Flip-flop forming machine for heat preservation building module blocks

A molding machine and heat preservation technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of complex production process, large mold occupancy, light weight and viscosity, etc., and achieve convenient use, improved brick-making efficiency, and brick-making speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

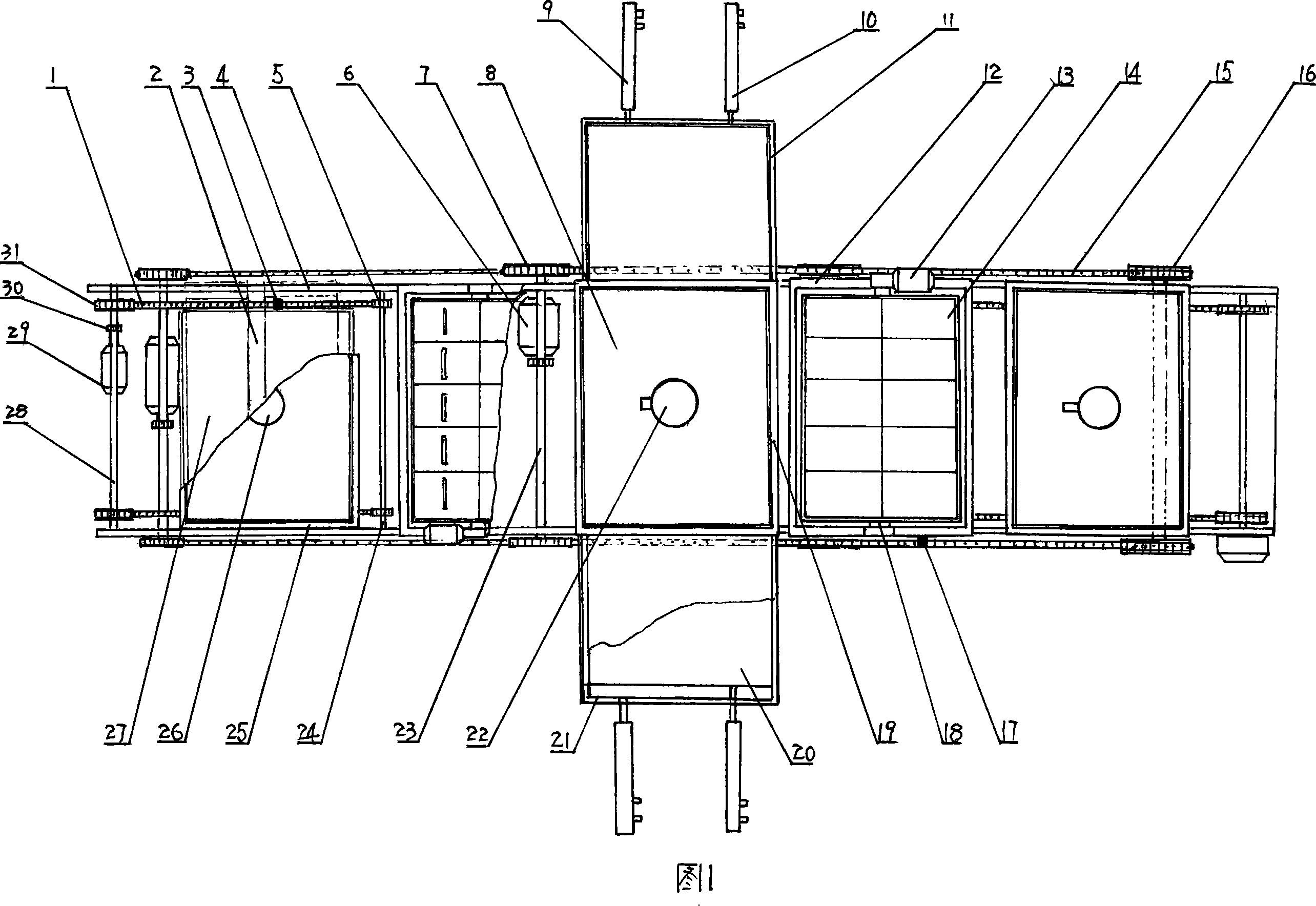

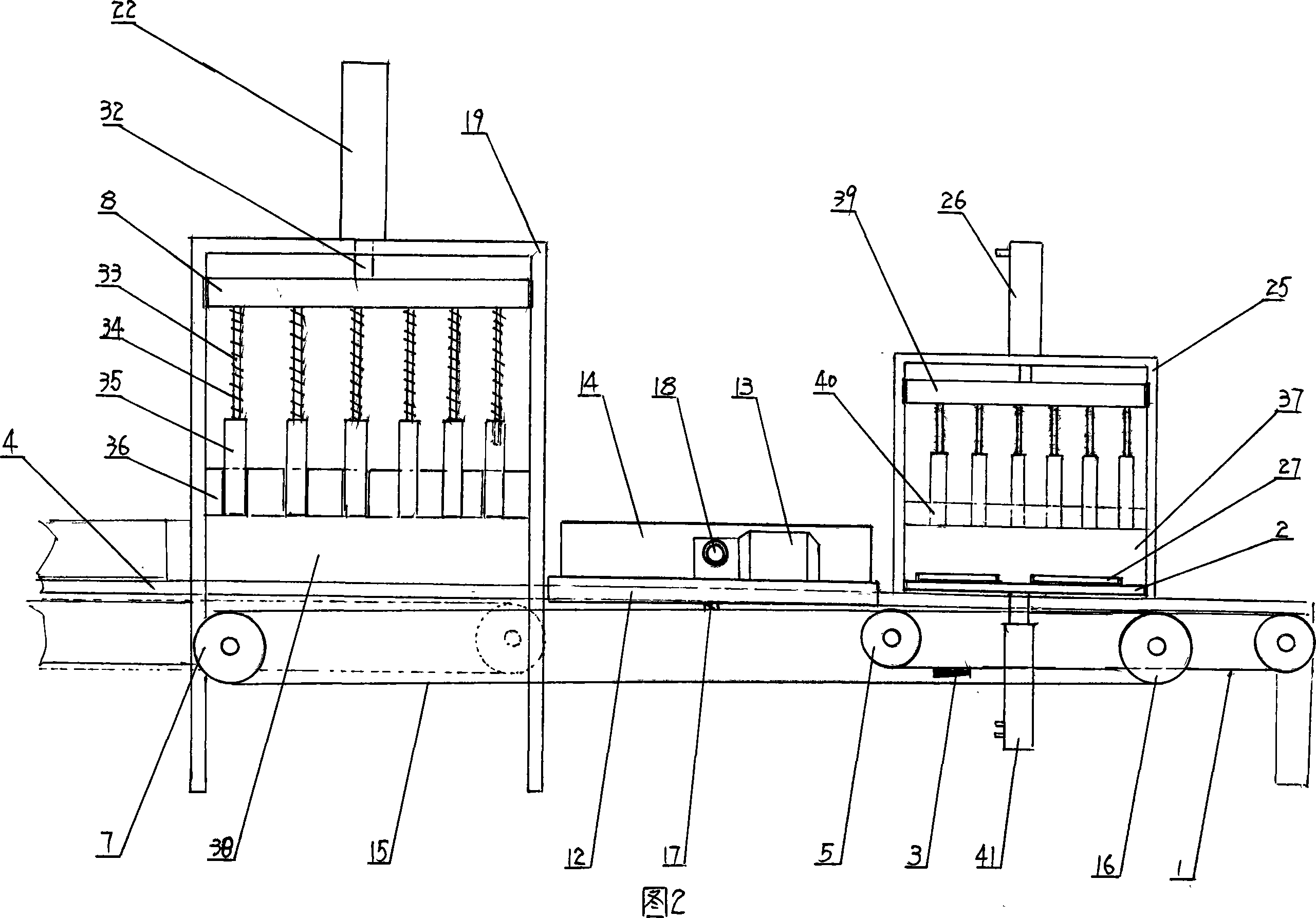

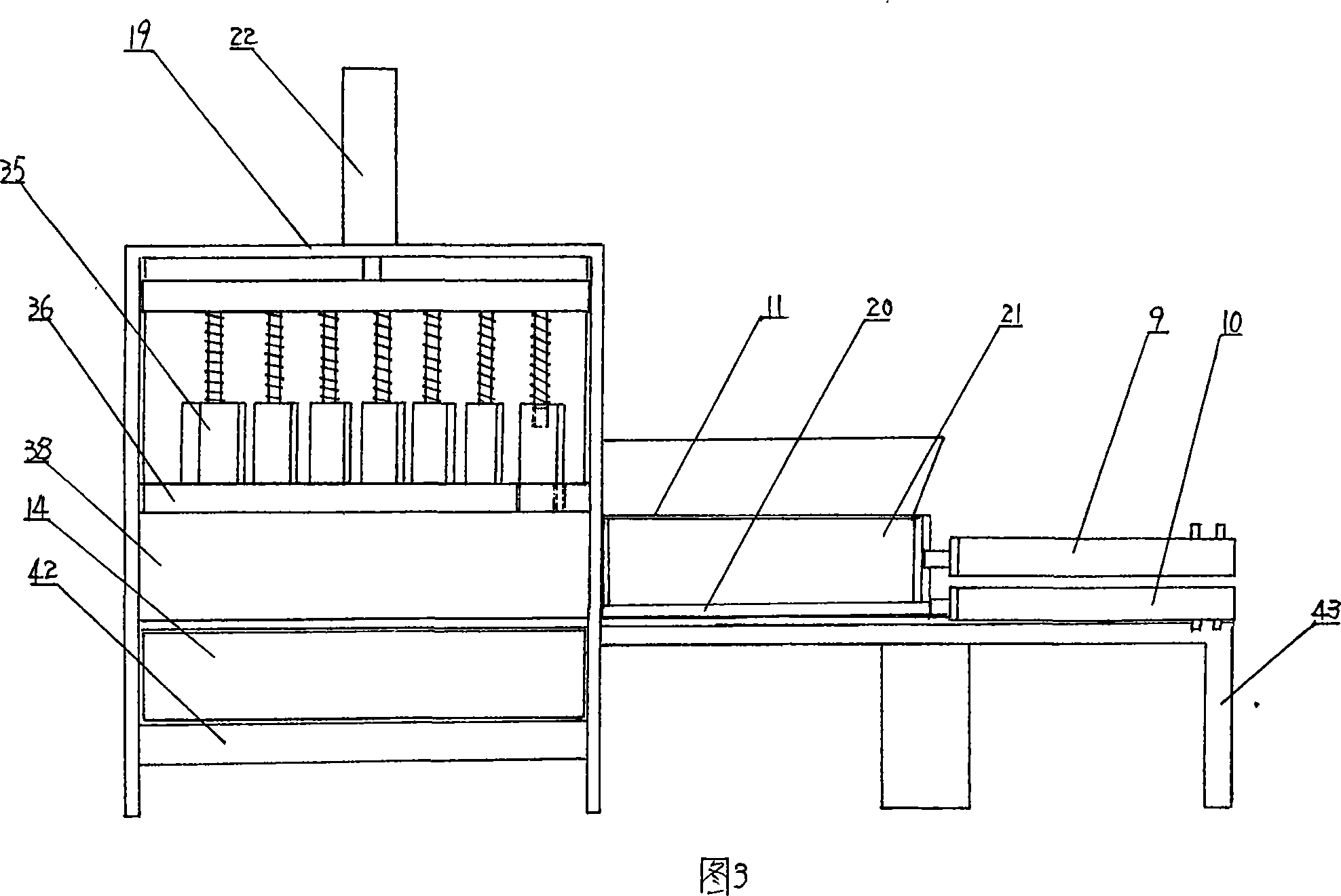

[0010] As shown in FIGS. 1 to 4 , obviously, the pressing structure is located in the middle of the frame 43 . The feeding structure is distributed at both ends of the pressing structure, the overturning mold structure and the demoulding structure are located at the other two ends of the pressing structure, and the structures on both sides are the same, so only the structure on one side will be described. Of course, the present invention can also be unilateral setting, so it will not be repeated.

[0011] An insulated building block turning molding machine includes a main hydraulic cylinder 22 , a demoulding hydraulic cylinder 26 , a feeding hydraulic cylinder 9 , a main motor 6 and a guide rail 4 . The forming machine is composed of four parts: feeding structure, pressing structure, turning die structure and demoulding structure. The overturning die structure is located between the pressing structure and the demoulding structure, and the feeding structure is located at the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com