Brick Mould Clamping Device

A technology of clamping device and mold, which is applied in the direction of mold fixing device, manufacturing tools, mold auxiliary parts, etc., can solve the problems of low brick-making efficiency, inability to realize automatic locking and unlocking of brick-making molds, etc., and improve brick-making efficiency. Efficiency, saving time for manual locking and manual unlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

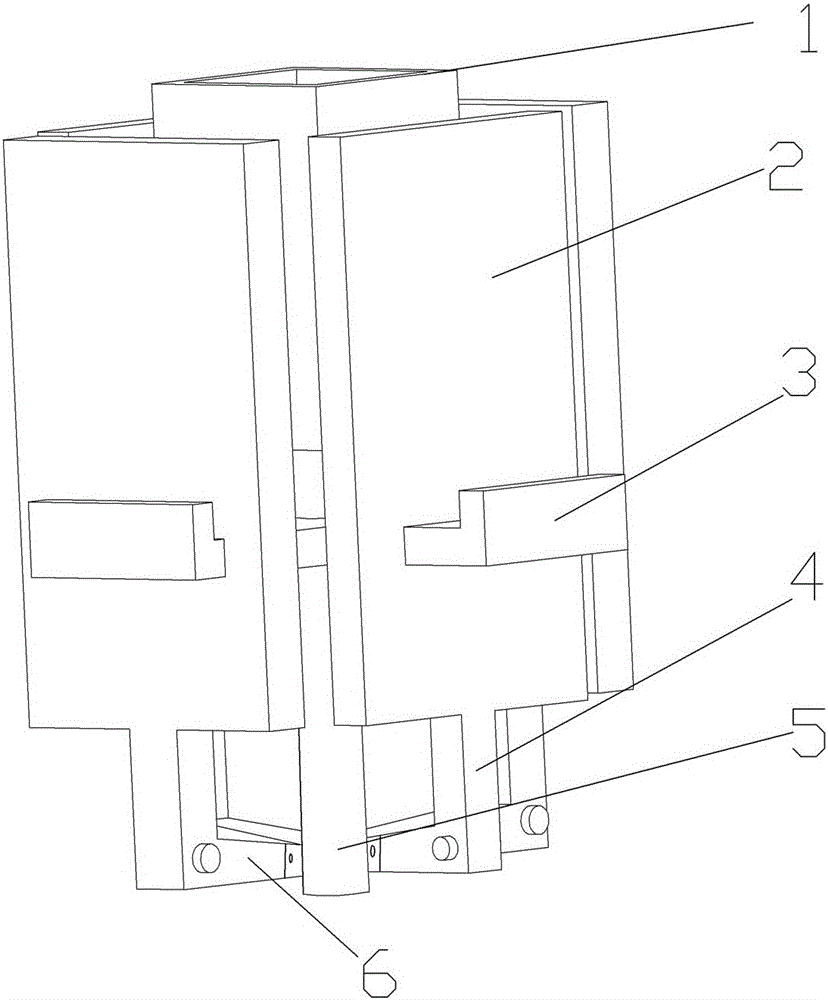

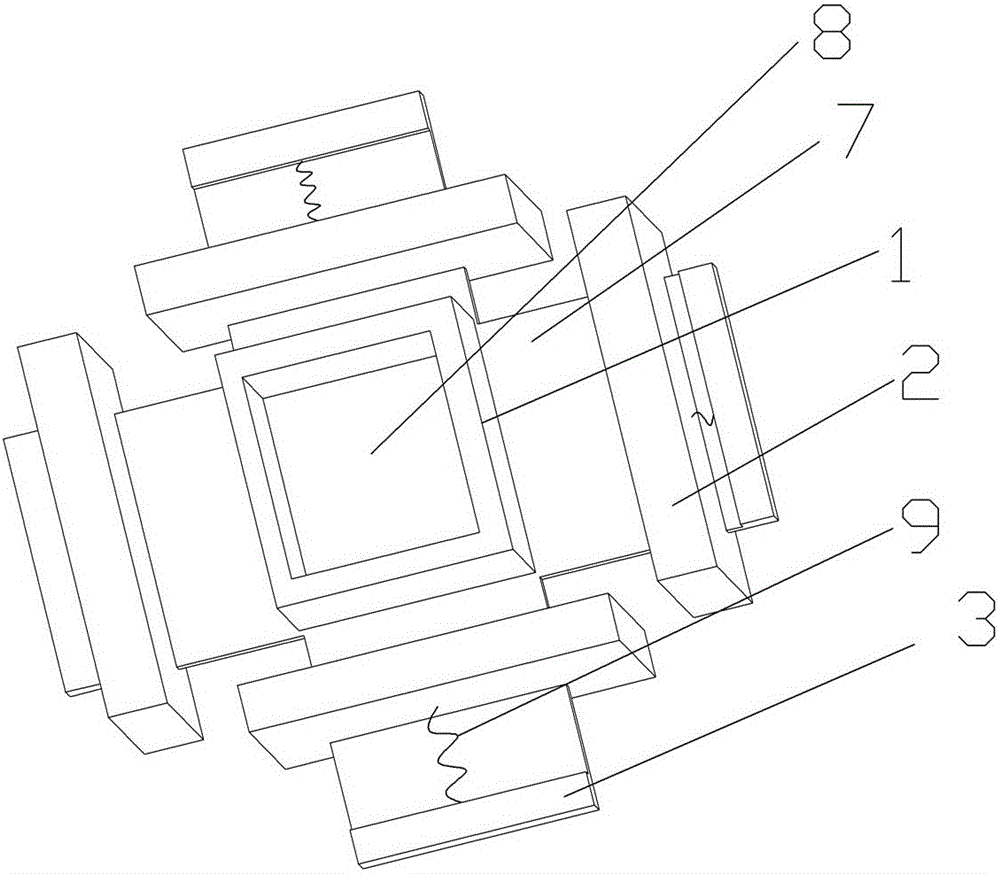

[0013] Such as figure 1 and figure 2 As shown, the base plate 7 is a cross-shaped flat plate, the lock plate 2 is a rectangular plate, and the bottom of the lock plate 2 is provided with a square hole matching the output end of the base plate 7, so that the lock plate 2 and the output end of the base plate 7 slide through the square hole Connect, there are four locking plates 2, each outgoing end of the bottom plate 7 passes through a square hole and is vertically connected with the locking plate 2, the ends of the four outgoing ends of the bottom plate 7 protrude with stoppers 3, and the stoppers 3 and the bottom plate 7 are Integral design, the bottom of the four lock plates 2 is provided with a support rod 4, the support rod 4 and the lock plate 2 are designed in one piece, a spring 9 is welded between the stopper 3 and the lock plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com