Brick making die clamp

A jig and mold technology, applied in the direction of manufacturing tools, mold fixtures, mold auxiliary parts, etc., can solve the problems of inability to automatically lock and unlock molds, low brick-making efficiency, and time-consuming, saving manual locking. And the time of manual unlocking, the effect of improving the efficiency of brick making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

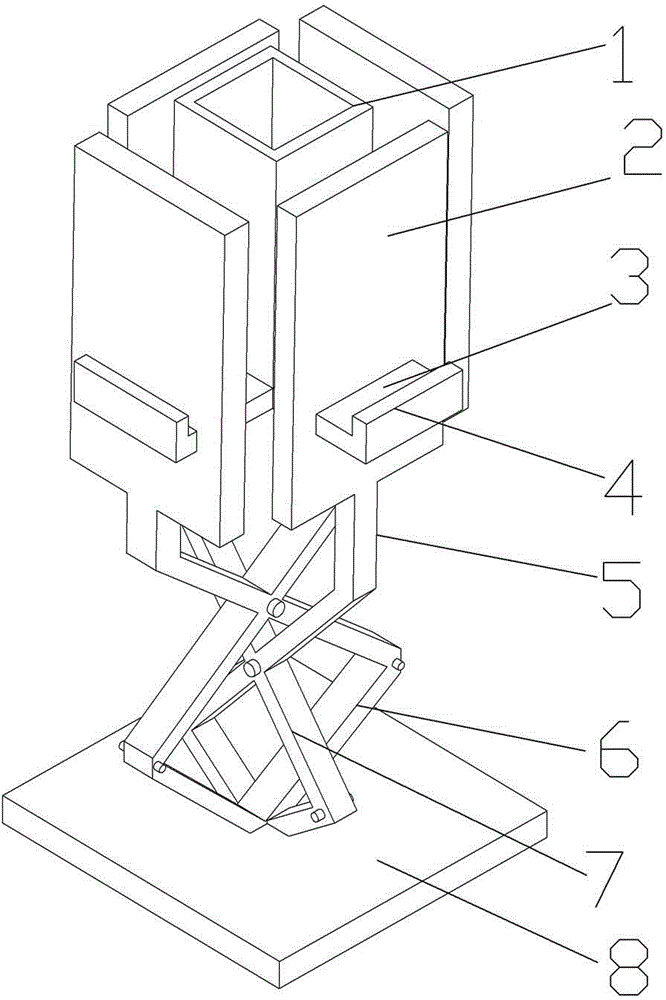

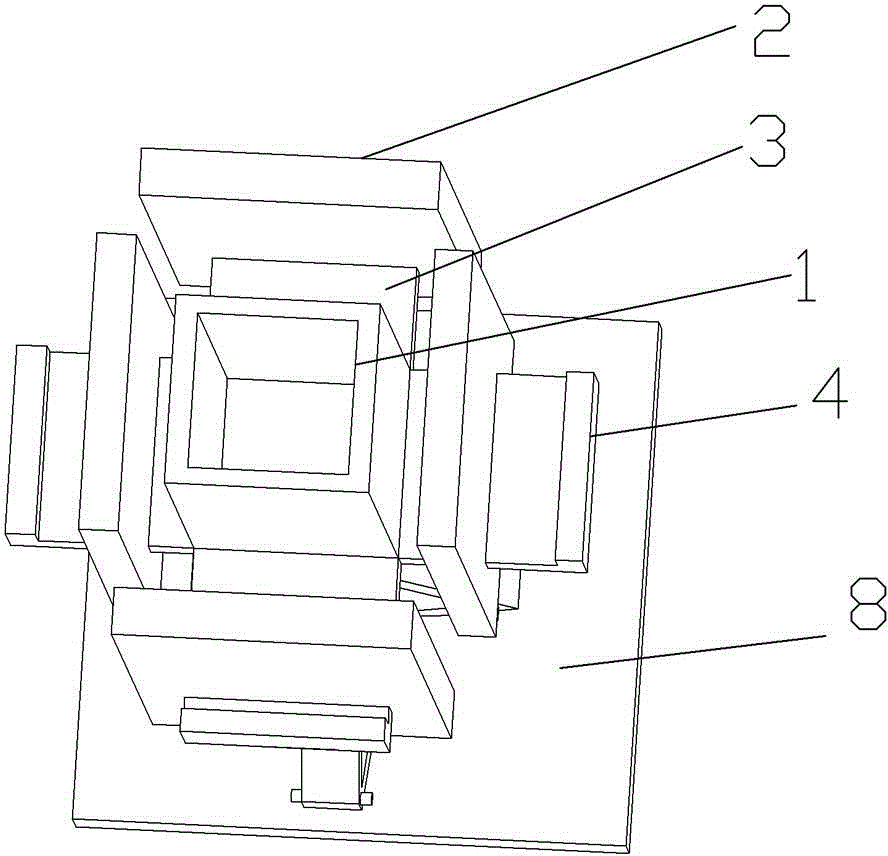

[0012] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0013] like figure 1 and figure 2 As shown, the base plate 3 is a cross-shaped flat plate, and the lock plate 2 is a rectangular plate. The bottom of the lock plate 2 has a square hole that makes the lock plate 2 slide on the output end of the base plate 3. There are four lock plates 2, and the bottom plate 3 Each output end passes through a square hole and is vertically connected to the lock plate 2. The ends of the four output ends of the bottom plate 3 protrude with stoppers 4. The stoppers 4 and the bottom plate 3 are designed as one body. The four lock plates 2 are welded below. Strut 5, wherein two opposite struts 5 are longer, and the end of strut 5 is connected with straight rod 7, and the included angle between straight rod 7 and strut 5 is 135 °, and two opposite straight rods 7 are in the middle The positions are hinged toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com