Patents

Literature

133results about How to "Activity has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

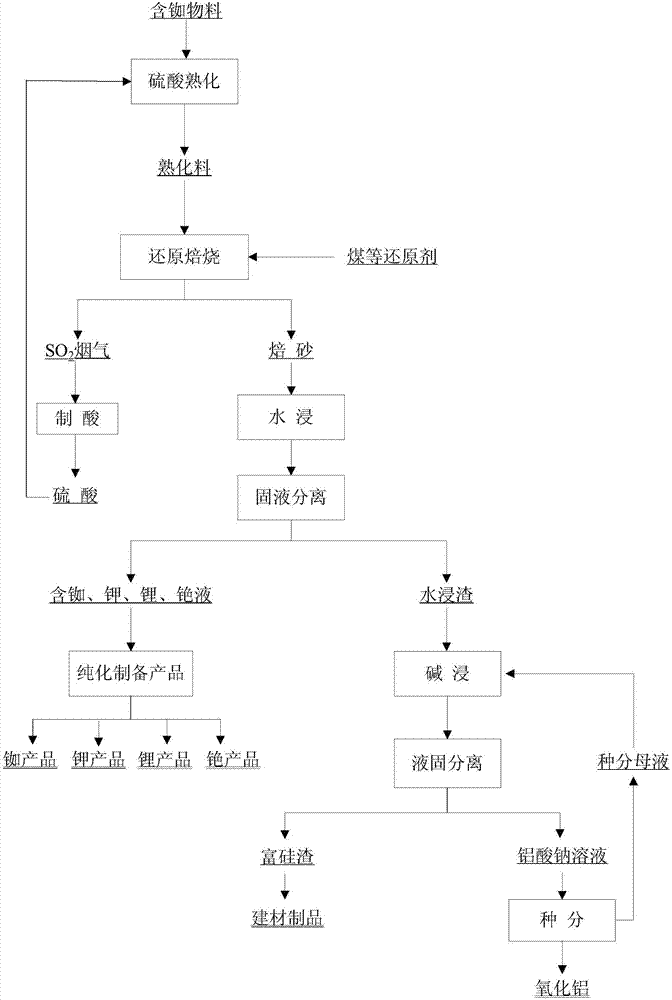

New method for extracting rubidium from rubidium-containing ore

The invention discloses a new method for extracting rubidium from rubidium-containing ore, and belongs to the technical field of rubidium extraction. The method includes the steps that rubidium concentrate produced through levigation or beneficiation of the rubidium-containing ore including low-grade mica, pollucite, feldspar and the like is evenly mixed with a proper amount of concentrated sulfuric acid to be cured, and then is subjected to high-temperature fast reduction roasting desulfurization with a reducing agent under a certain temperature condition, and flue gas containing sulfur achieves sulfuric acid regenerative cycle and utilization by means of acid making; rubidium, lithium, potassium, caesium and other elements are extracted from reduced calcine through water, a rubidium-containing solution is further purified, and the wet metallurgy processes such as a fractional crystallization separation method, an ion exchange method, a precipitation method and an extraction method are mainly adopted to obtain a corresponding rubidium product and lithium, potassium and caesium products; and liquid leached residues are subjected to alkaline leaching to prepare aluminium oxide. By the adoption of the new method, the sulfuric acid can be recycled through decomposition of aluminosilicate in the concentrated sulfuric acid reinforced rubidium-containing ore and decomposition of sulfate in a cured material under the reducing atmosphere, and therefore the new method for economic recovery of rubidium, lithium, potassium and caesium resources from the rubidium-containing ore like the low-grade mica, the pollucite and the feldspar or the rubidium concentrate is formed.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

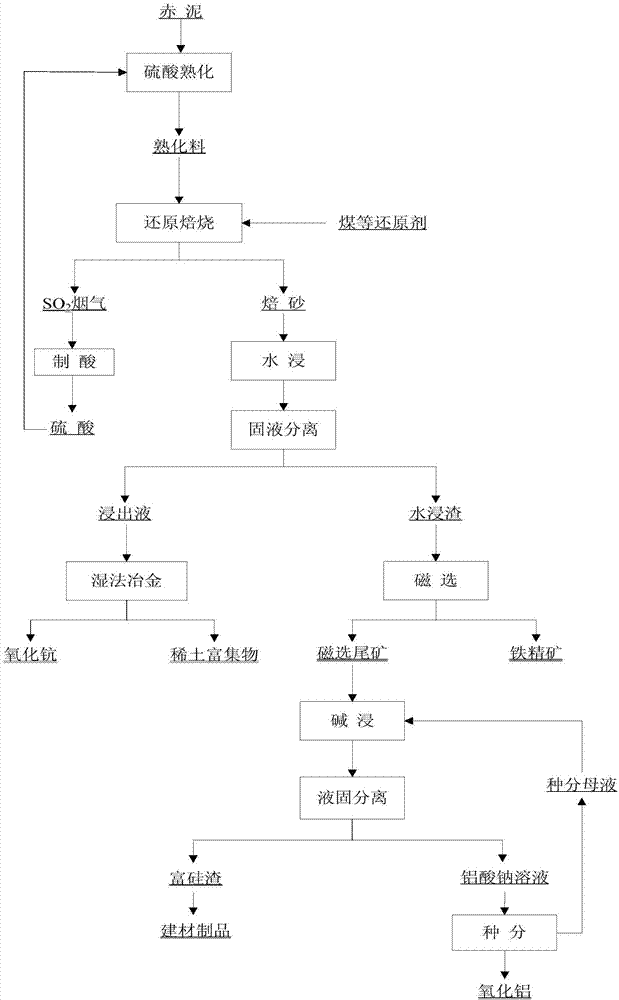

Method for high-value comprehensive utilization of red mud

ActiveCN107326182AEfficient separationEase of industrial productionSulfur compoundsMagnetic separationRed mudRare earth

The invention discloses a method for extracting aluminum, ferrum, rare earth and scandium from red mud, and belongs to the field of high-value comprehensive utilization of red mud. The method comprises the steps that after the red mud and a proper amount of concentrated sulfuric acid are evenly mixed and cured, rapid reduction roasting is conducted on the mixture with a reducing agent at a certain temperature for desulfuration, and regeneration and recycling of sulfuric acid is achieved through acid making with smoke containing SO2; water leaching is conducted on reduced roasted sand for extracting rare earth and scandium, and a water extract is concentrated, separated and purified through wet metallurgy, so that an Sc2O3 product and a rare earth-enriched product are obtained; and magnetic separation is conducted on water leaching residues, so that iron ore concentrate and magnetic separation tailings are obtained, and alkaline leaching is conducted on the magnetic separation tailings, so that aluminum oxide is prepared. According to the method, based on the principle that each component in the red mud is separated out in each step, effective separation can be achieved, the technique for each step is an existing industrial production technique, and industrial production can be achieved easily.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

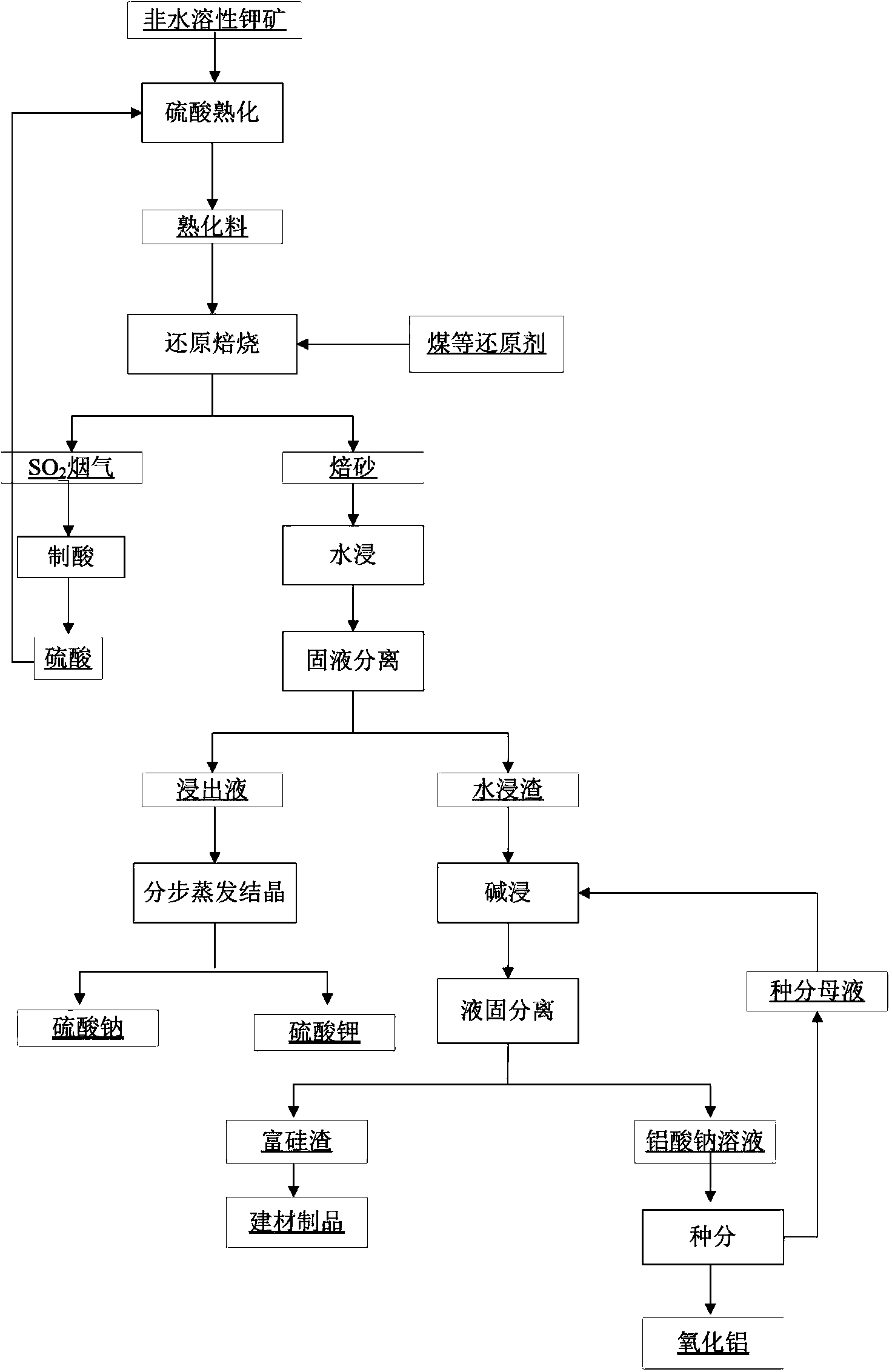

Method applied to acid-base combined extraction of aluminum, potassium and sodium from water-insoluble potassium ore

ActiveCN104388668AAchieve dissolutionKeep aliveProcess efficiency improvementAluminium recyclingFlue gas

The invention discloses a method applied to acid-base combined extraction of aluminum, potassium and sodium from water-insoluble potassium ore resource such as nepheline, potassium feldspar and the like. The method comprises the following steps: uniformly mixing finely-ground water-insoluble potassium ore with a proper amount of concentrated sulfuric acid, curing, and carrying out rapid high-temperature reduction roasting desulfurization at a certain temperature by a reducing agent, wherein the sulfur-containing flue gas is used for acid preparation to achieve regeneration and cyclic utilization of sulfuric acid; extracting potassium and sodium by water from the reduced calcine, and preparing aluminum oxide by alkaline leaching. By virtue of the method, the decomposition of aluminosilicate-containing material phase in the water-insoluble potassium ore resource such as nepheline, potassium feldspar and the like is enhanced by high-temperature reaction of concentrated sulfuric acid; the cyclic utilization of sulfuric acid is realized. The method can be used for comprehensively recycling aluminum, potassium and sodium resources; the recycling rate of aluminum oxide is high; the energy consumption is low; the corrosion to equipment is small; the large-scale industrialization is easy to implement.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

