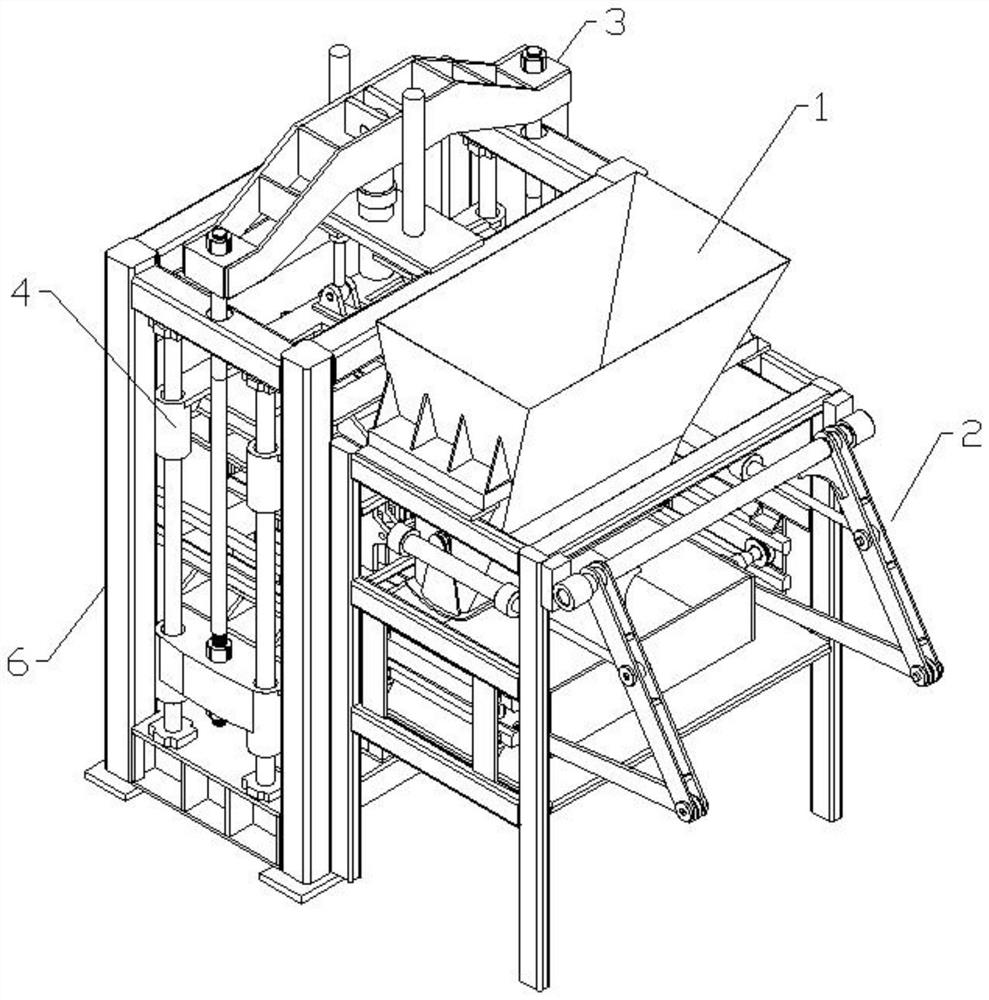

Preparation process of ecological brick taking household garbage incineration slag as raw material

A domestic waste incineration and preparation technology, which is applied in the direction of manufacturing tools, unloading devices, auxiliary molding equipment, etc., can solve the problems of low strength and poor durability of ecological bricks, and achieve the goals of avoiding waste, improving strength, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

