A pallet-free brick making machine

A brick making machine and pallet technology, applied in the direction of manufacturing tools, ceramic molding machines, supply devices, etc., can solve the problems of low manufacturing efficiency, poor yield rate, etc., achieve fast transfer speed, simplify molding and demoulding procedures, The effect of improving the vibration transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

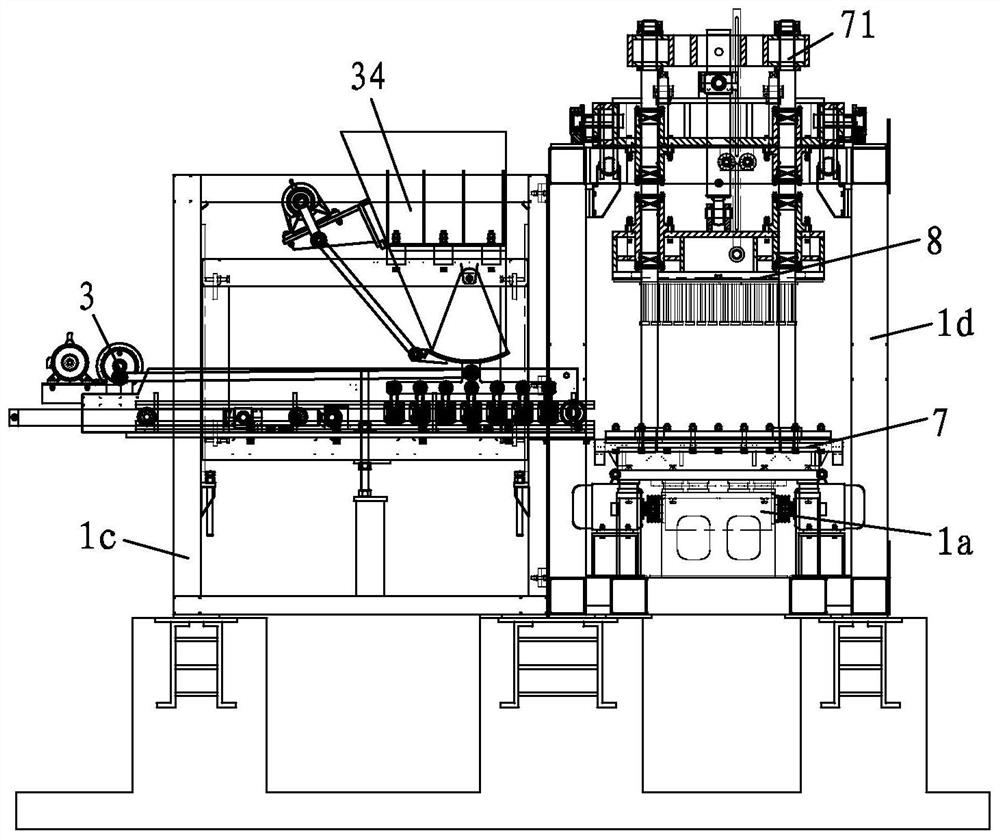

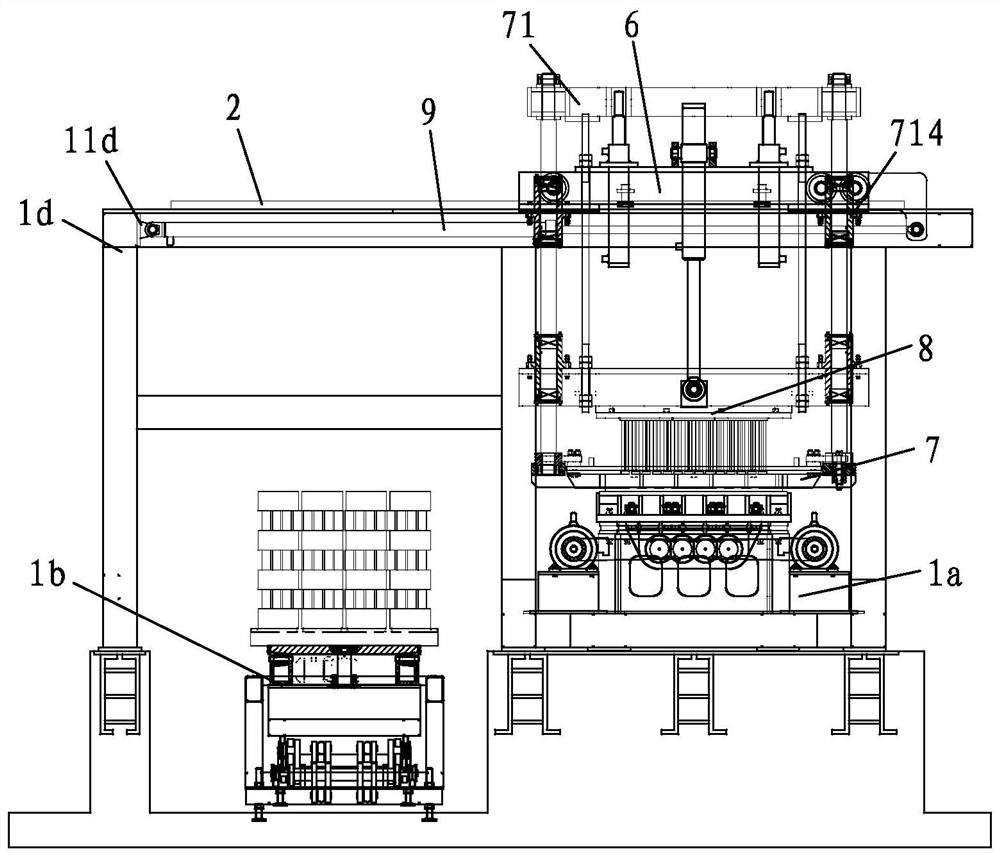

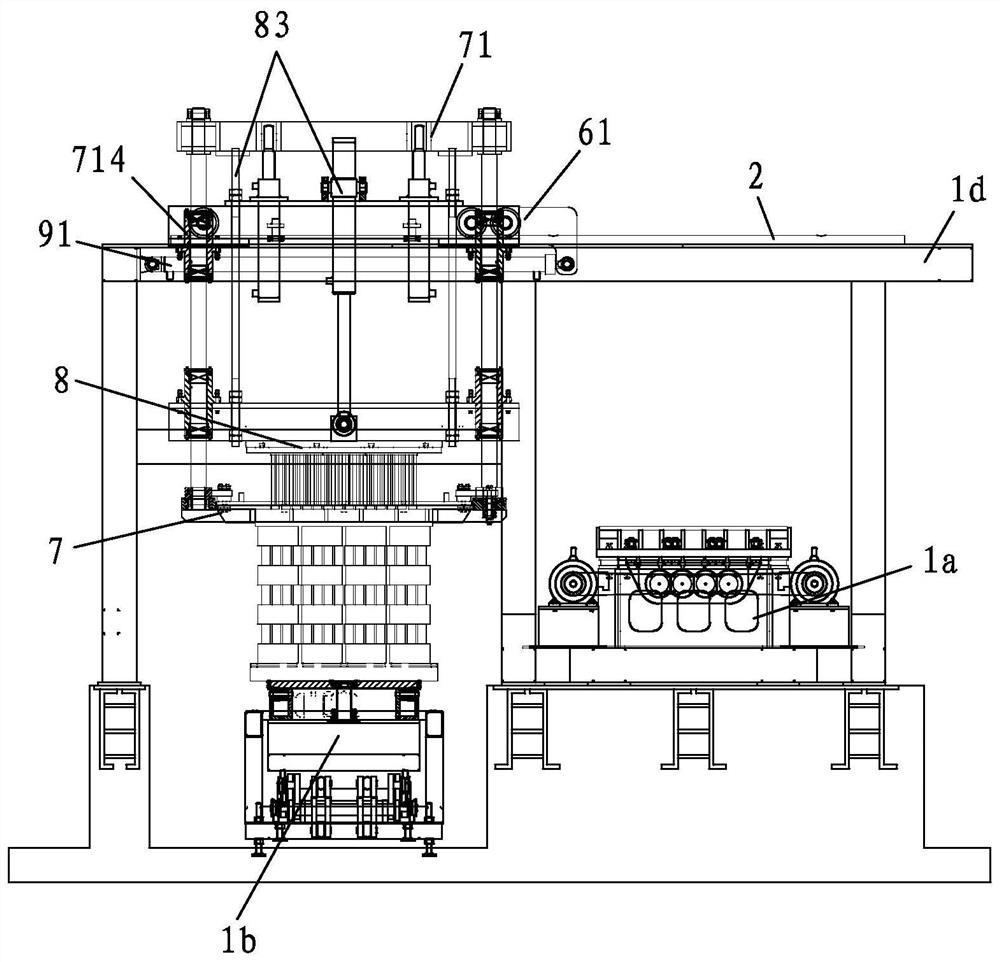

[0086] see Figure 1 to Figure 16 As shown, a preferred embodiment of a pallet-free brick making machine of the present invention includes a first walking track 1, a second walking track 2, a distribution cart 3 arranged on the first walking track 1, and driving the The distribution cart 3 moves along the first traveling track 1 from the material receiving position to the material receiving position or the first driving mechanism 4 for moving from the material receiving position to the material receiving position, and the swing scraping mechanism 5 provided on the material distribution vehicle 3 , a mold-moving mechanism 6 arranged on the second walking track 2, a brick forming mold frame 7 for forming bricks arranged on the mold-moving mechanism 6, and a brick-forming mold frame 7 arranged on the mold-moving mechanism 6 and located on the brick The indenter mechanism 8 above the forming mold frame 7 drives the mold transfer mechanism 6 to travel along the second walking track...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com