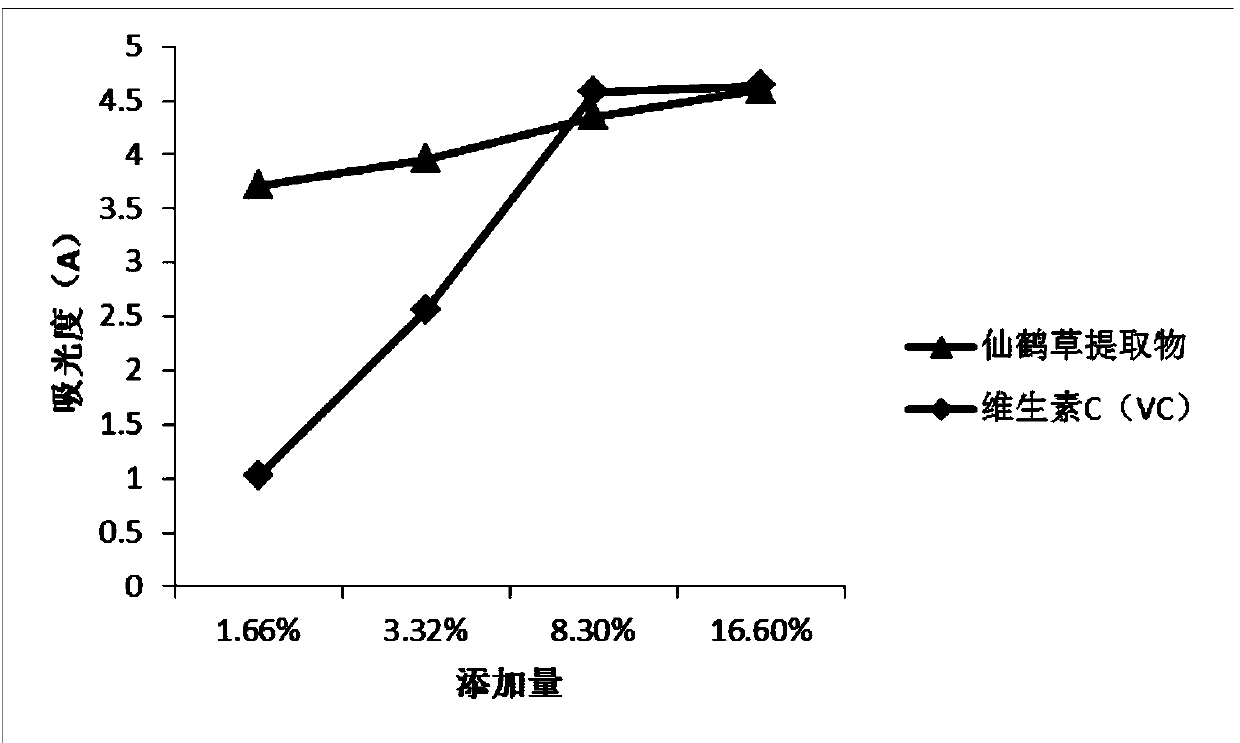

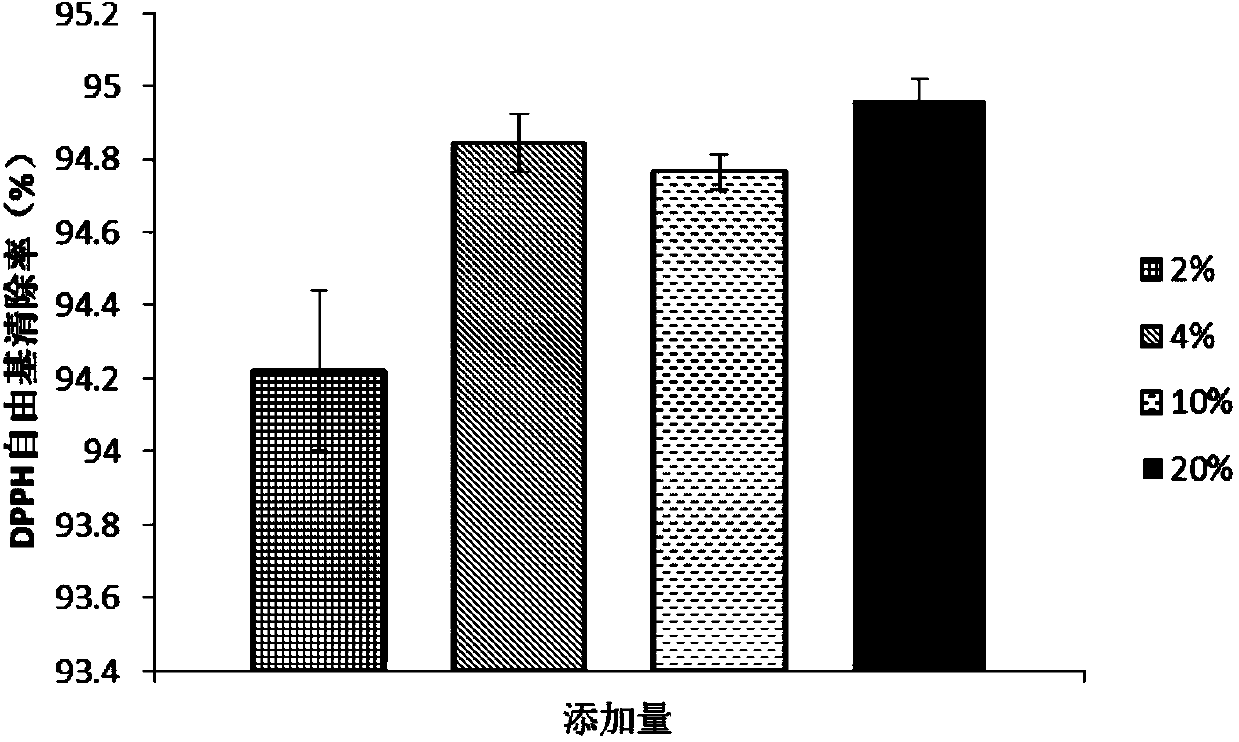

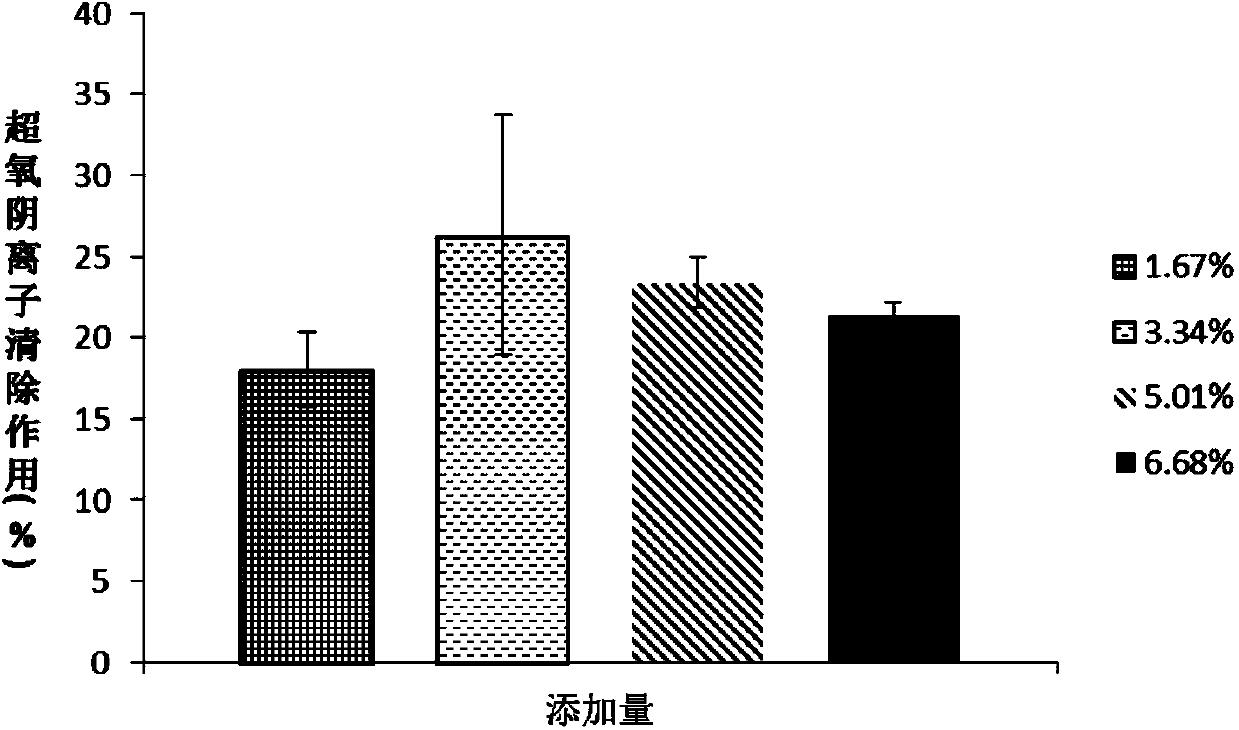

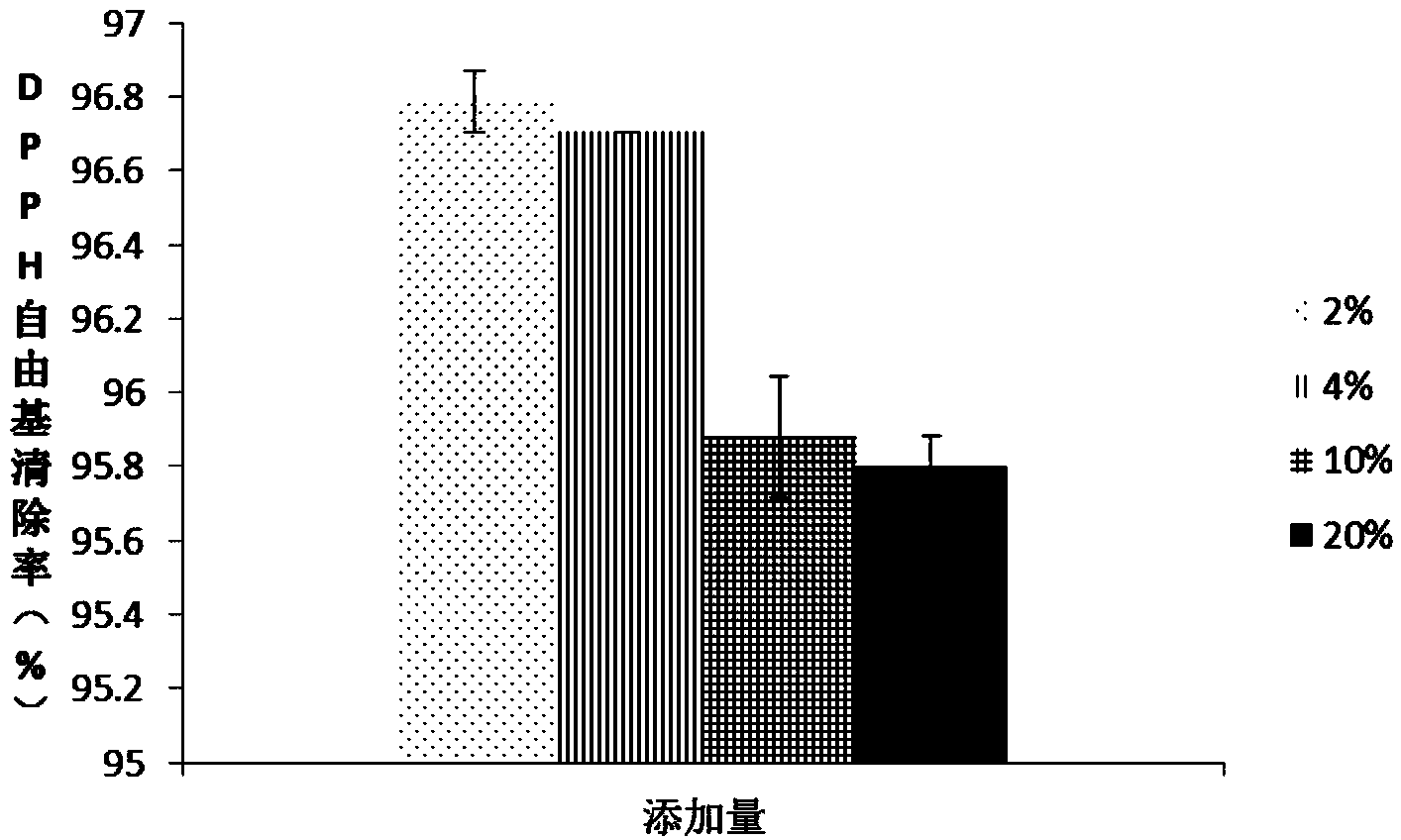

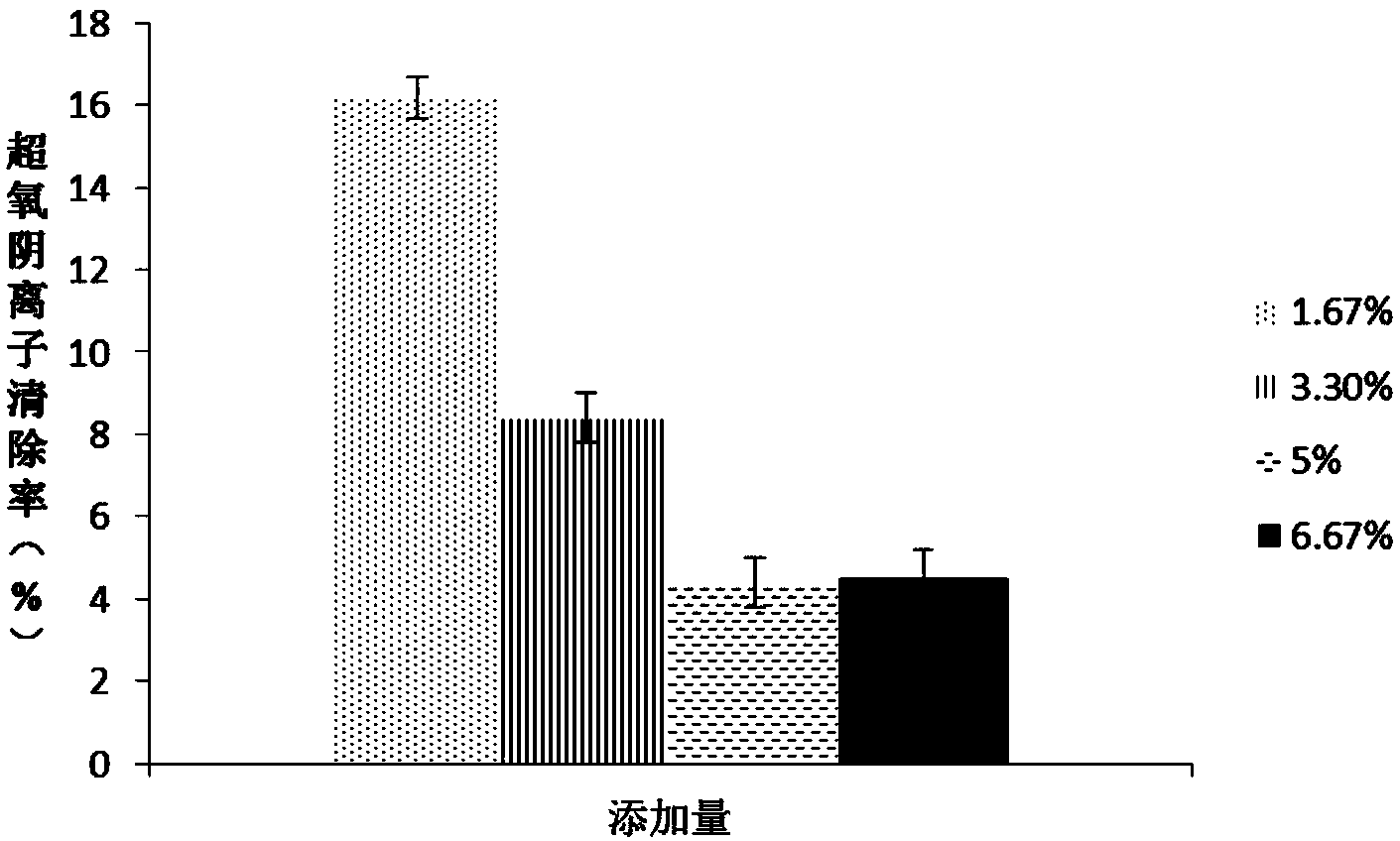

Preparation method and use of hairyvein agrimony effective ingredient

ActiveCN103735659AActivity hasActive ingredient, has anti-inflammatory propertiesCosmetic preparationsAntipyreticAdditive ingredientPotassium cyanide

The invention relates to a preparation method and a use of a hairyvein agrimony effective ingredient, and belongs to the traditional Chinese medicine effective ingredient extraction field. The preparation method comprises the following steps: a, taking the hairyvein agrimony and extracting the hairyvein agrimony by using a 75-95wt% ethanol aqueous solution with the weight being 8-12 times the weight of the hairyvein agrimony to obtain an extract; b, adding activated carbon to the extract, decoloring by heating reflux, filtering, and concentrating until no alcoholic smell to obtain a concentrated liquor; c, sieving the concentrated liquor, adding water to the concentrated liquor for diluting, putting the diluted concentrated liquor on macroporous adsorption resin, washing with water at first until the effluent I is colorless, and then washing with a 70-90wt% ethanol aqueous solution until the effluent II is identified with polyphenol to be negative by the ferric trichloride-ferric potassium cyanide to obtain an eluate; d, concentrating the eluate til no alcoholic smell, and then drying to obtain the hairyvein agrimony effective ingredient. The preparation method has the beneficial effect that the antioxidation effect is achieved by virtue of rational extraction, enrichment and separation methods; the preparation method can be applied to preparing the hairyvein agrimony effective ingredient of an oxidation resisting product.

Owner:H&B COSMETICS

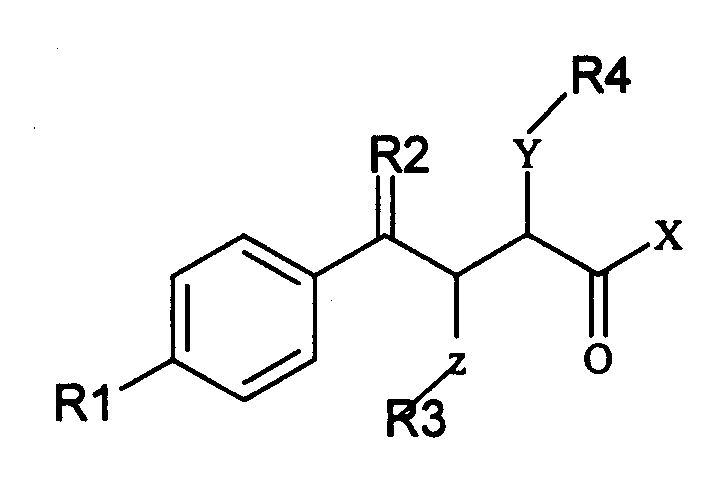

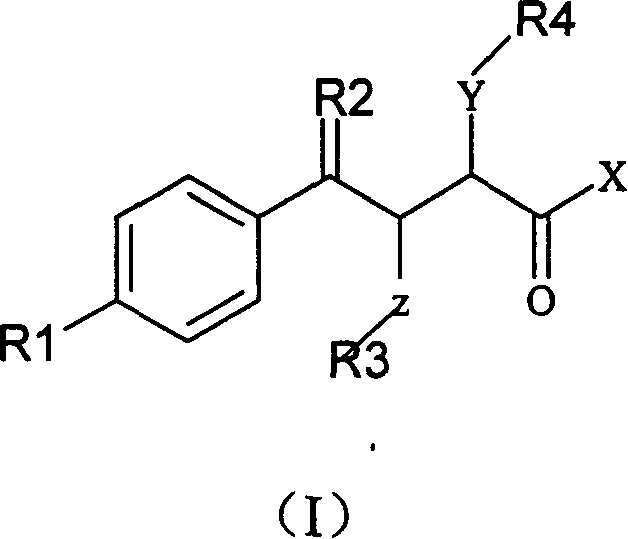

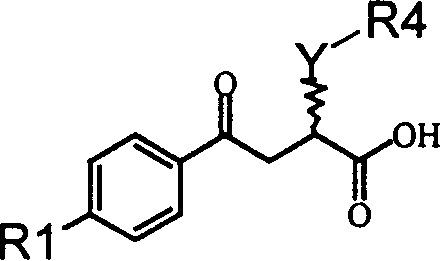

Alpha position heteroatom substituted gamma aryl ketobutyric acid derivative, process, pharmaceutical combination and uses thereof

InactiveCN1566065AActivity hasSelective inhibitionOrganic chemistrySkeletal disorderKetoneAcid derivative

The invention relates to a gamma methyl ethyl ketone acid derivative represented by general formula (I), and contains gamma-aryl-alpha-amido-beta, its preparing process, pharmaceutical compositions containing them and use as medicament, in particular as medicament for treating osteoarthritis and tumor.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

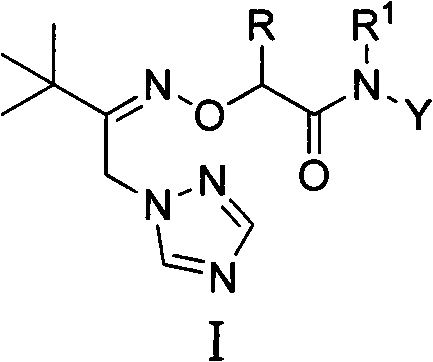

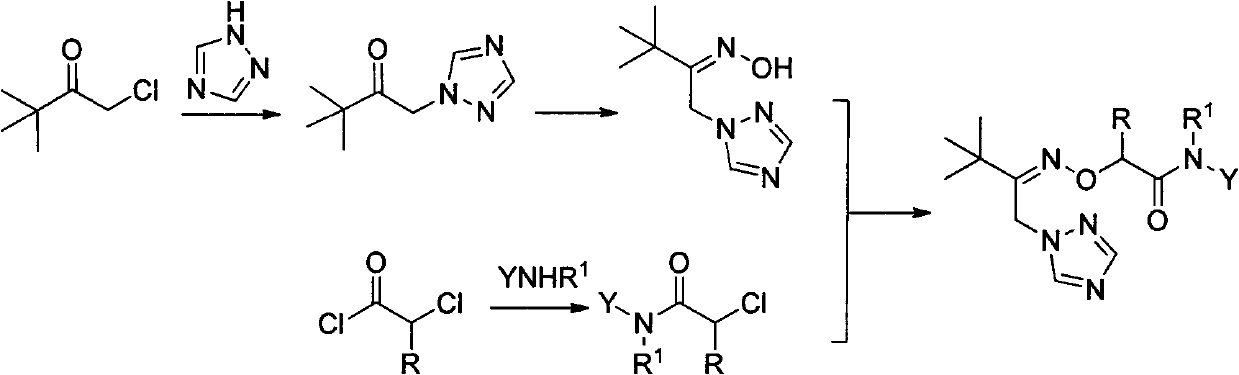

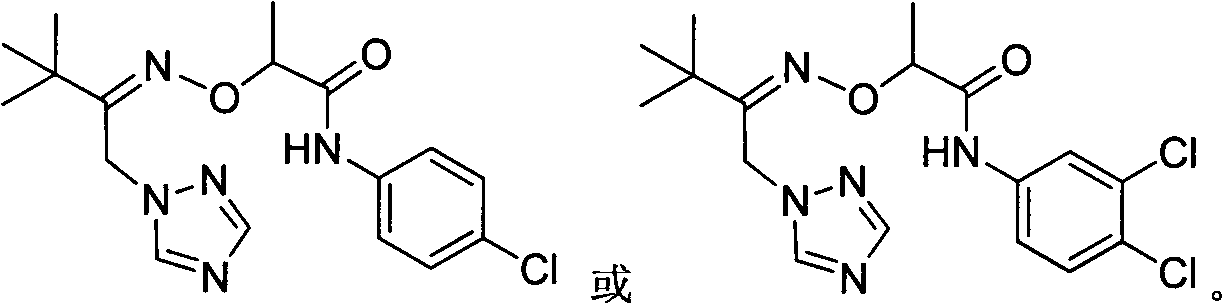

1-(1,2,4-Triazolyl) Ketoxime Ether Amide and Its Application

InactiveCN102260219ANo activity against Sclerotinia sclerotiorumActivity against Sclerotinia sclerotiorumBiocideOrganic chemistryHydrogenSclerotinia

The invention discloses 1-(1,2,4-triazolyl)ketoxime ether-acylamide disclosed as a chemical structural formula I, wherein R is selected from hydrogen, C1-C2 alkyl group, and C3-C4 straight-chain or branched alkyl group; R1 is selected from hydrogen, C1-C2 alkyl group, and C3-C4 straight-chain or branched alkyl group; and Y is selected from aromatic group or benzyl group. The 1-(1,2,4-triazolyl)ketoxime ether-acylamide disclosed as the chemical structural formula I can be used for preparing bactericide or weedicide for killing Sclerotinia scleotiorum.

Owner:HUNAN UNIV

Magnesia-alumina spinel material prepared by waste activated alumina and preparation method thereof

InactiveCN101580383AGood economic and social benefitsStrong market competitivenessSolid waste disposalActivated aluminaMagnesium

The invention provides a magnesia-alumina spinel material prepared by waste activated alumina and a preparation method thereof. The raw material formula mainly comprises the waste activated alumina and basic magnesium carbonate; and the preparation method comprises the following steps of: taking the waste activated alumina and the basic magnesium carbonate as raw materials, mixing, pressing and forming the raw materials, leading the raw materials to react at high temperature, cooling the reaction products, thus obtaining the prepared magnesia-alumina spinel material. The material and the method are beneficial for waste utilization and solve the severe pollution of the waste activated alumina on the environment; the produced products have high-quality refractories which have high added value and no pollution, save the production cost, and have obvious economic benefits and popularization and application values.

Owner:FUZHOU UNIVERSITY

Method for preparing functional grease and active protein powder from abelmoschus manilhot

ActiveCN104342282AProtect nutritionHigh activityProtein composition from vegetable seedsFatty-oils/fats refiningDistillationActive protein

The invention provides a method for preparing functional grease and active protein powder from abelmoschus manilhot. The method comprises the following steps: washing abelmoschus manilhot seeds, drying, peeling, and pressing the seeds into a mould; subjecting the seed mould to a sub-critical extraction treatment, separating the solid-liquid phases after the extraction to obtain solid wet meal and a mixed solution; subjecting the mixed solution to an evaporation treatment to remove the extractant to obtain a grease solution; further subjecting the grease solution to molecular steaming refinement to obtain functional grease with an acid value of 0.21 to 0.23 mg / g; removing residual solvent on the solid wet meal which is separated out after the extraction, drying the meal at a low temperature, grinding, and sieving with a 60-mesh sieve so as to obtain the active protein powder. The provided method omits the tedious processes in the conventional grease refining technology such as deacidification, decoloring, and deodorizing through various chemical or physical processes, and has the advantages of short process procedure and high efficiency. The refined oil acid value is 0.21 to 0.23 mg / g after molecular distillation, and reaches the national A-grade edible oil standard. Furthermore, the obtained active protein powder is not processed at a high temperature, and is not modified, so the active protein powder is a high quality raw material for preparing foods with a high protein content.

