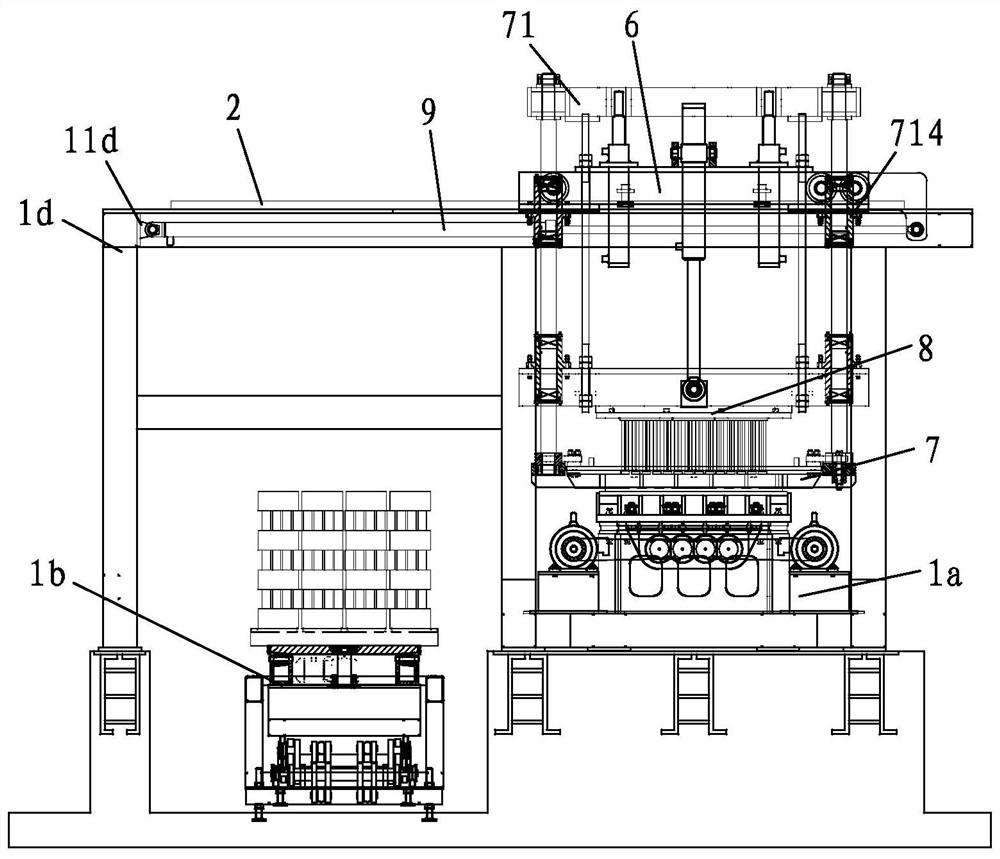

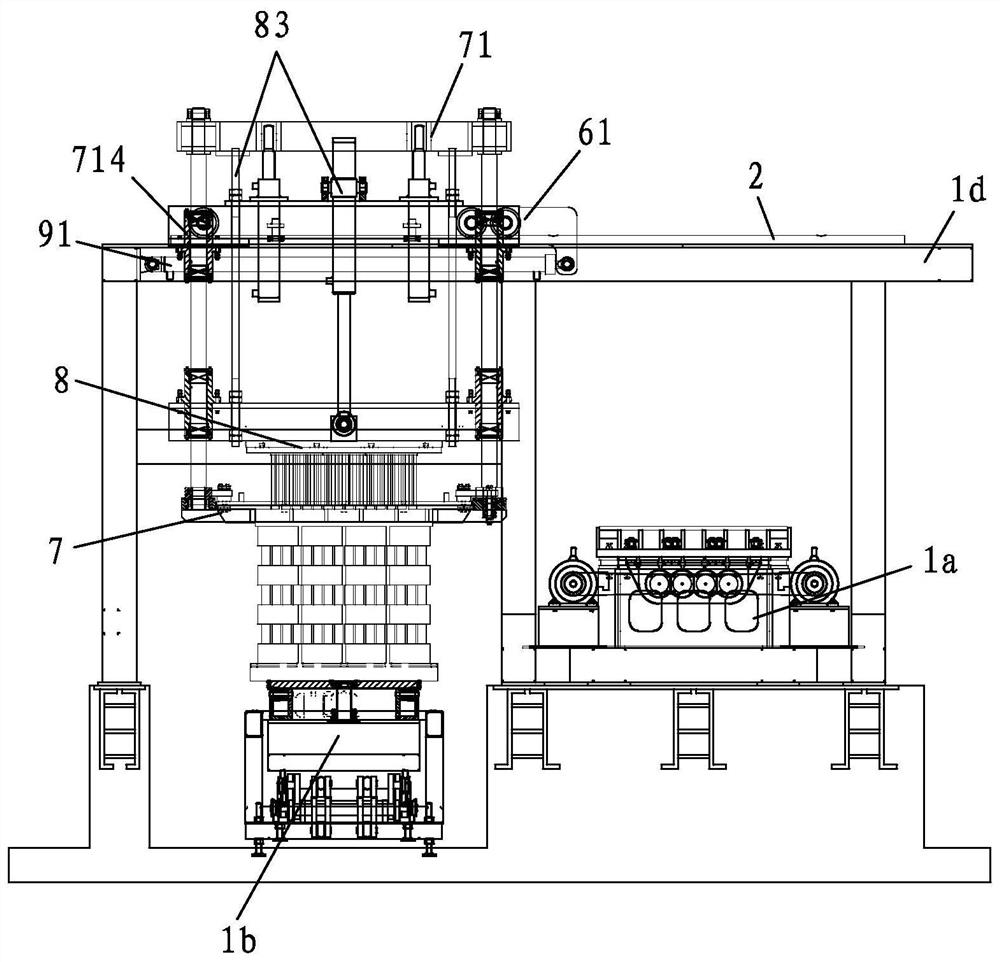

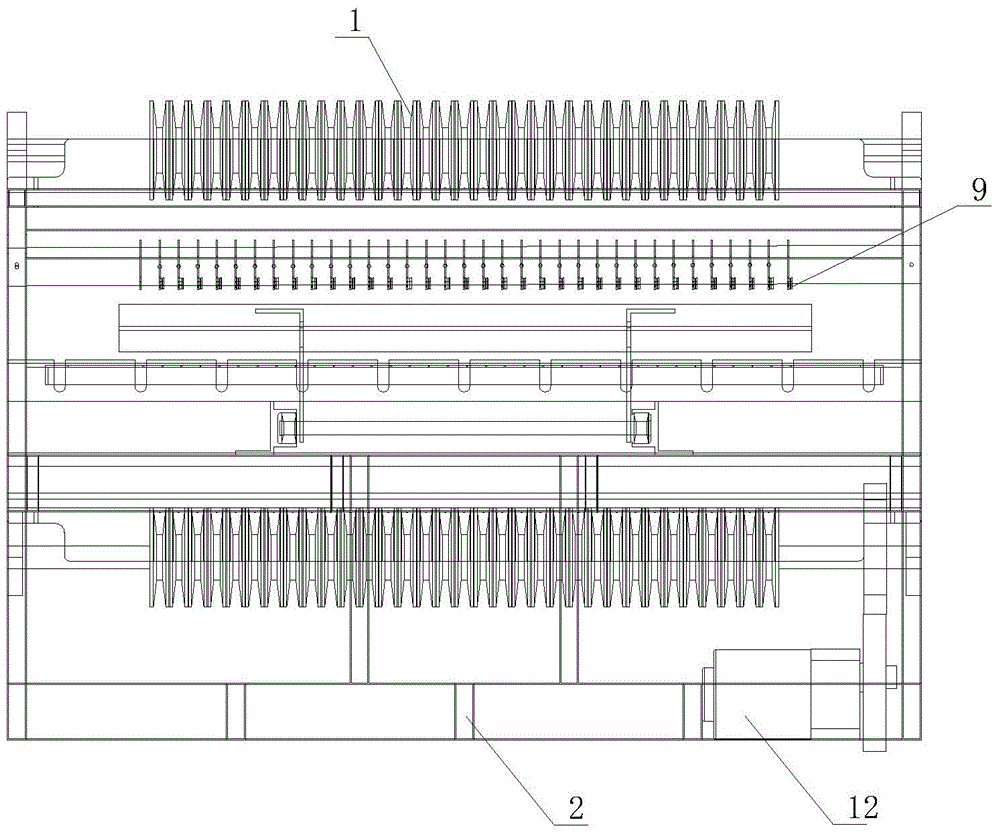

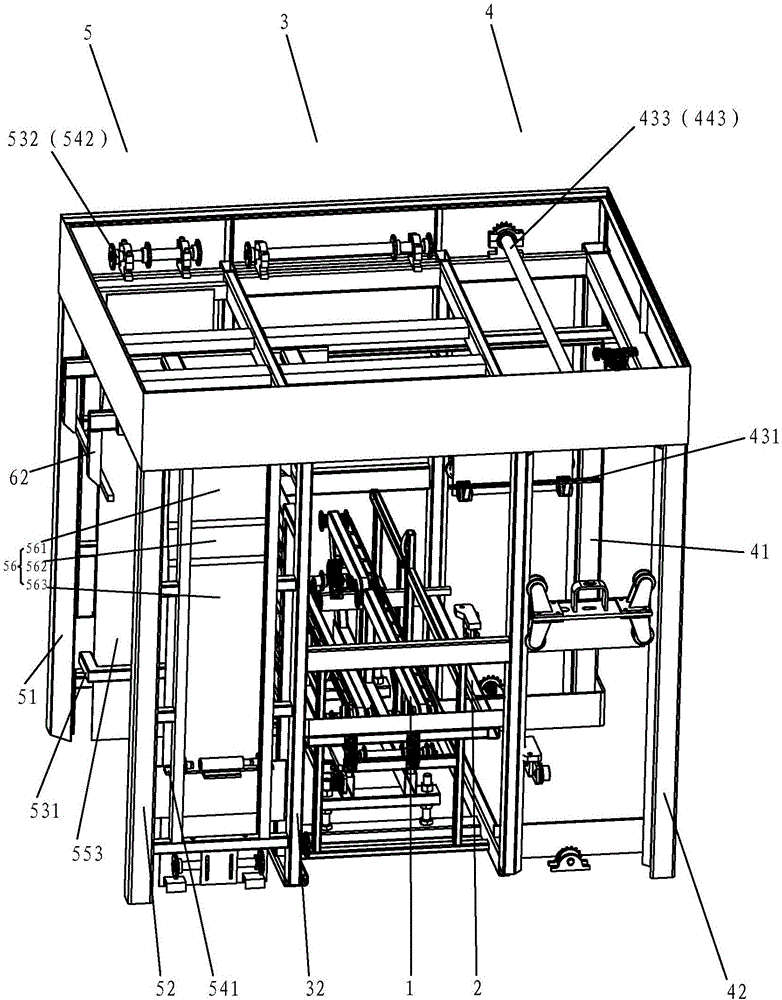

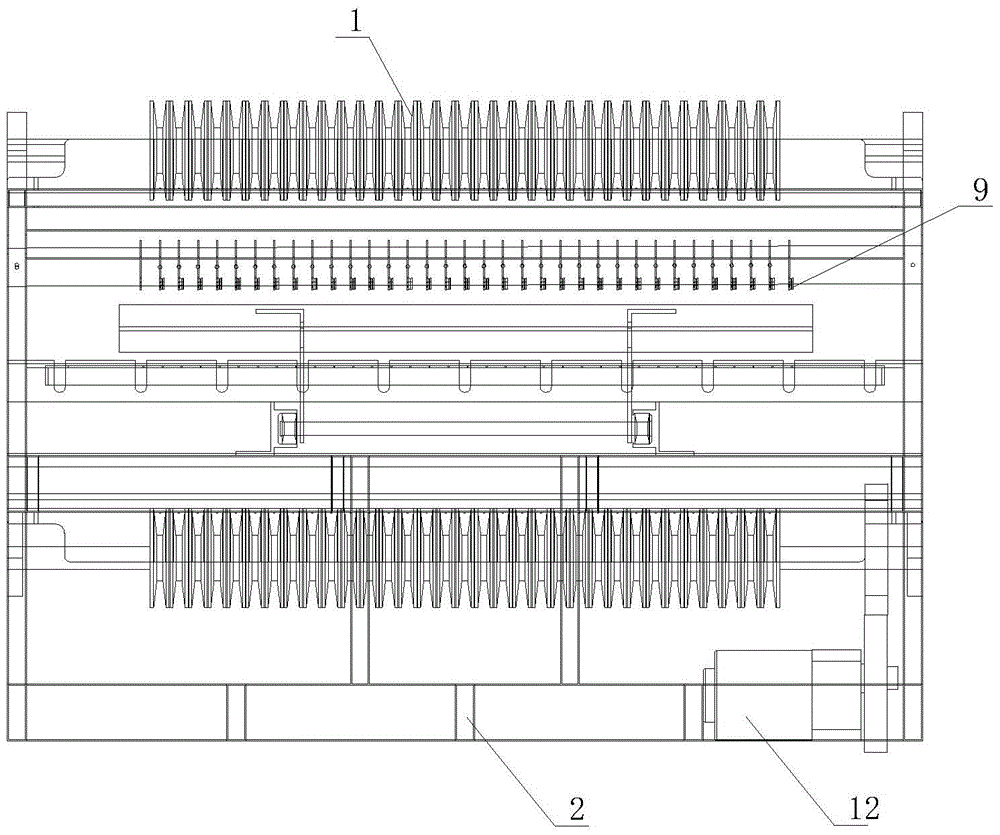

Supporting-plate-free brick making machine

ActiveCN112339102AImprove compression efficiencyImprove yield rateDischarging arrangementFeeding arrangmentsBrickStructural engineering

The invention provides a supporting-plate-free brick making machine. The brick making machine comprises a first walking track, a second walking track, a material distribution vehicle arranged on the first walking track, a first driving mechanism for driving the material distribution vehicle to walk along the first walking track, a swinging material scraping mechanism arranged on the material distribution vehicle, a mold moving mechanism arranged on the second walking track, a brick forming mold frame arranged on the mold moving mechanism, a pressure head mechanism arranged on the mold moving mechanism and located above the brick forming mold frame, a second driving mechanism for driving the mold moving mechanism to walk along the second walking track, a vibration table mechanism arranged at a forming position, and a finished brick bracket arranged at a demolding position; the vibration table mechanism is provided with a supporting platform; and a movable material distribution frame isarranged on the material distribution vehicle, and the swinging material scraping mechanism is arranged on the movable material distribution frame. The supporting-plate-free brick making machine has the advantages that the formed brick transferring speed is high, and the overall brick making efficiency can be improved; and through the arrangement of the swinging material scraping mechanism, the pressing efficiency of the pressure head mechanism can be improved, and the yield of formed bricks can be increased.

