Method for synthesizing magnesium-silicon intermediate and preparation of high-magnesium aluminum alloy thereby

A technology of high-magnesium aluminum alloy and synthesis method, which is applied in the field of synthesis of magnesium-silicon intermediates from natural perlite ore as a silicon source, and in-situ synthesis of high-magnesium aluminum alloys, which can solve the high cost of silicon sources and the probability of Si formation Small, single species of Mg2 and other problems, to achieve the effect of abundant reserves and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

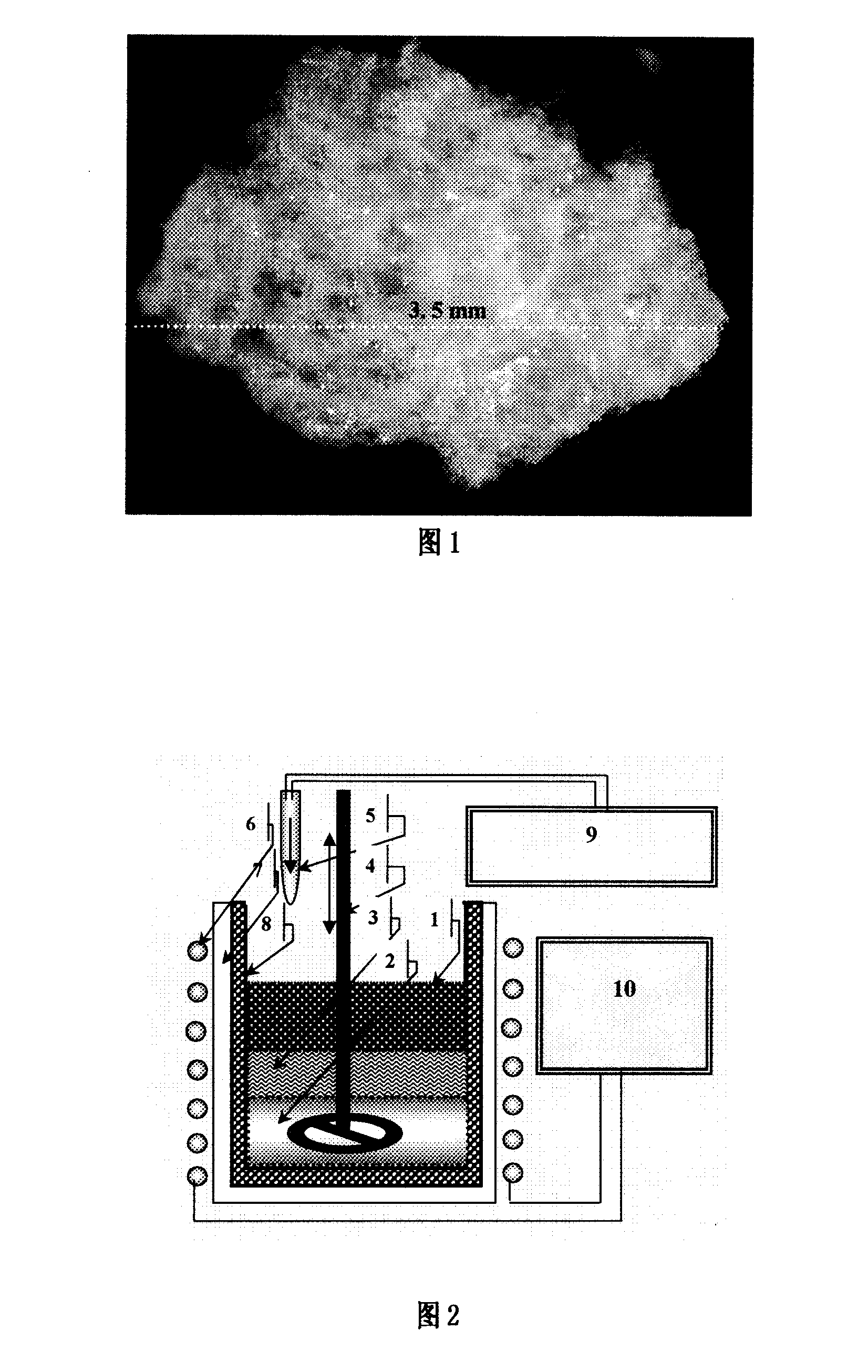

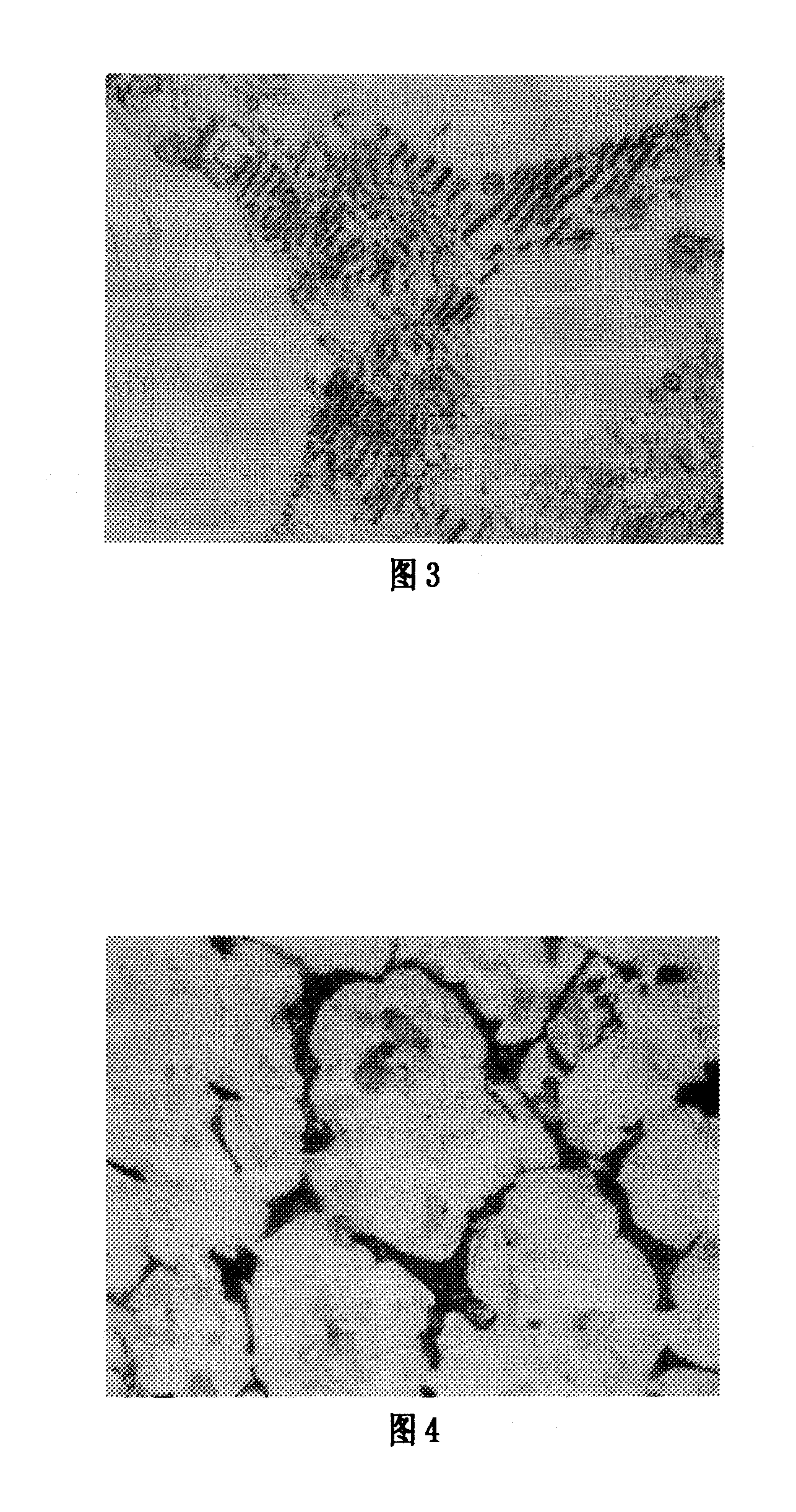

[0029] Using commercially available magnesium metal with a purity of 99.5% and expanded perlite with a purity of 99% as raw materials, the composition analysis results obtained by measuring the expanded perlite as stable oxides are: SiO 2 72.5wt%, Al 2 o 3 13.5wt%, K 2 O is 4.25wt%, Na 2 O is 3.75wt%, CaO is 0.1wt%, Fe 2 o 30.9wt%, MgO is 0.075wt%, H or O and other analytical non-displays are 4.925wt%, and the sum of the composition of various component analytes constitutes 100%; with commercially available KCl of 99.5% purity as the reaction medium; Add 370g metal magnesium nugget in the crucible 8 of accompanying drawing 2 of the present invention, pour into the liquid state