CS30 spraying steel fiber concrete prepared from ferrous mill tailings

A technology of steel fiber concrete and iron tailings, which is applied in the field of construction engineering to achieve the effects of improving toughness, saving safety maintenance costs, and reducing over-exploitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment.

[0020] CS30 sprayed steel fiber concrete prepared with iron tailings is made of ordinary Portland cement, silica fume, fly ash, gravel, iron tailings, steel fibers, water reducer and water in a certain proportion. The preparation method adopts the wet spraying preparation process, the method: crushed stone + sand + cement + silicon powder + 75% water - mixing for not less than 30 seconds - water reducing agent + 25% water - mixing time for not less than 30 seconds. In addition, the accelerator is mixed with the mixture at the nozzle.

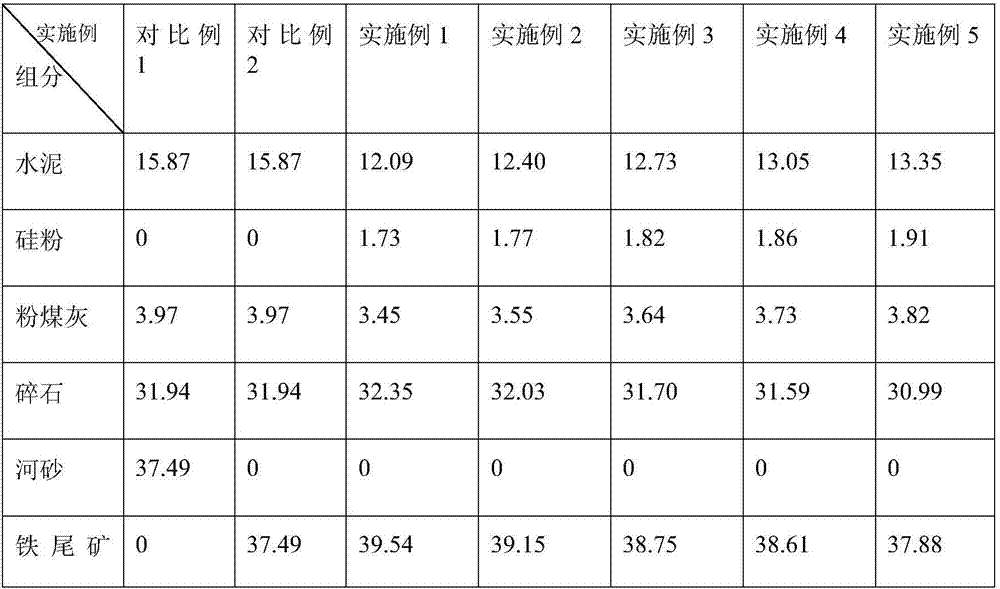

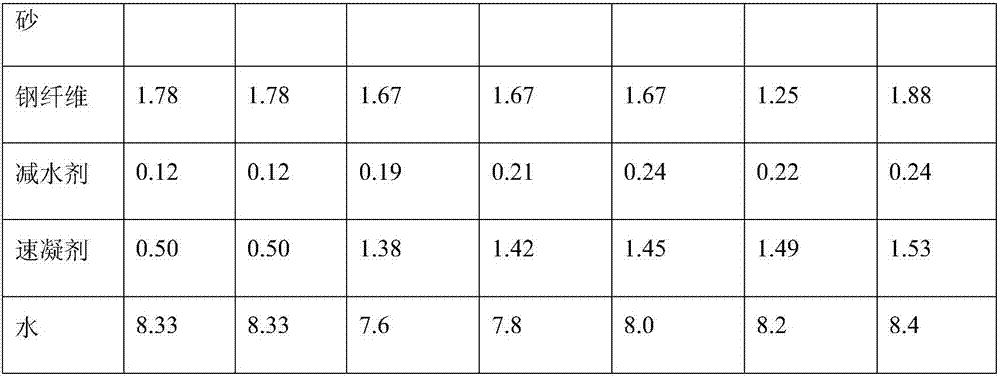

[0021] Preparation utilizes the CS30 sprayed steel fiber concrete component of iron tailing sand preparation to have weight percent as follows:

[0022]

[0023]

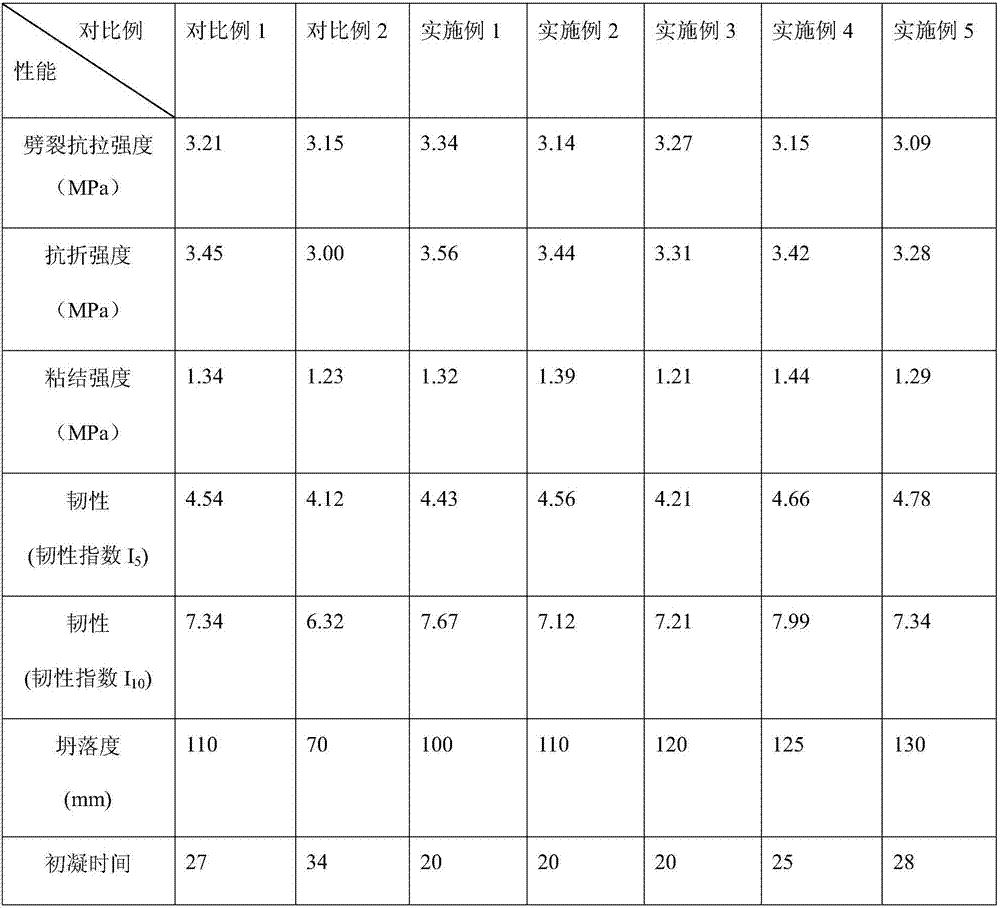

[0024] Performance comparison of CS30 iron tailing sand sprayed steel fiber concrete and C30 common river sand steel fiber sprayed concrete

[0025]

[0026]

[0027] Note: Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com