Owner:泉州市益鑫机械科技有限公司

Method of automatically replacing steel wire for raw brick cutting machine

ActiveCN104626345AAvoid fatigueImprove brick making efficiencyCeramic shaping apparatusBrickEngineering

The invention provides a method of automatically replacing a steel wire for a raw brick cutting machine. According to the method, when a steel wire rope on a raw brick cutting table meets a replacing condition, a first steel wire rope holding device and a second steel wire rope holding device are controlled to release the steel wire rope, and a second steel wire rope winding shaft is driven to wind until a new steel wire rope is located on the raw brick cutting table; then the first steel wire rope holding device and the second steel wire rope holding device are driven in sequence to tighten the new steel wire rope, and the tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device. By means of the scheme, the raw brick cutting machine can work without stop around the clock, the efficiency of making bricks is greatly improved, and the cost is saved. The tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device, and the new steel wire rope can be tensioned exactly.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

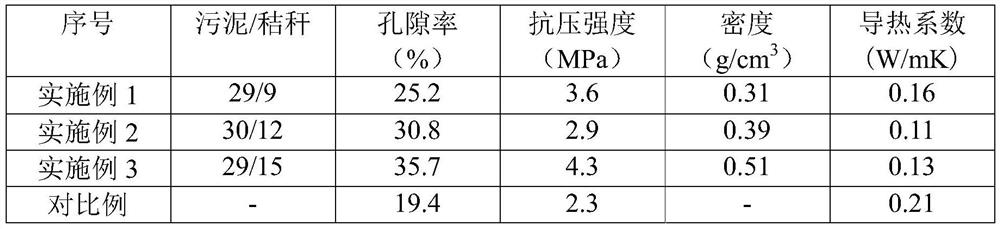

Spherical hole insulating brick and preparation method thereof

InactiveCN111925230ALow priceLow densityCeramic shaping apparatusCeramic materials productionBrickSludge

The invention discloses a spherical hole insulating brick and a preparation method thereof. The spherical hole insulating brick comprises the following raw materials in percentage by mass: 10-25% of riverway sludge, 5-12% of river bank sludge, 3-7% of papermaking waste, 5-11% of ceramsite, 2-12% of glass beads, 2-6% of calcium carbonate, 3-6% of sepiolite, 2-7% of calcium sulfate, 5-20% of straw,2-7% of lime, 2.5-10% of carbon black, 2-8% of sodium citrate, 1-10% of malic acid, 1-5% of a water repellent and 1-12% of a flame retardant. The invention further discloses a preparation method of the spherical hole insulating brick. The preparation method is simple in process, easy to operate, low in raw material price and low in production cost, the obtained insulating brick has low density andhigh strength and insulating performance, and the problems that in the prior art, cost is high, environmental pollution is large, and the insulating brick is poor in performance are effectively solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

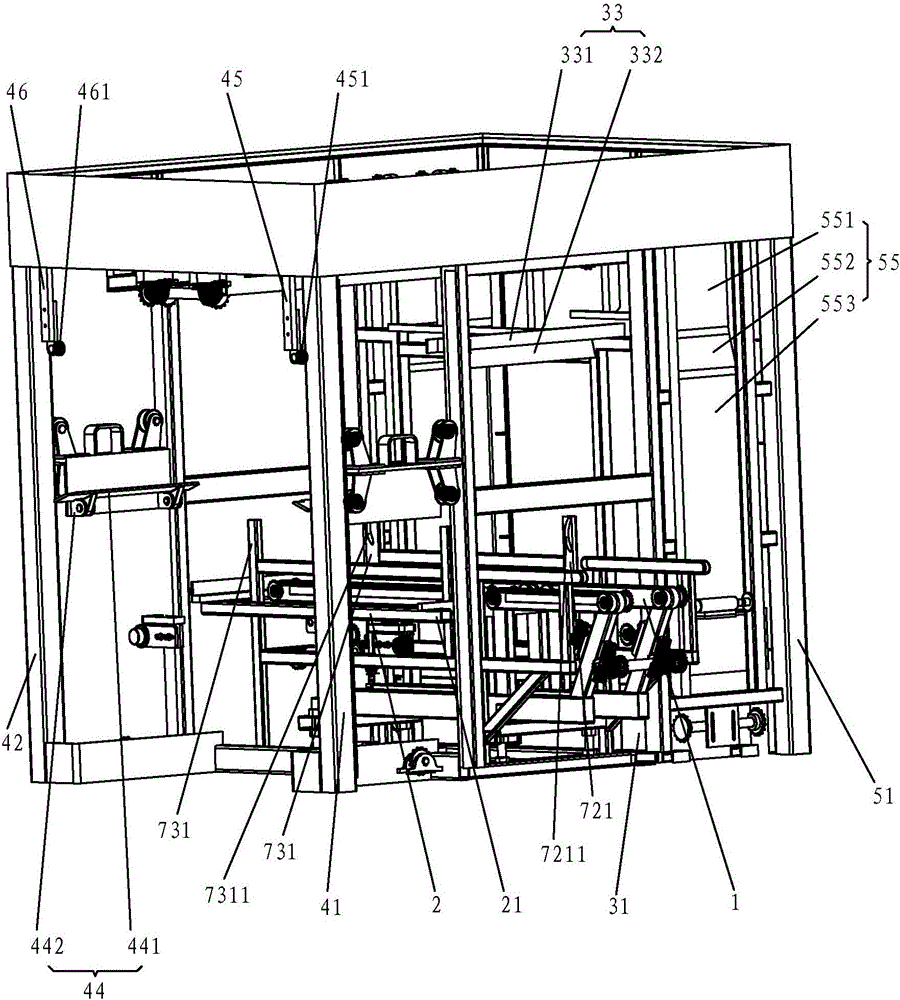

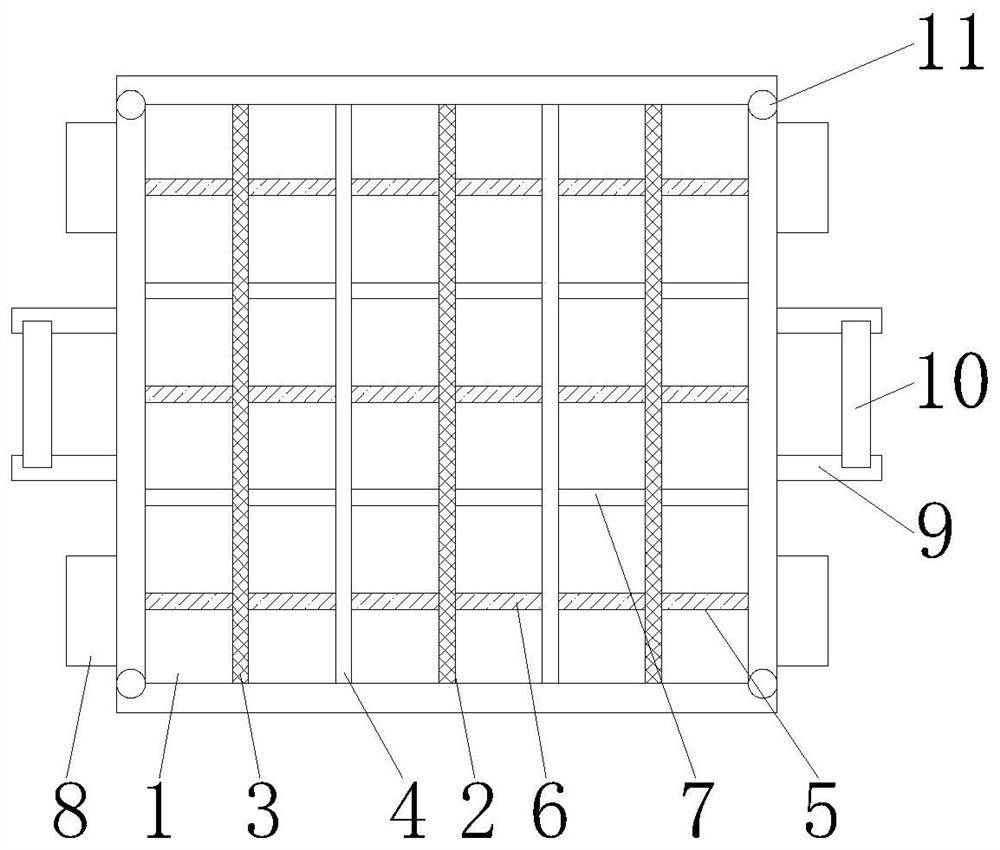

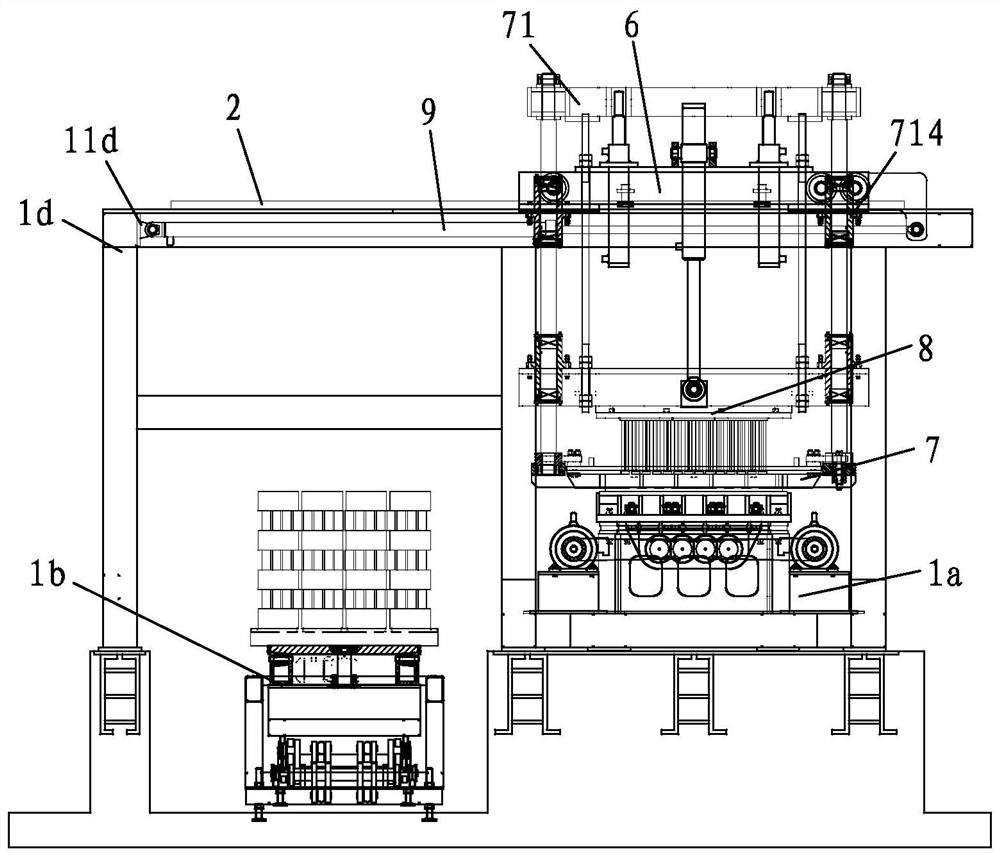

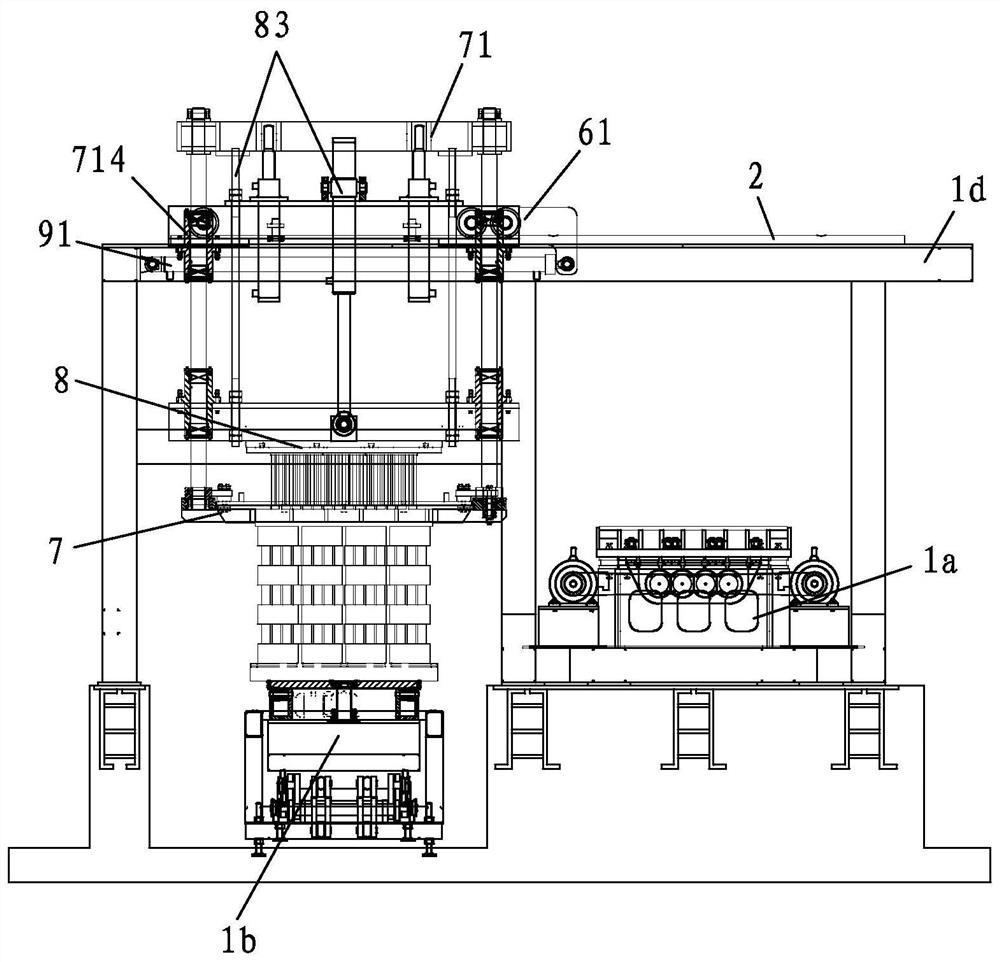

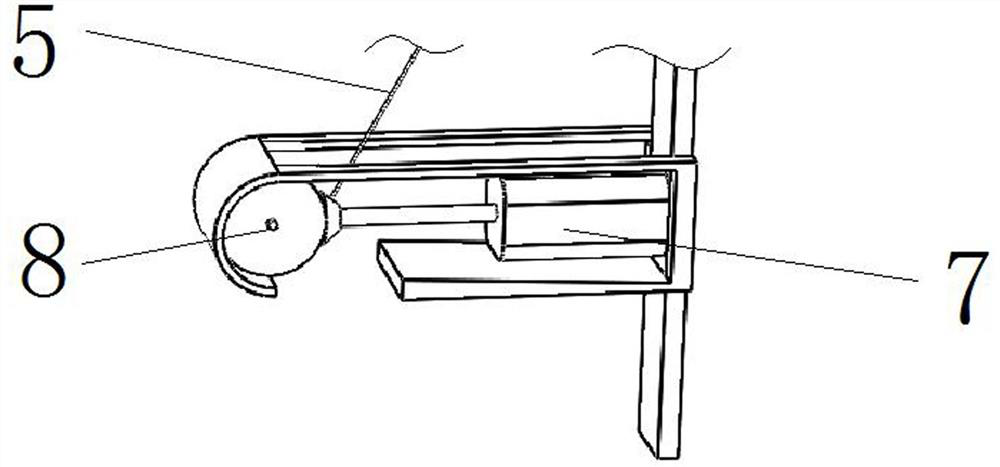

Transfer device for bricks

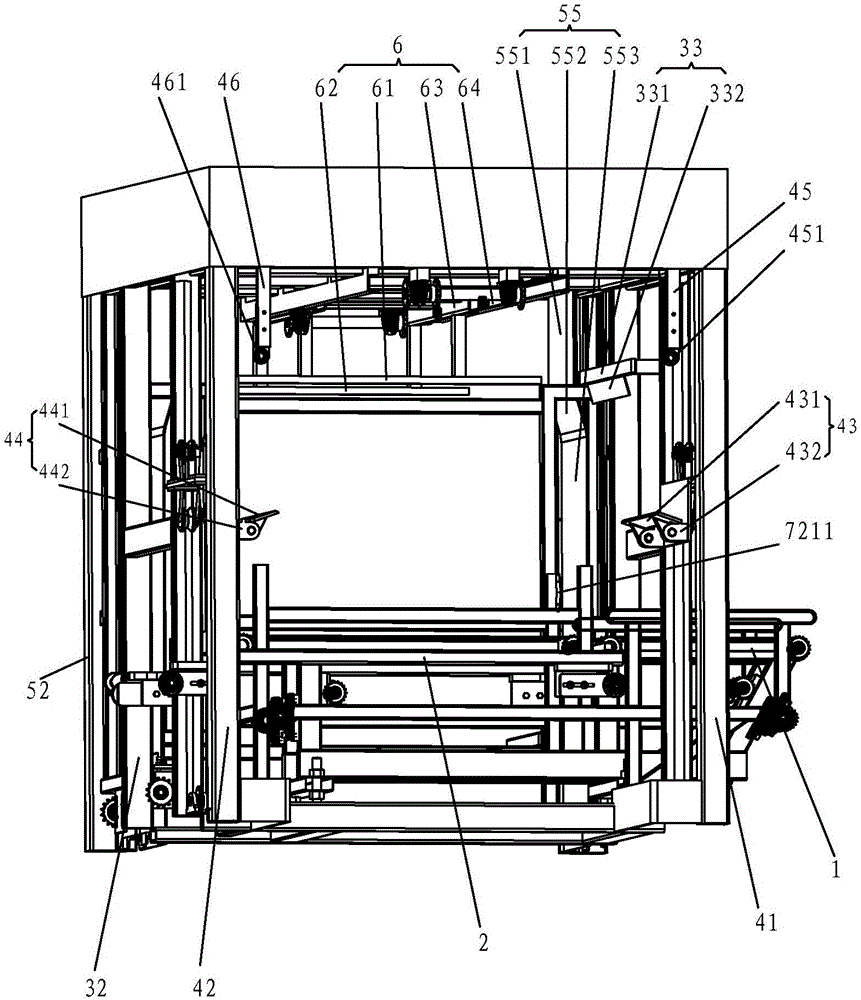

ActiveCN106586575AImprove brick making efficiencyNovel and reasonable structureStacking articlesConveyor partsBrickAssembly line

