Method for high-value comprehensive utilization of red mud

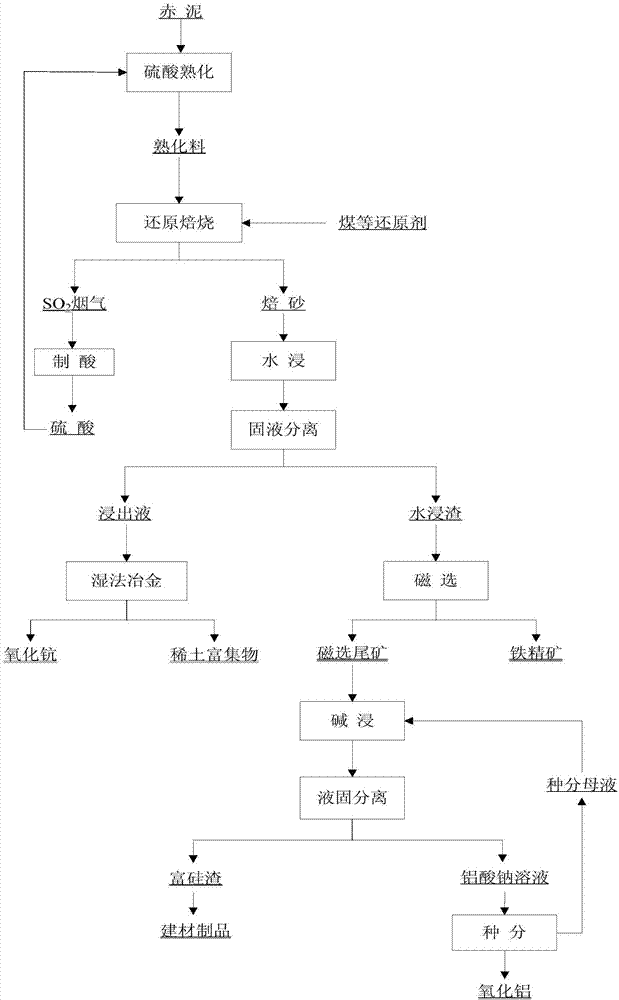

A high-value red mud technology, applied in the fields of rare earth, scandium, aluminum and iron extraction, can solve the problems of acid consumption, difficulty in metal extraction, and low purity of product scandium oxide, and achieve the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Red mud is mixed with 90% concentrated sulfuric acid, and the amount added based on 98% concentrated sulfuric acid is 1.6 times the mass of the red mud. After mixing evenly, the sulfuric acid clinker is obtained under the conditions of a curing temperature of 200° C. and a curing time of 8 hours. The sulfuric acid slaking material is mixed evenly according to the coal ratio of 8%, and the rapid reduction roasting is carried out at a temperature of 750 ° C for 5 minutes.

[0070] The reduced calcined sand is leached at a temperature of 90°C, for 60 minutes, and at a liquid-solid ratio of 4:1, so that the rare earth and scandium enter the water leaching solution. The leaching rate of rare earth is 70%, and the leaching rate of scandium is 85%. Enrichment, separation and purification to obtain Sc 2 o 3 Products and Rare Earth Concentrates.

[0071] The water leaching slag is subjected to magnetic separation at a magnetic field strength of 500kA / m to enrich and prepare ir...

Embodiment 2

[0074] Mix the red mud after washing and attaching alkali with 93% concentrated sulfuric acid, and add 2.2 times the mass of the red mud based on the 98% concentrated sulfuric acid. After mixing evenly, obtain sulfuric acid at a curing temperature of 320°C and a curing time of 8 hours. Cooking material. The sulfuric acid slaking material is uniformly mixed with coal powder at a coal ratio of 15%, and is subjected to rapid reduction roasting at a temperature of 800°C, and the roasting time is 10 minutes.

[0075] The reduced calcined sand is leached at a temperature of 70°C for 30 minutes, and the liquid-solid ratio is 3:1, so that the rare earth and scandium enter the water leaching solution, the leaching rate of rare earth is 80%, and the leaching rate of scandium is 92%. Enrichment, separation and purification to obtain Sc 2 o 3 Products and Rare Earth Concentrates.

[0076] The water leaching slag is subjected to magnetic separation at a magnetic field strength of 300kA / ...

Embodiment 3

[0079] Red mud is mixed with 95% concentrated sulfuric acid, and the amount added is 1.8 times the mass of the red mud based on 98% concentrated sulfuric acid. After mixing evenly, the sulfuric acid clinker is obtained under the conditions of a curing temperature of 380° C. and a curing time of 4 hours. The sulfuric acid slaking material is passed into the gas in the fluidized roasting furnace, and the rapid reduction roasting is carried out at a temperature of 750 ° C, and the roasting time is 1 min.

[0080] The reduced calcined sand is leached at a temperature of 90°C, for 30 minutes, and at a liquid-solid ratio of 5:1, so that the rare earth and scandium enter the water leaching solution. The leaching rate of rare earth is 82%, and the leaching rate of scandium is 90%. Enrichment, separation and purification to obtain Sc 2o 3 Products and Rare Earth Concentrates.

[0081] The water leaching slag is subjected to magnetic separation at a magnetic field strength of 600kA / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com