Owner:台建祥 +5

High voltage sulphur resistant translation catalyst of CO and preparation method thereof

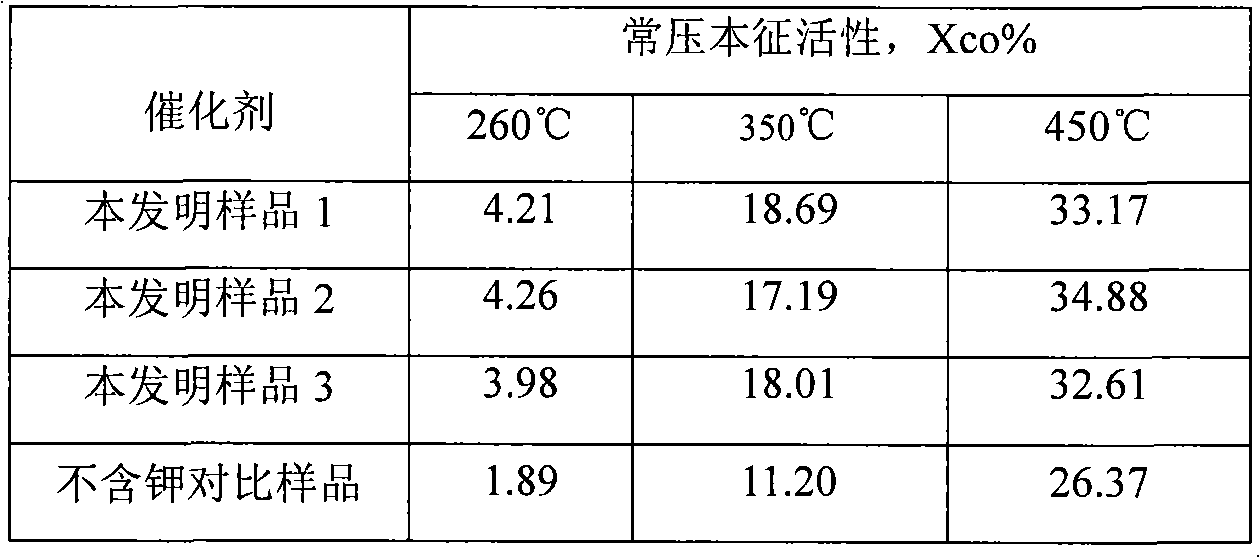

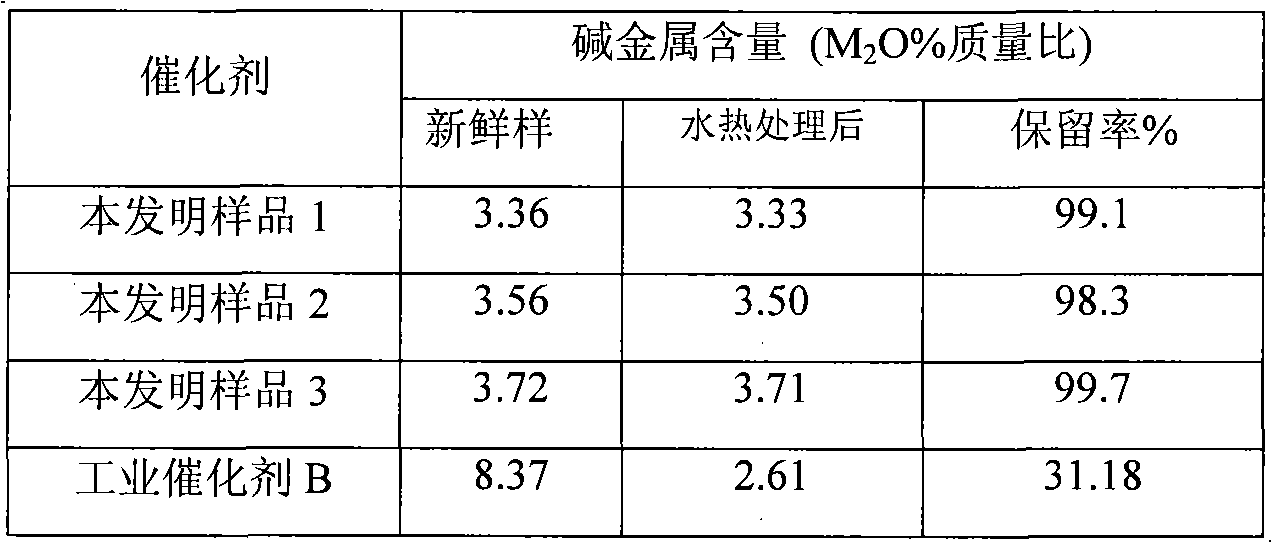

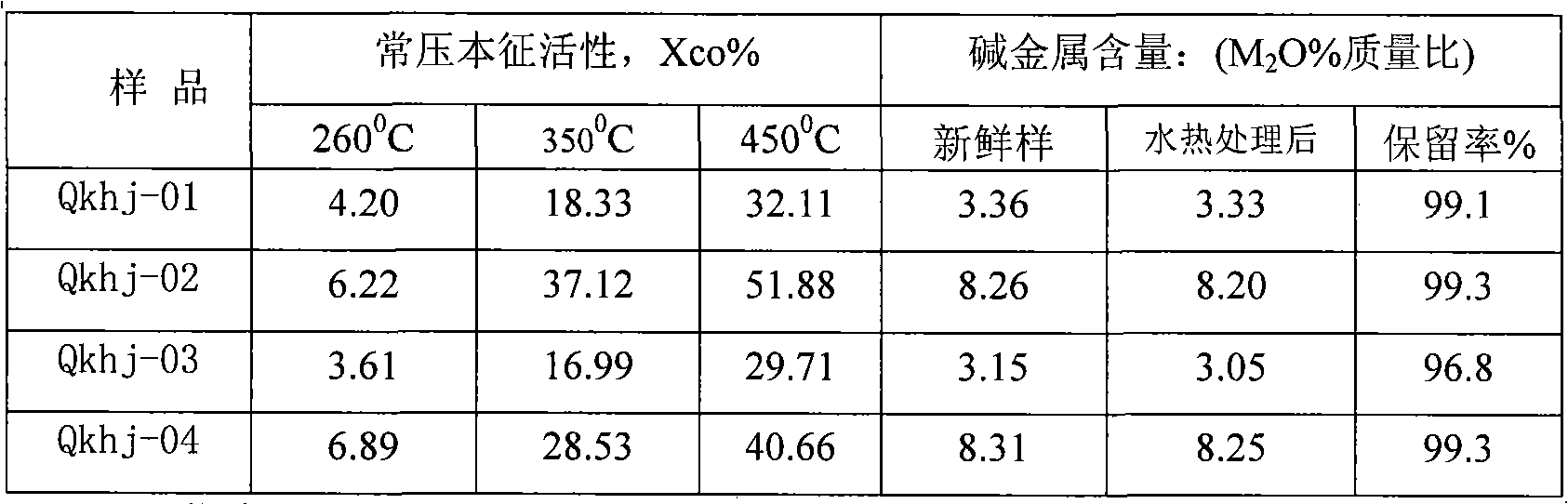

ActiveCN101318137AHigh retention rateActivity hasMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideHigh pressure

The invention discloses a carbon monoxide high pressure sulfur-tolerant shift catalyst, comprising a catalyst active component, an alkali metal activated assistant and a carrier, which is characterized in that the alkali metal activated assistant is an alkali metal mineralizer. The alkali metal mineralizer is an albite, a potash feldspar, a sodium nepheline or / and a kalsilite, wherein, the sodium nepheline or / and a kalsilite is preferable. An alkali metal oxide accounts for 0.1 to 15 percent of the total weight of the catalyst. The invention also provides the preparation method of the catalyst. The operation technology is simple and the catalyst can be prepared by kneading, extruding and calcining. The prepared catalyst has low light-off temperature. Under the conditions of high pressure, high temperature and high water-gas ratio, the alkali metal has little drain rate or even no drain and has high strength and strength stability.

Owner:青岛联信催化材料有限公司

Novel method for preparing catalpol medicament composition containing the same and uses thereof

InactiveCN101220063AImprove developmentActivity hasOrganic active ingredientsNervous disorderDrugPharmaceutical Resources

The invention relates to a new preparation method of catalpol of general formula (I), wherein R1 is a monosaccharide; R3, R4, R5 and R8 are H; while R6 is OH and R7 is -OCH2OH. The invention also relates to the application of the compound and the drug combination thereof in the prevention and treatment of Alzheimer disease and Parkinson disease, which provides the new preparation method of the compound and the drug combination thereof for researching and developing new drugs against the Alzheimer disease and the Parkinson disease, being beneficial to further develop natural pharmaceutical resources.

Owner:DALIAN UNIV OF TECH

Active calcium silicate, and preparation method and application thereof

InactiveCN104194404AActivity hasGood dispersionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCalcium silicateBlow molding

The invention discloses an active calcium silicate, and a preparation method and application thereof. The preparation method comprises the following steps: (1) mixing a coupling agent and water to prepare a dispersion solution; (2) adding calcium silicate into the dispersion solution prepared in the step (1), and stirring; carrying out vacuum filtration to obtain modified active calcium silicate; and (3) drying the active calcium silicate prepared in the step (2). The invention also discloses a plastic stuffing which comprises the active calcium silicate, a lubricant, polymers and a compatilizer. The invention also discloses a method for preparing the plastic stuffing. When being used in blow molding, running, injection molding and other plastic products, the active calcium silicate or plastic stuffing has favorable dispersion effect and toughening effect.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT +1

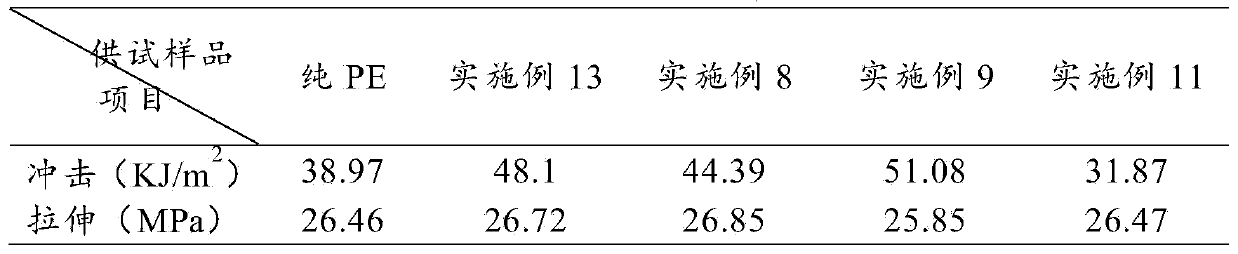

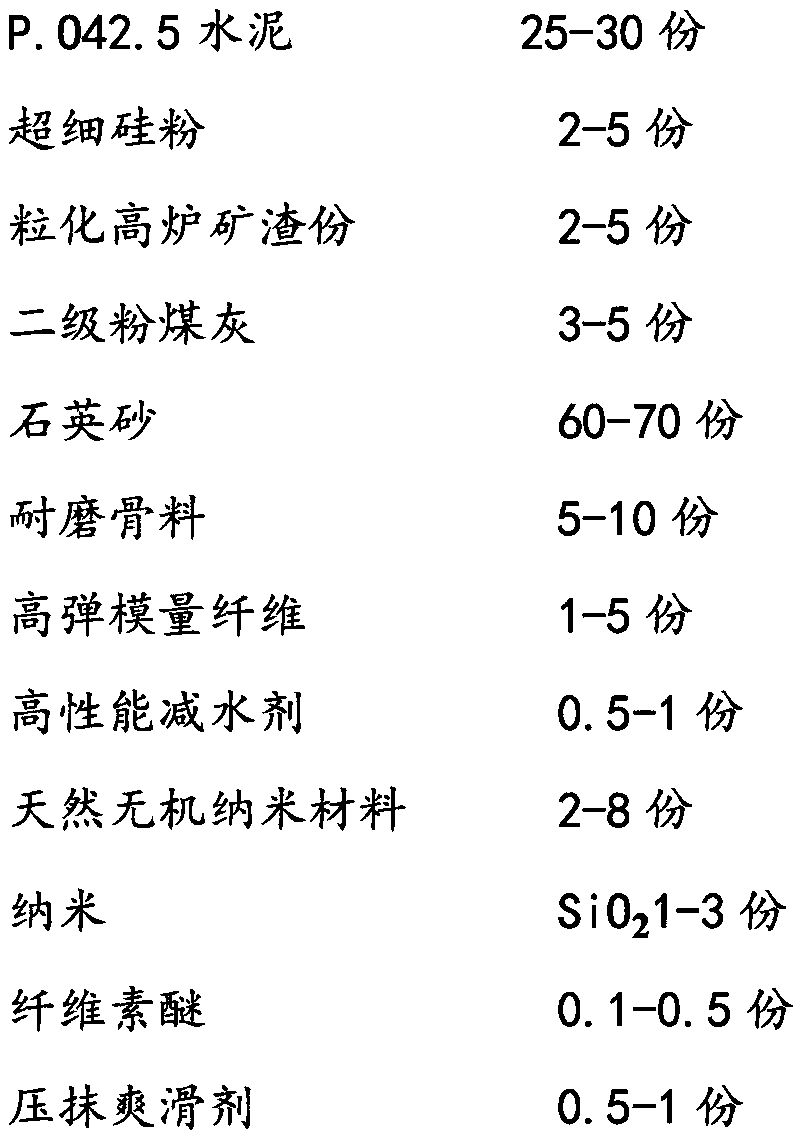

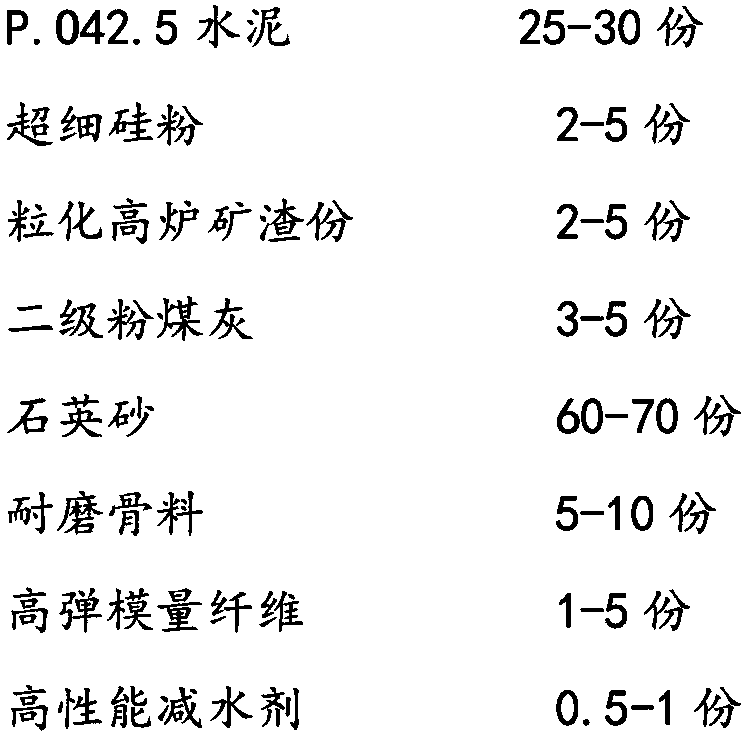

Impact-resistant and wear-resistant composite material for hydraulic structure

The invention relates to the technical field of building materials, and concretely relates to an impact-resistant and wear-resistant composite material for a hydraulic structure. The composite material is used for solving the problem of poorer impact resistance and wear resistance of a composite material for manufacturing concrete in the prior art. The composite material comprises 25-30 parts of P.042.5 cement, 2-5 parts of ultrafine silicon powder, 2-5 parts of granulated blast furnace slag, 3-5 parts of secondary fly ash, 60-70 parts of quartz sands, 5-10 parts of wear-resistant aggregate, 1-5 parts of a high-elastic modulus fiber, 0.5-1 part of a high-performance water reducing agent, 2-8 parts of a natural inorganic nano-material, 1-3 parts of nano-SiO2, 0.1-0.5 part of cellulose etherand 0.5-1 part of a pressing and smearing slipping agent. The composite material prepared from the components has effectively improved impact resistance and wear resistance, and has the properties ofwater resistance, seepage resistance, corrosion resistance, high fatigue resistance and the like.

Owner:甘肃土木工程科学研究院有限公司

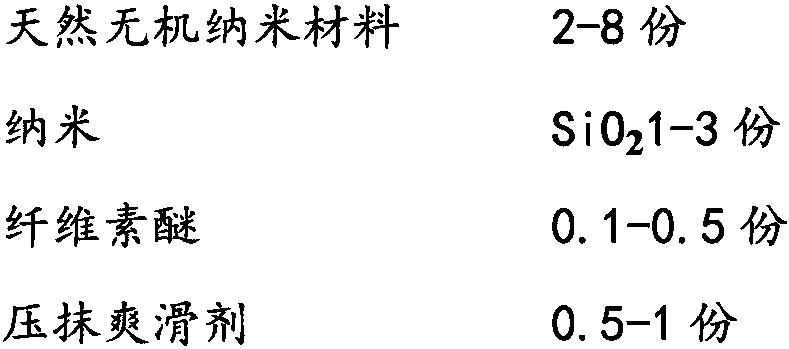

Endometrium stem cell serum-free medium

InactiveCN106701660AStrong self-renewal abilityMild ingredientsCulture processArtificial cell constructsL-glutamineSerum free media

The invention relates to an endometrium stem cell serum-free medium, which is prepared from the following components in percentage by total volume: 70 to 85 percent of low-sugar DMEM (Dulbecco Modified Eagle Medium), 5 to 10 percent of serum replacement, 2 to 10 percent of vitamin C, 1 to 5 percent of L-glutamine, 1.25 to 15 percent of glucose, 1 to 10 percent of 2-mercaptoethanol, 0.8 to 1.5 percent of mycillin double-antibody solution, and 0.8 to 1.5 percent of gentamicin sulphate. The endometrium stem cell serum-free medium provided by the invention is adopted for carrying out cell culture, and has the characteristics of less medium component, stable endometrium stem cell growth, high multiplication capacity and high purity.

