System of making bricks by utilizing construction waste and method of making bricks by utilizing construction waste

A technology of construction waste and garbage production, which is applied in the direction of construction waste recycling, recycling technology, manufacturing tools, etc., can solve the problems of destroying the ecological environment, soil desertification, etc., achieve a high degree of automation, improve quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

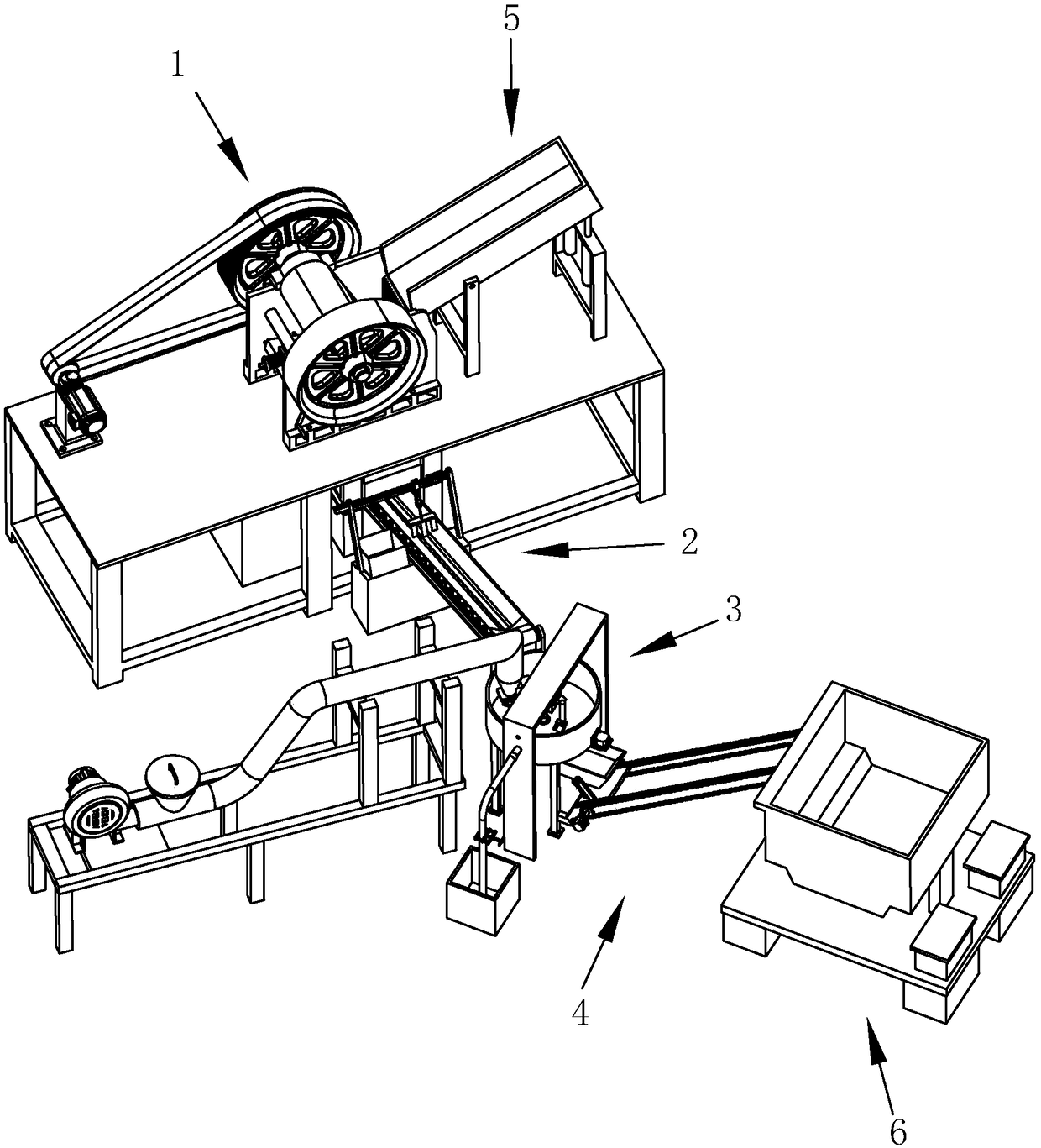

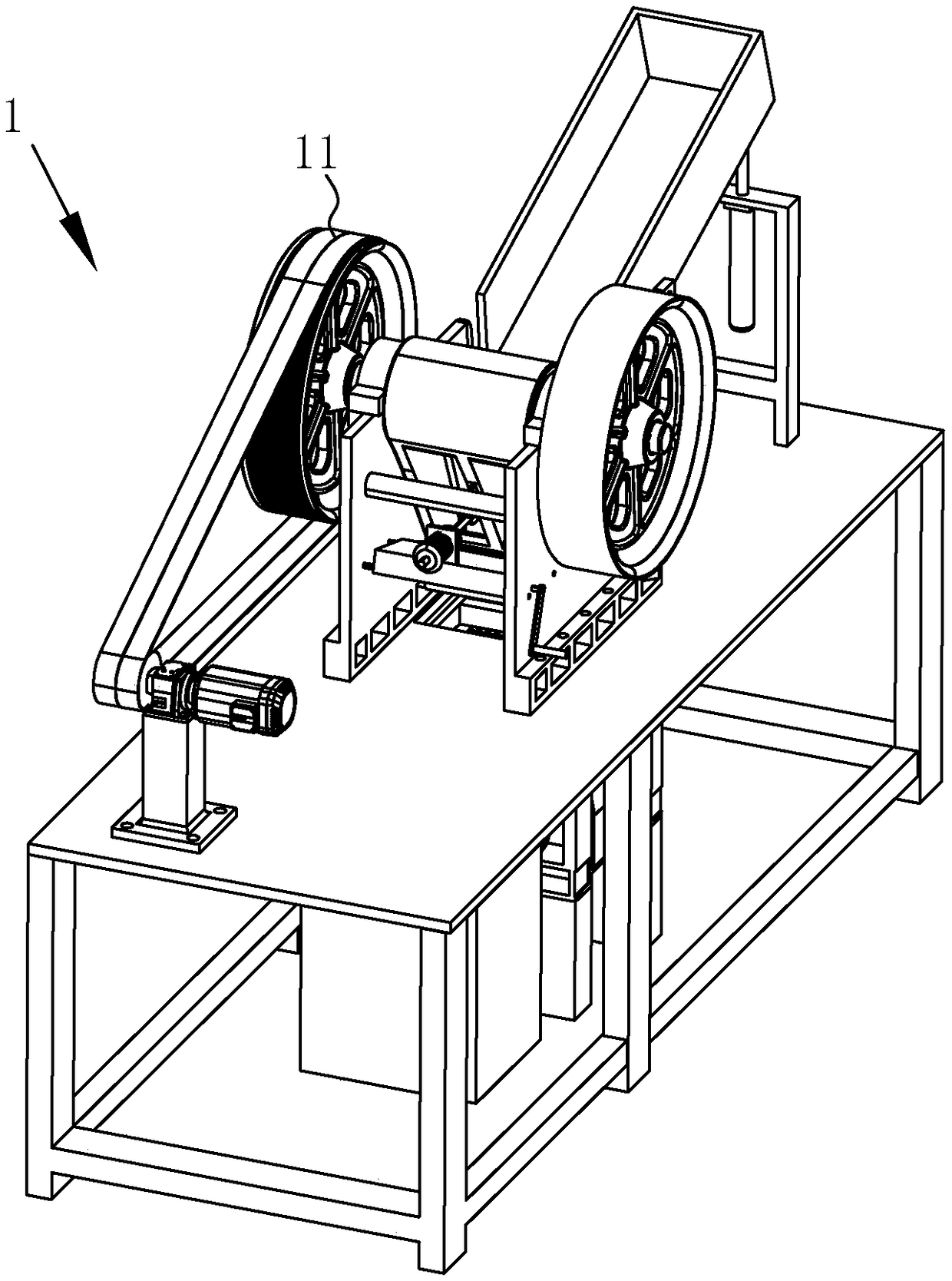

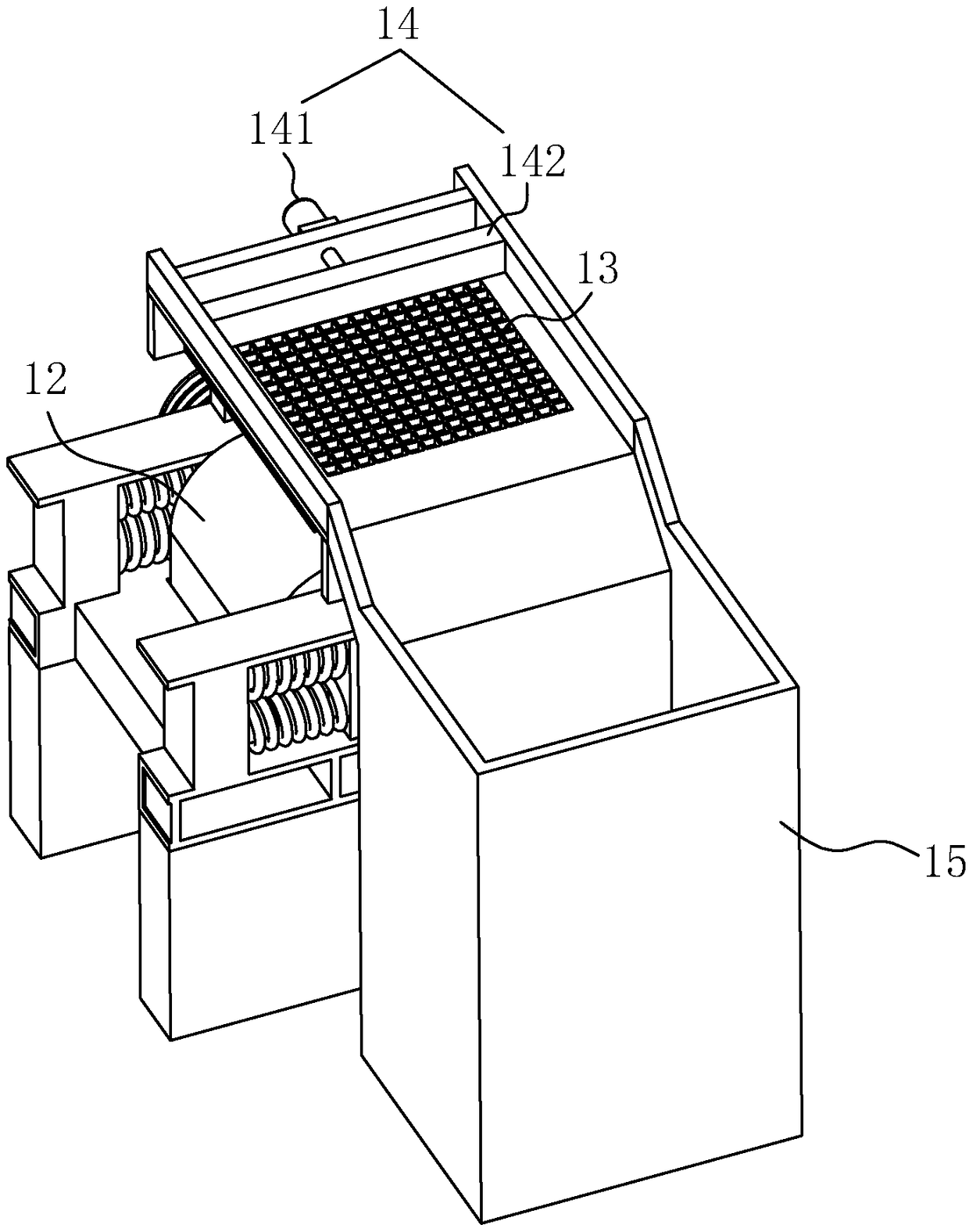

[0087] A brick making system using construction waste, combined with figure 1 As shown, it includes: a hopper 5, a crushing device 1, a screening device 2, a stirring device, a feeding device 42 and a brick making machine 6.