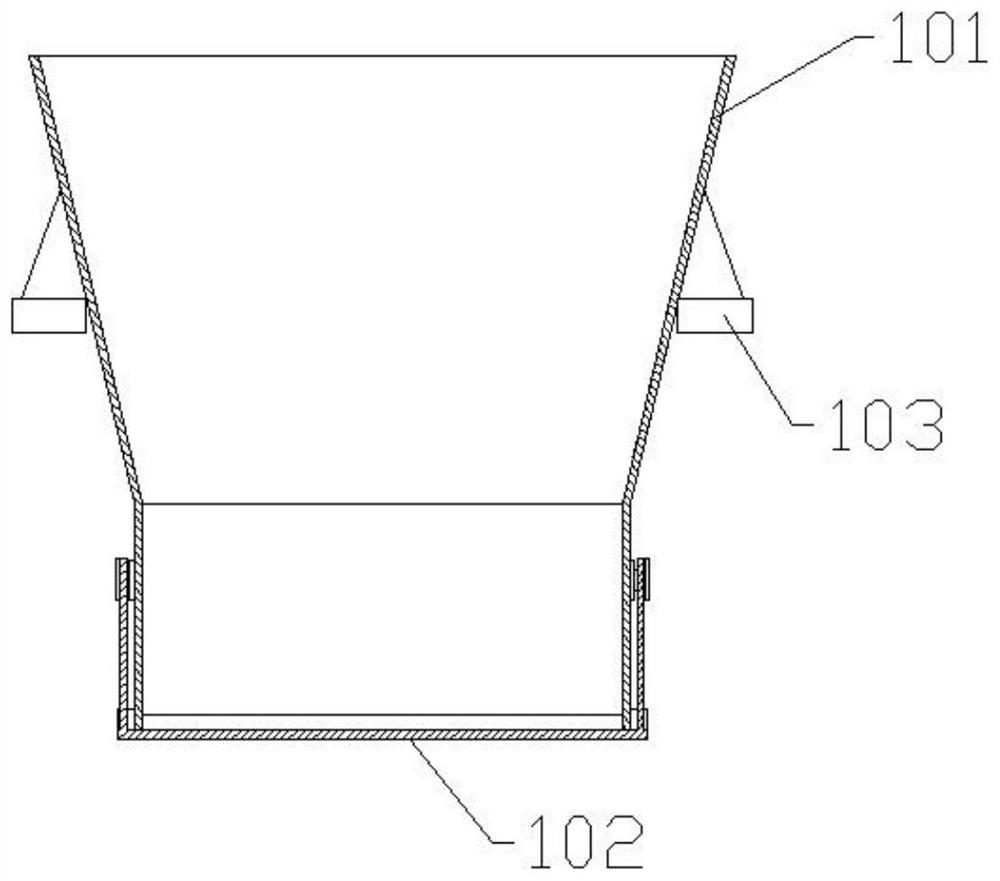

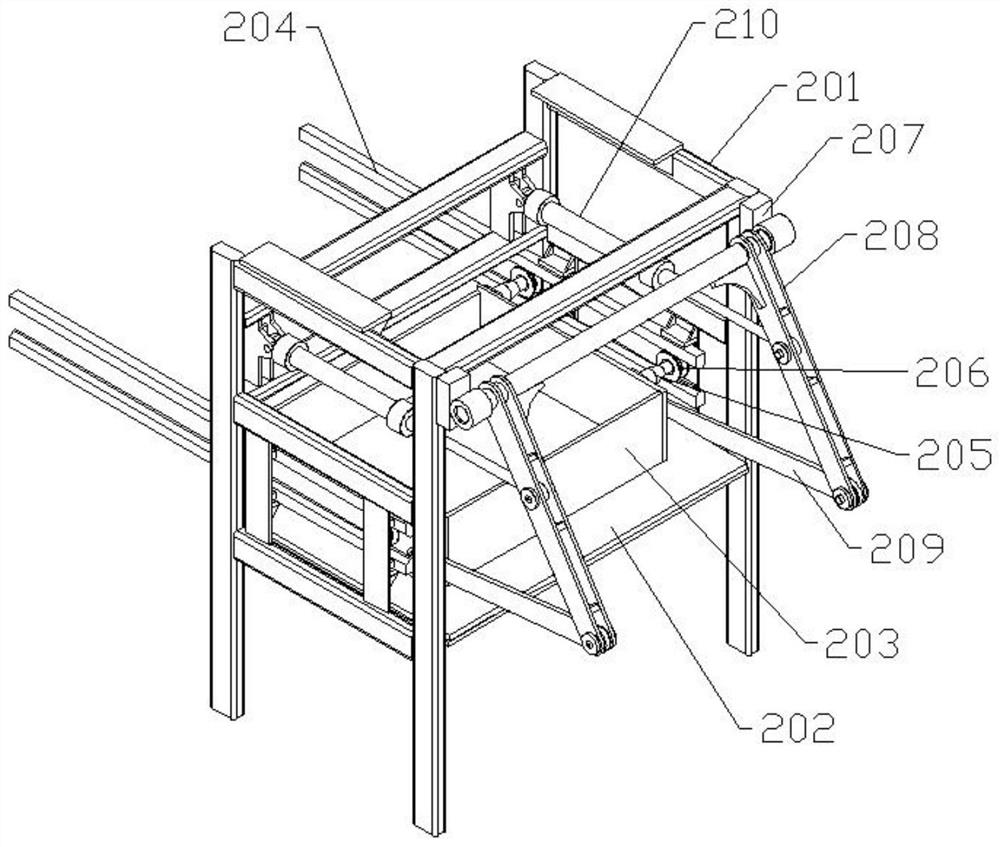

Method used

Image

Examples

Embodiment 1

[0036] A preparation process of an ecological brick using domestic waste incineration slag as a raw material, specifically comprising the following steps:

[0037] Step 1. Put 40 parts by weight of slag into a drying oven to dry first, then put it into a ball mill after drying, pass through a 100-mesh sieve after ball milling, take the slag from the bottom of the sieve for later use, and return the slag on the sieve to the ball mill for ball milling again;

[0038] Step 2. Dissolve 0.1 parts by weight of water strength agent in water and prepare a 0.5% aqueous solution of water strength agent for future use. Mix 3 parts by weight of cement, 4 parts by weight of gypsum powder, 10 parts by weight of lime powder and 2 parts by weight of silicon Sodium bicarbonate is mixed and passed through a 200-mesh sieve to obtain a mixed powder. The slag sieved in step 1 is added to the mixed powder, and then an aqueous solution of a water strength agent is added for stirring and mixing. After...

Embodiment 2

[0045] A preparation process of an ecological brick using domestic waste incineration slag as a raw material, specifically comprising the following steps:

[0046] Step 1. Put 50 parts by weight of slag into a drying oven to dry first, and then put it into a ball mill after drying, pass through a 200-mesh sieve after ball milling, take the slag at the bottom of the sieve for later use, and return the slag on the sieve to the ball mill for ball milling again;