The invention provides a transfer device for bricks. Structure forms of traditional transfer devices for the bricks are broken through. The transfer device comprises brick loading molds for loading the bricks, a brick conveying device for conveying the brick loading molds, a mold bracket for supporting the brick loading molds, a lifting bearing device for performing lifting bearing on the mold bracket, a setting device for setting the brick loading molds loaded with the bricks, a supply device for supplying the empty brick loading molds as well as a transfer device for transferring the brick loading molds loaded with the bricks onto the setting device and transferring the empty brick loading molds on the supply device onto the lifting bearing device. With the transfer device, assembly line work such as automatic conveying, setting and the like of the brick loading molds can be realized, the brick making efficiency is remarkably improved, and the transfer device is novel and reasonable in structure, smooth, stable and reliable in running and high in practicability.

Owner:福建省东方水泥制品有限公司

Brick making die clamp

ActiveCN104924420ARealize automatic lockingRealize automatic unlockMould fastening meansBrickEngineering

The invention relates to the technical field of building material manufacturing, in particular to a brick making die clamp. The device comprises a bottom plate and locking plates. The bottom plate is of a crossed structure. Four locking plates are arranged and provided with holes respectively. Four extended ends of the bottom plate penetrate through the holes to be connected with the lock plates. The four extended ends of the bottom plate are provided with blocking blocks. Supporting rods are arranged below the four locking plates respectively. The tail ends of the supporting rods are connected with straight rods. The two opposite straight rods are hinged together. The tail ends of all the straight rods are hinged to connection rods respectively. The tail ends of the four connection rods are connected to the same supporting plate. The brick making die clamp has the advantages that automatic locking and unlocking are achieved, the manual locking / unlocking time is saved, and brick making efficiency is improved.

