New method for extracting rubidium from rubidium-containing ore

A new method and ore technology, applied in the field of rubidium extraction, can solve problems such as environmental pollution, high energy consumption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

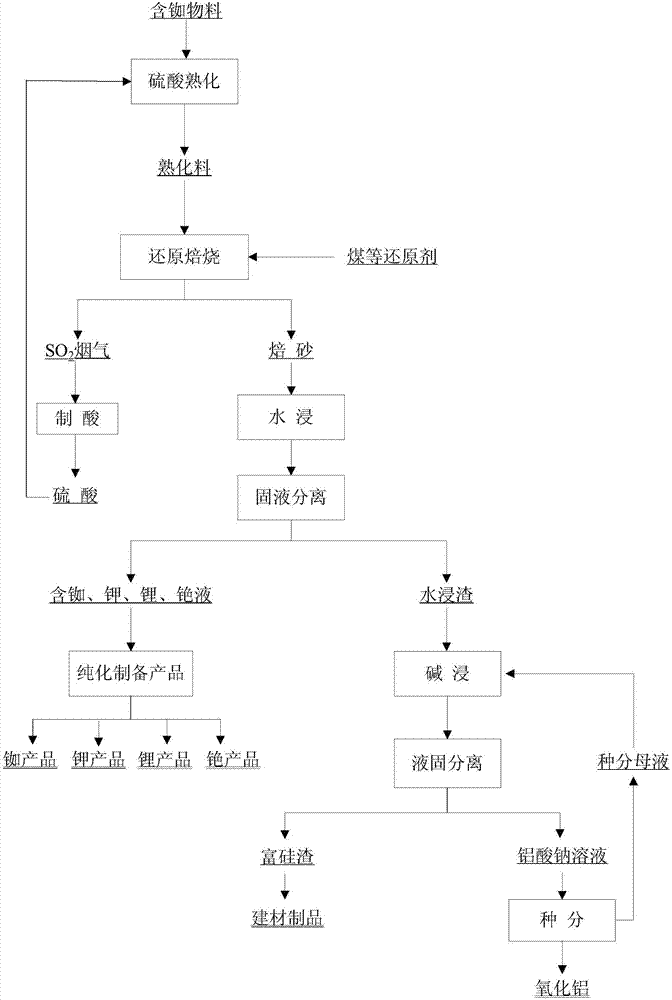

Method used

Image

Examples

Embodiment 1

[0060] Mix lepidolite-containing rubidium-containing ore with a particle size of -0.074mm, accounting for more than 88%, and 90% concentrated sulfuric acid. The sulfuric acid slaking material was obtained under the conditions of temperature 200°C and slaking time 8h. The sulfuric acid slaking material is mixed uniformly according to the coal ratio of 12%, and the rapid reduction roasting is carried out at a temperature of 750 ° C, and the roasting time is 5 minutes.

[0061] The reduced calcine leaching temperature is 90°C, the time is 60min, and the liquid-solid ratio is 2:1, so that lithium, potassium, and rubidium enter the water immersion solution. The lithium leaching rate is 90%, and the rubidium leaching rate is 85%. Potassium solution is purified to prepare rubidium, lithium and potassium products.

[0062] Alkali dissolution is carried out on the water leaching residue, and the dissolution conditions are: dissolution temperature 100°C, alkali concentration 150g / L, in...

Embodiment 2

[0064] Mix the rubidium-containing ore with a particle size of -0.074mm and more than 90% of the finely ground cesium garnet with 93% concentrated sulfuric acid. Sulfuric acid slaking material was obtained under the conditions of 320°C slaking temperature and 8h slaking time. The sulfuric acid slaking material is uniformly mixed with coal powder at a coal ratio of 15%, and is subjected to rapid reduction roasting at a temperature of 800°C, and the roasting time is 10 minutes.

[0065] The reduced calcined sand is leached at a temperature of 70°C, for 30 minutes, and at a liquid-solid ratio of 3:1, so that rubidium and cesium enter the water immersion solution. The leaching rate of rubidium and cesium is 90%, and the leaching rate of cesium is 92%. Purify the solution containing rubidium and cesium. Preparation of rubidium and cesium products.

[0066] Alkali dissolution is carried out on the water leaching residue, and the dissolution conditions are: dissolution temperature 9...

Embodiment 3

[0068] Mix the potassium feldspar-containing rubidium-containing ore with a particle size of -0.074mm accounting for more than 93% and 95% concentrated sulfuric acid, and the addition amount is 1.8 times the quality of the rubidium-containing ore based on 98% concentrated sulfuric acid. The sulfuric acid slaking material was obtained under the conditions of 380°C slaking temperature and 4h slaking time. The sulfuric acid slaking material is passed into the gas in the fluidized roasting furnace, and the rapid reduction roasting is carried out at a temperature of 750 ° C, and the roasting time is 1 min.

[0069] The reduced calcined sand is leached at a temperature of 90°C, for 30 minutes, and at a liquid-solid ratio of 3:1, so that rubidium and potassium enter the water immersion solution, the leaching rate of rubidium and potassium is 89%, and the leaching rate of potassium is 90%, and the solution containing rubidium and potassium is purified. Preparation of rubidium and pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com