[0088] The input hopper 5 is made of iron material and is in the shape of a rectangular funnel. The input hopper 5 is used to accept large pieces of construction waste; the crushing device 1 breaks large pieces of construction waste into coarse materials and fine materials; the screening device 2 crushes the fine materials The iron impurities in the material are separated; the stirring device stirs the fine materials after screening into building materials; the feeding device 42 transmits the building materials to the brick making machine 6; the brick making machine 6 presses the building materials into bricks. Large pieces of construction waste are poured into the hopper 5, and then the large pieces of construction waste fall into the crushing device 1 ...

specific Embodiment 2

[0104] A method for making bricks by utilizing construction waste, combining figure 1 and Figure 4 As shown, including the above-mentioned brick making system utilizing construction waste, comprising the following steps:

[0105] a. Pour large pieces of construction waste into the hopper 5;

[0106] b. The large pieces of construction waste in the hopper 5 fall into the crushing device 1 according to gravity, and then the crushing device 1 crushes the large pieces of construction waste into two types: coarse material and fine material. The fine material remains, and the coarse material continues to be crushed The device 1 is crushed in a cycle until it is broken into fine materials and then retained;

[0107] c. the screening device 2 utilizes the electromagnet 21 to separate the ferrous impurities in the fine material, and retains the fine material that does not contain ferrous impurities;

[0108] d. The stirring device mixes the fine material without iron impurities and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com