Owner:CHONGQING RUIXUAN HAOBANG NEW BUILDING MATERIAL

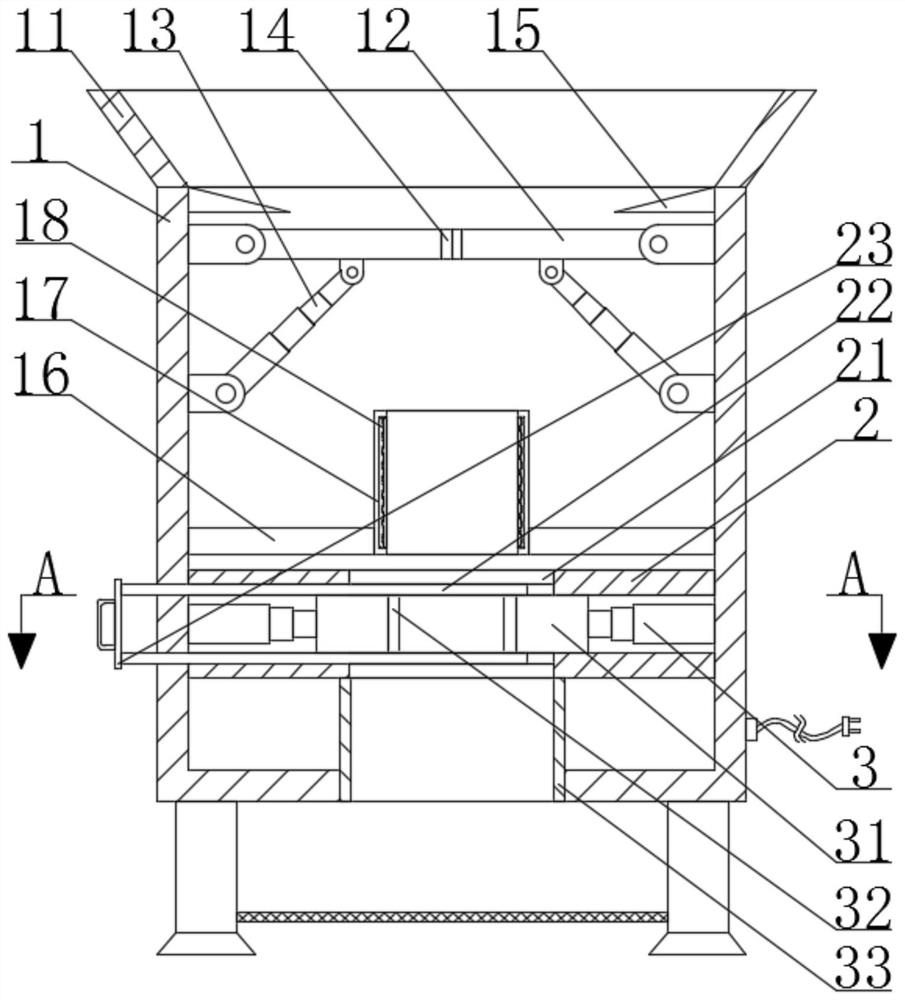

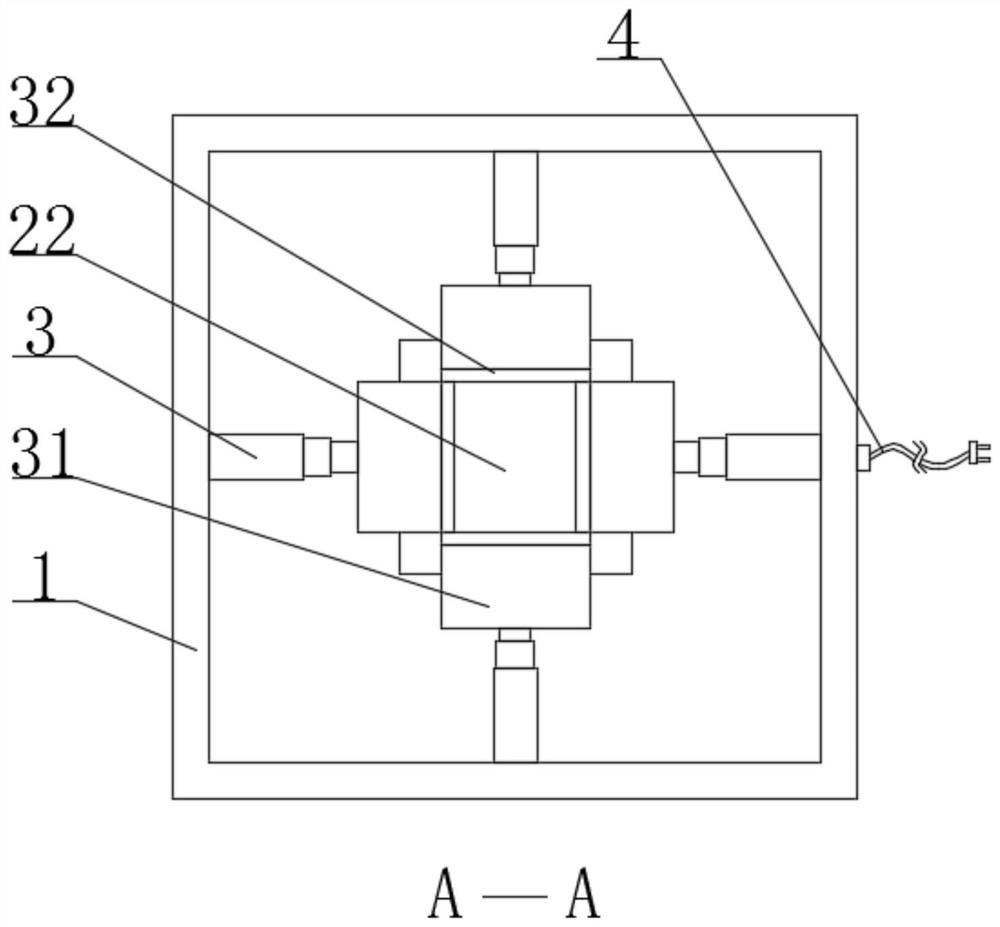

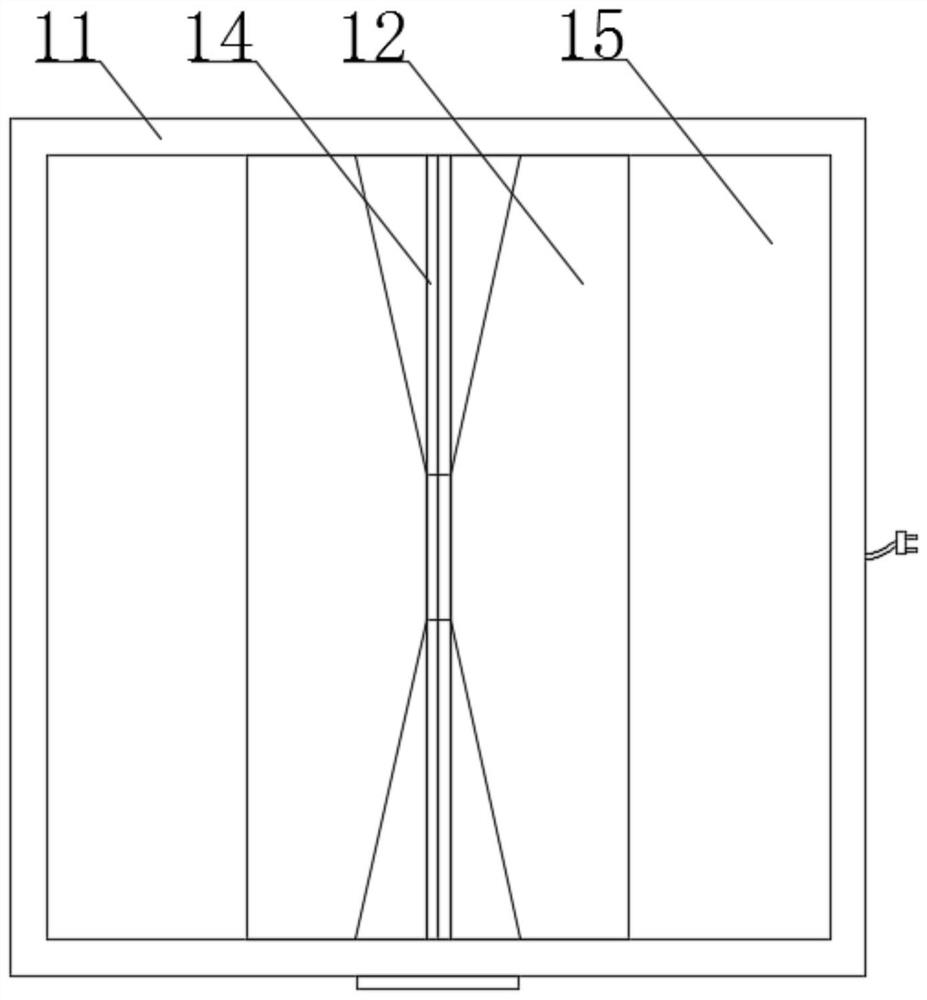

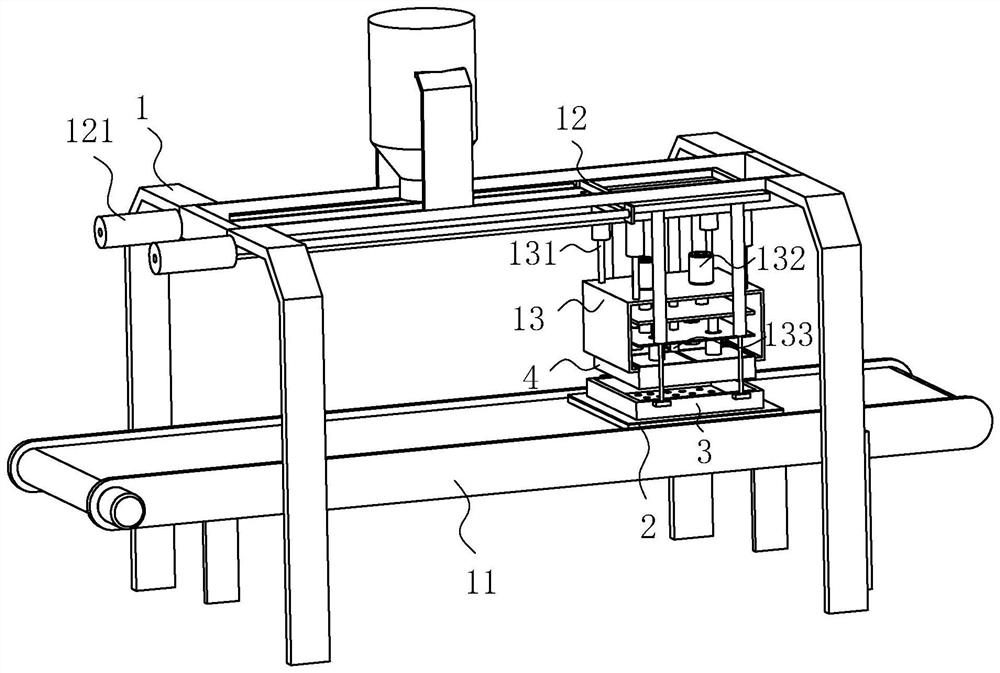

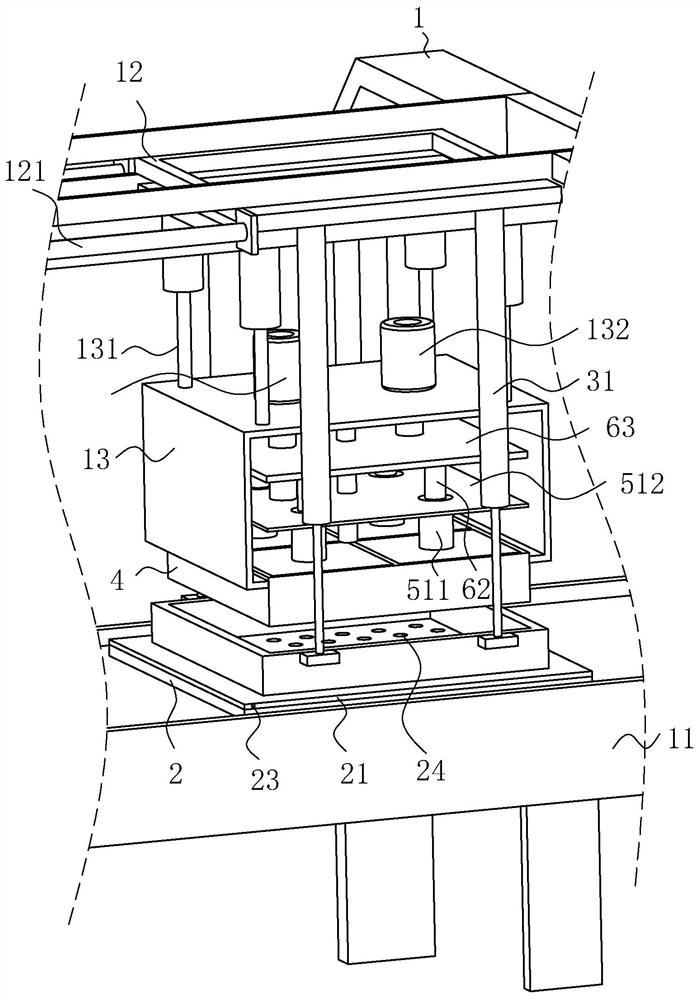

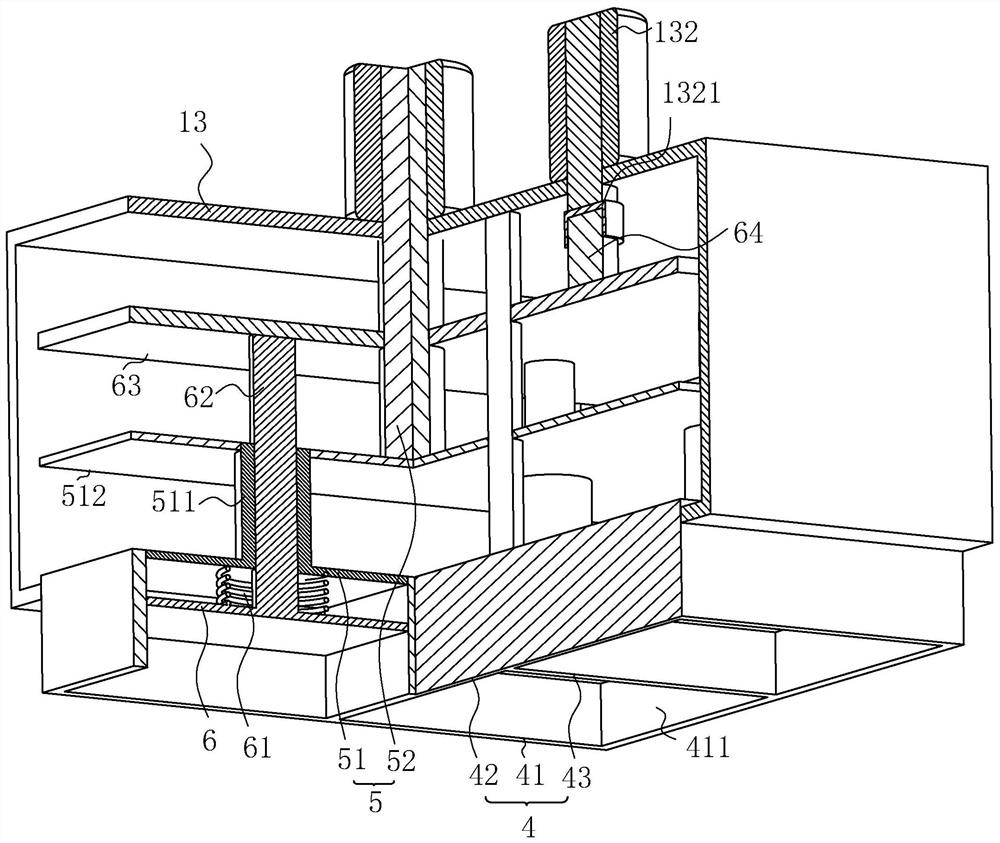

Preparation process of ecological brick taking household garbage incineration slag as raw material

InactiveCN112549252AReduce overexploitationOverexploitation benefitsDischarging arrangementSolid waste managementEnvironmental resource managementBrick

The invention discloses a preparation process of an ecological brick taking household garbage incineration slag as a raw material. The preparation process comprises the following steps of 1, drying, ball-milling and sieving the slag; 2, preparing an aqueous solution of a water strength agent, uniformly stirring the raw materials, and passing through an edge runner mill to prepare a brick raw material; 3, pressing and molding the brick raw material into green bricks by using a green brick molding machine; and 4, moving the green bricks into a steam curing chamber for curing, and then transferring the green bricks into a finished product warehouse for storage so as to obtain ecological brick finished products. The green brick molding machine comprises a feeding part, a pushing part, a molding part, a pressing part, a base and a rack assembly, the pushing part is located on one side of the rack assembly, the feeding part is located above the pushing part, the pressing part is located above the interior of the rack assembly, the molding part is located in the rack assembly, the molding part is located below the pressing part, and the base is located below the molding part. The preparation process solves the problems of low strength and poor durability of the ecological brick prepared from the household garbage incineration slag in the prior art.

Owner:佛山市绿富域环保科技有限公司

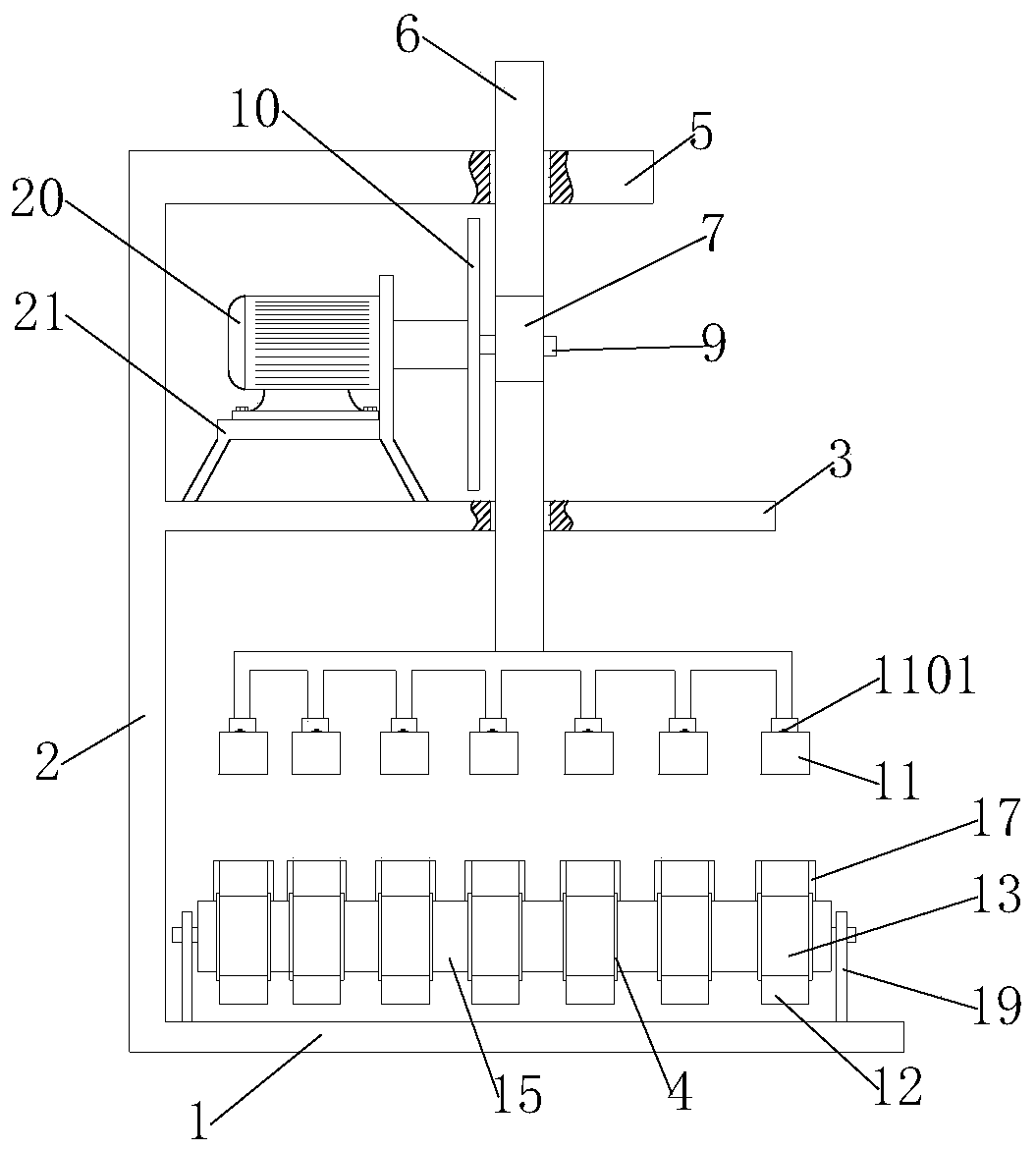

Intelligent brick-making system equipment

ActiveCN110605775AChange the cumbersome wayImprove securityFeeding arrangmentsAuxillary shaping apparatusBrickSelf locking

The invention provides intelligent brick-making system equipment. The equipment comprises a brick-making raw material mixer, a mixing operation platform, a platform building pillar, a supporting base,an intelligent main control integrated machine, a platform operation protective fence, a pipe for discharging the mixed brick-making raw material, a discharge electromagnetic control valve, a mobileclimbing ladder, an auxiliary flattening cylinder, a flattening slab, a brick-making mold, a brick-making shaking table, a rotatable self-lifting self-locking machine structure, a slidable self-controlling raw material lifting bucket structure, a quantity controllable type raw material filtering and vibrating bucket structure, a heat-dissipative dust-proof spraying branch pipe structure and a self-moving brick lead-out wheel structure, wherein the brick-making raw material mixer is bolted at the upper right middle position of the mixing operation platform. Through the arrangement of a liftingrope, an I-shaped storage wheel and a self-locking reduction motor, the cumbersome way of lifting raw materials of an original crane is changed. The self-locking reduction motor is used for lifting the rope, so that good self-locking effect can be achieved, and the security is improved.