Owner:GUANGDONG PANGUARD CELL BIOLOGICAL TECH CO LTD

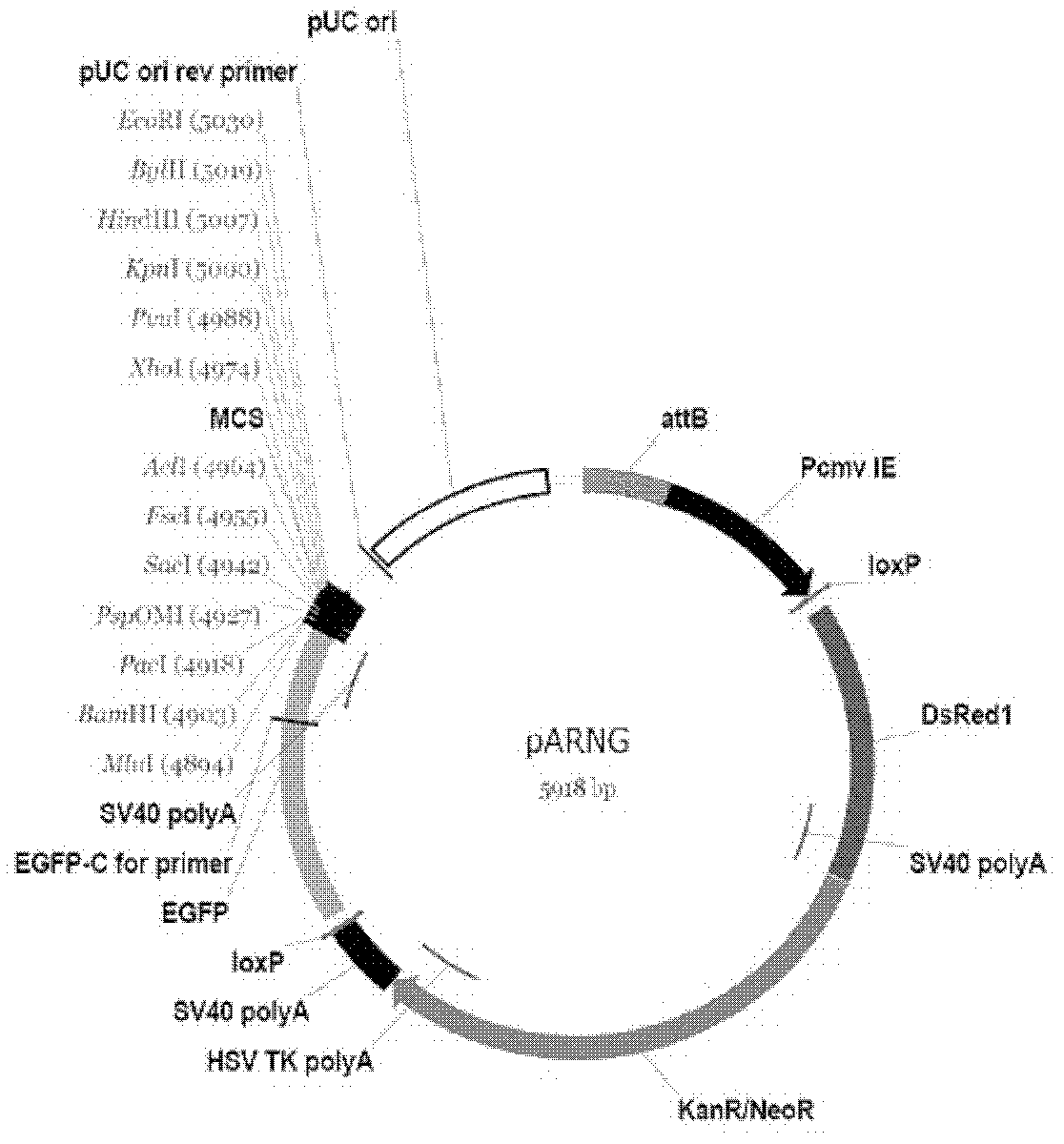

HBD3 mammary gland specific expression vector and constructed recombinant cell

InactiveCN102628061ATo achieve antibacterial functionAvoid safety hazardsFermentationVector-based foreign material introductionEmbryoΦc31 integrase

The invention discloses a HBD3 mammary gland specific expression vector and a constructed recombinant cell. The vector comprises a HBD3 gene with a signal transduction peptide, and CSN5 and CSN3 are set upstream and downstream of the HBD3 gene respectively for serving as regulating and controlling elements. The host cell of the recombinant cell is a bovine fetal fibroblast cell, an exogenous expression vector pARNG-HBD3 is integrated to a pseudo attP locus under the action of phiC31 integrase, positive cloning is realized through medicament screening, and an antibiotic screening marker between two homodromous LoxP sequences on the vector is removed through Cre recombinase treatment. A HBD3-containing bovine fetal fibroblast cell from which an antibiotic screening marker is removed is taken as a nuclear donor cell of a transgenic cloning embryo through nucleus transplantation, gene cloning embryos are obtained through SCNT (Somatic Cell Nuclear Transfer), and a milk cow which is free from a HBD3 transgenic gene of the antibiotic screening marker can be produced by transferring these embryos into a receptor cow.

Owner:NORTHWEST A & F UNIV +1

Hard polyvinyl chloride active impact resistant assistants

An active assistant for improving the impact performance of hard polyvinyl chloride material is prepared from the active PVC microparticles with high compatibility with basic resin and filler, and modified organic and inorganic materials through proportional mixing. Its advantages are high effect to improving the impact and refractory performance of PVC material, low dosage and low cost.

Owner:四川新元材料工程研究所

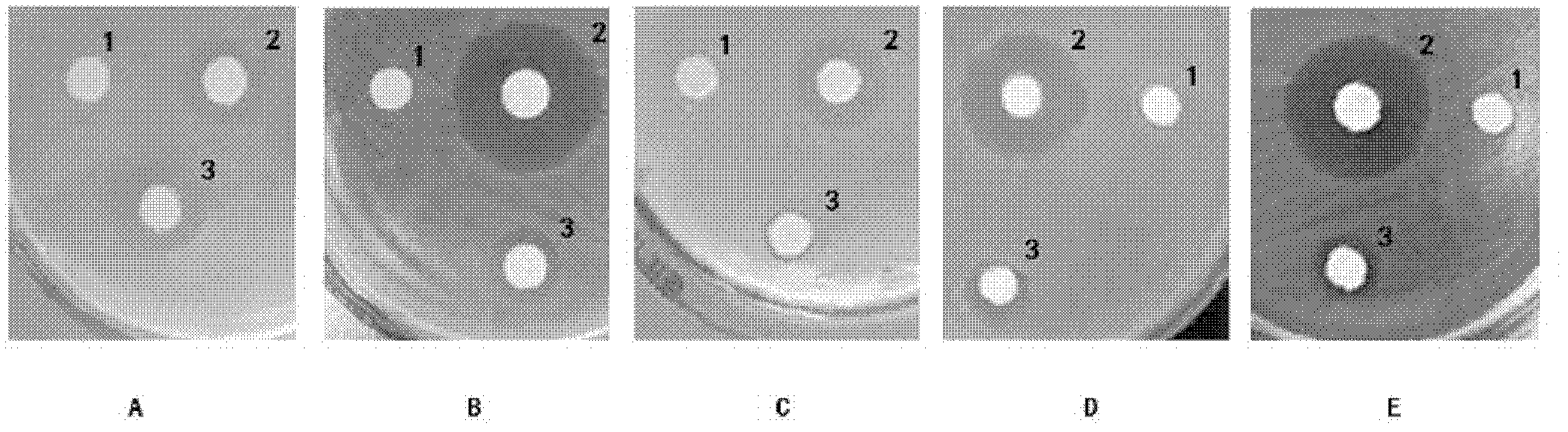

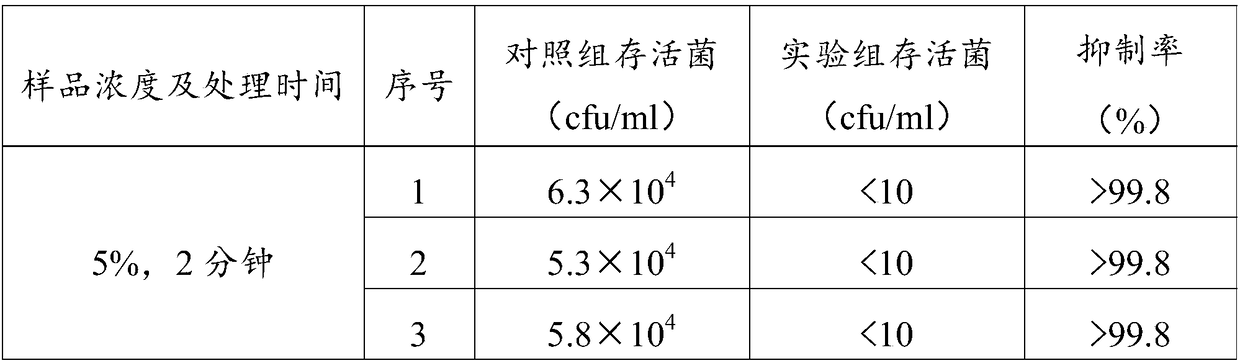

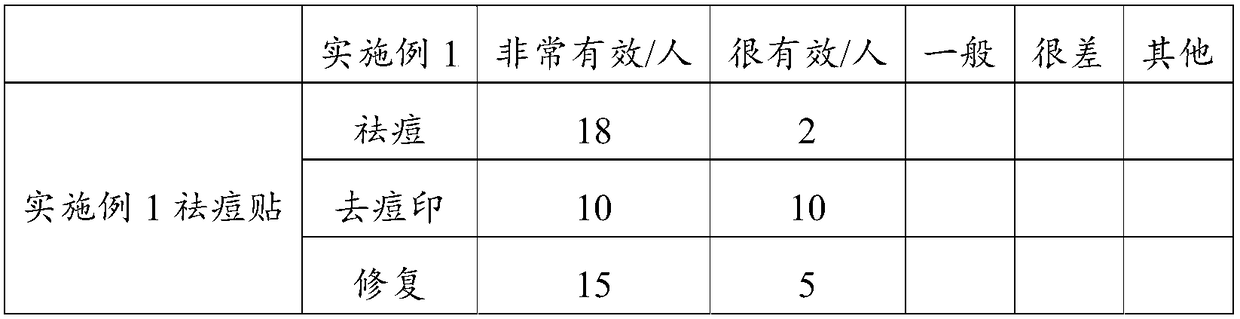

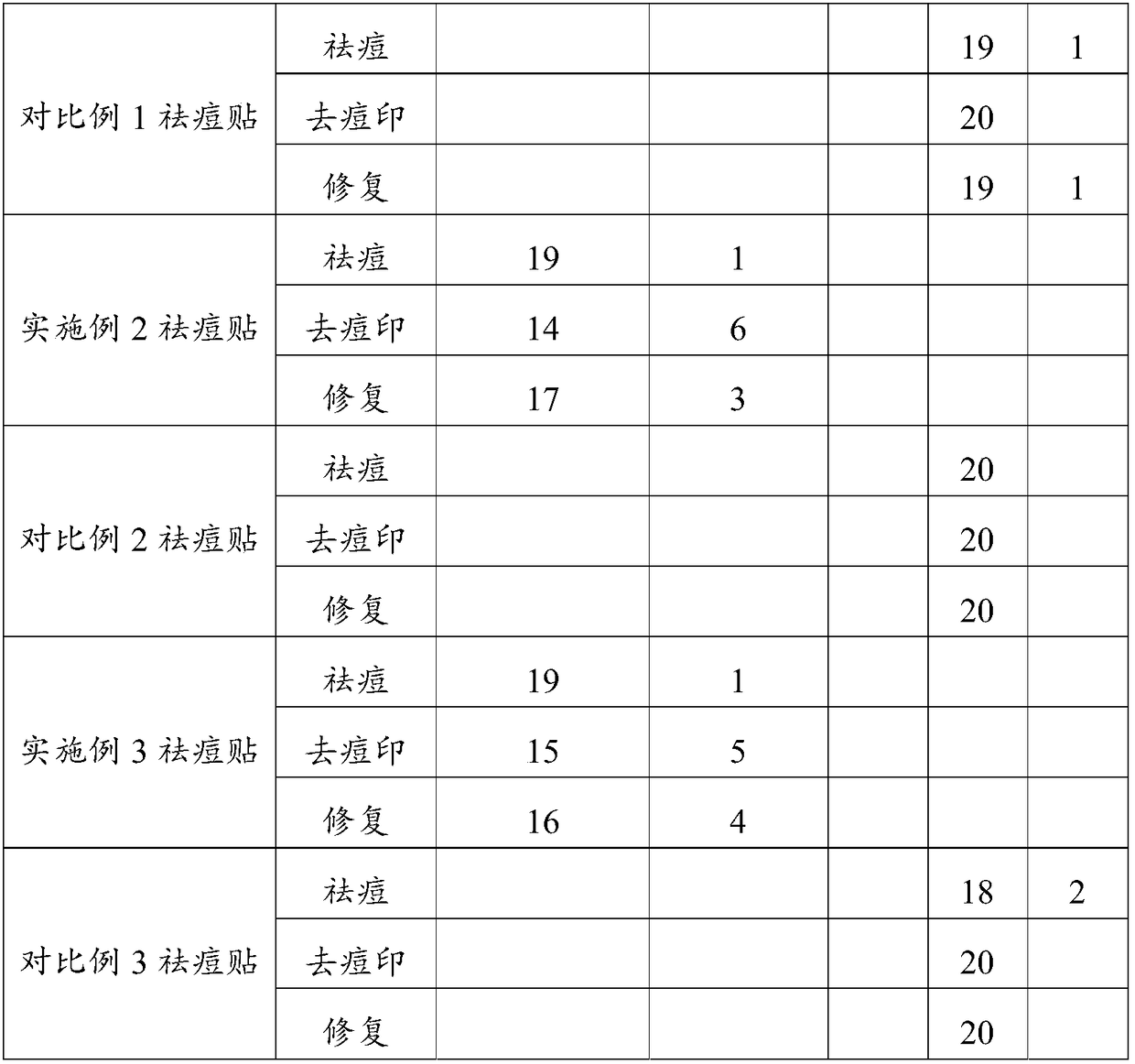

Acne removing patch and preparation method thereof

ActiveCN109276485APromote wound healingAvoid scaringCosmetic preparationsToilet preparationsPichia pastorisMedicine

The invention discloses an acne removing patch and a preparation method thereof, and belongs to the technical field of cosmetics. The acne removing patch is composed of a patch body and a content which is cured on the patch body, wherein the content consists of the following components in percentage by mass: 5-90% of a pichia pastoris fermented lystate filtrate, 5-90% of glycerol, 0.5-1% of p-hydroxyacetophenone, 0.5-1% of 1,2-hexanediol, 0-1% of hydroxyethyl cellulose and the balance of water. The prescription of the acne removing patch and the preparation method thereof, which supplement each other, can obviously improve an acne removing effect.

Owner:伯德创研(广州)生物科技有限公司

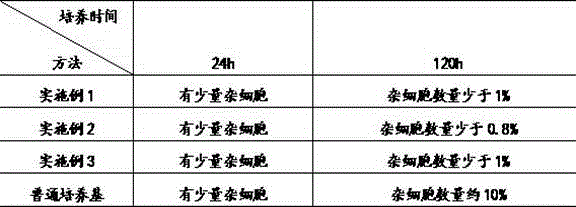

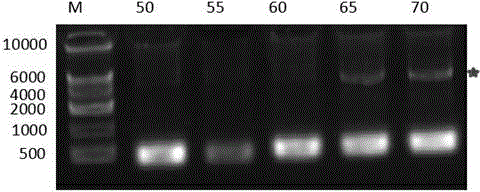

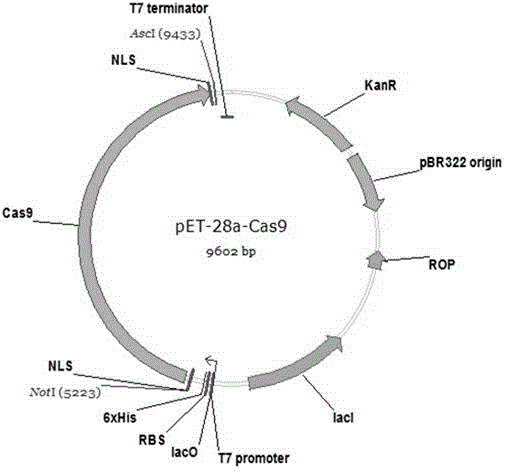

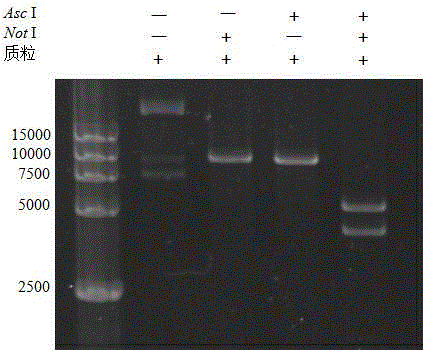

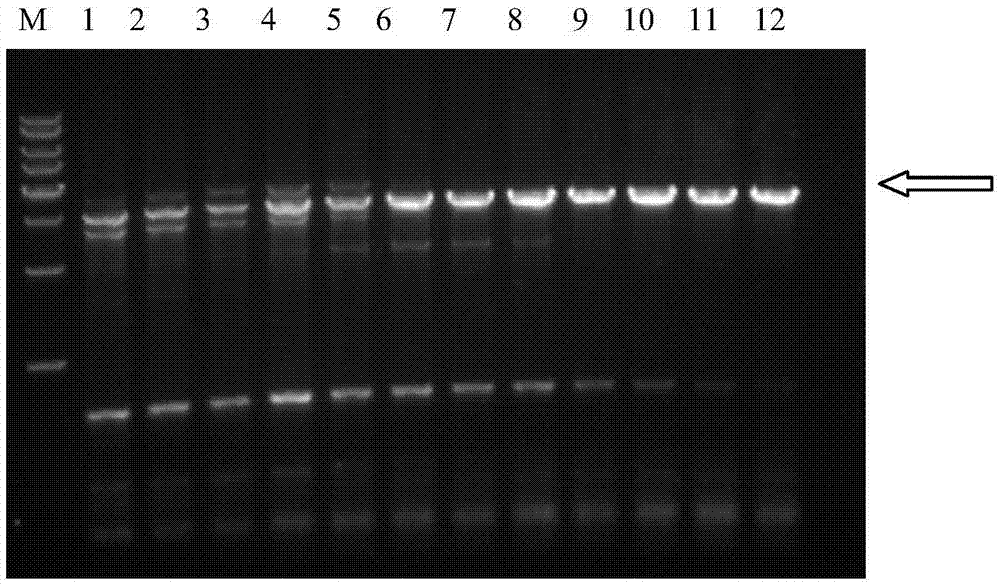

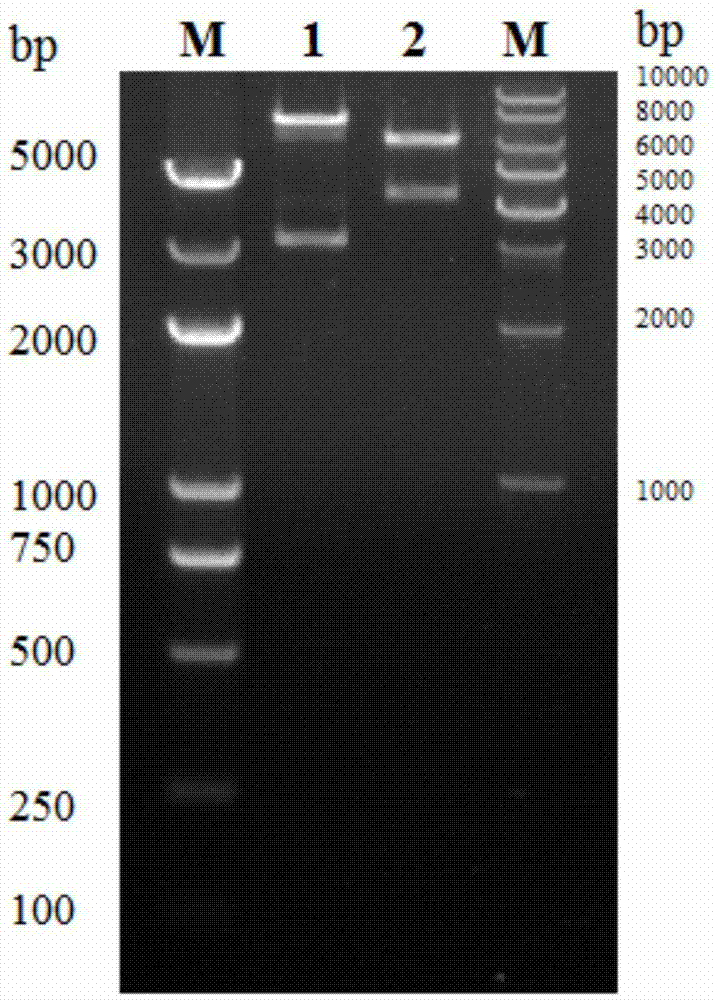

Method for preparing Cas9 protein capable of being used for embryo injecting and knockout mice preparing

The invention discloses a method for preparing Cas9 protein capable of being used for embryo injecting and knockout mice preparing. A Cas9 protein sequence is converted into pET28a-ccdB-CmR carrier and is then converted to a prokaryotic expression bacterial strain, a bacterial body is collected after inducible expression is carried out, and the purified Cas9 protein is obtained after affinity purification, concentration purification with an ultrafiltration pipe and dialysis; and the pET28a-ccdB-CmR carrier is characterized in that a prokaryotic expression carrier pET28a serves as a foundation, a NotI-ccdB-CmR-AscI sequence is inserted between an (i)Hind( / i)III enzyme cutting site and an (i)Xho( / i)I enzyme cutting site, and therefore the Cas9 protein is obtained. By means of the method, an efficient Cas9 protein prokaryotic expression system is constructed, in-vitro cutting experiments prove that the Cas9 protein obtained through expressions has the in-vitro activity, and peculiar in-vitro DNA cutting can be carried out; and embryo injecting experiments prove that the purified Cas9 protein has the in-vivo activity and can be used for preparing gene modification animals.