KCl of the equal weight of the magnesium nugget to the magnesium nugget surface then, start supersonic frequency induction heater 10 and start heating among the accompanying drawing 2 of the present invention, observe After KCl begins to melt again in the reaction system, add 43g expanded perlite im...

Embodiment 2

[0031] All the other are with embodiment 1. The difference is: ① Add 20g of metal magnesium block to the crucible 8; ② The amount of expanded perlite added is 4.3g; ③ The reaction temperature is controlled at 785°C; ④ The stirring frequency is 2 times per minute; ⑤ The Si content of the intermediate 1.51wt%, Al 0.02wt%, Fe content range 0.09wt%, other impurity elements 0.05wt%. ⑥The as-cast density of the intermediate is 1.737g / cm 3 ; As-cast Vickers hardness is 52.96HV.

Embodiment 3

[0033] All the other are with embodiment 1. The difference is: ① Add 37g metal magnesium block to the crucible 8; ② The amount of expanded perlite is 2.6g; ③ The reaction temperature is controlled at 800°C; ④ The stirring frequency is 6 times per minute; ⑤ The Si content of the intermediate The range is 1.78wt%, the Al is 0.05wt%, the Fe content is 0.01wt%, and other impurity elements are 0.11wt%. ⑥The as-cast density of the intermediate is 1.76g / cm 3 ; As-cast Vickers hardness is 53.52HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com