Owner:DEZHOU TIANYUAN GRP

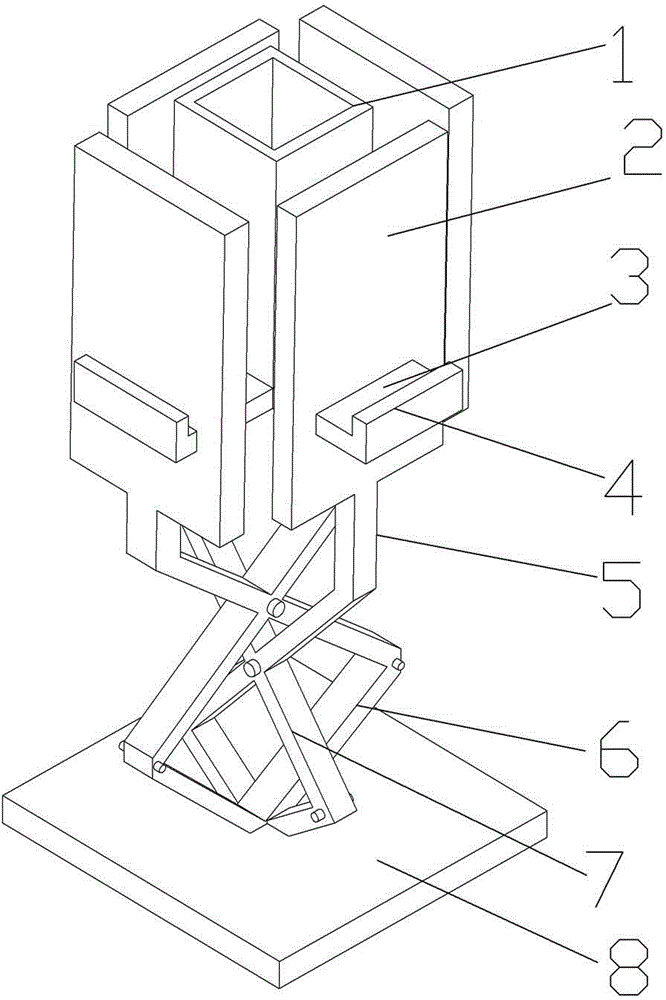

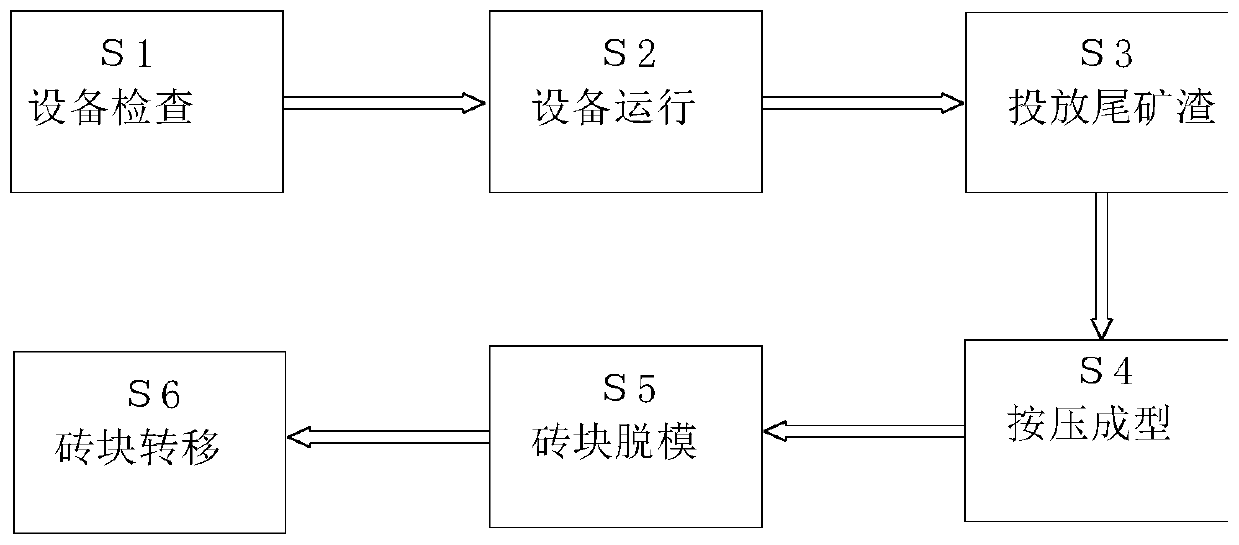

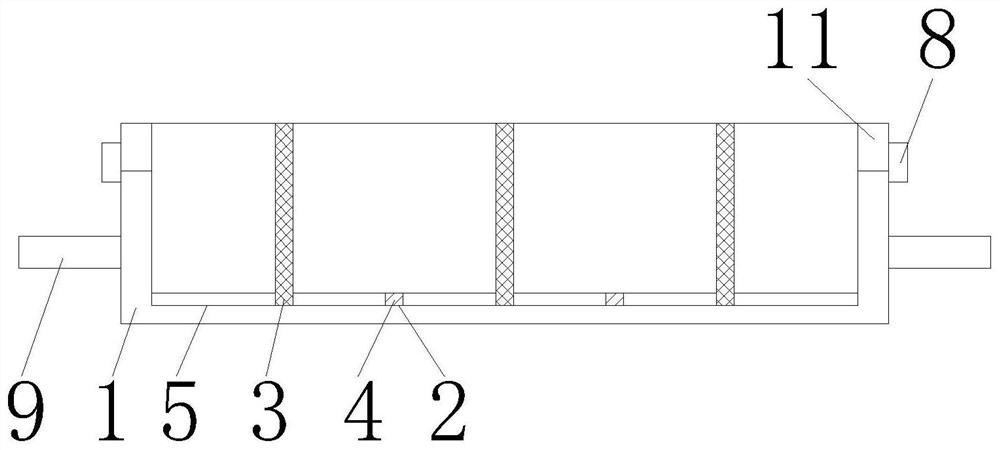

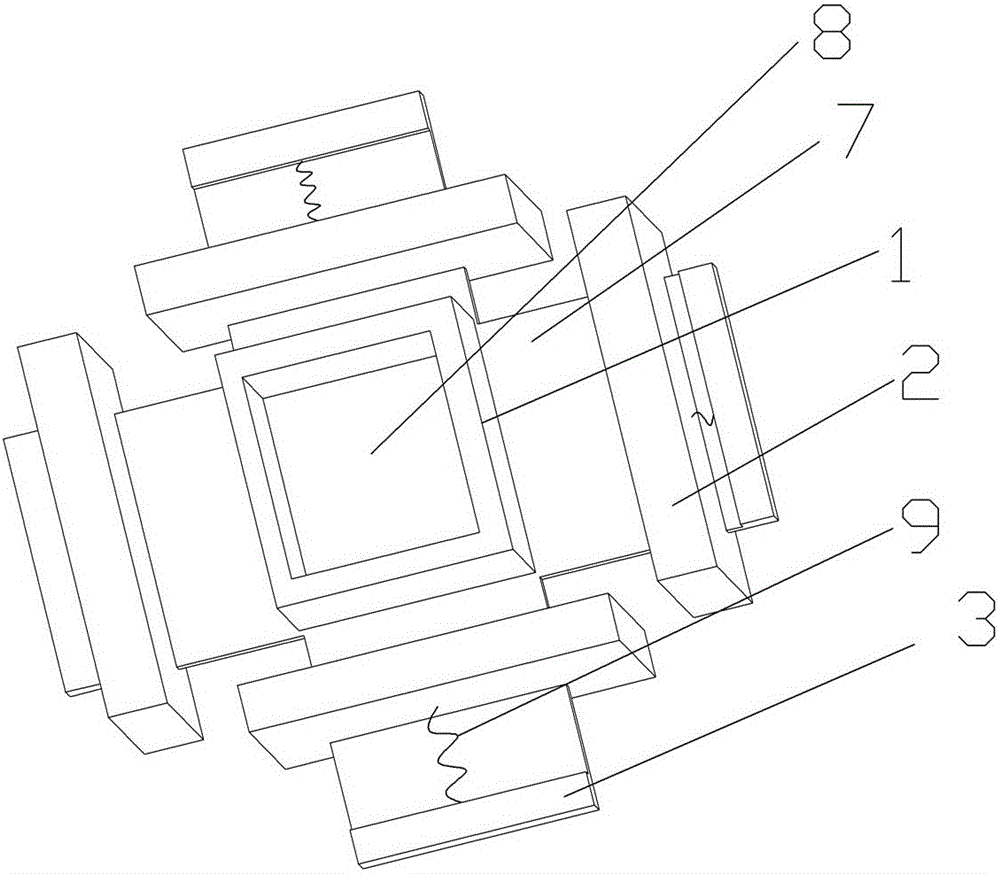

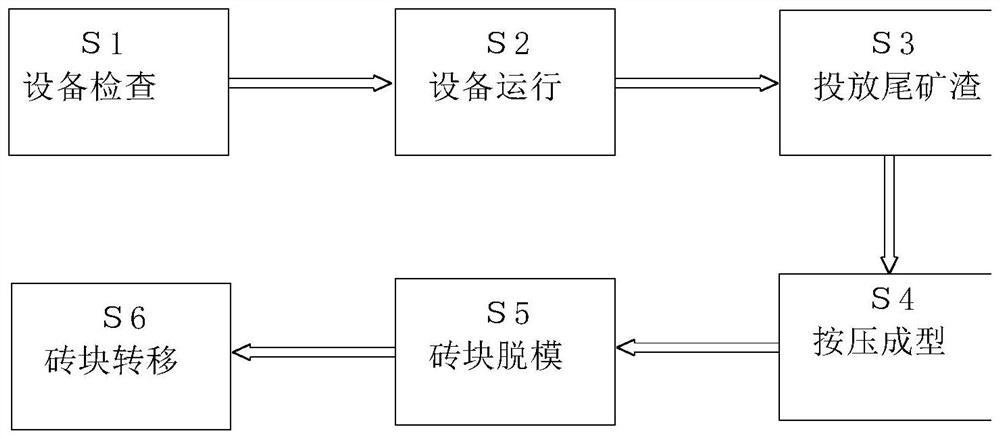

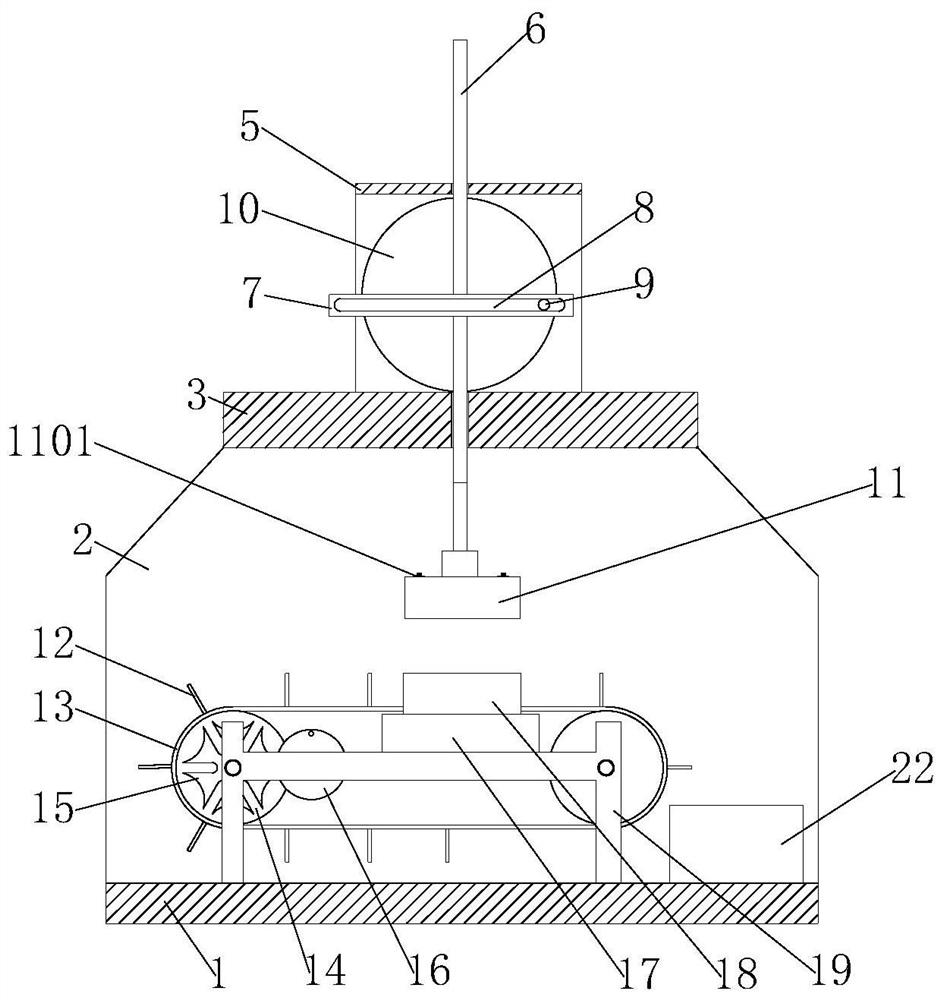

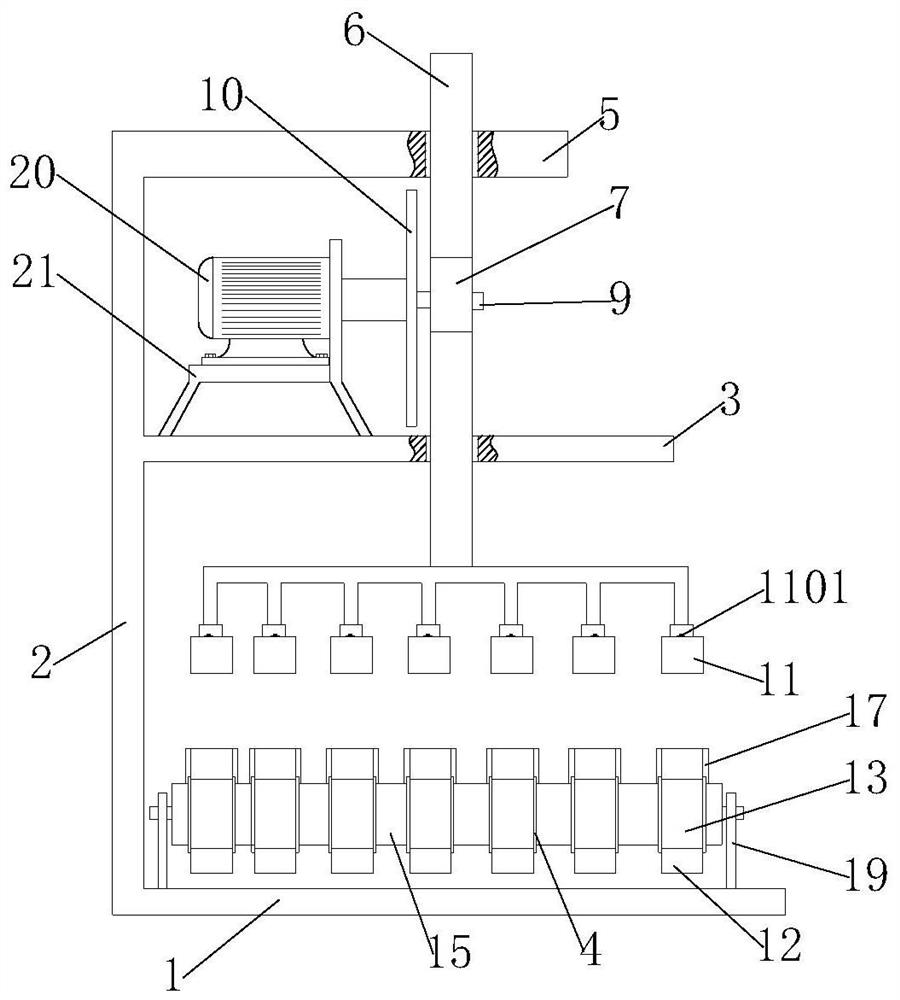

Method for re-utilizing tailing slag to manufacture building material refractory block

ActiveCN111267205AImprove brick making efficiencyIncrease productivityDischarging arrangementShaping press ramSlagArchitectural engineering

The invention discloses a method for re-utilizing tailing slag to manufacture a building material refractory block and relates to the technical field of energy manufacturing. A tailing slag refractoryblock manufacturing device which comprises a bottom support plate and a lifting shaft, wherein the bottom support plate is horizontally fixed on the ground; a support ribbed plate erected at the topend of the bottom support plate is fixed at the top end of the bottom support plate; a first transverse beam plate horizontally fixed is arranged in the middle of the support ribbed plate; a second transverse beam plate parallel with the first transverse beam plate is arranged at the top end of the support ribbed plate; and a penetrating circular hole is formed in the middle of each of the secondtransverse beam plate and the first transverse beam plate. Support blocks horizontally fixed are mounted in the middles of rollers on the two sides, are arranged on the inner ring of a conveyor belt,and are fixed in the middles of the top ends of roller brackets, so that when a pressing block is pressed downwards, the support blocks support the top surface of the conveyor belt, and the conveyor belt serves as the bottom surface of a cavity to be supported in a steadier and firmer manner.

Owner:罗田国盛物资有限公司

An operation method for making bricks by using a carbon dioxide carbonization device

The invention discloses an operation method for making a brick body by using a carbon dioxide carbonization device, and belongs to the field of civil engineering brick making. In the present invention, two processes of pre-carbonization and secondary carbonization are ad hoc, and after temporarily stabilizing the shape and strength of the brick body, demoulding and rapid strength growth are successfully completed. All systems in the device work in an orderly manner according to this method, so that loading, compaction and brick mold transmission are carried out at the same time, and brick materials are added and mixed in the pre-carbonization process, which greatly improves the brick production and transmission efficiency; up and down The conveyor belt rotates through the rotating shaft, and the brick body is demoulded through the spring stopper in the brick mould, and is absorbed and released by the electromagnet and conveyed by the conveyor belt, so as to realize the demoulding of the brick body and the efficient recycling of the empty brick mould. This brick-making method utilizes low-concentration carbon dioxide and construction waste. After carbonization, the carbon dioxide in the carbonization chamber can be pumped into the storage bin by the exhaust fan, and the carbon dioxide gas can be recycled to reduce tail gas emissions, which is beneficial to environmental protection and reduces production costs. brick cost.

Owner:NANJING FORESTRY UNIV

A slag brick-making device for domestic waste incineration power plant

InactiveCN110281354BEffective limit protectionEfficient manufacturingFeeding arrangmentsAuxillary shaping apparatusBrickPower station

The invention discloses a furnace clinker brickmaking forming device of a household waste incineration power plant. The device comprises a fixing seat, a limit plate and supporting columns. Through a limit hood arranged above the fixing seat, the collected furnace clinker input range is effectively expanded; in addition, through guide plates arranged on the two sides of the interior of the fixing seat, electric push rods drive a conveying plate inside the portion, located below the guide plates, of the fixing seat, and thus, a limit and guide effect can be achieved effectively through a guide groove formed above the conveying plate when furnace clinker is input; the furnace clinker brickmaking forming device can be used for effectively limiting and protecting the furnace clinker when the furnace clinker is obtained, the furnace clinker dripping and scattering situation is effectively avoided, and the purposes that the environment is protected and resources are utilized to the maximum extent are effectively achieved; and in addition, through connecting blocks and pressing plates which are arranged inside the fixing seat through electrohydraulic push rods, bricks with various length sizes can be effectively manufactured, and the requirements for sizes of users during brick manufacturing are met.

Owner:DATANG YUNCHENG POWER GENERATION CO LTD

Intelligent brick making system equipment

ActiveCN110605775BChange the cumbersome wayImprove securityFeeding arrangmentsAuxillary shaping apparatusBrickElectric machinery

The invention provides intelligent brick-making system equipment. The equipment comprises a brick-making raw material mixer, a mixing operation platform, a platform building pillar, a supporting base,an intelligent main control integrated machine, a platform operation protective fence, a pipe for discharging the mixed brick-making raw material, a discharge electromagnetic control valve, a mobileclimbing ladder, an auxiliary flattening cylinder, a flattening slab, a brick-making mold, a brick-making shaking table, a rotatable self-lifting self-locking machine structure, a slidable self-controlling raw material lifting bucket structure, a quantity controllable type raw material filtering and vibrating bucket structure, a heat-dissipative dust-proof spraying branch pipe structure and a self-moving brick lead-out wheel structure, wherein the brick-making raw material mixer is bolted at the upper right middle position of the mixing operation platform. Through the arrangement of a liftingrope, an I-shaped storage wheel and a self-locking reduction motor, the cumbersome way of lifting raw materials of an original crane is changed. The self-locking reduction motor is used for lifting the rope, so that good self-locking effect can be achieved, and the security is improved.