Owner:GUANGZHOU MAGIGEN BIOTECH

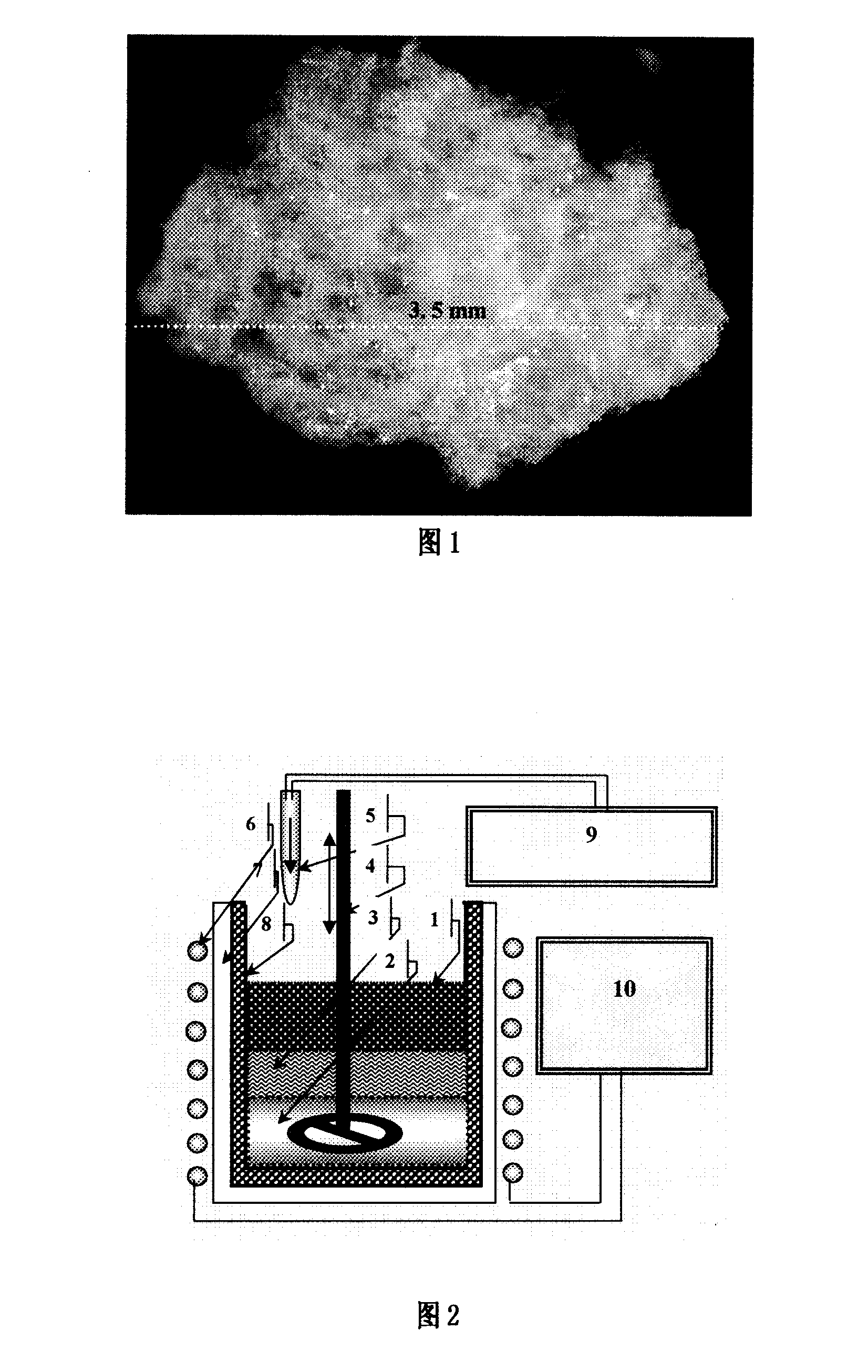

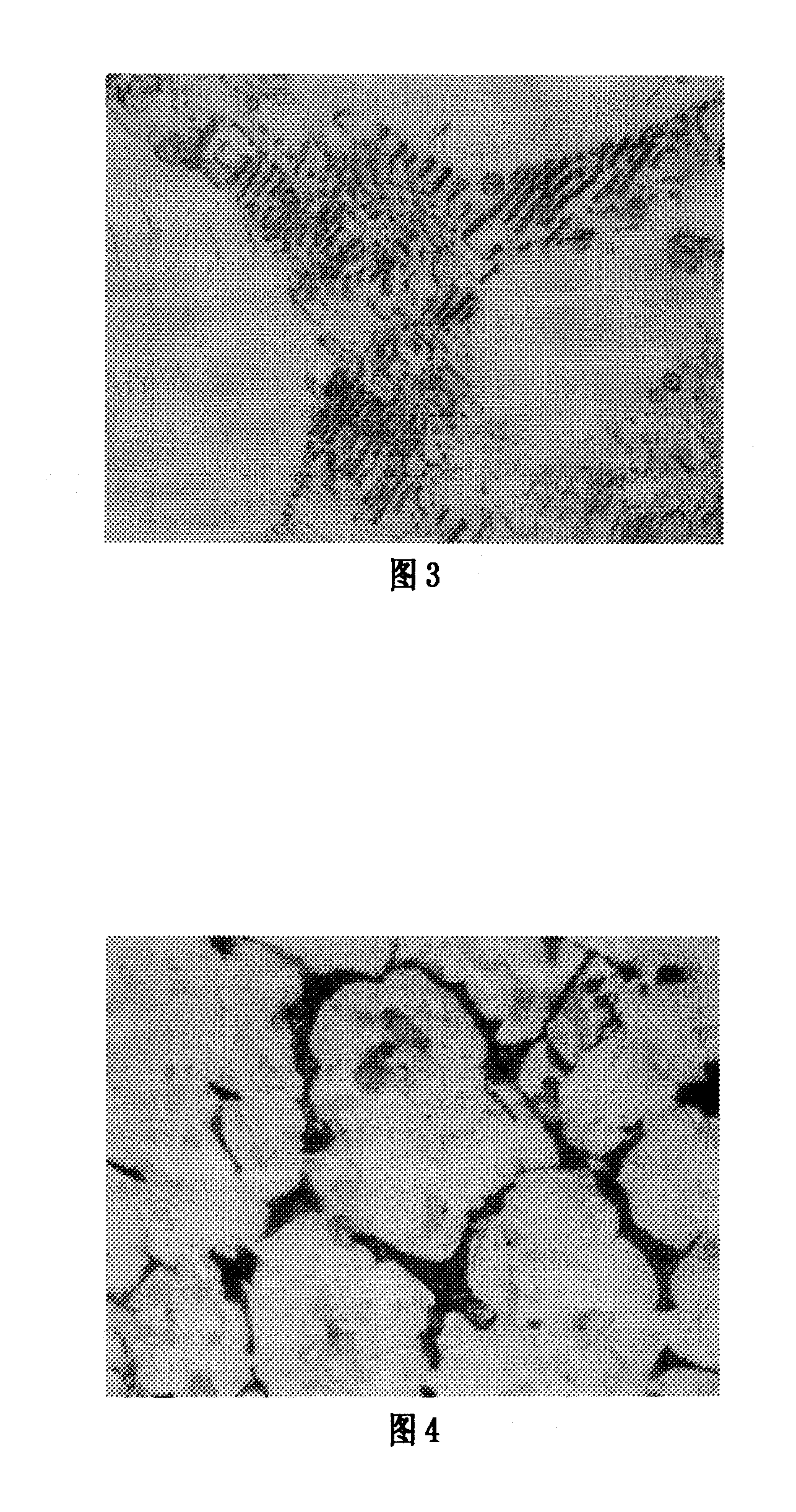

Method for synthesizing magnesium-silicon intermediate and preparation of high-magnesium aluminum alloy thereby

The invention relates to a synthesis method of magnesium-silicon intermediate and a method of preparing high magnesium aluminum alloy by using the intermediate, and particularly relates to a method of using natural perlite ore as silica source for synthesizing Mg-Si intermediate, and a method of using the intermediate to prepare the high magnesium aluminum alloy by means of in-situ synthesis. The Mg-Si intermediate is a special Mg-Si intermediate alloy containing low silicon, the special Mg-Si intermediate alloy and the in-situ synthesis method can solve the industrial difficult problems of high cost of silicon source, single variety and small generation possibility of Mg2Si, etc., in the process of making aluminum alloy with magnesium and silicon elements added synchronously.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

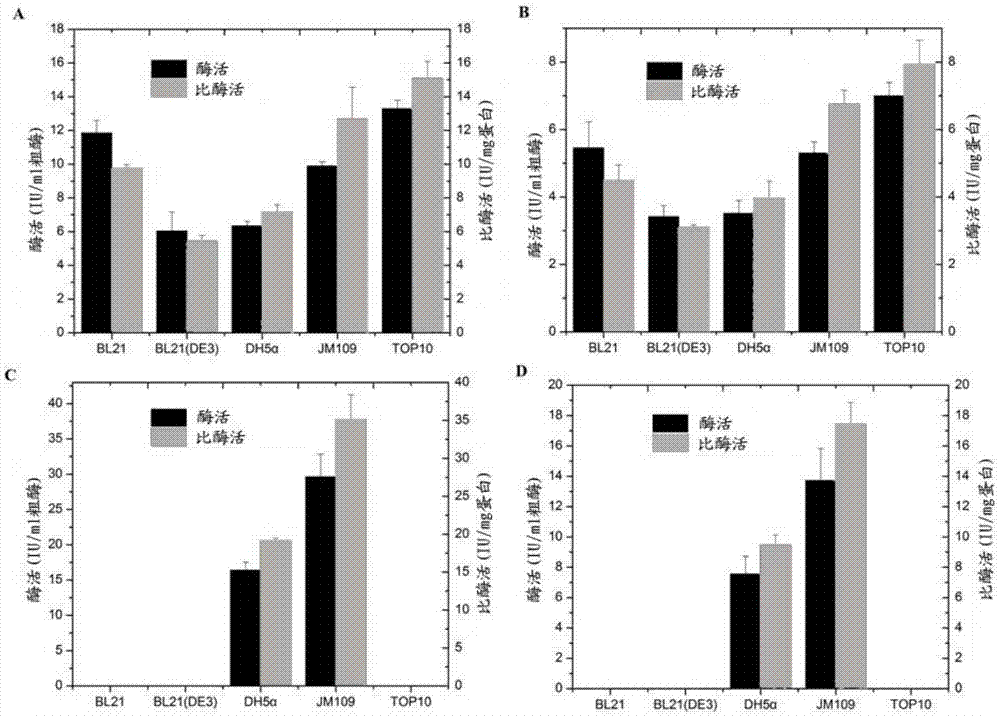

Preparation method and application of chondroitin sulfate ABC enzyme fusion protein

ActiveCN105441471AActivity hasSimplified purification procedureBacteriaOxidoreductasesChemistryExpression protein

The invention provides a method for expressing a chondroitin sulfate ABC enzyme fusion protein. The method comprises: 1) separately cloning a chondroitin sulfate ABC enzyme gene and a 3-glyceraldehyde phosphate apodehydrogenase gene, and connecting the genes to ensure that subsequently expressed 3-glyceraldehyde phosphate apodehydrogenase is connected with an N terminal of chondroitin sulfate ABC enzyme protein; 2) recombining the connected chondroitin sulfate ABC enzyme fusion protein gene into an expression vector; 3) converting the expression vector containing the chondroitin sulfate ABC enzyme fusion protein gene into a host cell for expression; and 4) harvesting and purifying expressed chondroitin sulfate ABC enzyme fusion protein. The active chondroitin sulfate ABC enzyme fusion protein obtained by the method accounts for 70% of the total expression protein quantity, so that subsequent purification processes are greatly simplified. The obtained ChSase ABC I fusion protein has high enzyme activity and can be used for producing chondroitin sulfate; moreover, the generation condition of the chondroitin sulfate is low, and the method for generating the chondroitin sulfate is simple and convenient and is easy to control.

Owner:BEIJING POLYTECHNIC

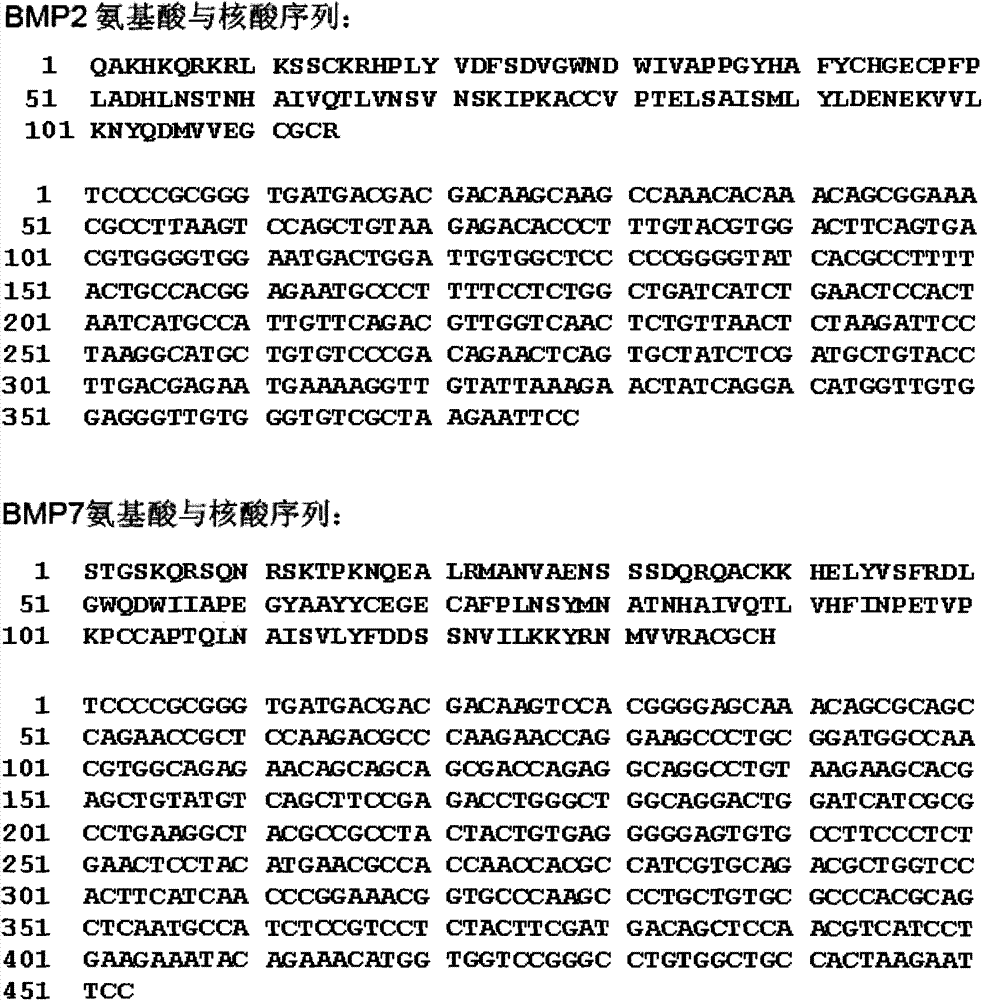

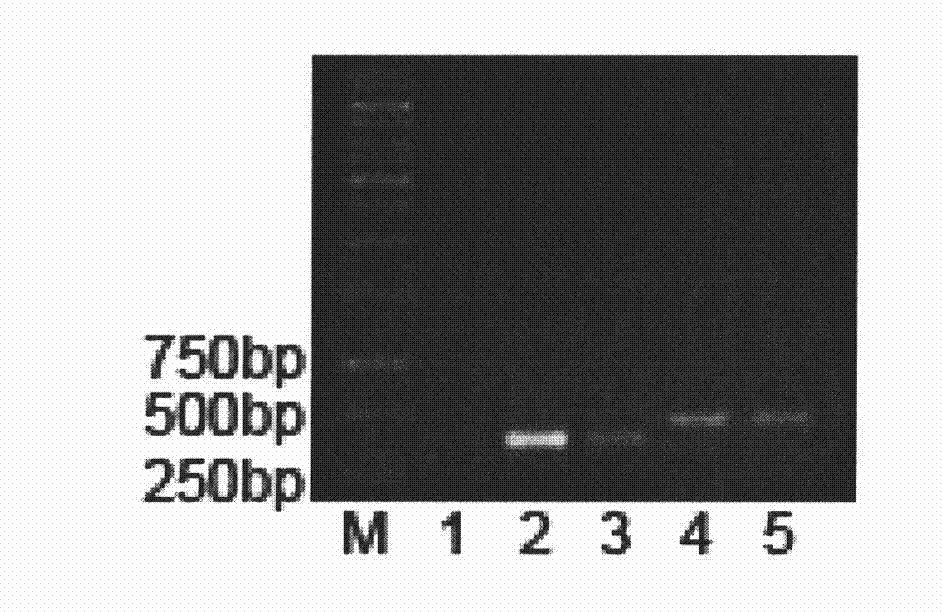

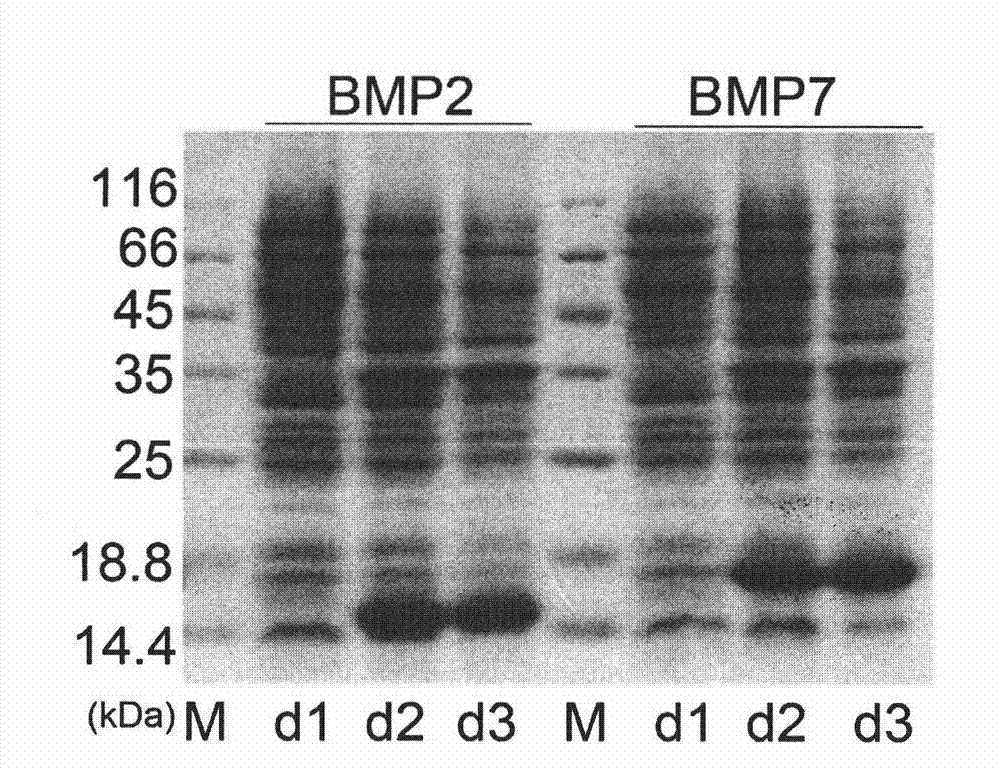

Method for expressing recombinant human bone morphogenetic protein in insect cell

InactiveCN102776198AIncrease alkaline phosphatase activityActivity hasPeptide preparation methodsViruses/bacteriophagesADAMTS ProteinsNa k atpase activity

The invention relates to a method for expressing a recombinant human bone morphogenetic protein in insect cells. The method comprises the following steps of cloning a mature peptide gene segment of the human bone morphogenetic protein (BMP) to an an improved insect cell-baculovirus protein expression vector; co-transfecting sf9 insect cells; preparing recombinant baculovirus having mature peptide gene segment of the BMP; then transfecting High5 insect cells; highly expressing the BMP mature peptides; and purifying the expressed BMP mature peptides via an Ni affinity column. Detections on in-vitro alkaline phosphatase activity and induced-bone experiments of muscular pouch embedded in mice demonstrate that both expressed BMP2 and BMP7 have activities for inducing ectopic bone formation. By using an improved insect cell-baculovirus protein expression system,, 40 mg purified BMP2 or BMP7 mature peptide can be obtained per litre cultured insect cells; and cost is reduced at least 10 times than that in CHO cells.

