Transfer device for bricks

A technology of a running device and a conveying device, applied in the field of brick manufacturing equipment, can solve the problems of manual coordination, unsatisfactory conveying effect, rough structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

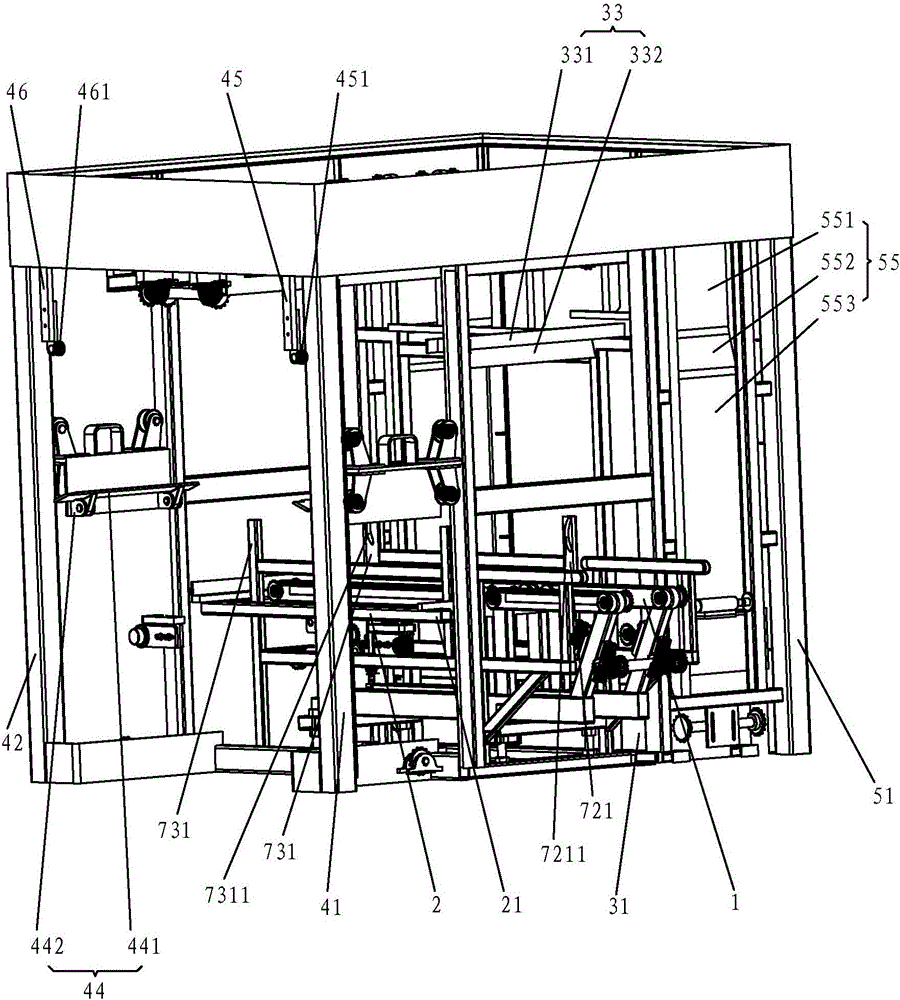

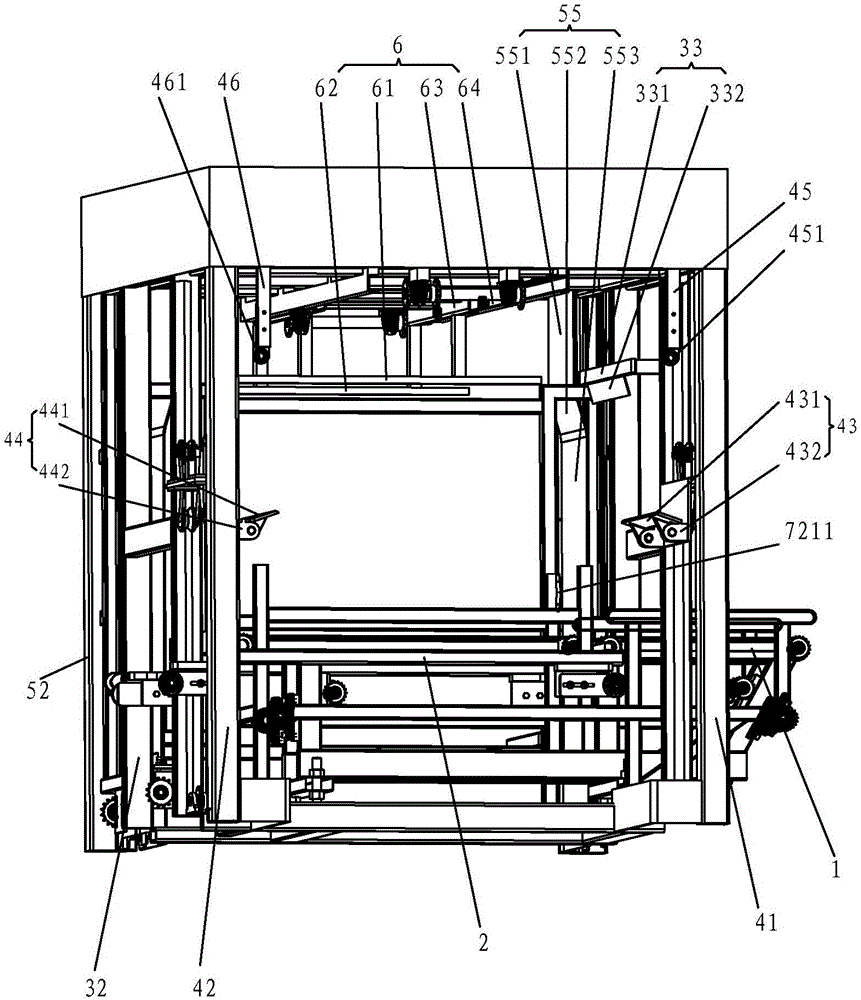

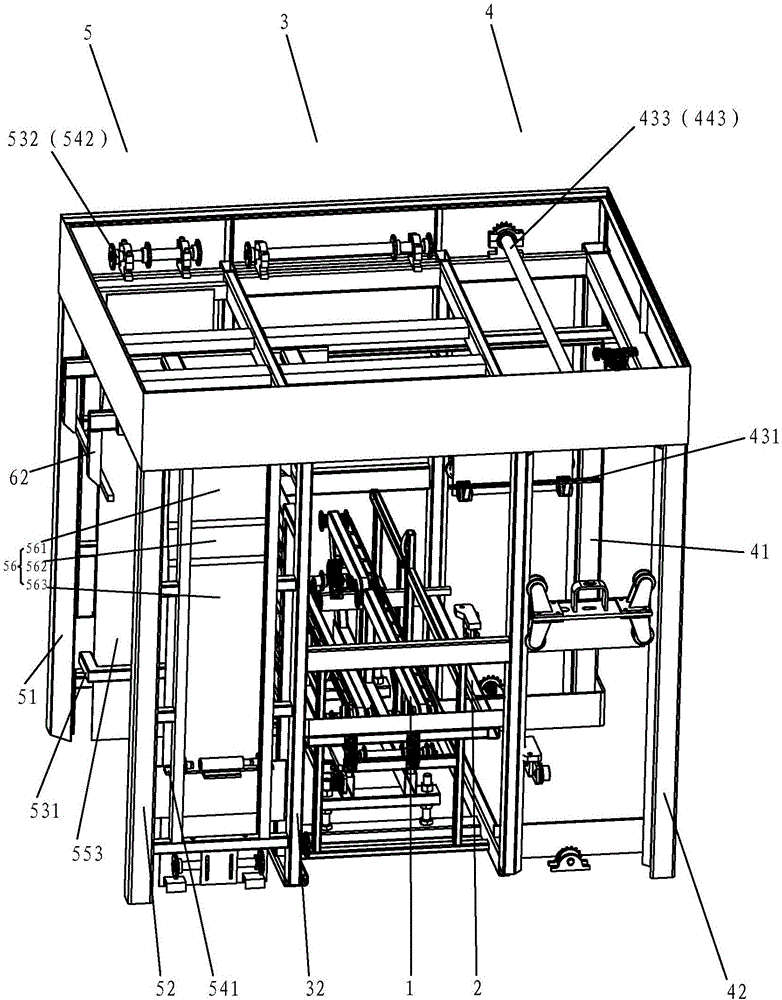

[0048] A brick operating device of the present invention, such as Figure 1-7 As shown, it includes a brick-carrying mold for loading bricks, a brick conveying device 1 for transporting the brick-carrying mold, a mold bracket 2 for supporting the brick mold, and a lifting and lowering device 3 for lifting and lowering the mold bracket 2. The arrangement device 4 for arranging the brick-carrying molds loaded with bricks, the supply device 5 for supplying empty brick-carrying molds, and the brick-carrying molds for transferring the brick-carrying molds loaded with bricks to the arrangement device 4 and emptying the supply device 5 Transshipment to the transfer device 6 on the lifting carrier device 3;

[0049]The mold bracket 2 extends along the conveying direction of the brick conveying device 1, and has a first end at one end and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com