Owner:DEZHOU TIANYUAN GRP

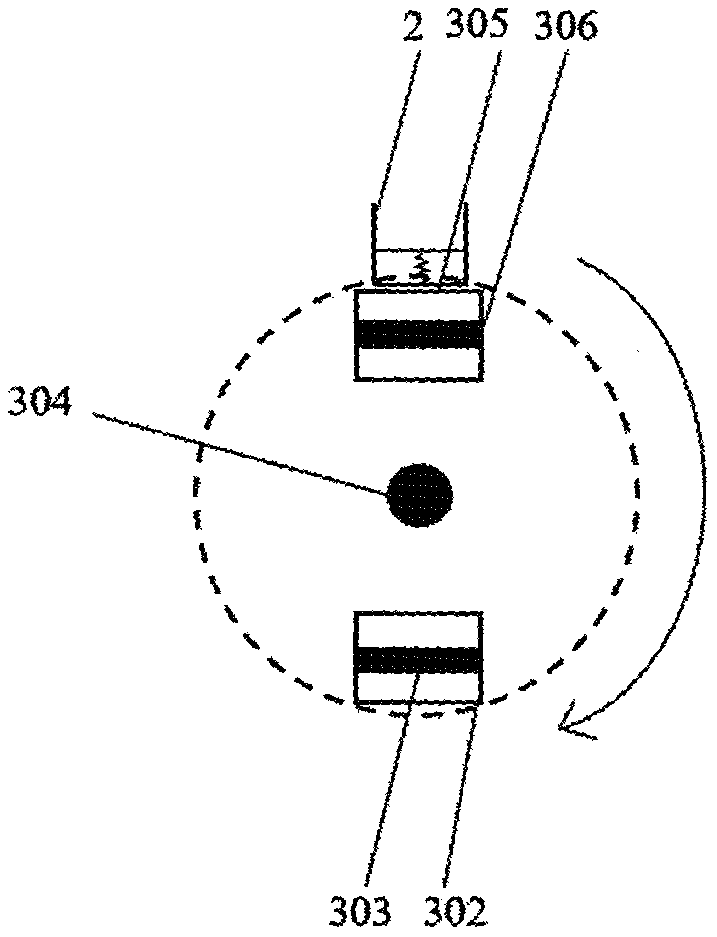

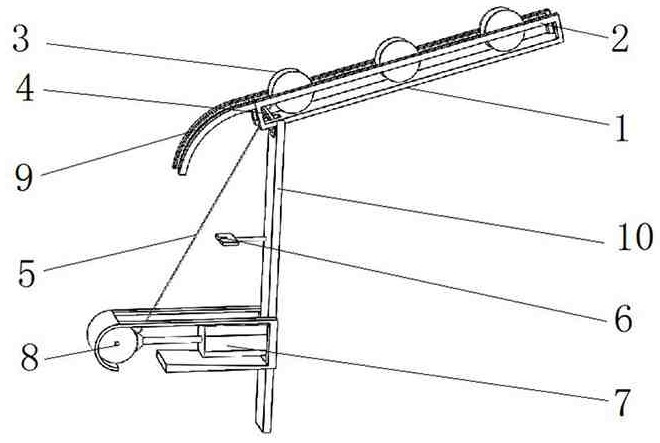

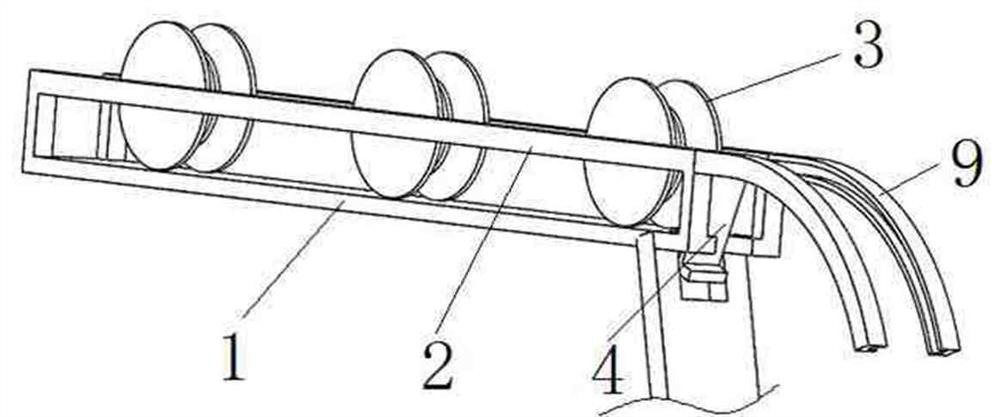

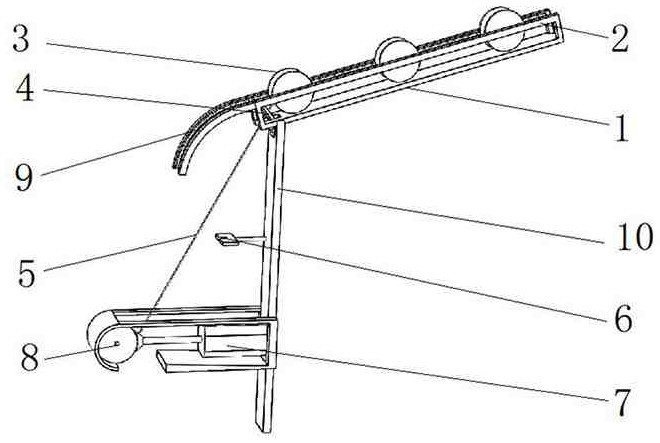

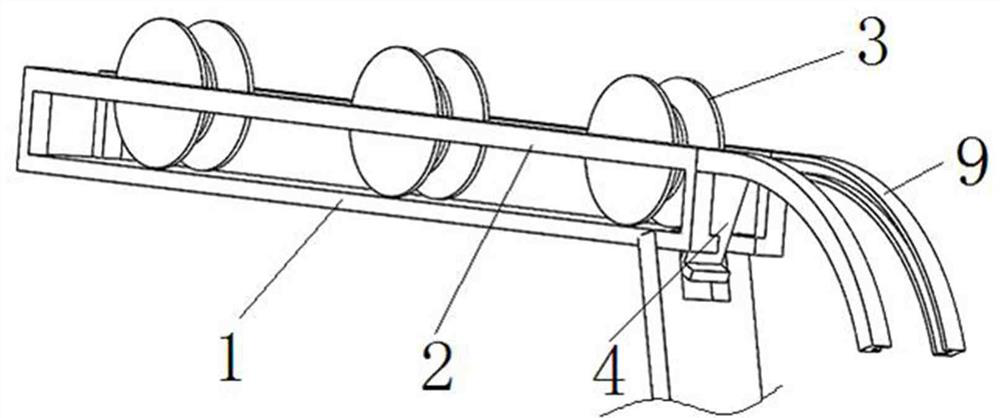

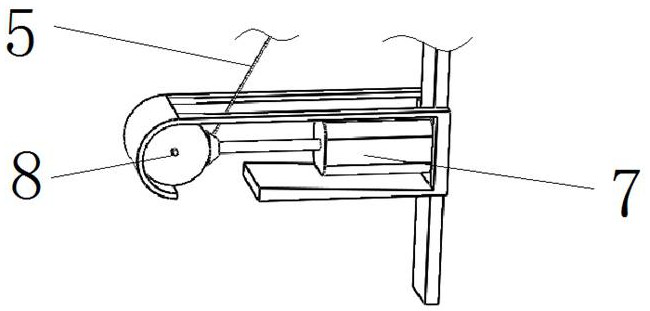

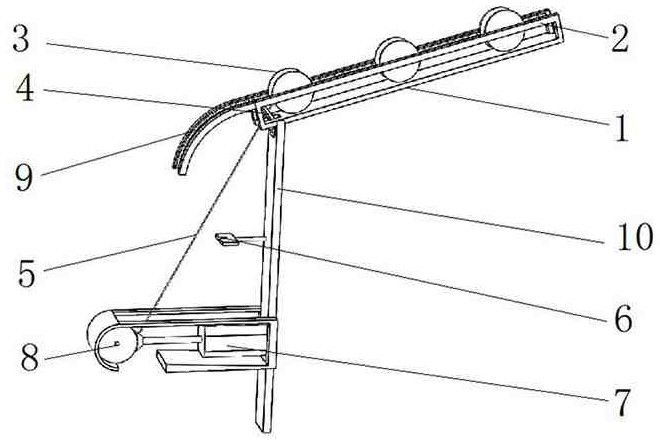

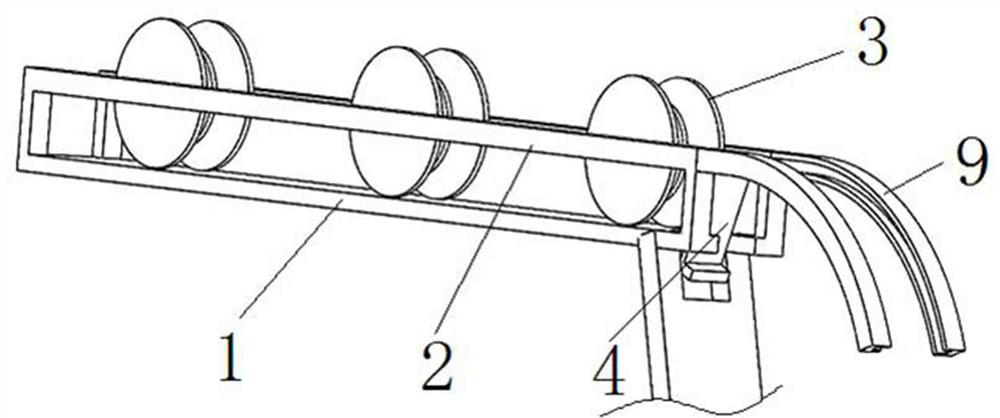

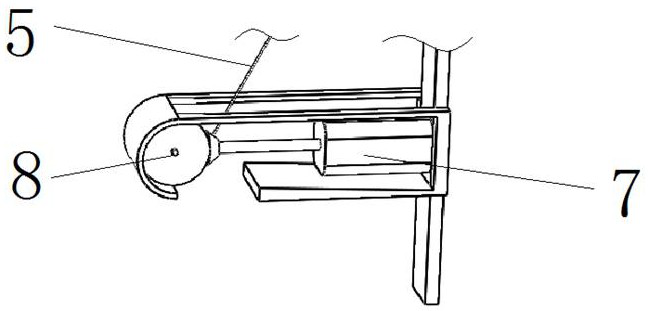

A method for intelligently exchanging billet steel wire

ActiveCN111775289BReduce labor intensityNo manual operationAuxillary shaping apparatusBrickWire wheel

The invention belongs to the technical field of brick and tile production equipment. The invention discloses an intelligent method for exchanging billet steel wires, including the following process: S1. Pneumatic stopper blocks the leftmost upper wire wheel, pneumatic clamp clamps the lower wire wheel, infrared The sensing device detects the state of the steel wire between the upper wire wheel and the lower wire wheel in real time; S2, the infrared sensing device detects that the steel wire is broken; S3, the pneumatic stopper and pneumatic clamp will be released at the same time, and the lower wire wheel will fall and be discarded. The upper wire wheel on the side slides down to the position of the lower wire wheel along the pre-stored track and the guide track; the second upper wire wheel on the left on the pre-stored track slides to the position of the leftmost upper wire wheel at the beginning; at this time, the pneumatic The stopper and the pneumatic clamp are clamped simultaneously, and the steel wire is straightened again. The device or method for intelligently exchanging blank cutting steel wires of the present invention realizes intelligent steel wire replacement without manual operation, and can realize 24-hour uninterrupted work of the blank cutting machine, thereby greatly improving brick-making efficiency and saving brick-making costs.

Owner:江苏科磊半导体有限公司

A sidewalk cement brick forming device for reprocessing raw materials

ActiveCN112265128BShorten production timeReduce manufacturing costDischarging arrangementMouldsBrickMechanical engineering

Owner:深圳市天健坪山建设工程有限公司

Method for Automatically Changing Steel Wires of Blank Cutting Machine

ActiveCN104626345BAvoid fatigueImprove brick making efficiencyCeramic shaping apparatusBrickEngineering

The invention provides a method of automatically replacing a steel wire for a raw brick cutting machine. According to the method, when a steel wire rope on a raw brick cutting table meets a replacing condition, a first steel wire rope holding device and a second steel wire rope holding device are controlled to release the steel wire rope, and a second steel wire rope winding shaft is driven to wind until a new steel wire rope is located on the raw brick cutting table; then the first steel wire rope holding device and the second steel wire rope holding device are driven in sequence to tighten the new steel wire rope, and the tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device. By means of the scheme, the raw brick cutting machine can work without stop around the clock, the efficiency of making bricks is greatly improved, and the cost is saved. The tightening motion of the first steel wire rope holding device is 0.05 s to 0.5 s earlier than the tightening motion of the second steel wire rope holding device, and the new steel wire rope can be tensioned exactly.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Brick Mould Clamping Device

ActiveCN104924421BShorten the timeImprove brick making efficiencyMould fastening meansBrickEngineering

The invention relates to the technical field of building material manufacturing, in particular to a brick making die clamping device. The device comprises a bottom plate and locking plates. The bottom plate is of a crossed structure. Four locking plates are arranged and provided with holes respectively. Four extended ends of the bottom plate penetrate through the holes to be connected with the lock plates. The four extended ends of the bottom plate are provided with blocking blocks. Springs are arranged between the blocking blocks and the locking plates. Supporting rods are arranged below the four locking plates respectively. The tail ends of the supporting rods are provided with connection rods hinged to the supporting rods. The center of the bottom plate is provided with an opening. A straight rod is arranged in the opening. The lower end of the straight rod is hinged to the four connection rods. The upper end of the straight rod is provided with a supporting plate. The brick making die clamping device has the advantages that automatic locking can be achieved through the gravity of a die, automatic unlocking can be achieved by upwards pushing the straight rod, the manual locking / unlocking time is saved, and brick making efficiency is improved.

Owner:CHONGQING RUIXUAN HAOBANG NEW BUILDING MATERIAL

A method for making building material bricks by reusing tailings slag

ActiveCN111267205BImprove brick making efficiencyIncrease productivityDischarging arrangementShaping press ramBrickArchitectural engineering

The invention discloses a method for re-utilizing tailing slag to manufacture a building material refractory block and relates to the technical field of energy manufacturing. A tailing slag refractoryblock manufacturing device which comprises a bottom support plate and a lifting shaft, wherein the bottom support plate is horizontally fixed on the ground; a support ribbed plate erected at the topend of the bottom support plate is fixed at the top end of the bottom support plate; a first transverse beam plate horizontally fixed is arranged in the middle of the support ribbed plate; a second transverse beam plate parallel with the first transverse beam plate is arranged at the top end of the support ribbed plate; and a penetrating circular hole is formed in the middle of each of the secondtransverse beam plate and the first transverse beam plate. Support blocks horizontally fixed are mounted in the middles of rollers on the two sides, are arranged on the inner ring of a conveyor belt,and are fixed in the middles of the top ends of roller brackets, so that when a pressing block is pressed downwards, the support blocks support the top surface of the conveyor belt, and the conveyor belt serves as the bottom surface of a cavity to be supported in a steadier and firmer manner.