[0047] Step 2. Dissolve 0.15 parts by weight of water strength agent in water, and prepare an aqueous solution of water strength agent with a mass fraction of 0.8% for later use. Mix 4 parts by weight of cement, 5 parts by weight of gypsum powder, 11 parts by weight of lime powder and 2 parts by weight of silicon Sodium bicarbonate is mixed and passed through a 200-mesh sieve to obtain a mixed powder. The slag sieved in step 1 is added to the mixed powder, and then an aqueous solution of a water strength agent is added fo...

Embodiment 3

[0054] A preparation process of an ecological brick using domestic waste incineration slag as a raw material, specifically comprising the following steps:

[0055] Step 1. Put 60 parts by weight of slag into a drying oven for drying first. After drying, add it to a ball mill. After ball milling, pass through a 300-mesh sieve. Take the slag at the bottom of the sieve for later use. The slag on the sieve is returned to the ball mill for ball milling again;

[0056] Step 2: Dissolve 0.2 parts by weight of water strength agent in water, and prepare a 1% aqueous solution of water strength agent by weight for future use. Mix 5 parts by weight of cement, 6 parts by weight of gypsum powder, 12 parts by weight of lime powder and 3 parts by weight of silicon Sodium bicarbonate is mixed and passed through a 200-mesh sieve to obtain a mixed powder. The slag sieved in step 1 is added to the mixed powder, and then an aqueous solution of a water strength agent is added for stirring and mixing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com