Owner:YANGZHOU TAIDA BIOTECH

Preparation method of exosome-containing cartilage repair material

InactiveCN111494707AKeep aliveActivity hasGenetically modified cellsCell culture supports/coatingOsteoblastEngineering

The invention relates to a preparation method of an exosome-containing cartilage repair material. The method comprises the following steps of exosome preparation, scaffold material preparation and composite material preparation. The exosome preparation comprises the following steps: step 1, constructing miRNA140 overexpressed plasmids by genetic engineering means; step 2, performing packaging to obtain lentiviruses, and transfecting 293T; step 3, infecting mesenchymal stem cells; and step 4, culturing hBMMSC-140, separating the exosome Exso-140 for over-expressed miRNA-140 from a culture medium, adding a preservation solution containing sodium gluconate and inorganic salt, and performing preserving at a temperature of 80 DEG C below zero. The invention aims at preparing a bionic cartilagescaffold material taking bi-component collagen and hydroxyapatite as elements. The exosome is effectively embedded in the bionic bone material, the original activity of the exosome is maintained, andthe functional cartilage repair material with activity is formed; and the material can play a role in osteoblast proliferation, can repair vascular injury, and enhances the functionality of the bionicbone material.

Owner:百澳瑞派(天津)生物科技有限公司

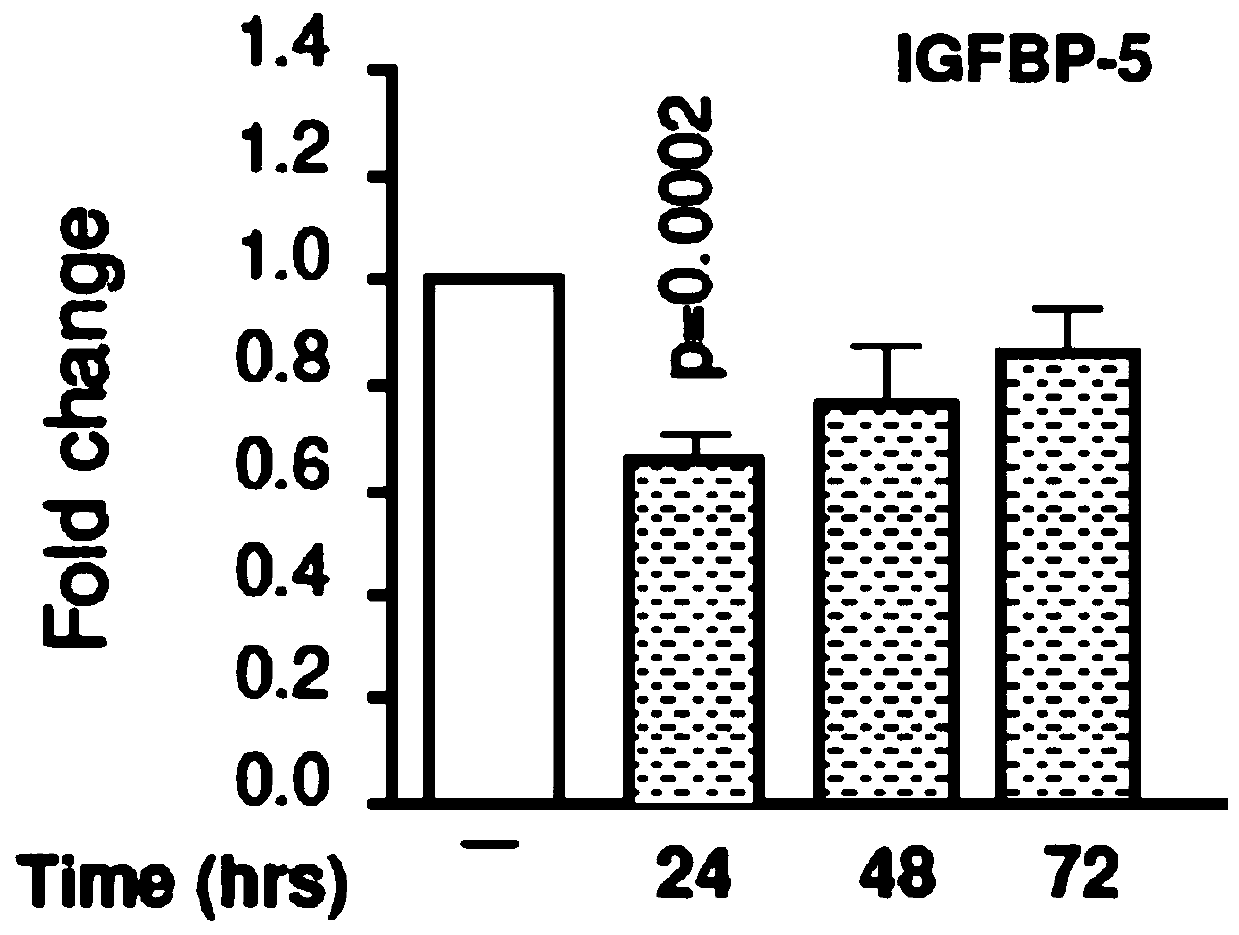

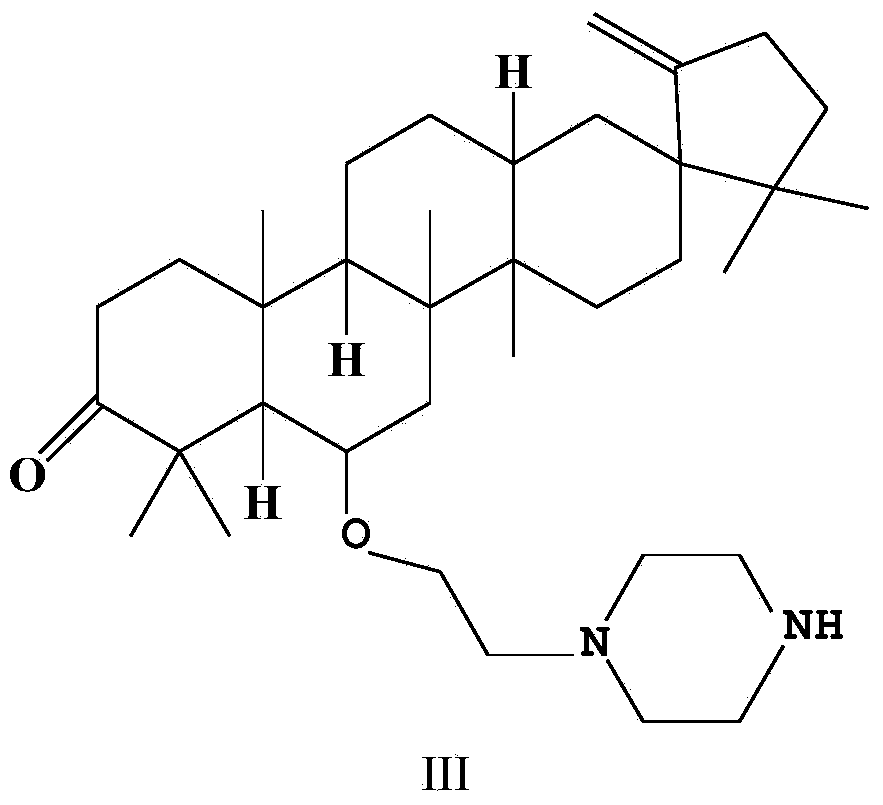

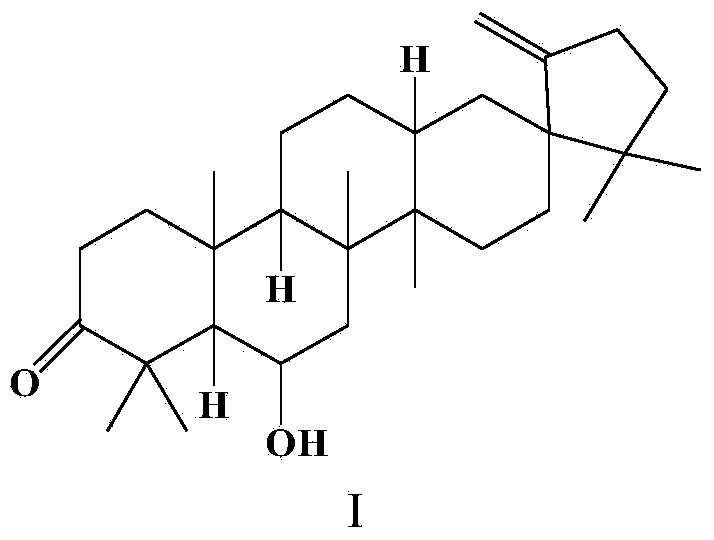

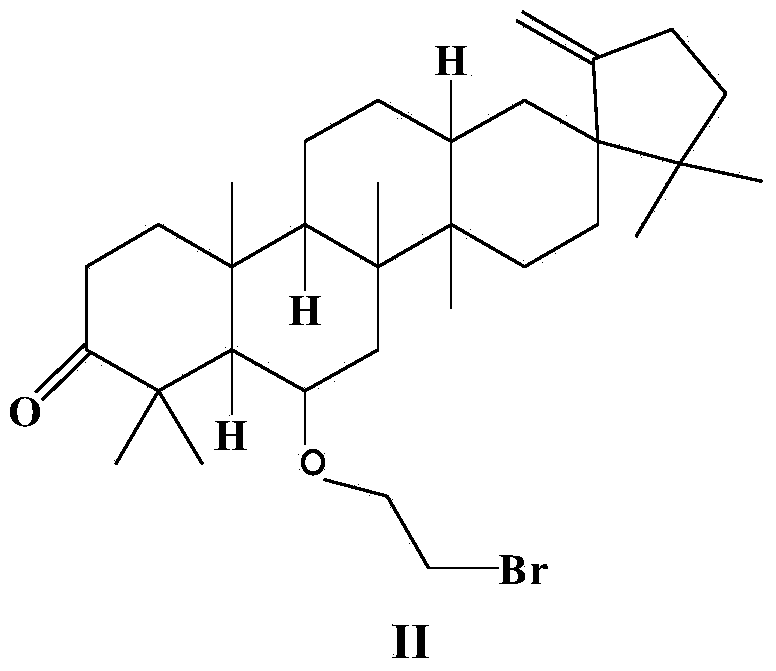

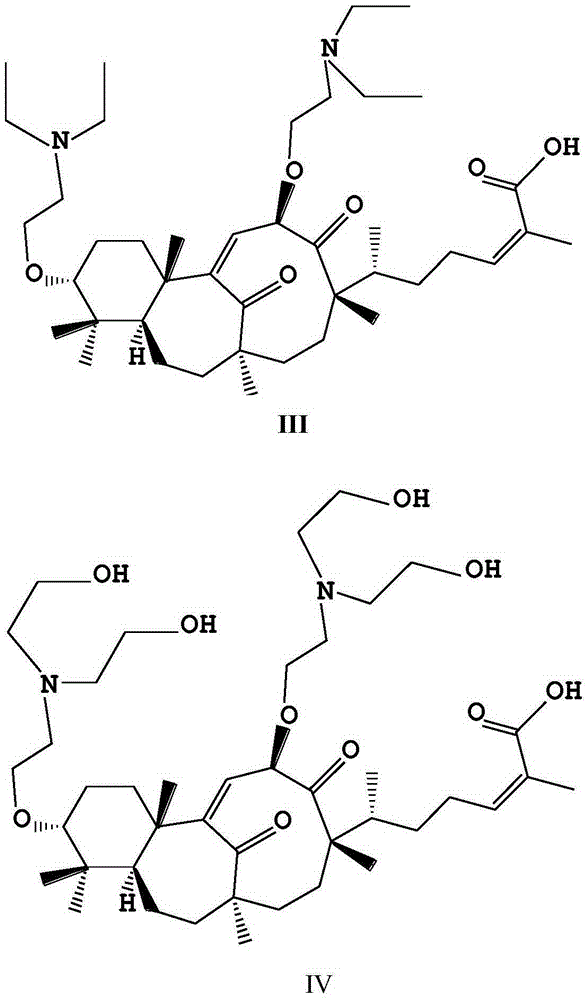

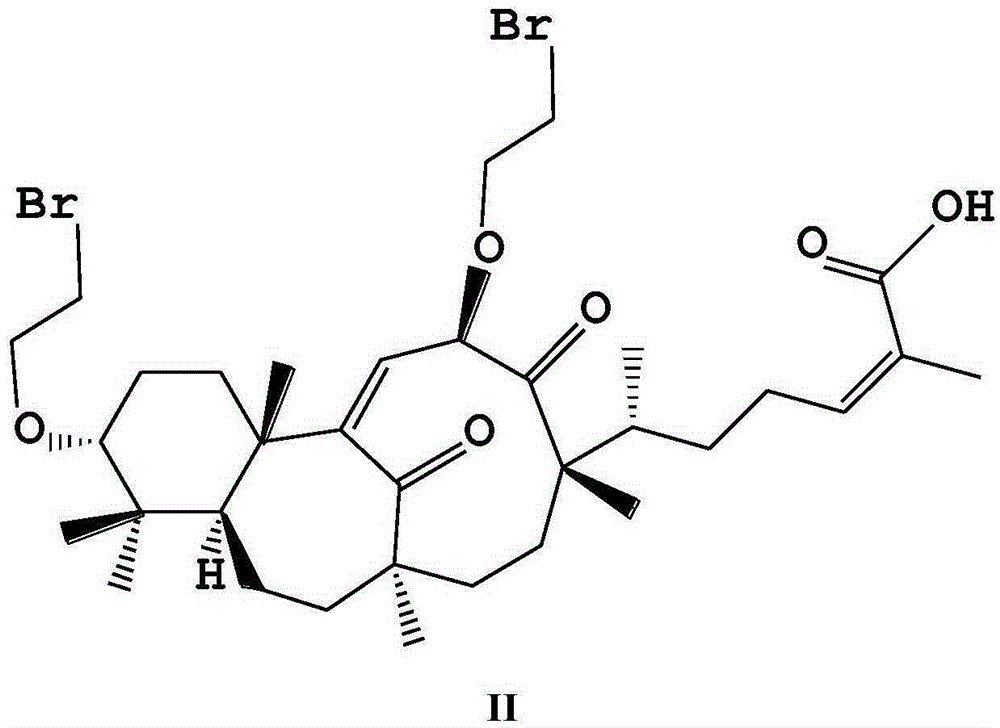

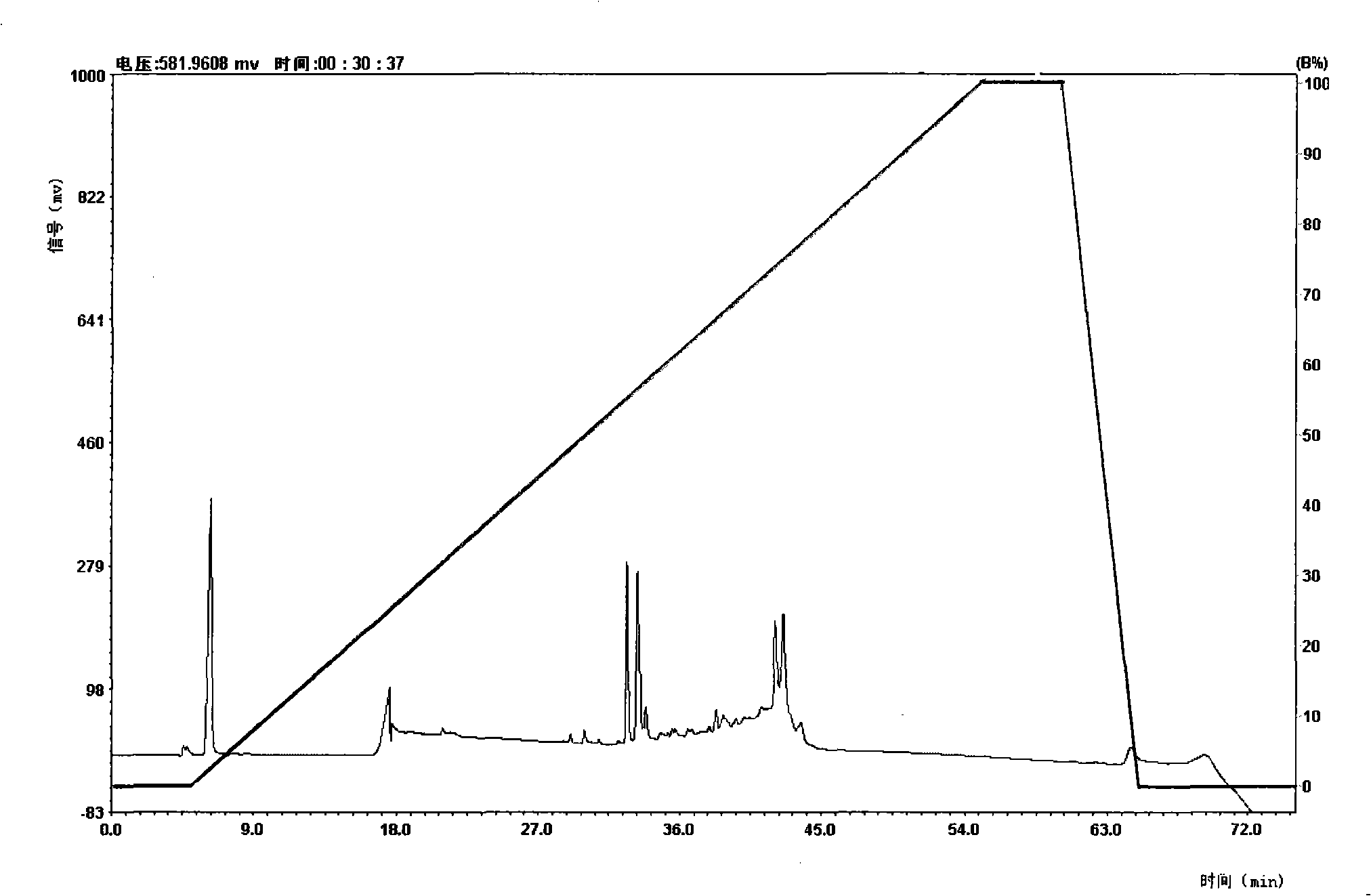

Application of O-(piperazinyl) ethyl derivative of cleistanone to preparation of medicine for resisting acute gout

InactiveCN104288160AReduce apoptosisHigh activityOrganic active ingredientsSkeletal disorderCleistanoneAcute gout

The invention relates to the fields of organic synthesis and pharmaceutical chemistry, in particular to O-(piperazinyl) ethyl derivative of cleistanone, and a preparation method and the application of the O-(piperazinyl) ethyl derivative to the preparation of medicine for resisting acute gout. The invention compounds new O-(piperazinyl) ethyl derivative, and discloses a preparation method thereof. Pharmacology experiments show that the O-(piperazinyl) ethyl derivative has the effect of resisting acute gout, and has the value of developing medicine for resisting acute gout.