Owner:罗田国盛物资有限公司

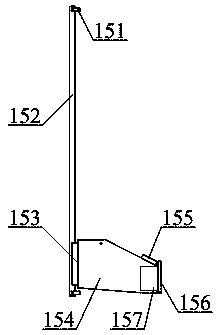

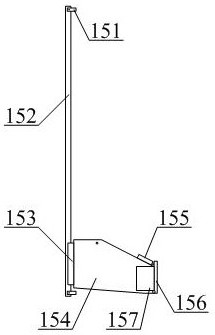

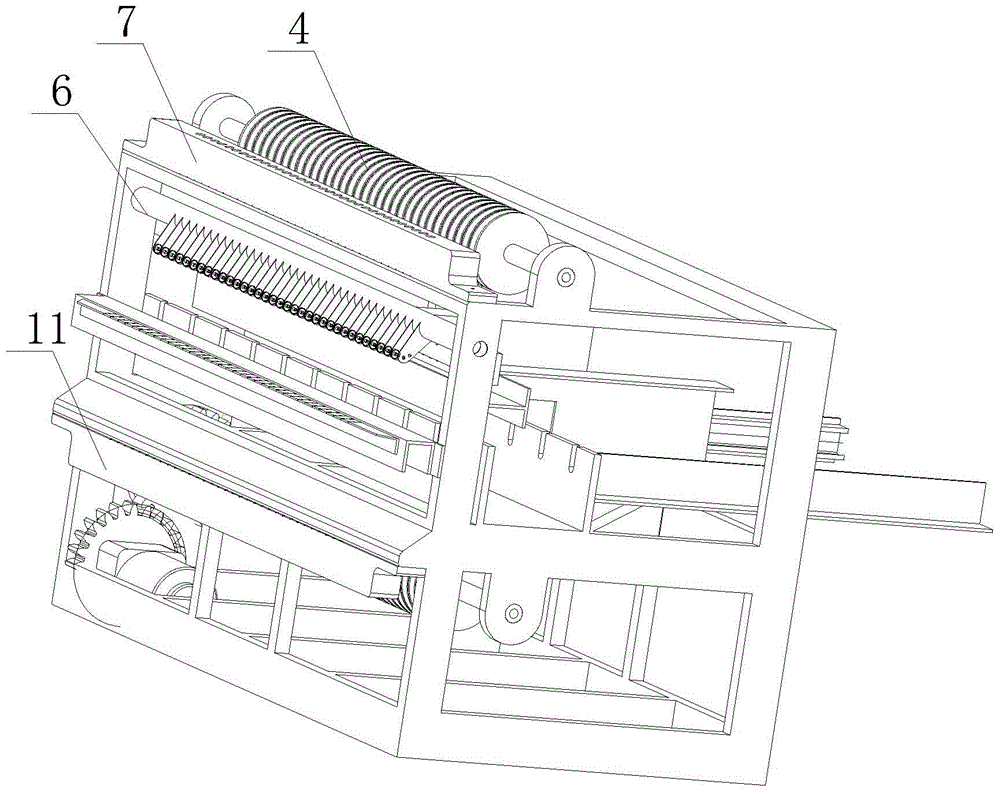

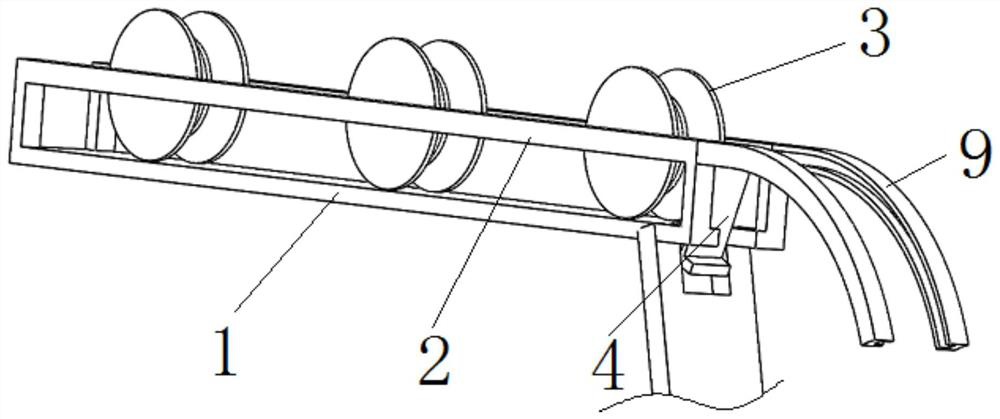

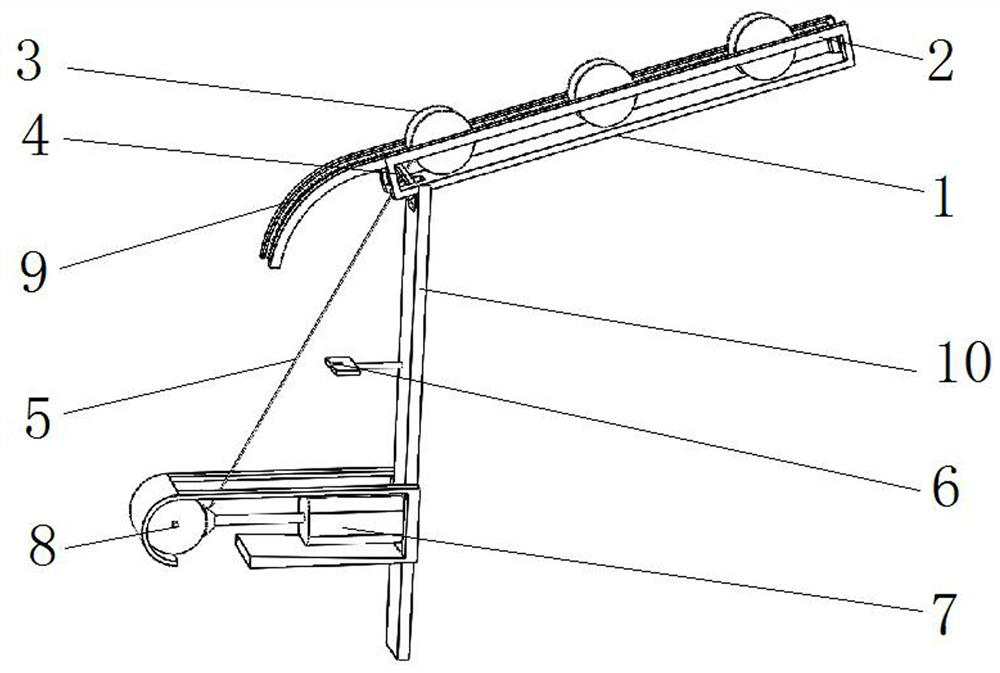

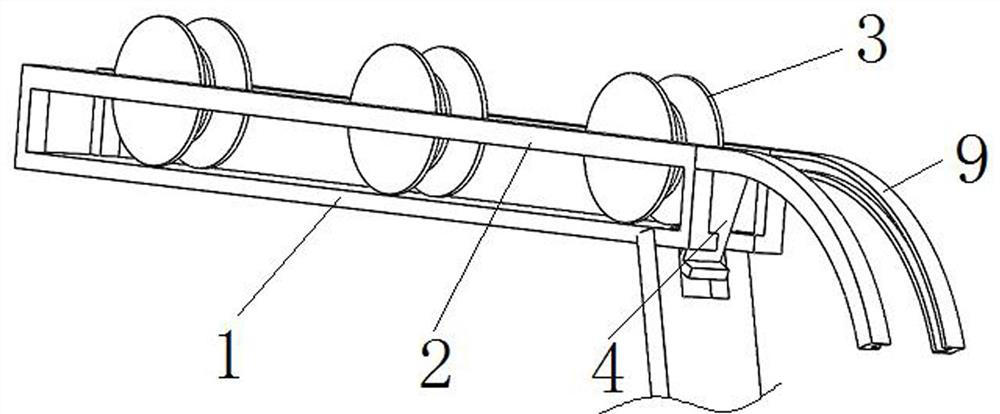

Smart device for steel wire exchanging and cutting

ActiveCN111775291AImprove brick making efficiencyReduce the cost of brick makingAuxillary shaping apparatusFixed frameElectrical and Electronics engineering

The invention relates to the technical field of brick and tile production devices. The invention discloses a smart device for steel wire exchanging and cutting. The device comprises a vertical fixed frame, a cutting rack, a pre-stored track, a plurality sets of upper wire wheels, a limit mechanism, a wire, a sensing device, a clamping mechanism and a lower wire wheel. The pre-stored track is fixedly connected with the upper of the cutting rack. The upper wire wheels are arranged on the pre-stored track. The limit mechanism is arranged at the leftmost of the pre-stored track, and limits a leftmost upper wire wheel. The lower wire wheel is clamped at the front end of the clamping mechanism. The sensing device is fixed to the vertical fixed frame and arranged at the upper end of the clampingmechanism. The sensing device is used to detect whether the wire between the upper wire wheels and the lower wire wheel is broken. The smart device for steel wire exchanging and cutting without manualoperation can realize the intelligent exchanging of steel wires, and can realize the 24-hour uninterrupted work of the cutting device. Therefore, the brick production efficiency is greatly improved and the brick production cost is saved.

Owner:NANTONG UNIVERSITY

Flip-flop forming machine for heat preservation building module blocks

InactiveCN101049712BEasy to manufactureEasy to useCeramic shaping apparatusHydraulic cylinderEngineering

A turning-over and shaping machine for manufacturing the insulating building blocks with different shapes is composed of a feeding unit, a material pressing unit, a turnover mould unit and a demoulding unit. The turnover mould of said turnover mould unit is driven by master motor via master chain to move on track to the material pressing unit and demoulding unit. The movable feeding box is drivenby the feeding hydraulic cylinder and the hydraulic cylinder of base plate to the material pressing unit. Said turnover mould is turned over on its holder.

Owner:付振顶

Automatic replacing equipment for blank cutting steel wire

ActiveCN113370364ANo manual operationImprove brick making efficiencyAuxillary shaping apparatusBrickWire wheel

The invention belongs to the technical field of brick and tile production equipment, and discloses automatic replacing equipment for a blank cutting steel wire. The equipment comprises a vertical fixing frame, a blank cutting rack, a pre-storage track, a plurality of sets of upper steel wire wheels, a limiting mechanism, a steel wire, a sensing device, a clamping mechanism and a lower steel wire wheel. The pre-storage track is fixedly connected to the upper portion of the blank cutting rack, the several sets of upper steel wire wheels are placed on the pre-storage track, and the limiting mechanism is arranged at the leftmost position of the pre-storage track and limits the leftmost upper steel wire wheel. The lower steel wire wheel is clamped at the front end part of the clamping mechanism. The sensing device is fixed to the vertical fixing frame and arranged at the upper end of the clamping mechanism. The sensing device is used for detecting whether the steel wire between the upper steel wire wheels and the lower steel wire wheel is broken or not. According to the automatic replacing equipment for the blank cutting steel wire, manual operation is not needed, intelligent steel wire replacing is achieved, 24-hour uninterrupted work of a green brick cutting machine can be achieved, and therefore the brick making efficiency is greatly improved, and the brick making cost is saved.

Owner:NANTONG UNIVERSITY

Brick making method for sludge of sewage treatment plant

InactiveCN106673612ATake advantage ofImprove solubilitySludge treatmentSpecific water treatment objectivesBrickSound energy density

The invention relates to a brick making method for sludge of a sewage treatment plant. The method comprises the steps: (1) subjecting the sludge of the sewage treatment plant to ultrasonic wave radiation for 30 to 90 minutes, wherein the sound energy density of ultrasonic waves is 0.5w / mL to 3w / mL; (2) mixing the radiated sludge, coal cinder, crushed construction waste and wood sawdust according to the volume ratio of 10: 5: 3: 1, and carrying out stirring, so as to obtain a brick making raw material; (3) preparing unburnt bricks from the brick making raw material through die pressing; (4) roasting the unburnt bricks at the roasting temperature of 700 DEG C to 800 DEG C under the condition that the degree of vacuum is smaller than 0.1, thereby obtaining finished bricks. The method is not only environmentally friendly, but also is high in brick making efficiency.

Owner:SUZHOU TANGSHI MACHINERY MFG

A brick production equipment for recycling construction waste

ActiveCN113001733BImprove brick making efficiencyEvenly distributedFeeding arrangmentsBrickConveyor belt

The application relates to the field of brick production equipment, and specifically discloses a brick production equipment for recycling construction waste, which includes a body, the body is provided with a conveyor belt and a forming device, and the forming device includes a bottom plate, a pouring frame, and a cutting die, The bottom plate is placed on the upper surface of the conveyor belt, and the casting frame is placed above the bottom plate. In connection, the outer wall of the cutting die can abut against the inner wall of the casting frame. The present application has the effect of improving brick-making efficiency.

Owner:深圳市宏恒星再生科技有限公司

An intelligent device for changing and cutting steel wire

ActiveCN111775291BNo manual operationImprove brick making efficiencyAuxillary shaping apparatusBrickWire wheel

The invention belongs to the technical field of brick and tile production equipment. The invention discloses an intelligent device for exchanging billet-cutting steel wires, which includes a vertical fixing frame, a billet-cutting frame, pre-stored tracks, several groups of upper wire wheels, a limit mechanism, steel wires, induction device, clamping mechanism and lower steel wire wheel; the pre-storage track is fixedly connected above the billet cutting frame, several sets of upper steel wire wheels are placed on the pre-storage track, and the limit mechanism is set at the leftmost position of the pre-storage track and the leftmost The upper steel wire wheel is used to limit the position; the lower steel wire wheel is clamped at the front end of the clamping mechanism; the sensing device is fixed on the vertical fixing frame and placed at the upper end of the clamping mechanism, and the sensing device is used to detect the upper wire wheel and the lower Whether the wire between the wire wheels is broken. The intelligent steel wire changing device of the present invention realizes intelligent steel wire changing without manual operation, and realizes the 24-hour uninterrupted work of the blank cutting machine, thereby greatly improving brick-making efficiency and saving brick-making costs.

Owner:NANTONG UNIVERSITY

A pallet-free brick making machine

ActiveCN112339102BImprove compression efficiencyImprove yield rateDischarging arrangementFeeding arrangmentsBrickTransfer mechanism

The invention provides a pallet-free brick making machine, which comprises a first traveling track, a second traveling track, a distribution vehicle arranged on the first traveling track, and a first driving mechanism for driving the distribution vehicle to travel along the first traveling track , the swing scraping mechanism set on the distribution car, the mold moving mechanism set on the second walking track, the brick forming mold frame set on the mold moving mechanism, the brick forming mold frame set on the mold moving mechanism and above the brick forming mold frame The indenter mechanism, the second drive mechanism that drives the mold-moving mechanism to walk along the second travel track, the vibrating table mechanism located at the forming position and the finished brick bracket located at the demoulding position; the vibrating table mechanism has a support Platform; the distribution vehicle has a movable distribution frame, and the swing scraping mechanism is arranged on the movable distribution frame. The invention has the advantages that the transfer speed of the formed bricks is fast, which can improve the overall brick-making efficiency; the setting of the swing scraping mechanism can improve the pressing efficiency of the pressure head mechanism and improve the yield rate of the formed bricks.

Owner:泉州市益鑫机械科技有限公司

Blank cutting steel wire full-automatic replacement method

ActiveCN113119286AReduce labor intensityNo manual operationAuxillary shaping apparatusWire wheelStructural engineering

The invention discloses a blank cutting steel wire full-automatic replacement method. The blank cutting steel wire full-automatic replacement method comprises the following steps that S1, a pneumatic check block blocks an upper steel wire wheel on the leftmost side, a pneumatic clamp clamps a lower steel wire wheel, and an infrared induction device detects the state of a steel wire between the upper steel wire wheel and the lower steel wire wheel in real time; S2, the infrared induction device detects that the steel wire is broken; and S3, the pneumatic check block and the pneumatic clamp are loosened at the same time, the lower steel wire wheel falls off and is abandoned, and the upper steel wire wheel on the leftmost side slides to the initial position of the lower steel wire wheel along a pre-stored track and the guide track; a second upper steel wire wheel on the left side of the pre-stored track slides to the initial position of the upper steel wire wheel on the leftmost side; and at the moment, the pneumatic check block and the pneumatic clamp simultaneously clamp, and the steel wire is straightened again. According to an intelligent blank cutting steel wire replacement device or method, manual operation is not needed, intelligent steel wire replacement is achieved, 24-hour uninterrupted work of a blank cutting machine can be achieved, and therefore the brick making efficiency is greatly improved, and the brick making cost is saved.

Owner:NANTONG UNIV

Brick making method

InactiveCN106673611AHigh porosityImprove insulation effectCeramic materials productionClaywaresBrickCoal

The invention relates to a brick making method. The brick making method comprises the following steps: 1) smashing the following raw materials in parts by volume: 30-40 parts of building waste materials, 20-30 parts of shale, 10-15 parts of coal cinder and 50-80 parts of clay, and then mixing to obtain a brick making raw material; 2) adding water into the brick making raw material, stirring to obtain pug, and then ageing for more than two days; 3) preparing the pug into green bricks by adopting a vacuum brick extruding machine; and 4) roasting at the temperature of 700-800 DEG C under the condition that the vacuum degree of the green bricks is less than 0.1, so that the finished product brick is obtained. The method provided by the invention is environment-friendly, and brick making efficiency is high.

