Spherical hole insulating brick and preparation method thereof

An insulating brick and spherical technology, applied in the field of spherical hole insulating brick and its preparation, can solve the problems of high strength and insulating performance, poor performance of insulating brick, low density of insulating brick, etc., and achieve high compressive strength and flexural strength, Good thermal insulation performance, good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

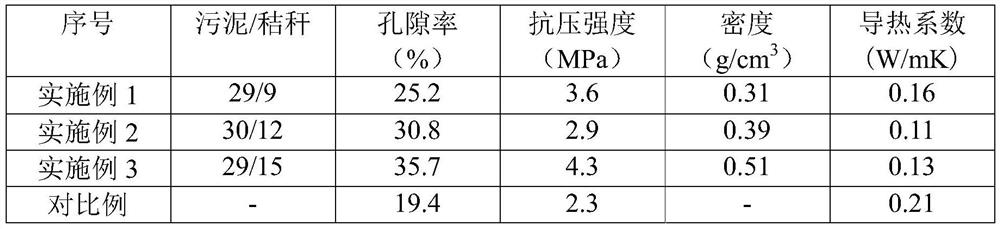

Examples

Embodiment 1

[0024] A spherical hole insulation brick, comprising the following raw materials in mass percentage: 17% of river sludge, 12% of river bank sludge, 5% of papermaking waste, 8% of ceramsite, 10% of vitrified microbeads, 5% of calcium carbonate, sepiolite 3%, calcium sulfate 7%, straw 9%, lime 4%, carbon black 3%, sodium citrate 5%, malic acid 5%, water repellent 3% and flame retardant 4%.

[0025] Wherein, the stalk is corn stalk. Papermaking waste is waste cloth and wood. The water repellent is FN-80; the flame retardant is aluminum hydroxy.

[0026] The preparation method of the above-mentioned spherical hole insulation brick is characterized in that it comprises the following steps:

[0027] (1) Pulverize and grind river sludge and river bank sludge, bake at 600°C for 14 hours, and then pulverize papermaking waste, ceramsite, vitrified beads, calcium carbonate, sepiolite, straw, lime and carbon black to 0.09mm, mixed to obtain the first mixture;

[0028] (2) Sodium citra...

Embodiment 2

[0032] A spherical hole insulation brick, including the following raw materials in mass percentage: 20% of river sludge, 10% of river bank sludge, 4% of papermaking waste, 7% of ceramsite, 4% of vitrified microbeads, 5% of calcium carbonate, sepiolite 3%, calcium sulfate 5%, straw 12%, lime 5%, carbon black 5%, sodium citrate 6%, malic acid 4%, water repellent 2% and flame retardant 8%.

[0033] Wherein, the straw is rice straw. Papermaking waste is waste cloth, wood blocks and woven bags. The hydrophobic agent is SHP-50; the flame retardant is tris(dibromopropyl) phosphate.

[0034] The preparation method of the above-mentioned spherical hole insulation brick is characterized in that it comprises the following steps:

[0035] (1) Pulverize and grind river sludge and river bank sludge, bake at 600°C for 13 hours, and then pulverize papermaking waste, ceramsite, vitrified beads, calcium carbonate, sepiolite, straw, lime and carbon black to 0.12mm, mixed to obtain the first m...

Embodiment 3

[0040] A spherical hole insulation brick, comprising the following raw materials in mass percentage: 19% of river sludge, 10% of river bank sludge, 4% of papermaking waste, 8% of ceramsite, 5% of vitrified microbeads, 4% of calcium carbonate, sepiolite 3%, calcium sulfate 3%, straw 15%, lime 5%, carbon black 4%, sodium citrate 6%, malic acid 5%, water repellent 5% and flame retardant 5%.

[0041] Wherein, the straw is a mixture of corn straw and rice straw at a mass ratio of 1:2.5. Papermaking waste is waste cloth and wood. The water repellent is FN-80; the flame retardant is aluminum hydroxy.

[0042] The preparation method of the above-mentioned spherical hole insulation brick is characterized in that it comprises the following steps:

[0043] (1) Pulverize and grind river sludge and river bank sludge, bake at 600°C for 13.5 hours, and then mix papermaking waste, ceramsite, vitrified beads, calcium carbonate, sepiolite, straw, lime and carbon black Crushed to 0.2mm, mixed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com