Owner:广州往圣生物科技有限公司

Composition and application thereof in drug for resisting acute gout

InactiveCN105343043AReduce apoptosisHigh activityOrganic active ingredientsOrganic chemistryAcute goutOrganic synthesis

The invention relates to the fields of organic synthesis and medicinal chemistry, and in particular relates to a composition, a preparation method and application of the composition in preparing a drug for resisting acute gout. The invention discloses a composition and a preparation method thereof. Based upon pharmacological experiments, the composition disclosed by the invention has an effect on resisting the acute gout, so that the composition has the value of developing the drug for resisting the acute gout.

Owner:NANJING GUANGKANGXIE BIOLOGICAL MEDICAL TECH

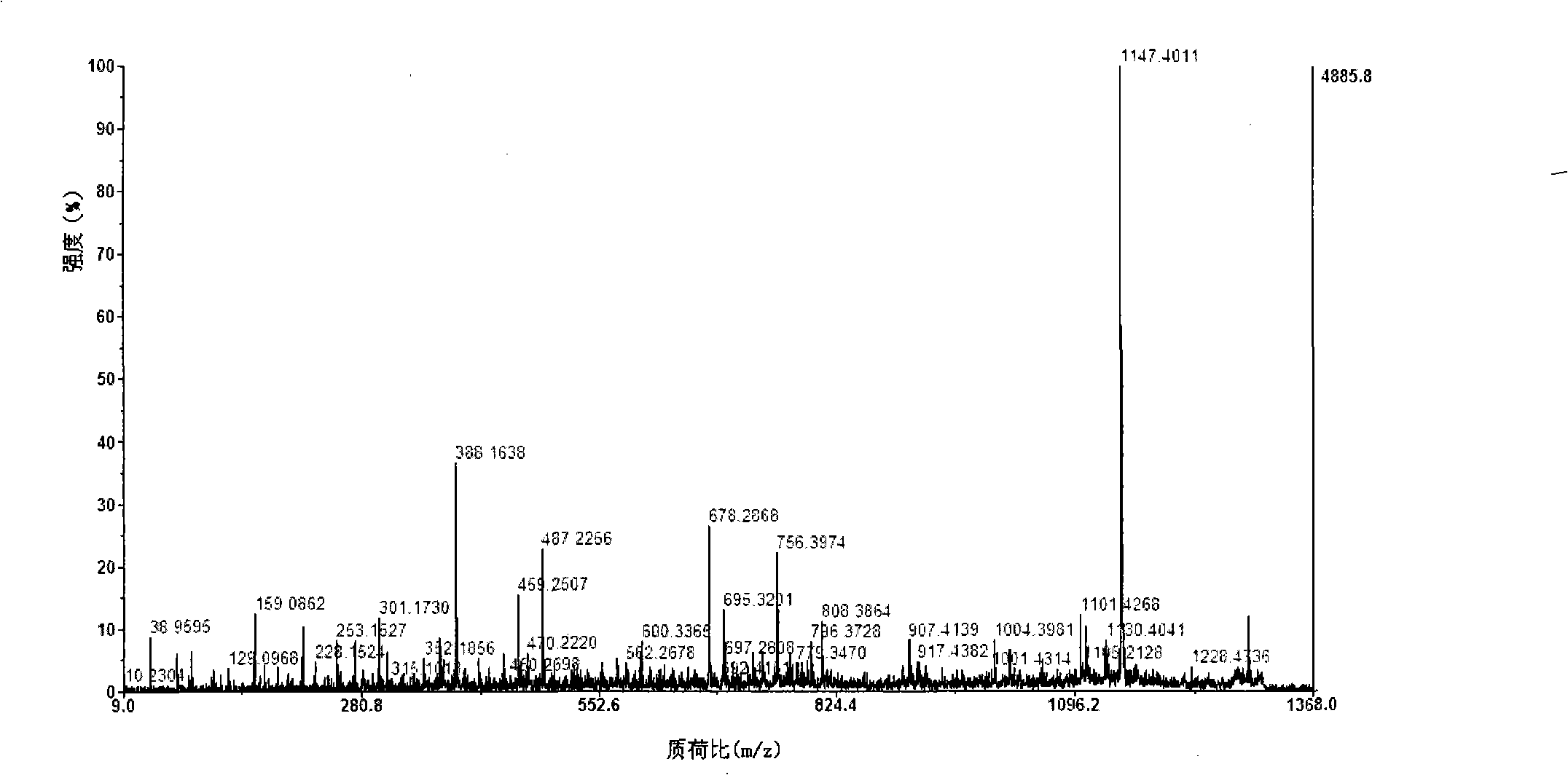

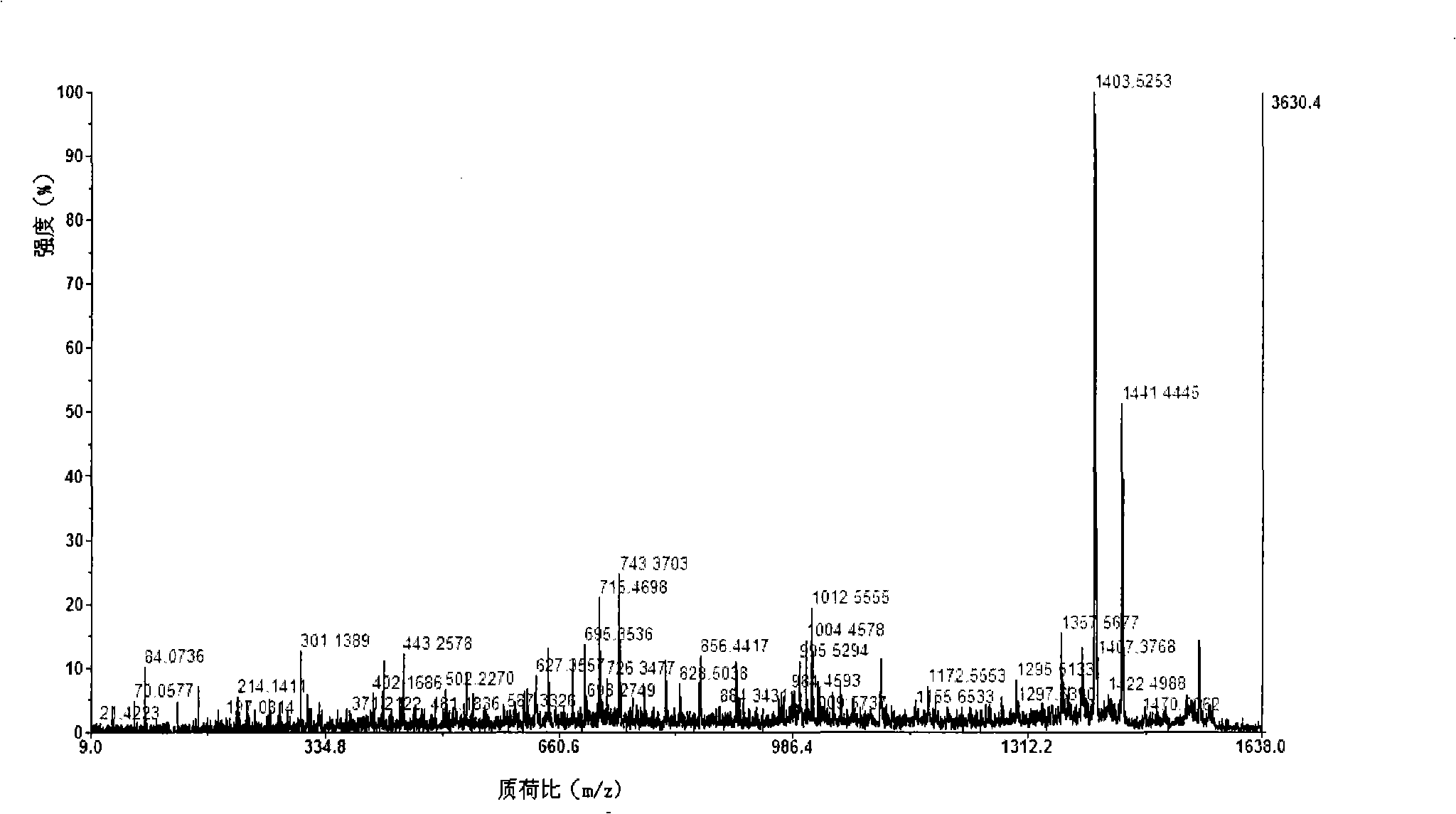

Polypeptides substances, preparing method and use thereof

ActiveCN101265292AActivity hasHigh activityPeptide/protein ingredientsPeptide preparation methodsActivity measurementsActivity measurement

The invention discloses a polypeptide substance, preparation method and application thereof. The invention also discloses extraction process of two polypeptides, and determines molecular weight and amino acid sequence of the polypeptides. The polypeptides are synthesized by the chemical method, and purity analysis and molecular weight measurement results of the polypeptides indicate that molecular ion peak (m / z) completely satisfies theoretical molecular weight. Amino acid analysis result of the polypeptides indicates that amino acid content and the composition of the peptides are in accordance with theoretical values. Amino acid sequence measurement result of the polypeptides indicates primary structure thereof is in accordance with the designed sequence. At the same time, activity measurement result of the polypeptides indicates that the two peptides have activity, and remarkable effect on the treatment of myocardial ischemia, cerebral ischemia, and hepatic ischemia.

Owner:大连珍奥药业股份有限公司

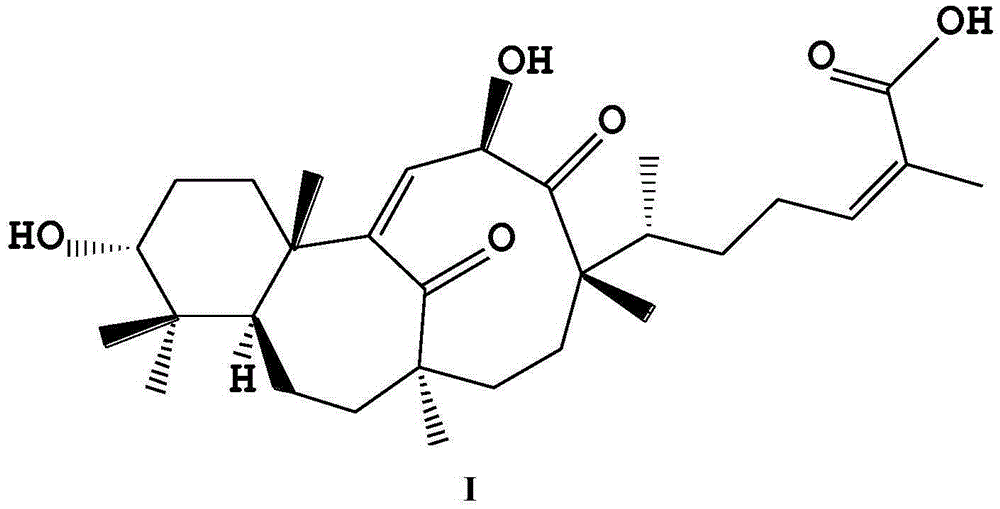

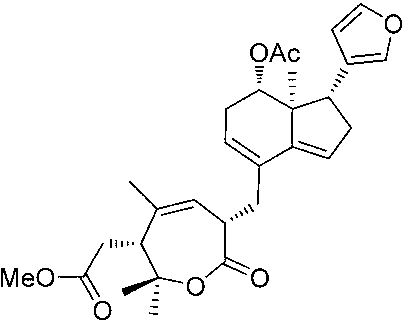

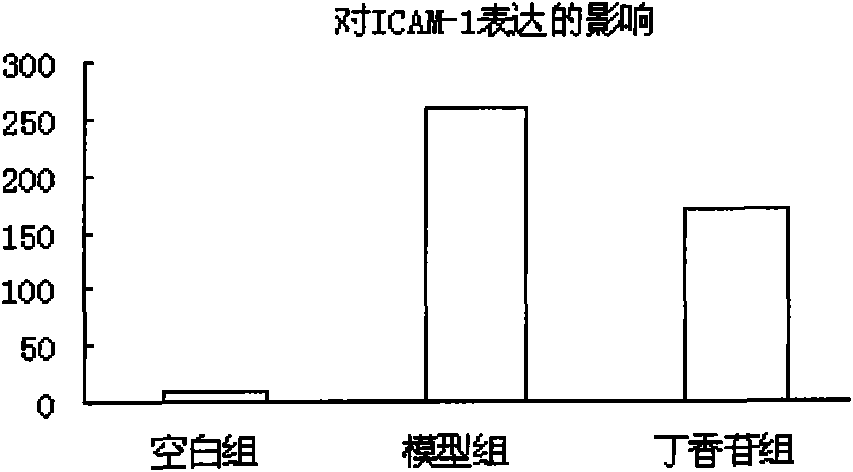

Application of Aphanamixoid A in medicines curing acute gout

InactiveCN103127087AStrong control activityHighlight substantive featuresOrganic active ingredientsSkeletal disorderIntercellular cell adhesion moleculeAcute gout

The invention provides a new use of Aphanamixoid A in medical science, and particularly relates to application of preparation of the Aphanamixoid A in medicines curing acute gout. Experiment research indicates that the Aphanamixoid A has protective effect on an acute gout model in which urate causes damage of vascular endothelial cell, and restrains expression of intercellular cell adhesion molecule (ICAM)-1. Therefore, the Aphanamixoid A can be used for preparation of the medicines curing acute gout inflammation. Use of the Aphanamixoid A in preparation of the medicines curing the acute gout is made public for the first time. Due to the fact that skeleton type belongs to completely novel skeleton type, and the Aphanamixoi A has an unexpectedly high activity of preventing and curing the acute gout, probability of other compounds giving any revelation for the Aphanamixoi A does not exist, outstanding substantive features are provided, meanwhile, prominent improvement is evidently possessed in preventing and curing the acute gout.

Owner:吴俊华

Preparation method and applications of osmanthus fragrans efficient components

ActiveCN104042499AEffectively retains active ingredientsActivity hasCosmetic preparationsToilet preparationsAlcoholRoom temperature

The invention relates to a preparation method and applications of osmanthus fragrans efficient components, belonging to the field of extracting traditional Chinese medicine effective components. The preparation method comprises the following steps: a. taking osmanthus fragrans, adding ethanol for extraction, filtering, and concentrating to obtain concentrated liquor; and b. cooling the concentrated liquor to room temperature, adding ethanol with the mass percentage concentration of 80%-95% for alcohol precipitation, standing, filtering and concentrating to obtain osmanthus fragrans effective components. The preparation method and applications have the beneficial effects that the preparation method is simple and feasible, and capable of effectively retaining the effective components in the osmanthus fragrans. The effective components are safe to use, mild to act, have the activities of being antioxidized, anti-aging, skin-protective, are capable of delaying the skin aging, and can be used as an additive of food, health-care products, cosmetics and drug products, or as raw materials.

Owner:SHANGHAI YUEMU COSMETICS

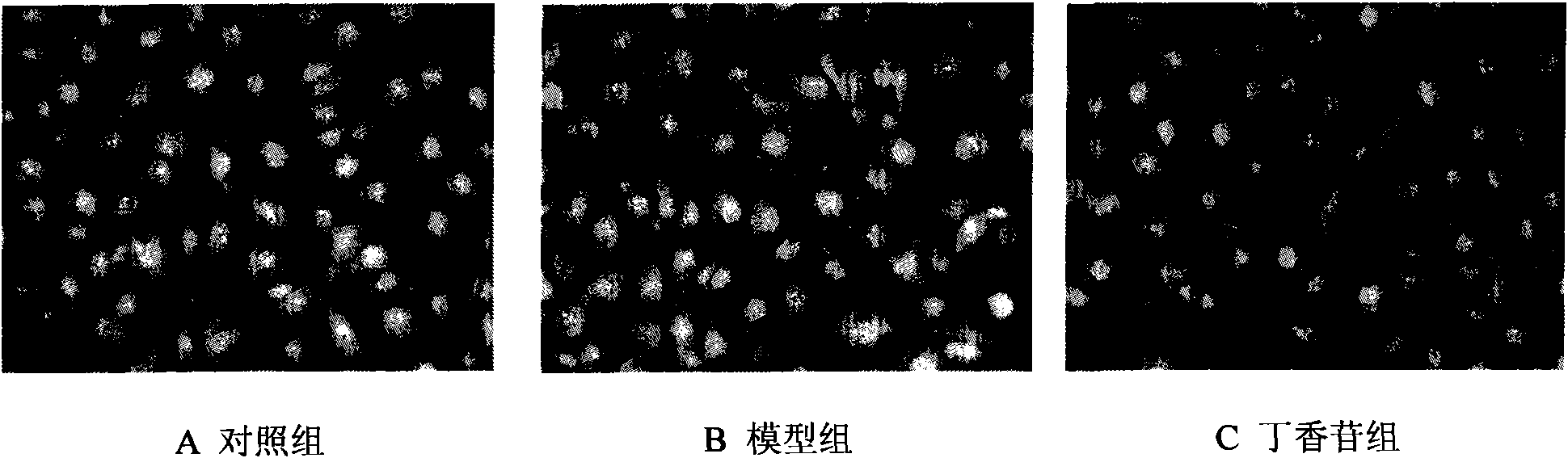

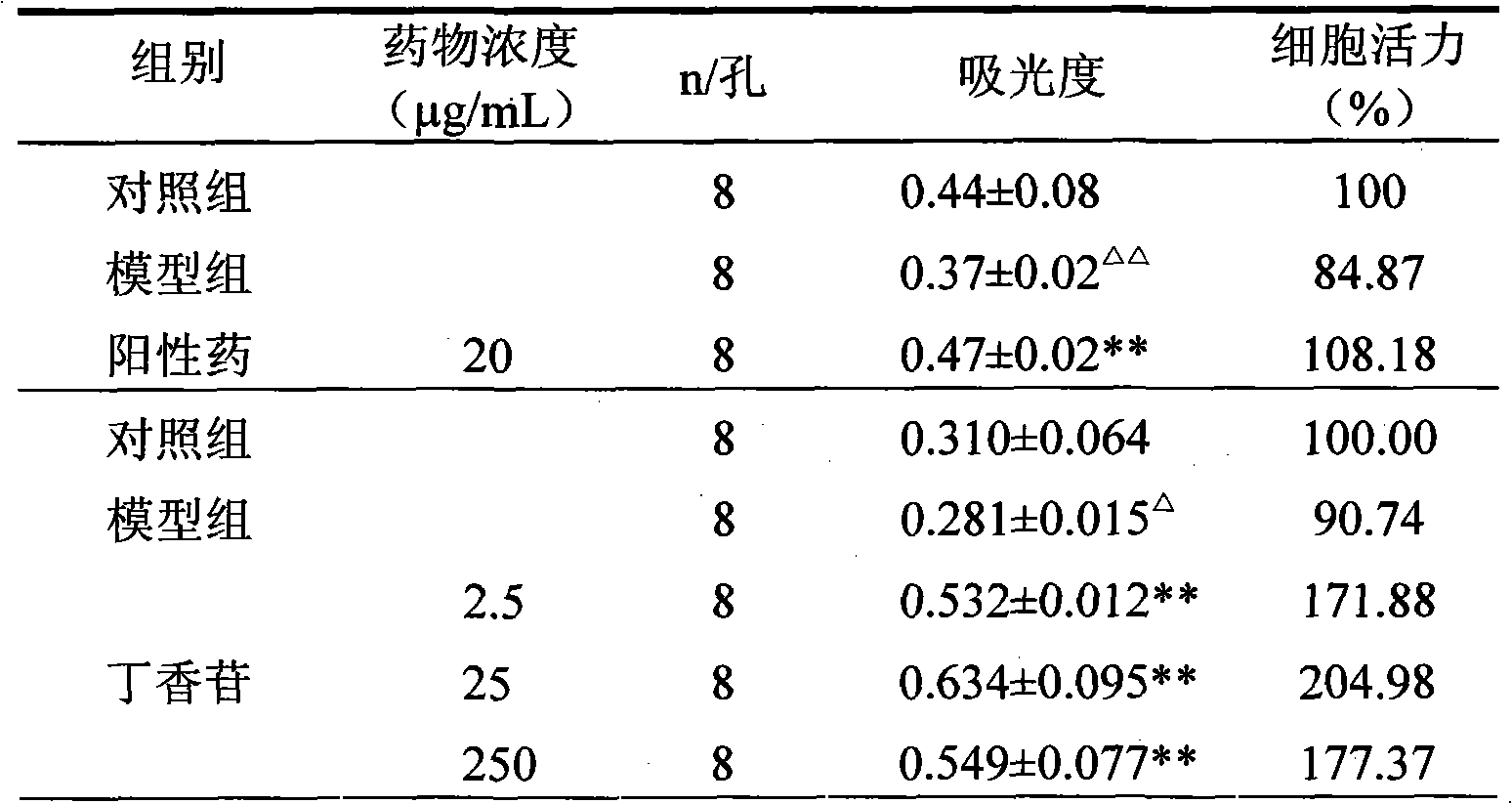

Application of syringin in preparation of medicine for treating acute gout

InactiveCN101953842AReduce apoptosisHigh activityOrganic active ingredientsSkeletal disorderEleutherococcus senticosusAcute gout