Owner:SUZHOU TANGSHI MACHINERY MFG

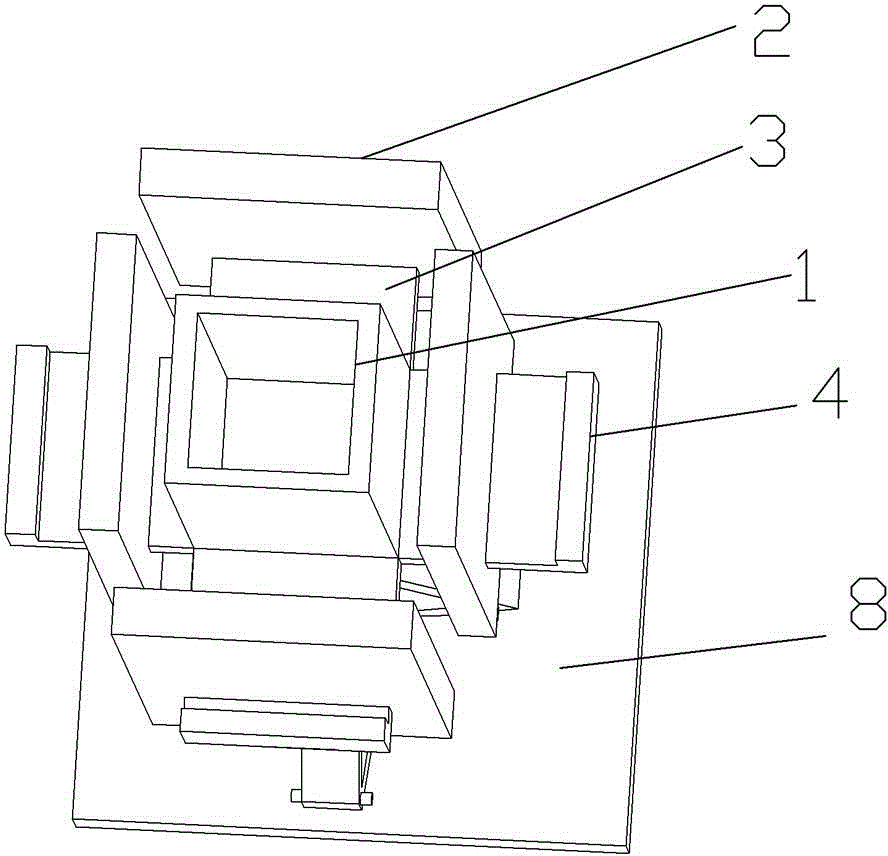

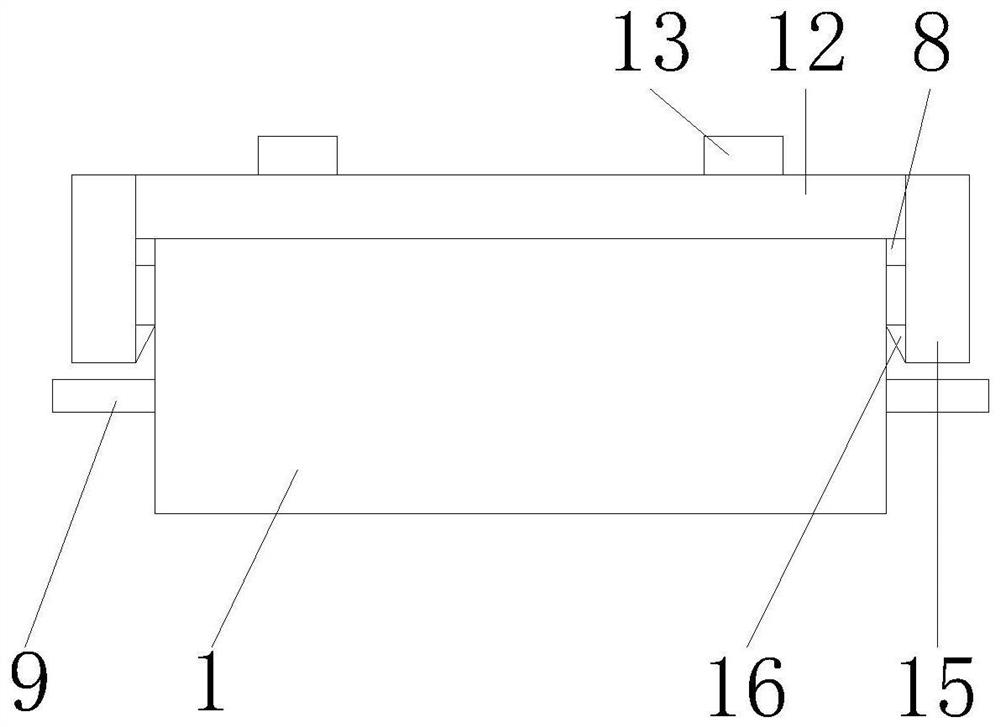

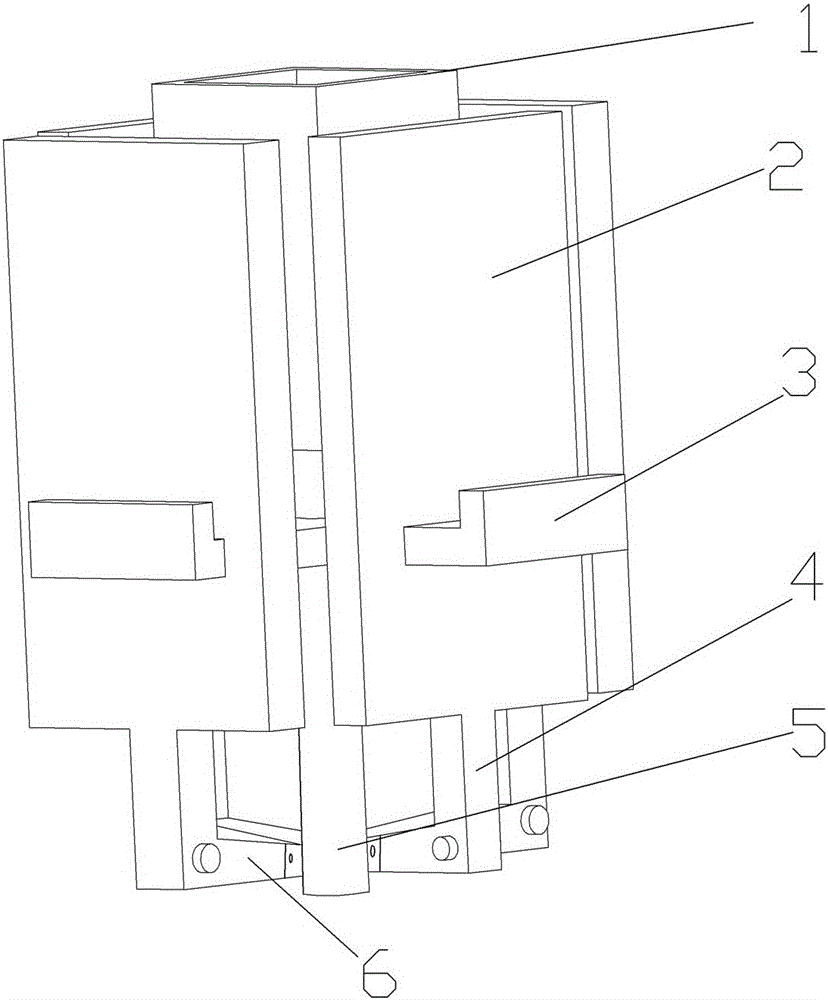

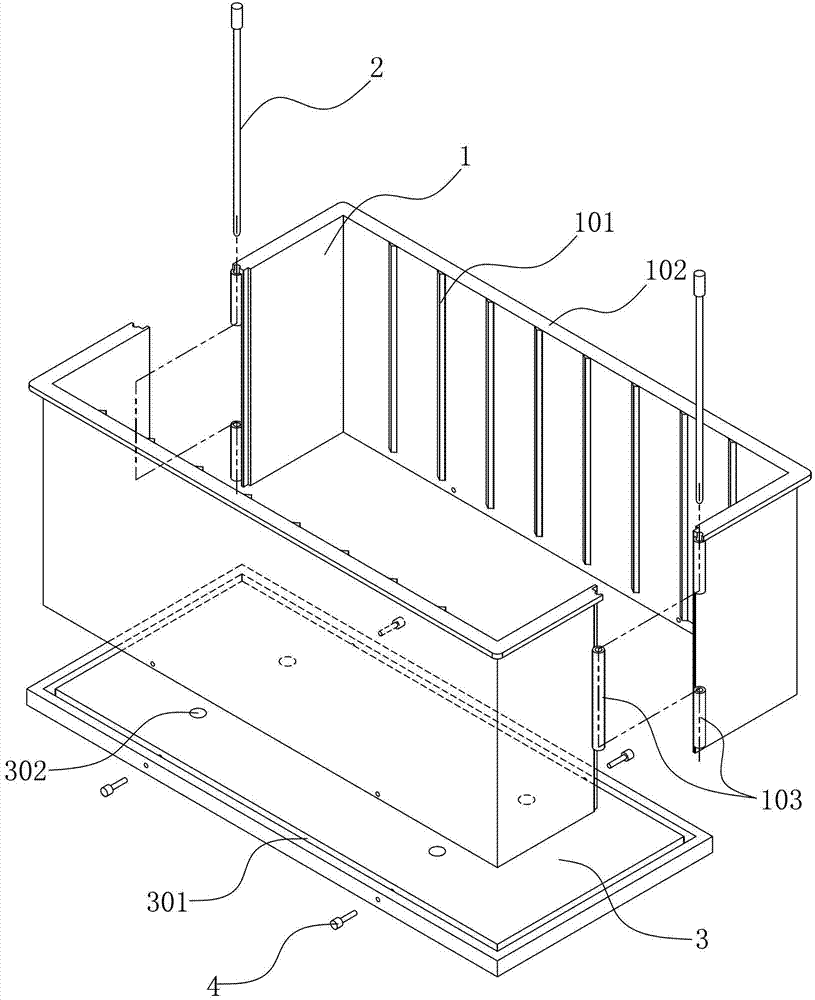

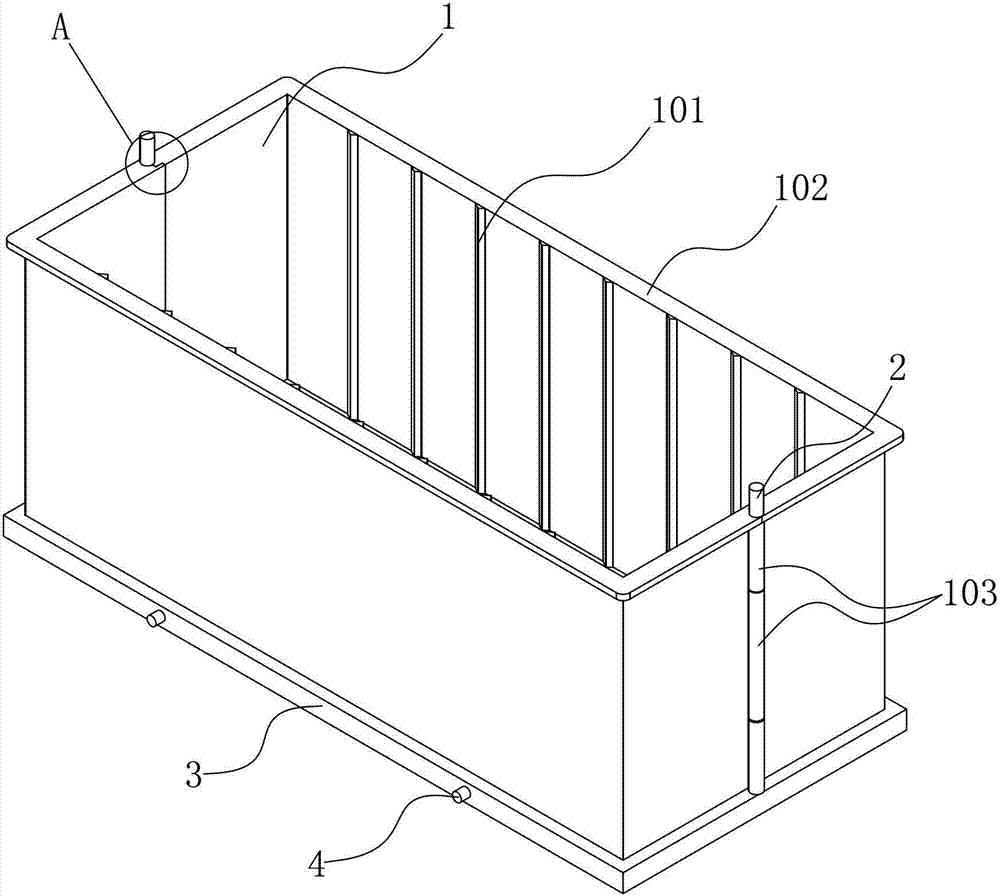

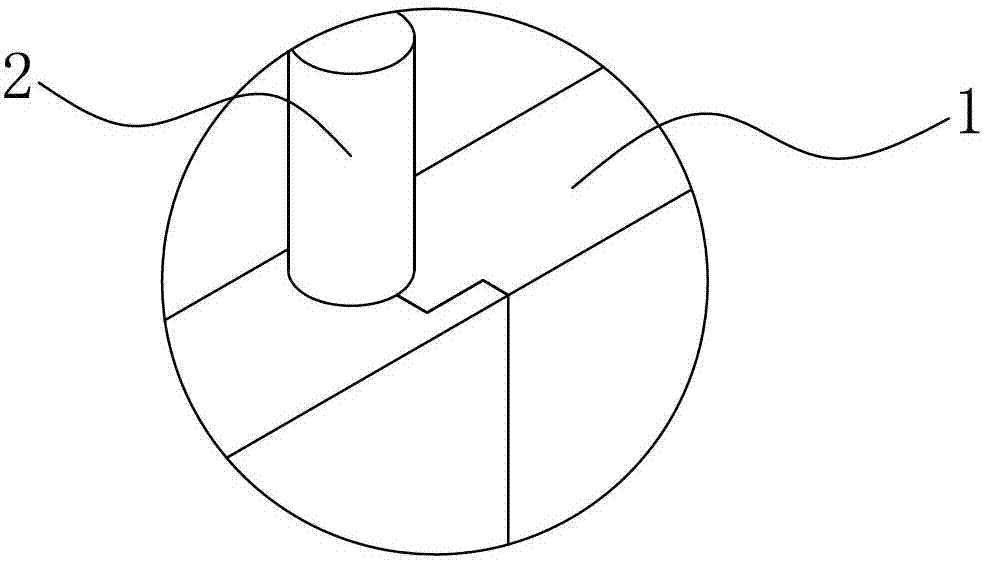

Self-insulation concrete composite building block casting box and use method thereof

InactiveCN103350450BImprove sealingImprove brick making efficiencyCeramic shaping apparatusHigh volume manufacturingMaterials science

The invention relates to a self-insulation concrete composite building block casting box and a use method of the self-insulation concrete composite building block casting box, which are designed to solve the technical problems of large volume of a like product, high manufacturing cost, inconvenience in assembly and disassembly, waste of time and energy in operation. The casting box is formed by connecting a cubic frame with a rectangular bottom plate, the key point of design is that the upper end and the lower end of the frame are open, the frame is formed by combining and connecting two complementary side plates, the bottom plate is provided with an embedded slot matched with the bottom side of the frame, and the bottom plate and the frame are locked and located through a locating piece. The moulding is completed only by combining the two side plates into the frame, matching the bottom side of the frame with the embedded slot of the bottom plate and locating and tightly locking the bottom plate and the frame; and during demoulding, the reverse operations are conducted. The self-insulation concrete composite building block casting box is relatively simple in structure, small in size, low in manufacturing cost, convenient in assembly and disassembly and high in efficiency of making the building block, saves time and labor in use and operation, and is applicable to being used as a mould of a building block in mass production or a structural improvement of a like product.

Owner:宁波市景廷建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com