The invention provides a new application of syringin in medical science, in particular to application of syringin in the preparation of a medicine for treating acute gout. Syringin is extracted and separated from acanthopanax roots and other plants, and the extraction method comprises the following steps of: refluxing and extracting dry acanthopanax root powder with ethanol, recovering the ethanol, adding water to the concentrated solution, stirring to obtain a mixed suspension, extracting with petroleum ether, extracting the water layer with acetic ether, merging the acetic ether layer, concentrating under reduced pressure to obtain an extract, separating by using a silica gel column, carrying out gradient elution by using chloroform and methanol in sequence to obtain a coarse crystal, and recrystallizing with methanol to obtain a syringin crystal. Experimental researches show that syringin can protect an acute gout model due to human vascuoar endothelial cell damages caused by urate and inhibit the expression of ICAM-1 (Intercellular Adhesion Molecule-1); thus, syringin can be used for preparing a medicine for treating acute gout.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

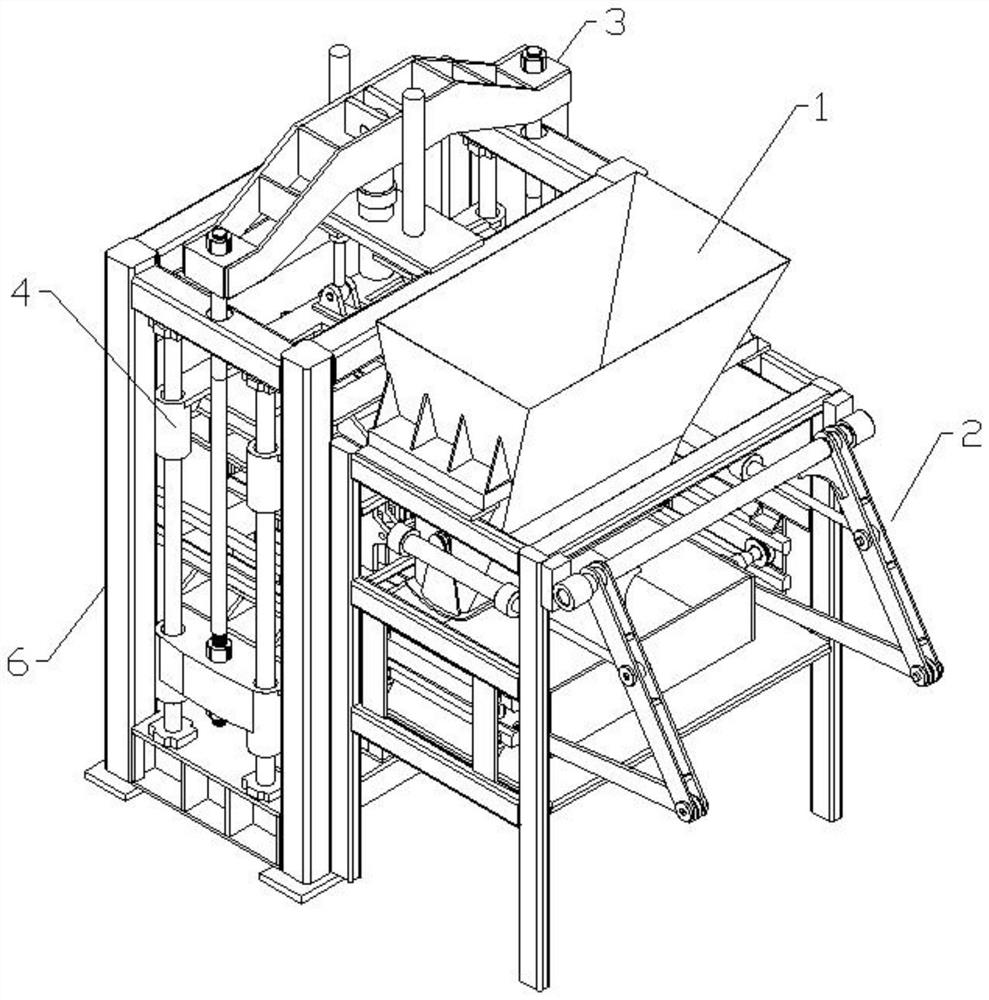

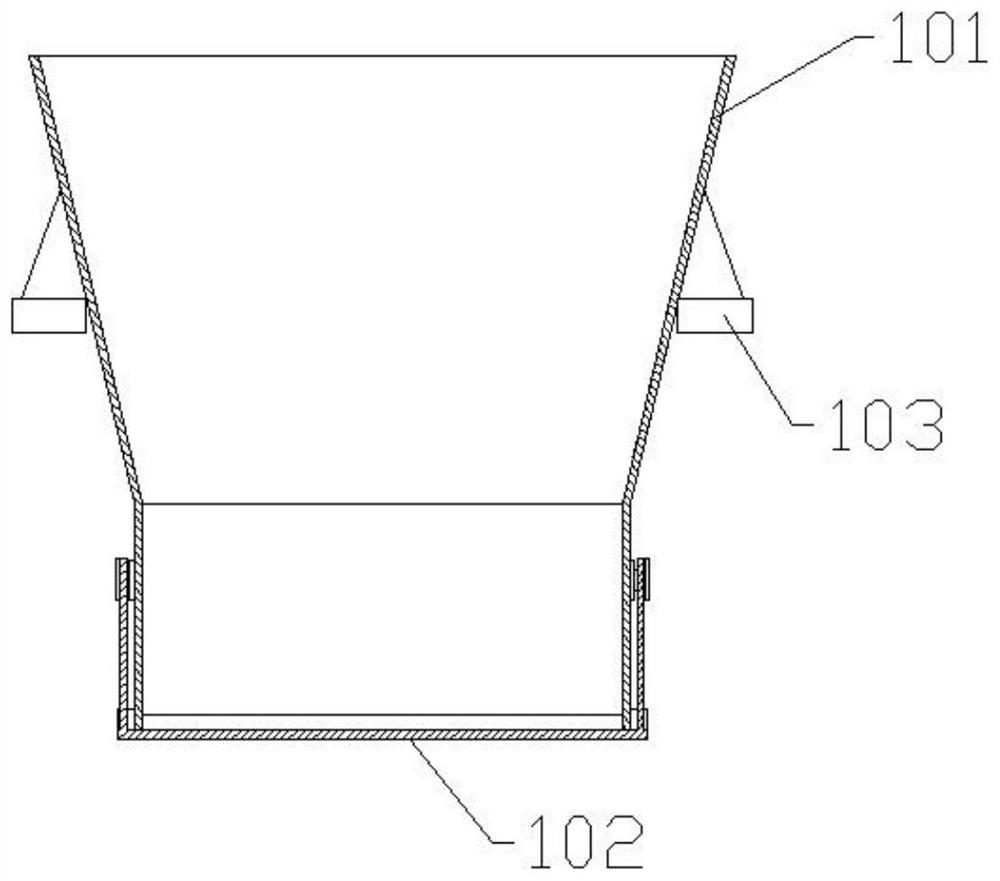

Preparation process of ecological brick taking household garbage incineration slag as raw material

InactiveCN112549252AReduce overexploitationOverexploitation benefitsDischarging arrangementSolid waste managementEnvironmental resource managementBrick

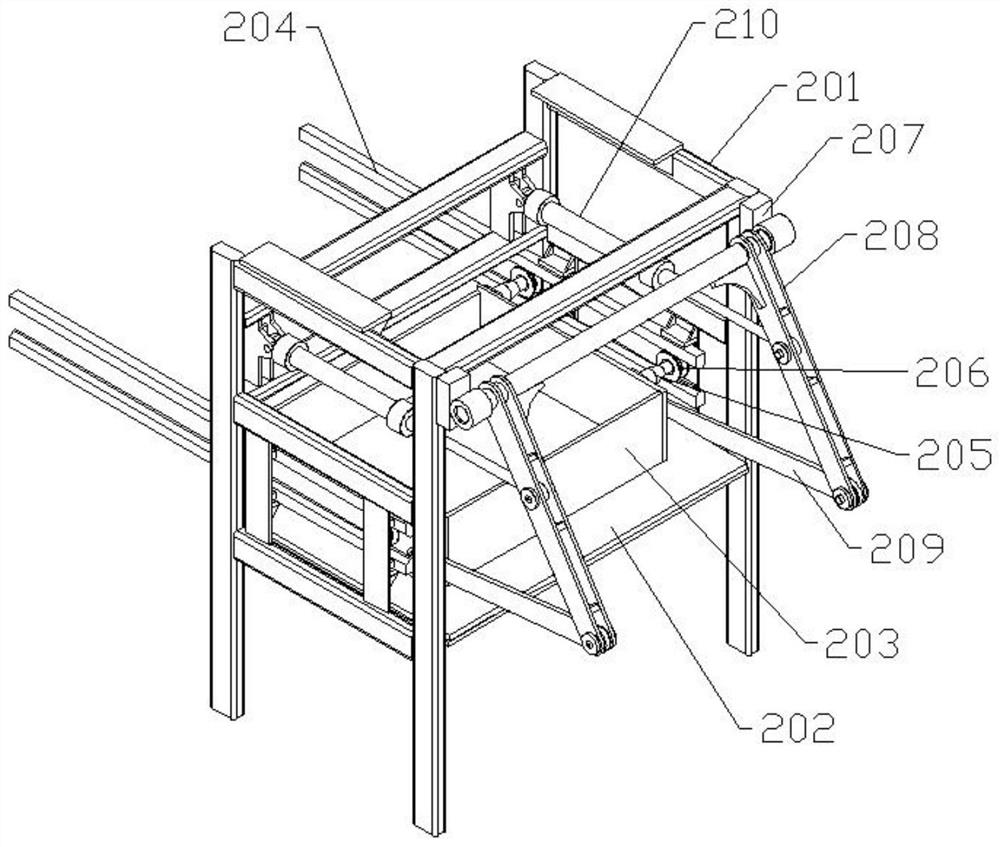

The invention discloses a preparation process of an ecological brick taking household garbage incineration slag as a raw material. The preparation process comprises the following steps of 1, drying, ball-milling and sieving the slag; 2, preparing an aqueous solution of a water strength agent, uniformly stirring the raw materials, and passing through an edge runner mill to prepare a brick raw material; 3, pressing and molding the brick raw material into green bricks by using a green brick molding machine; and 4, moving the green bricks into a steam curing chamber for curing, and then transferring the green bricks into a finished product warehouse for storage so as to obtain ecological brick finished products. The green brick molding machine comprises a feeding part, a pushing part, a molding part, a pressing part, a base and a rack assembly, the pushing part is located on one side of the rack assembly, the feeding part is located above the pushing part, the pressing part is located above the interior of the rack assembly, the molding part is located in the rack assembly, the molding part is located below the pressing part, and the base is located below the molding part. The preparation process solves the problems of low strength and poor durability of the ecological brick prepared from the household garbage incineration slag in the prior art.

Owner:佛山市绿富域环保科技有限公司

Methyl reduced oleanane triterpenoid saponin, preparation method of its active composition and application thereof

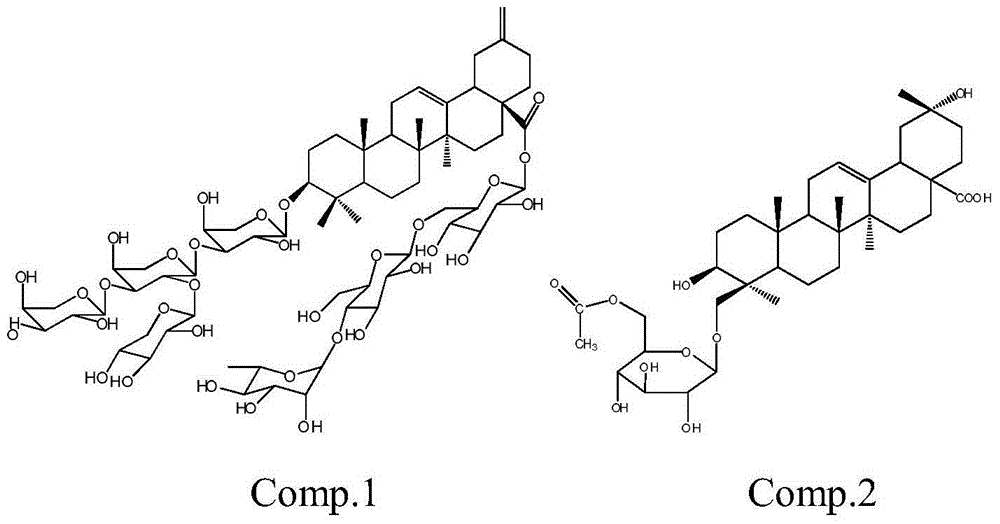

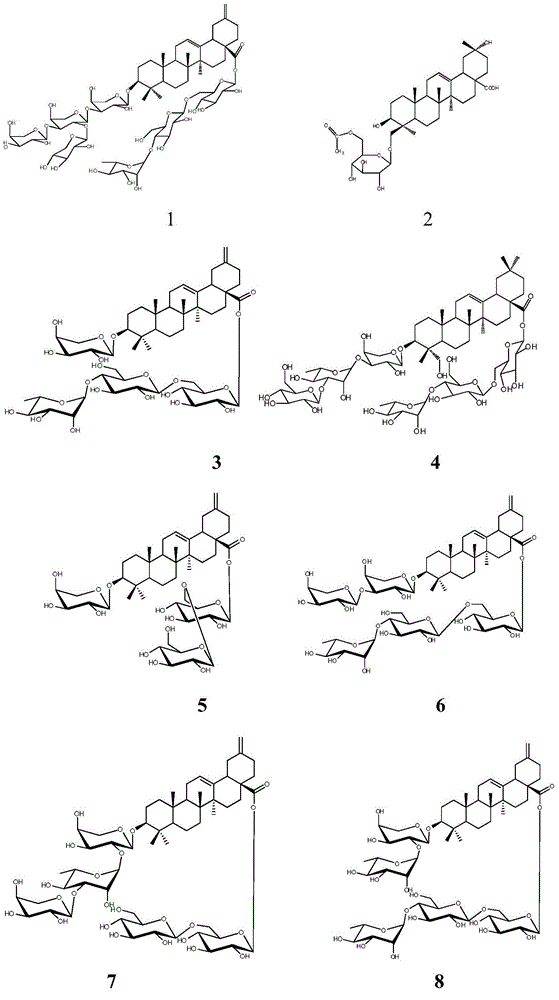

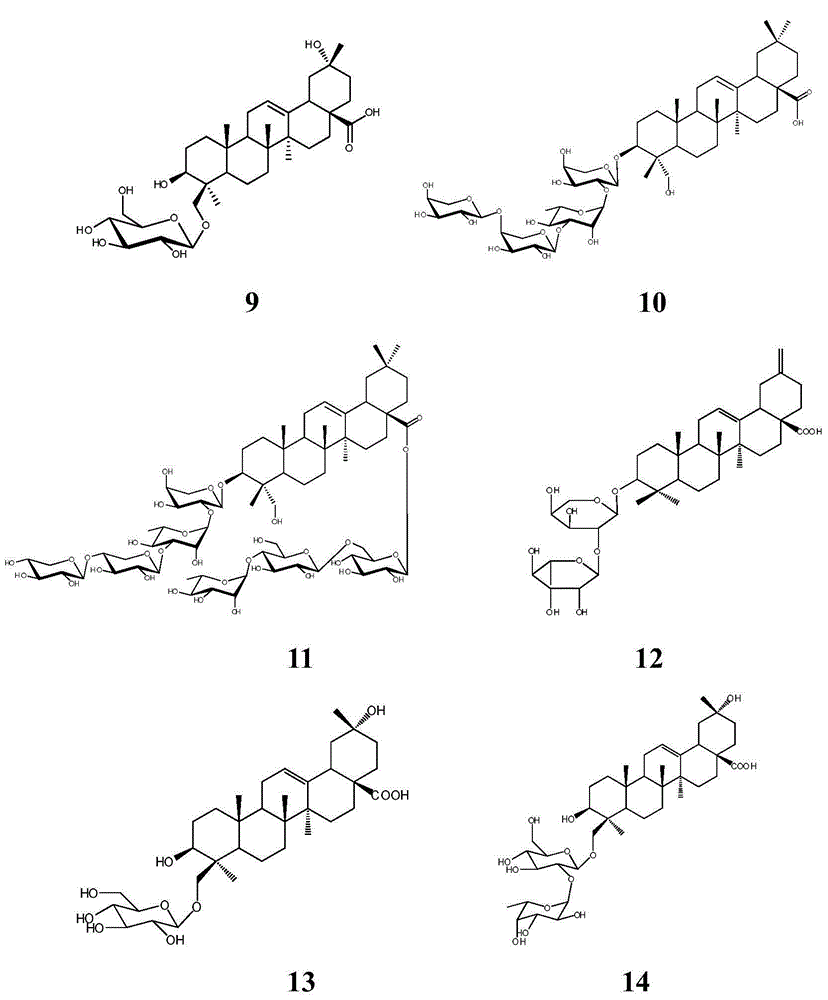

ActiveCN104910237AActivity hasAnti-inflammatoryOrganic active ingredientsSugar derivativesStauntoniaOleanane

The invention belongs to the technical field of medicine, which relates to two methyl reduced oleanane triterpenoid saponin compound stauntonia brachyanthera saponin, and two mthyl reduced oleanane triterpenoids have the following structure. The invention also comprises two compound compositions, its preparation method, and the exploitation and application of the composition on medicine, health product and functional food for anti inflammatory, analgesia, liver protecting, and dieresis.

Owner:SHENYANG PHARMA UNIVERSITY

Plant antifreezing agent for enhancing enzyme activity and preparation method thereof

InactiveCN106719810AReduce transpirational dehydrationIncrease the activity of ATPaseBiocidePlant growth regulatorsOn cellsUrea

The invention discloses a plant antifreezing agent for enhancing enzyme activity and a preparation method thereof. The plant antifreezing agent is characterized in that it is prepared from the following raw materials by weight: 1-2 parts of ethephon, 6-12 parts of polylactic acid, 1-2 parts of paclobutrazol, 3-6 parts of sorbitan fatty acid ester, 8-15 parts of chloroform, 25-35 parts of water, 6-12 parts of corn protein powder, 2-3 parts of calcium chloride, 1-3 parts of glucose, 2-4 parts of amino acid, 4-6 parts of glycerin, 1-2 parts of sodium dodecyl sulfate, 2-5 parts of magnesium chloride, and 2-5 parts of urea. According to the invention, corn protein powder is soaked in glucose and amino acid, and is adhered to a plant through the bonding effect of polylactic acid, thus achieving a heat preservation effect, also the glucose and amino acid therein can significantly increase the content of sugar and free amino acids in plants, have a protective effect on cells, and effectively reduce the influence of freezing damage to plants. Through cooperation with the added ethephon and the like, the activity of enzyme in the cells can be promoted, and heat is generated.

Owner:安徽新视野园林绿化工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com